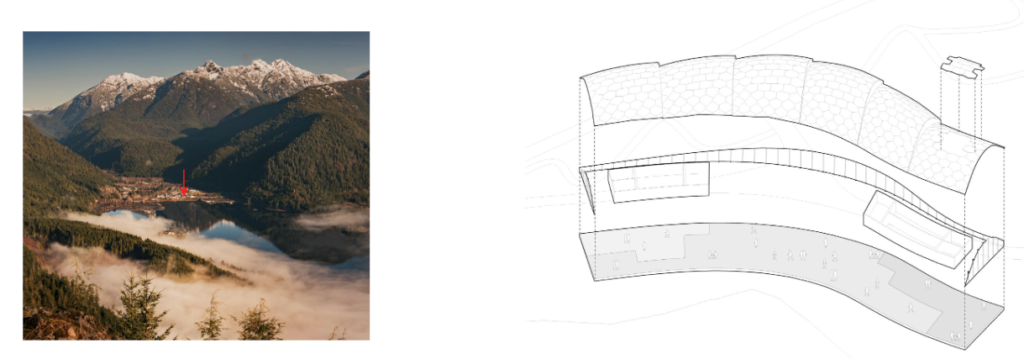

Tahsis BC Canada

Our project is located in Tahsis, BC a former timber milling town that has become dilapidated since the closure of the sawmill in 2001, with a population decline of 90%. We aim to reinvigorate the town by providing access for tourism, attracted by the wildlife that has returned to the inlet since the pollution from the mill ceased. Humpback whales in particular are a draw to the area.

Segmental Timber Panel Structures

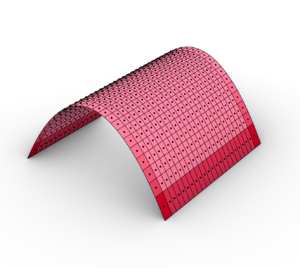

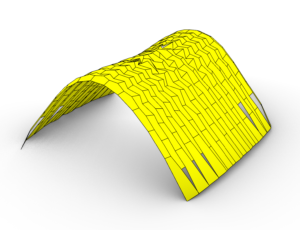

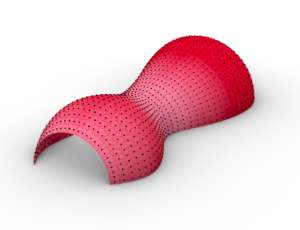

The concept of segmental timber panel structures seeks to leverage the structural capacity of double curved shells. Traditionally double curved shells have been formed in concrete, however the cost of building the formwork and then the structure has seen them fall out of favour. Modern robotic fabrication, engineered timber, and parametric design tools has seen the implementation of segmental timber shell structures over the last roughly 10 years, including the Landesgartenschau Exhibition Hall1, HexBox Canopy2, Recycleshell3, the livMatS Building4 and BUGA Pavilion5.

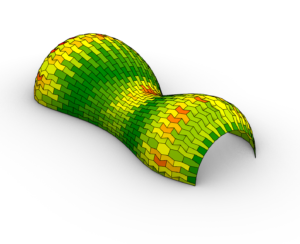

One critical component of the structural system is to find planarity such that the panels can be fabricated from flatstock. This requirement imposes restrictions on the curvature and the combination of curvatures that can be achieved. In particular positions that sit on the transition from positive to negative Gaussian curvature are problematic, requiring additional bounding conditions that allow for a solution. Recent work from Pluta, Edelstein, Vaxman and Ben-Chen provides a framework for initializing a mesh that will (almost always) planarize by ensuring that the mesh edges are oriented to the minimal curvature direction6. Below we show explorations of planar panels achieved for synclastic (positive Gaussian curvature) surfaces, anticlastic (negative Gaussian curvature) and mixed surfaces.

Structural FE model generation

Due to the need to initialize with a very regulated mesh the generation of the Finite Element mesh was straightforward. Below we show two animations of the process moving from form finding through planarization to the FE mesh.

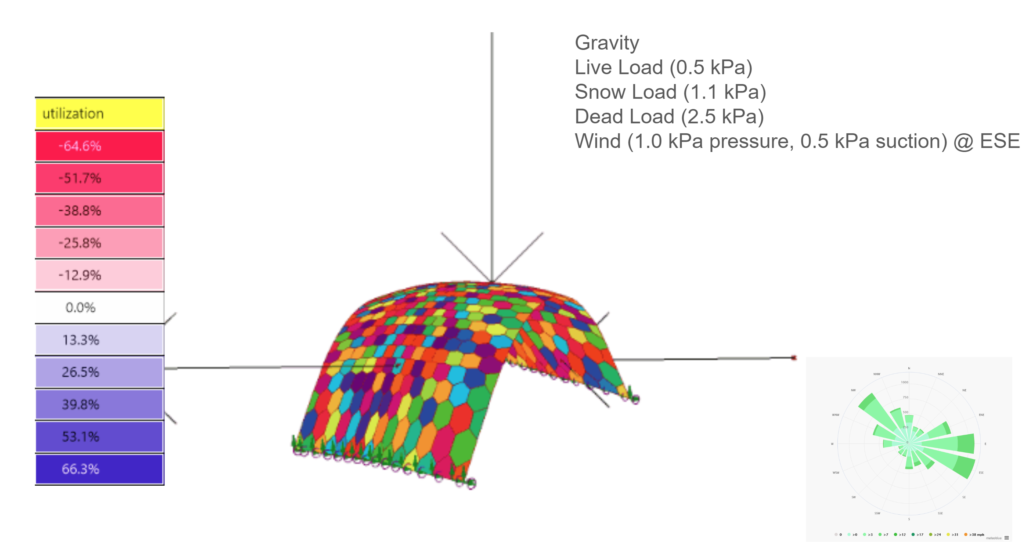

Structural FE Shell Analysis

We chose one shell to analyse and started by modelling it as a solid shell. Using Karamba3d our load case was generated for gravity, live loads, snow loads, wind loads and dead loads, this load case is presented below. We utilized the cross section optimizer to achieve a maximum utilization of 70% and maximum deflection of 7.5 cm per the BC Building Code for structural spans. Based on this analysis the most highly loaded panel condition was selected for further analysis.

Panel System Design Exploration

The individual panel was evaluated as a hollow box to check the build up of elements would sustain expected loading. The analysis was used to inform the thickness of the elements used for fabrication and evaluated using Galapagos solver with the goal of minimizing weight while resisting deflection and buckling.

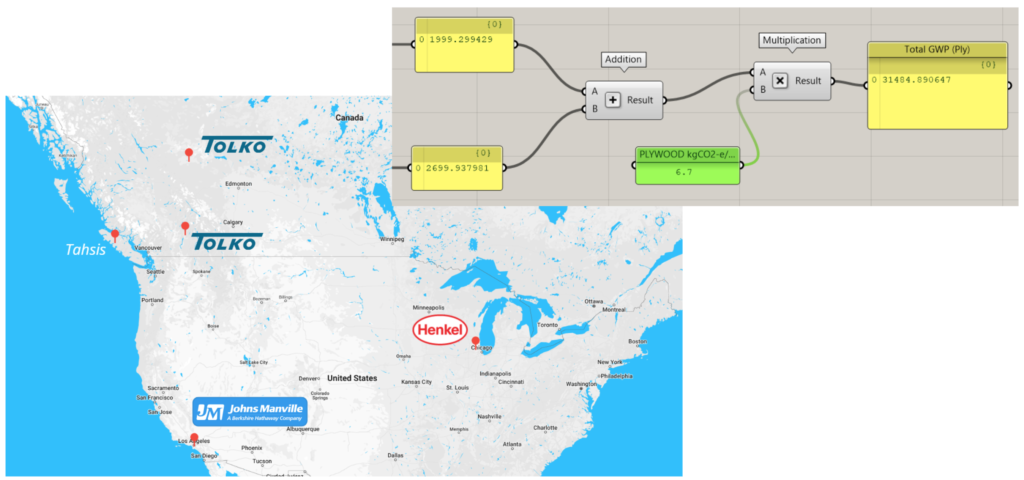

Embodied Carbon Emissions

We assessed the total volume of materials required for the structure and the sourcing options. For the timber structure the A1-A3 embodied carbon is of the order of 31.4 tonnes of CO2 equivalent. Based on recent publications from the WRI7,8 we do not consider biogenic carbon sequestration to be an accurate accounting of the effects of forestry on global emissions, this is particularly true of the Canadian forestry industry which is self regulated, thus we have excluded biogenic sequestration figures from our project.

References

- Menges, A., Schwinn, T., & Krieg, O. D. (2015). Landesgartenschau Exhibition Hall. Interlocking Digital and Material Cultures, 55-71. ↩︎

- Robeller, C., Barata, E. D. O., Tagliaboschi, E. V., & Schmidt-Kleespies, F. (2022). HexBox Canopy: a segmented timber plate shell with hardwood wedge joints. Journal of the International Association for Shell and Spatial Structures, 63(4), 221-231. ↩︎

- Robeller, C., & Von Haaren, N. (2020). Recycleshell: wood-only shell structures made from cross-laminated timber (CLT) production waste. Journal of the International Association for Shell and Spatial Structures, 61(2), 125-139. ↩︎

- Lauer, A. P. R., Benner, E., Stark, T., Klassen, S., Abolhasani, S., Schroth, L., Gienger, A., Wagner, H.J., Schwieger, V., Menges, A. & Sawodny, O. (2023). Automated on-site assembly of timber buildings on the example of a biomimetic shell. Automation in Construction, 156, 105118. ↩︎

- Bechert, S., Sonntag, D., Aldinger, L., & Knippers, J. (2021, December). Integrative structural design and engineering methods for segmented timber shells-BUGA Wood Pavilion. In Structures (Vol. 34, pp. 4814-4833). Elsevier. ↩︎

- Pluta, K., Edelstein, M., Vaxman, A., & Ben-Chen, M. (2021). PH-CPF: Planar hexagonal meshing using coordinate power fields. ACM Transactions on Graphics (TOG), 40(4), 1-19. ↩︎

- Searchinger, T., Peng, L., Zionts, J., & Waite, R. (2023). The global land squeeze: Managing the growing competition for land. World Resources Institute. https://doi.org/10.46830/wrirpt.20.00042* ↩︎

- Peng, L., Searchinger, T. D., Zionts, J., & Waite, R. (2023). The carbon costs of global wood harvests. Nature, 620(7972), 110-115. ↩︎