Introduction

The Self sufficient building studio students were tasked to use an old yet functional electronic equipment , understand its function and then integrate it into a new prototype body, repurposing its function which could later help sustain an architectural space. I, a one man group, decided to work with water in gaseous state- steam. In this term, two prototypes , two electronic equipment were used to understand how the purpose of the project’s aim could be accomplished. The previous prototype could be seen in detail using this link https://blog.iaac.net/air-guard-pro/. This post is focused on the second electronic equipment and its further understanding of its function , which can be repurposed to benefit the architectural space.

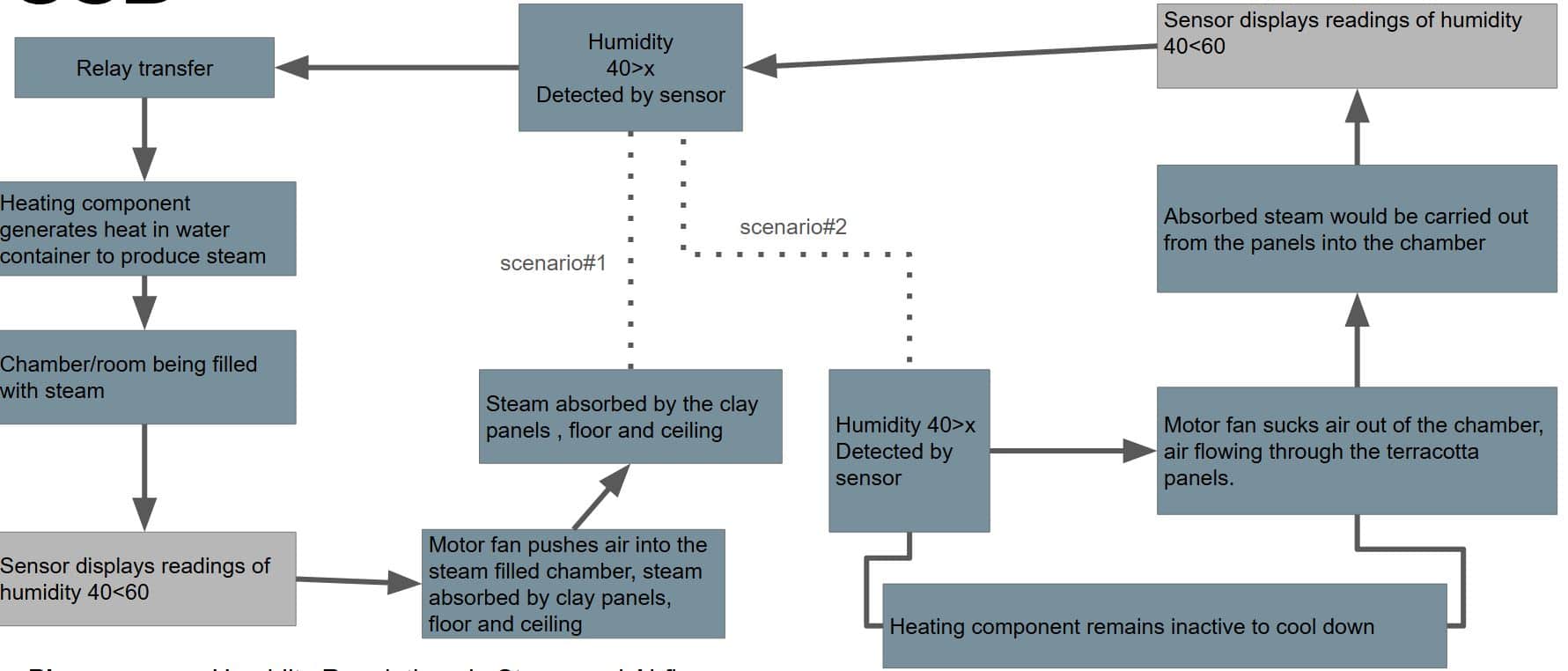

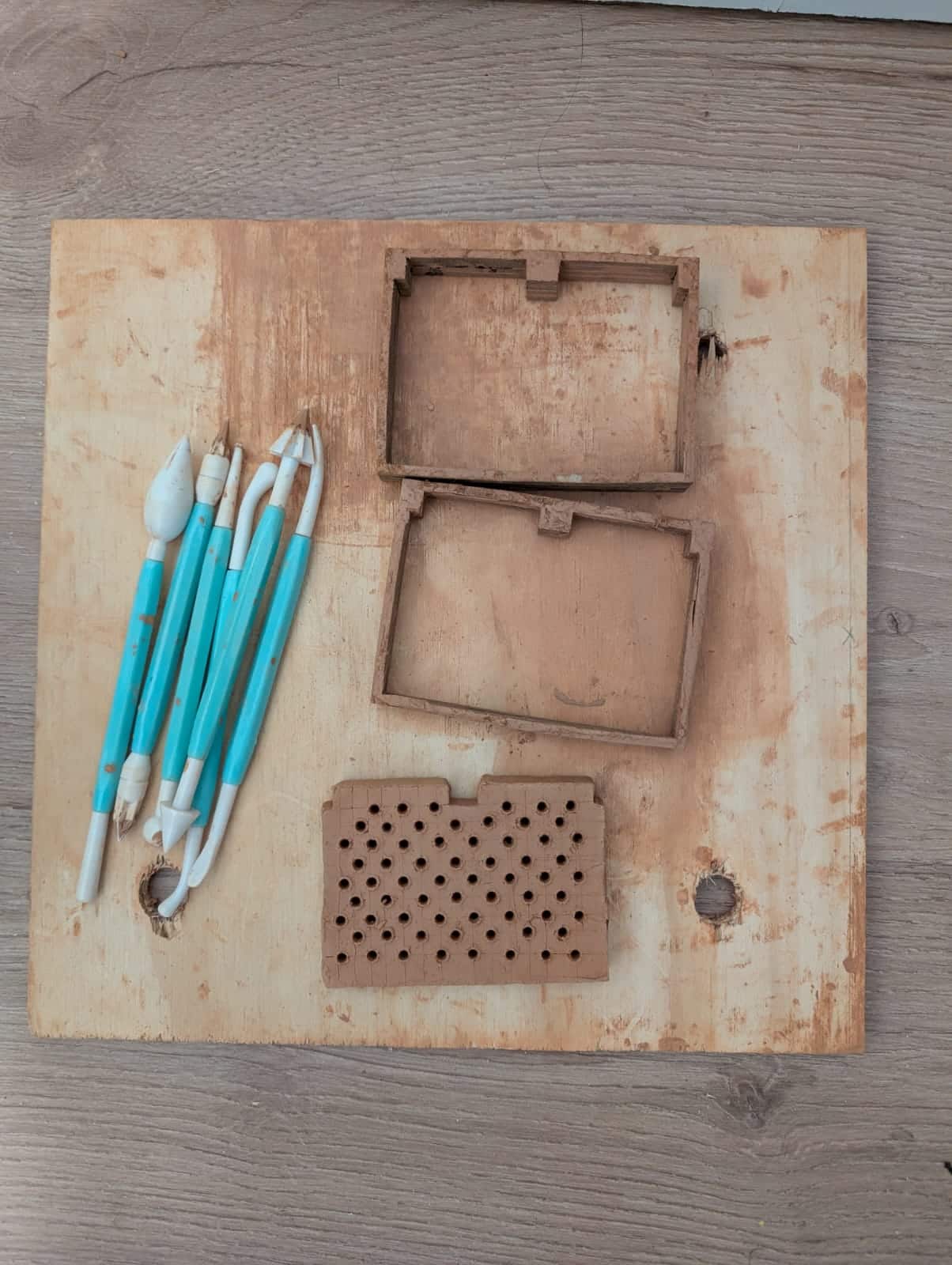

Image on the left – prototype using misting module . Image on the right- using Russel Hobbs heating component to generate steam and clay to regulate humidity in a space.

Performance – what is the phenomenon?

SteamSense is a unique system designed to regulate humidity using steam, airflow, and eco-friendly clay panels, ensuring optimal air quality and a healthier environment.

The core phenomenon of the SteamSense system relies on a dynamic feedback loop that regulates humidity by integrating steam generation, airflow circulation, and moisture absorption. Through continuous monitoring and real-time adjustments, the system maintains optimal indoor humidity levels for a healthier and more comfortable environment.

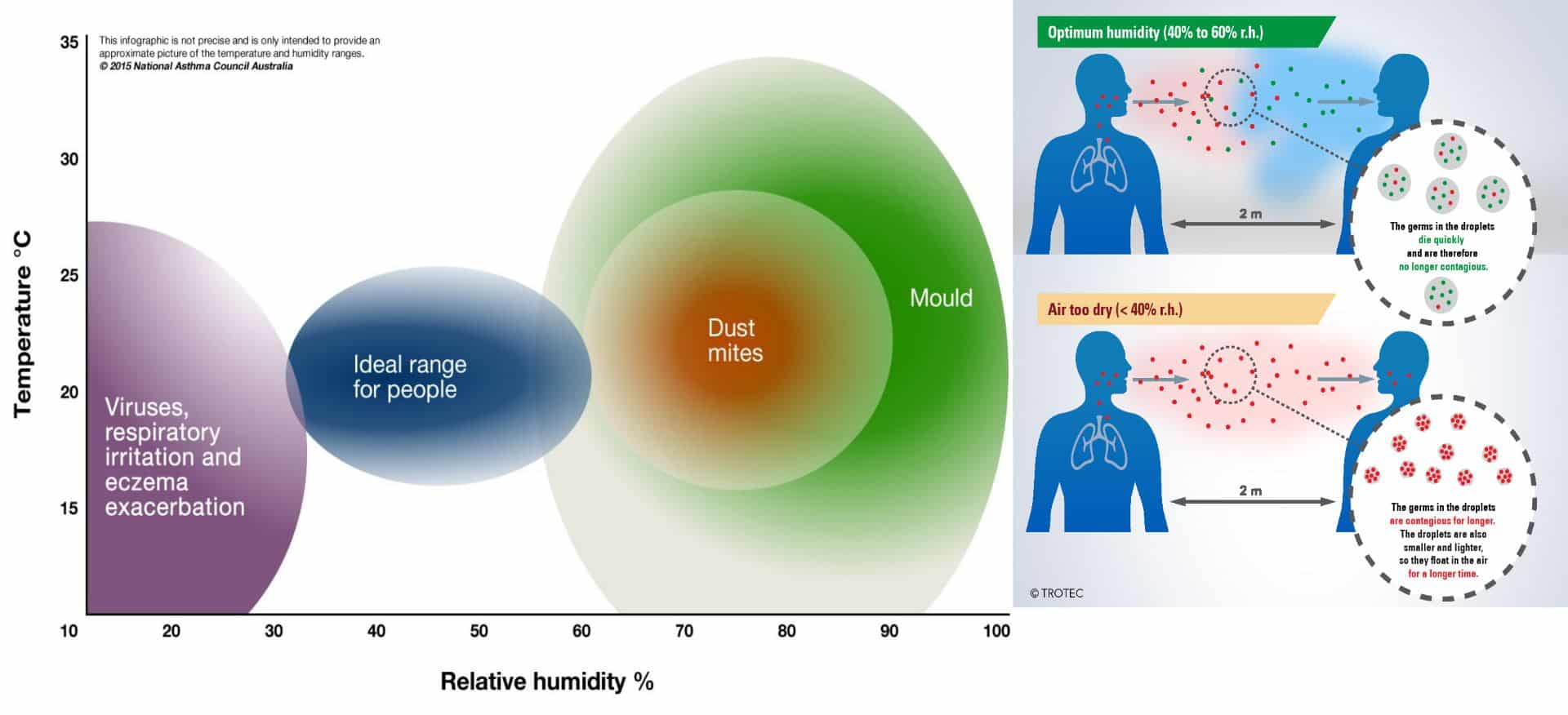

The SteamSense system’s ability to regulate humidity directly impacts the comfort and well-being of the human body. By maintaining balanced humidity levels, it can improve air quality, enhance skin hydration, reduce respiratory discomfort, and increase overall comfort in environments with fluctuating humidity. If the humidity level is below 40% , the human body will experience dryness from the surface of their skin to their respiratory system. Also, there are higher chances of viruses being airborne and inhaled into the human body. Above 60% humidity in the air would cause excessive yet inefficient sweating, more water loss from the human body causing dehydration, which can result in fatigue , disturbing the work flow. It can also cause discomfort as sweat would stick to the skin.

Material

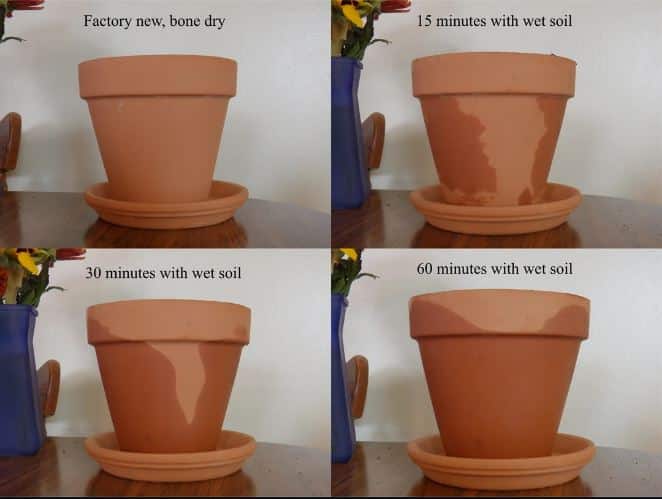

Clay plays a crucial role in the SteamSense system due to its high moisture absorption capacity. By acting as a natural dehumidifier, clay panels absorb excess moisture from the air, helping to balance humidity levels and create a more comfortable indoor environment. Its porous structure allows it to retain moisture and release it slowly, ensuring sustained control over air moisture. Terracotta structures breathe because of the capillary system made while being molded and later developed in the kiln, forming a permanent capillary interior that can store water vapors and later emit out the water vapors. If you look at a brick structure, bricks would absorb water vapors in the air, which them produce white salts on the surface which can be removed easily.

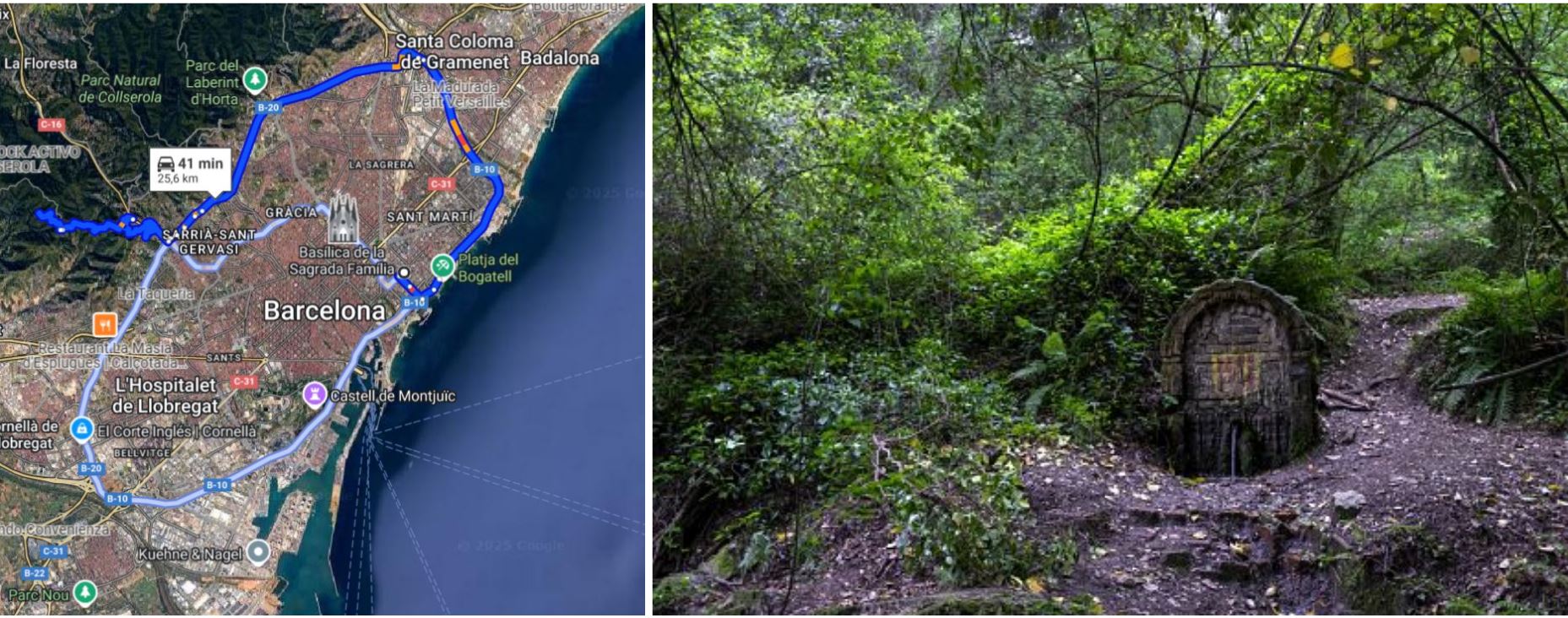

Material – Extraction site

The Collserola Range foothills, located near Barcelona, Spain, contain clay-rich soils that have historically been used for pottery and construction. The geological composition includes sedimentary deposits, with a mix of clay, silt, and sandstone, making it a suitable site for extracting terracotta-grade clay.While the Collserola foothills contain clay deposits, it’s essential to note that much of this area is now part of the Serra de Collserola Natural Park, a protected region dedicated to preserving biodiversity and providing ecosystem services. As such, new extraction activities within the park are likely restricted to maintain its ecological integrity. Overall, if you are looking for a clay, its the second layer of the ground after the ground you’re standing on, that is terracotta clay.

Material – Comparing project to vernacular case studies

SteamSense follows the wisdom of vernacular and traditional architecture, where clay has long been used for passive climate control. By integrating clay’s natural moisture regulation properties, the project modernizes an age-old technique for contemporary air quality solutions. Civilizations of old had knowledge of using terracotta clay as a construction material that is breathable , regulating humidity in the air, maintaining a form of environmental comfort for solstices and equinox seasons.

Despite terracotta clay being primitive, it has its benefits. Other than breathability, they can form stable structures with spaces to be dwelled in or any form of activities. Also, they can be sculpted to enhance an architectural elevation ( don’t know if I am saying that right) . Basically , you can use clay to enhance architectural elevation by sculpting intricate details, telling a story.

Material – How it was manipulated

In this project, clay will be utilized as a surface to absorb produced steam in the air. In the initial phase, clay was used to make perforated panels. On one face, the openings are equal in diameter, on the other face, the diameters vary for elevation aesthetics sake. Other than aesthetic, the panels are also functioned as de-humidifiers. They absorb steam and later re emit them in the air to regulate the humidity levels forming a comfortable environment.

A mold frame has to be formed using laser cut MDF boards. Ensure the clay is wet enough to easily cover the whole volume than have a semi wet clay and applying pressure on the surface to cover the mold’s volume. Once the shape is defined using the mold, start adding holes into the panel. The openings are inspired using a vernacular design of bottle openings. Wider bottle openings take in hot air, escaping into the smaller openings which is compressed to cooler air. In this scenario, , the panel’s face with wider, equal in diameter openings, will be facing outside where as the smaller openings will be facing inside. Steam cannot escape much from smaller openings. And even if steam enters into the smaller openings, it will be absorbed by the interior wall of the panel openings.

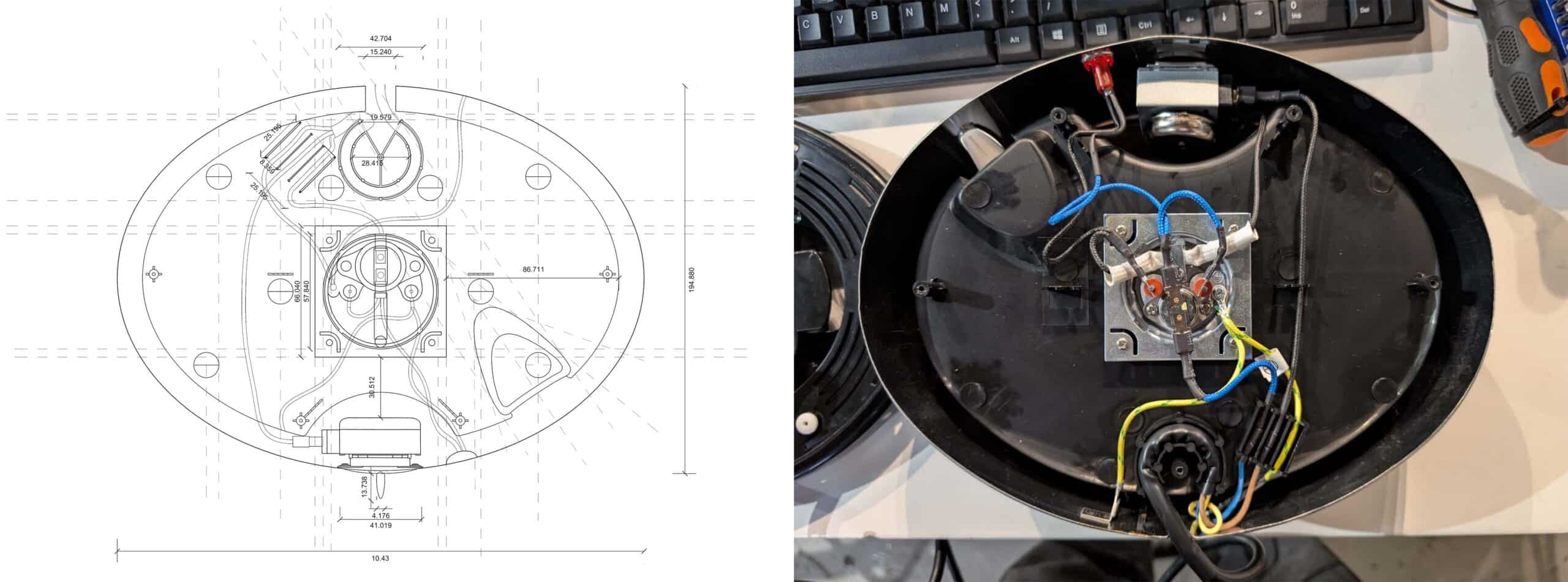

Fabrication – The use of Russel Hobbs steam cooker

The previous prototype , the misting module and fan of Sanda aromatic diffuser was used to emit water mist into the air. This time, an analog device was used to easily be activated using sensor readings and values.

The heating component, being the heart of the machine, generates heat to boil water, converting water into steam.

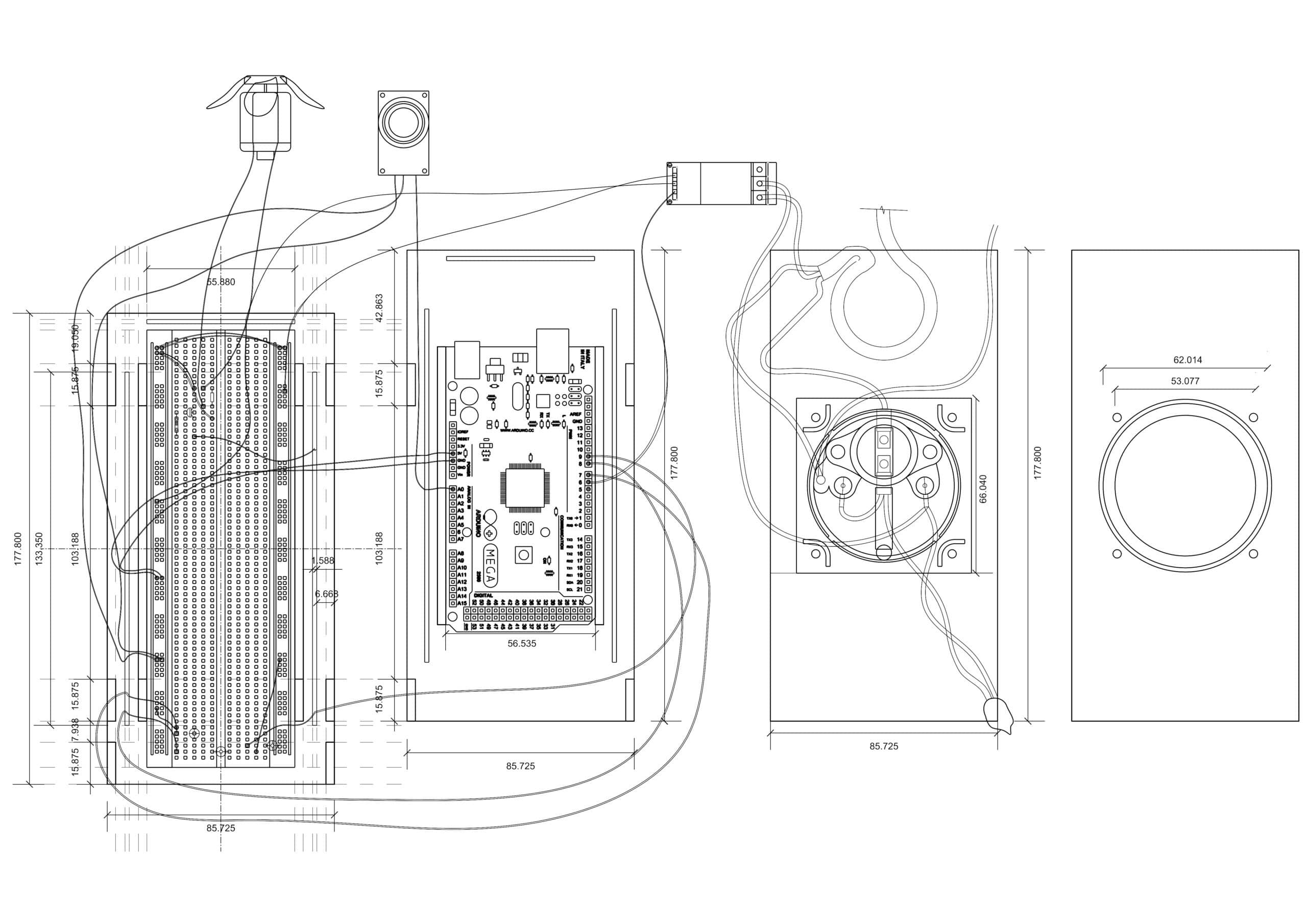

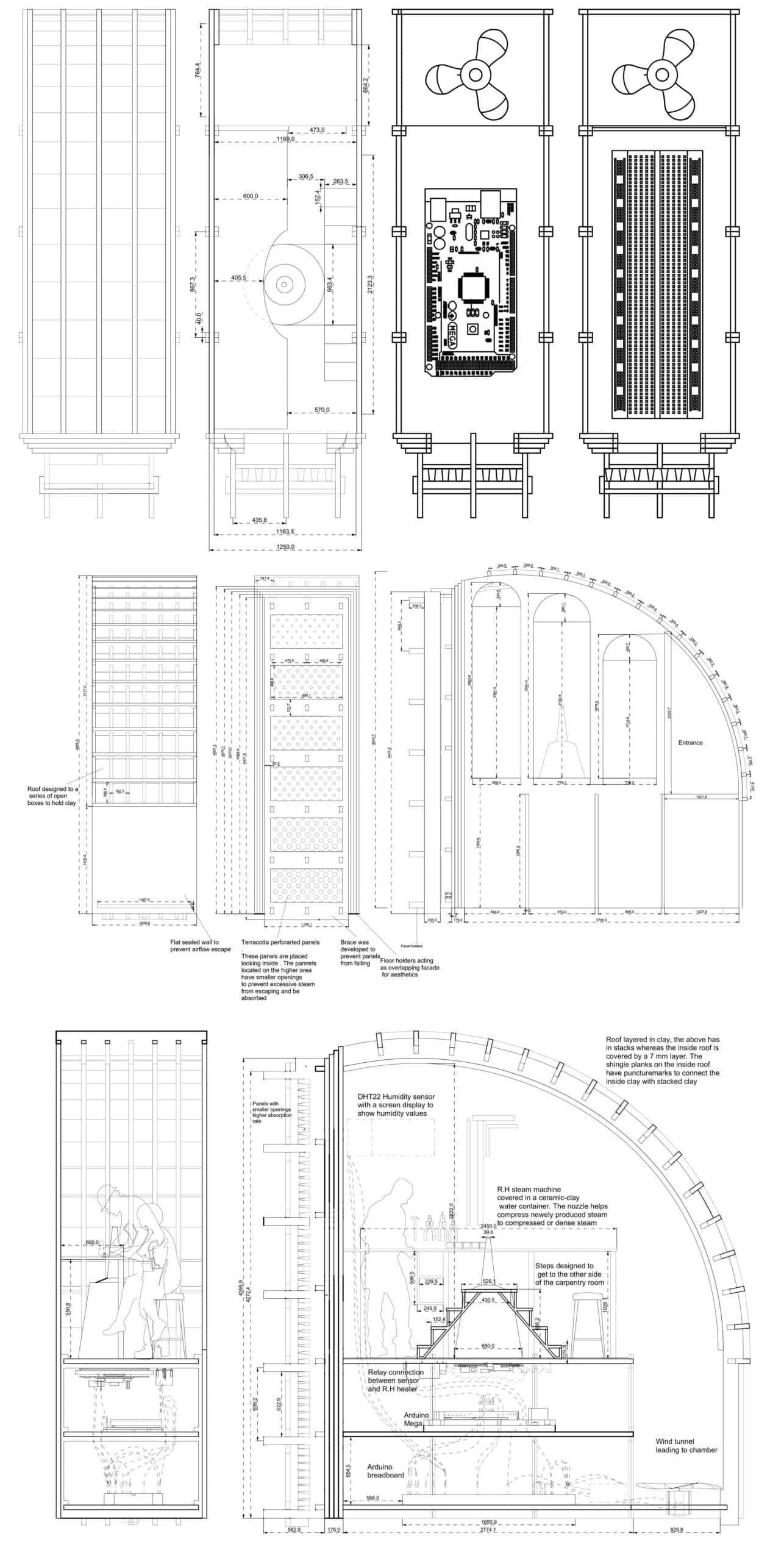

After dismantling and documenting in form of drafts, it was merged with the arduino sensor and fan system using a relay component. Components were : Arduino circuit, breadboard, jumpwires, DHT22 Humidity and temperature sensor, 3-6v motor fan and an LCD screen to display readings of humidity.

Fabrication – The physical fabrication

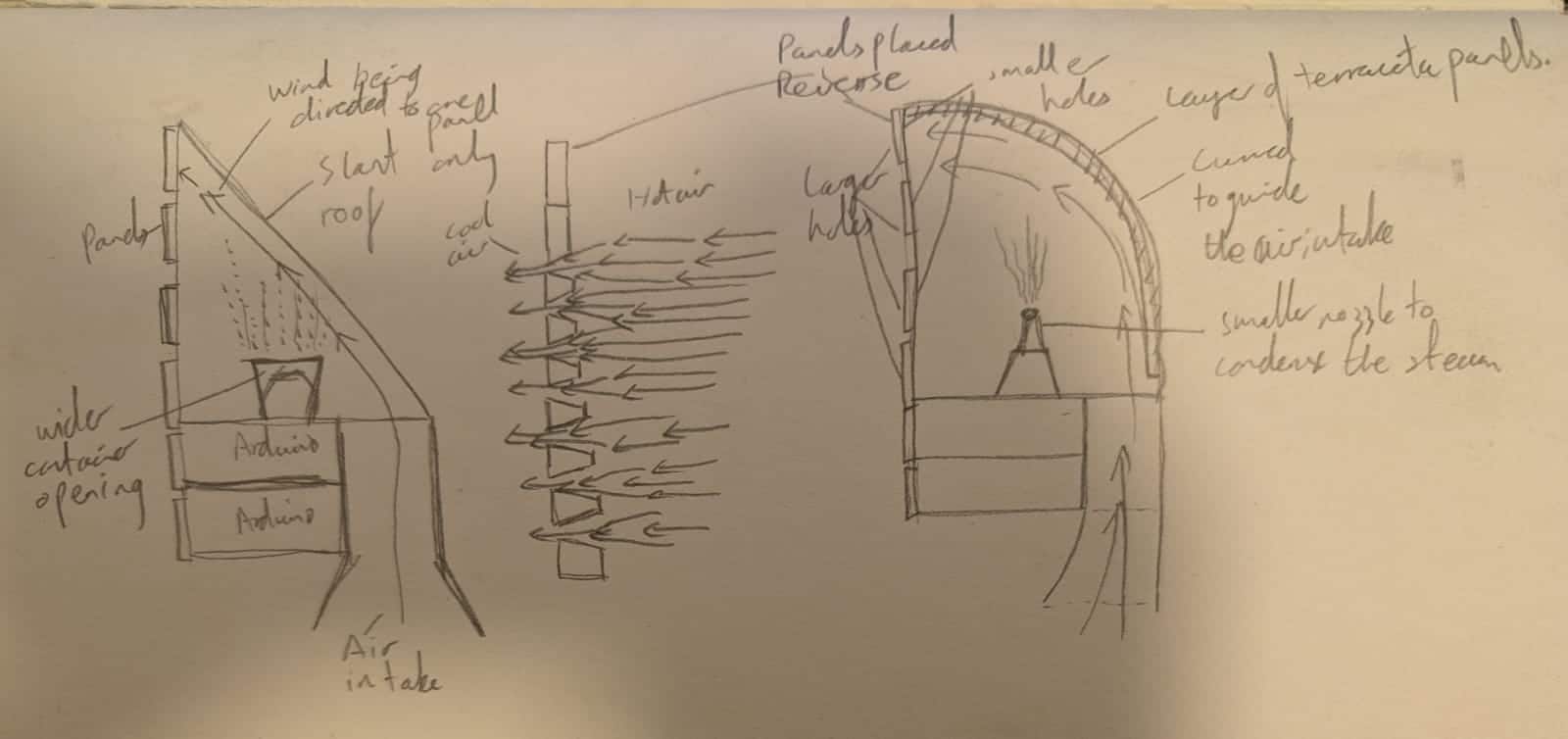

The prototype from midterm was just to understand how the flow of the air would work and distribute the steam. The sketch on the left , a flat yet slanted roof cannot properly guide the air intake towards the panels.

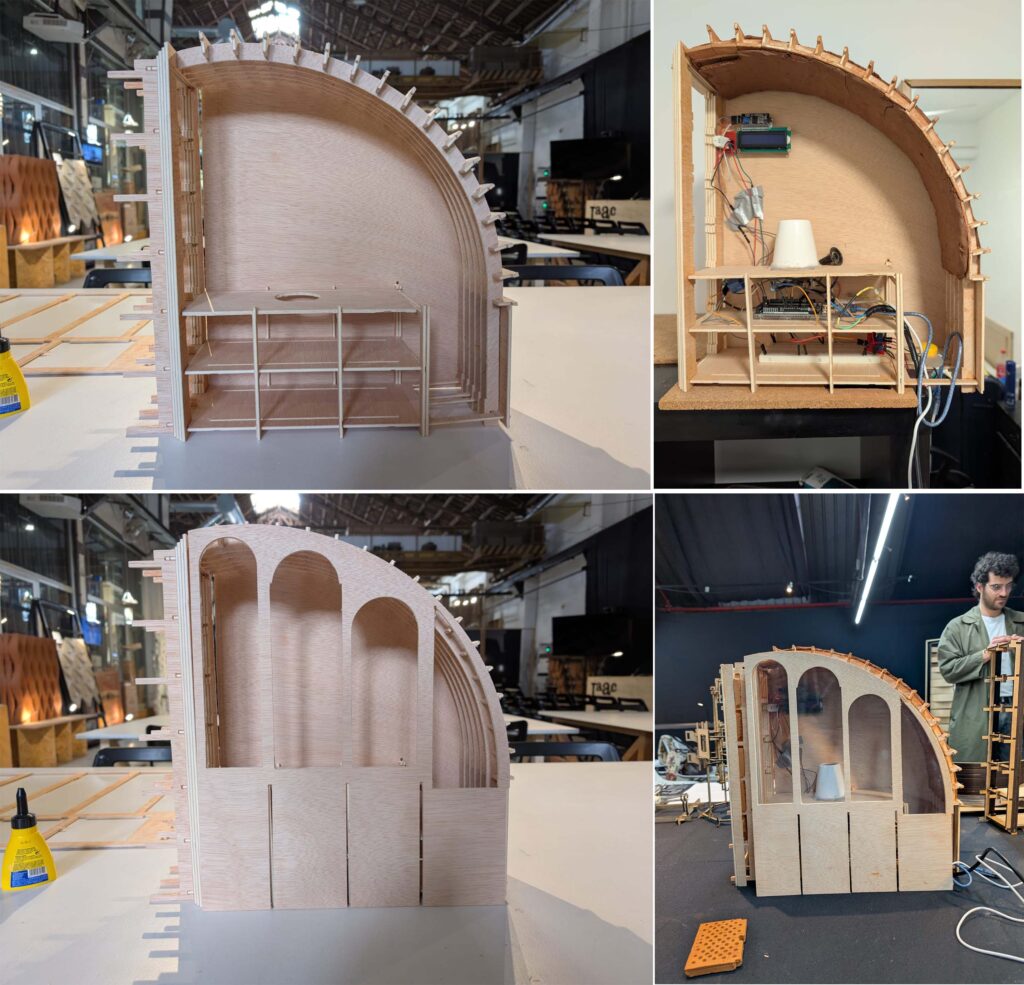

The water container was wide to let steam come out as a light vapor than a dense vapor. Changes were then made in the new prototype sketch. The roof was curved to guide the air intake towards the panels. The container has a smaller nozzle to condense steam , making it look like a thick gas visible to be seen in the air. The panels are placed reverse, the face with smaller holes would face the steam whereas the face with equal diameter holes will be facing outside( which will be explained in a bit ).

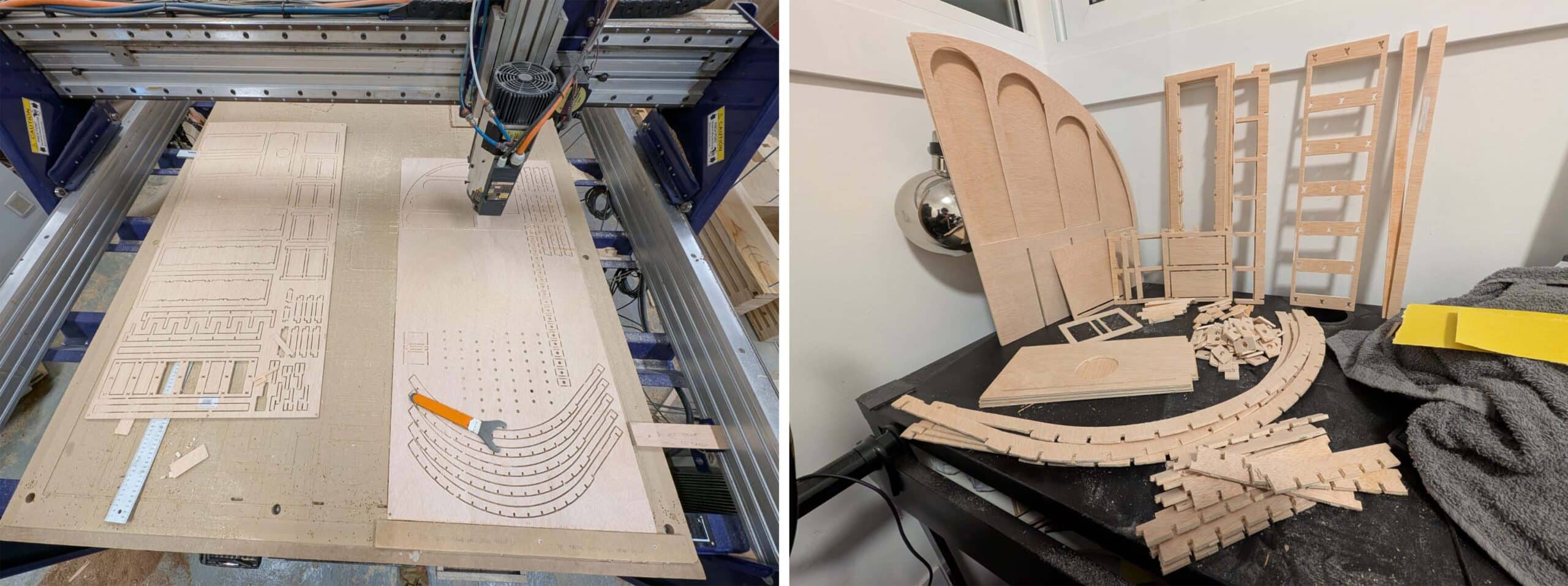

Using MDF laser cut board, a prototype was developed to have a clear idea of the physical form. The roof was made using strips of MDF board. Despite it accomplishing the form, in reality it was not practical if made at 1:10 scale. Once the prototype with few corrections were defined, the material was switched to using Plywood.

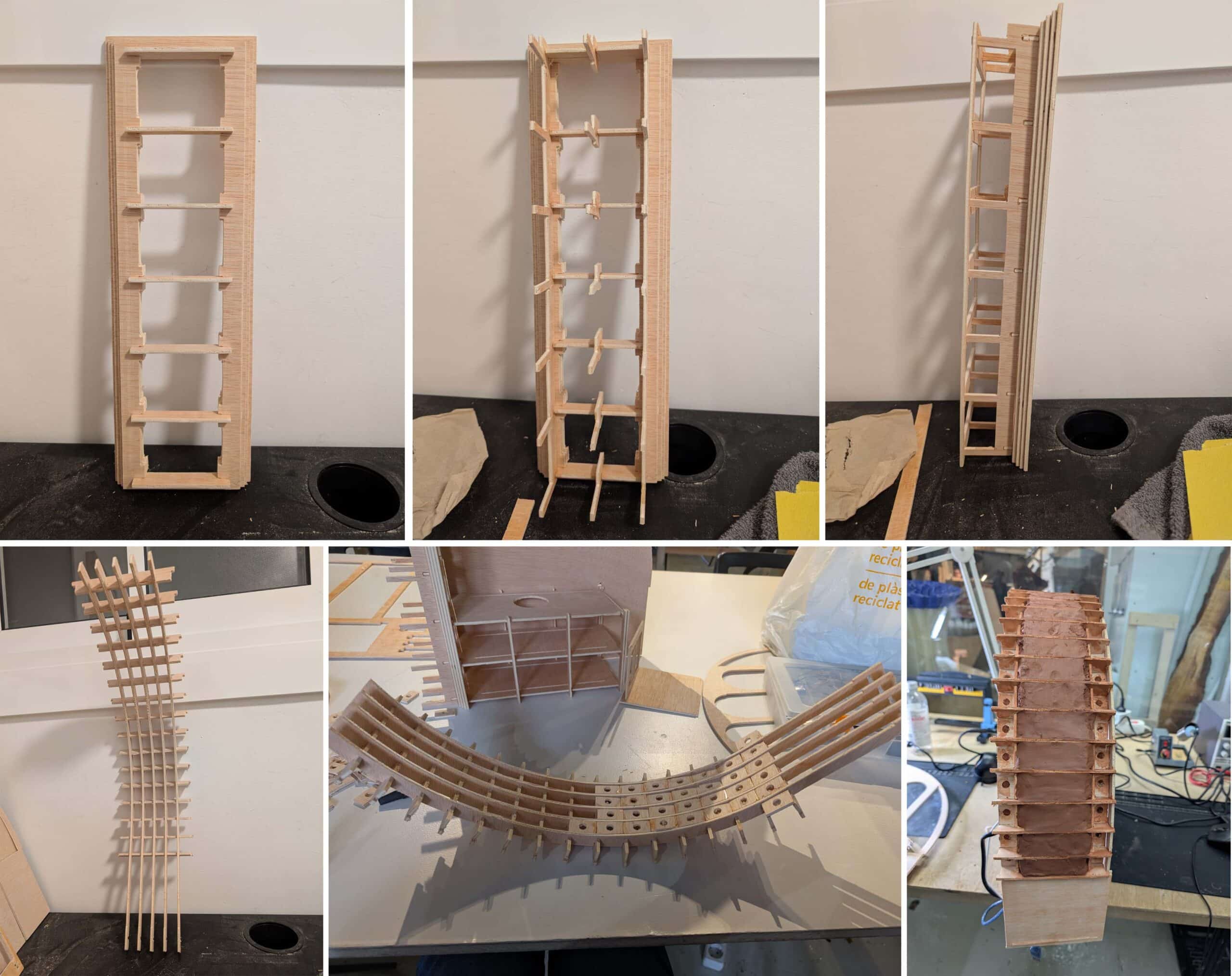

After 3d modelling the form and forming CNC drawings, ensure proper tolerance numbers for the joints.

The roof is in form of an interlocking spine, forming box like openings that will be covered by punctured shingles from the inside. The outside , which form boxes, hold the terracotta clay in stacks whereas the shingles with puncture holes act as a platform for a layer of terracotta. The puncture holes act as an opening connection between the inside and outside terracotta clay.

Plans, sections and elevations

The prototype was made 1:10 in scale, to form an architectural space. The space selected was a carpenter workshop. The prototype had a plus point that the steam can be used to suppress dust in the air , the dust caused from the shaving and sawing of wood.

Physical Computing

Pseudo Code Statements for Physical Computing scenario 1

Initialize System

- Start communication with LCD display.

- Set up DHT22 sensor to measure humidity.

- Define fan and steam release mechanism (relay).

- Ensure steam release is OFF at startup.

Read Humidity Value from DHT22 Sensor

Check Humidity Conditions:

Keep fan OFF.

If humidity < 50%

Display “Generating Steam” on LCD.

Activate steam release relay (turn ON).

Run for a set duration (e.g., 30 seconds).

Turn OFF steam release relay.

If humidity is between 50% and 60%

Display “Humidity Stable” on LCD.

Keep steam release OFF.

If humidity > 60%

Display “Extracting Steam” on LCD.

Turn ON fan in normal direction (blowing air into the system to push out excess steam).

Run for 10 seconds.

Turn OFF fan.

If humidity drops below 50% again after extraction

Display “Removing Residual Steam” on LCD.

Reverse fan direction (sucking air out from the clay panels).

Run fan in reverse for 10 seconds.

Turn OFF fan.

Repeat the Loop every second to update humidity values.

Conclusion

Improvements could be made such as :

have a R.H heating platform layered with a better heat resistant and water resistant material than silicon glue

Having a better fan than the 3-6 volt motor fan

Make a mold for the holes in the panels be uniformly/ cleanly made

SteamSense harnesses the power of natural humidity regulation by integrating steam, airflow, and clay absorption—bridging the gap between traditional material wisdom and modern adaptive climate control. By learning from vernacular techniques and refining them through controlled automation, this system offers a sustainable, low-energy solution for indoor comfort. Looking ahead, SteamSense has the potential to be adapted for various environments, from residential spaces to specialized industrial and agricultural applications, promoting a more resilient and balanced indoor atmosphere.