Exploring Boundaries and Breaking Limits: A Glimpse into the Structural Design for 3D Printing

Introduction

In the inspiring journey through the 3D Printing Architecture (3DPA) postgraduate program, we delved into the enigmatic world of structural design specific to 3D printing during our recent workshop. Grounded in the principles of architecture and pioneering the forefront of additive manufacturing technologies, the workshop catapulted our knowledge and skills into a realm where traditional and modern design methodologies collide and meld.

Key Takeaways from the Week

From the first introductions to computational tools and modeling to understanding the intricate structural behavior during 3D printing processes, every step was a meticulous blend of theory and hands-on experience. This blog unwraps the fascinating journey through a workshop that bridged the gap between conceptual knowledge and practical application.

Day 1: Nurturing Exploration through Computational Design

The initial day immersed us in exploring geometrical features using computational tools, focusing on the creation and analysis of NURB curves within a specified boundary box. Each participant was tasked with developing, analyzing, and refining 3D printed designs, culminating in a collective examination of structural performance and printed outcomes amongst groups. This methodical approach allowed teams to witness firsthand the repercussions of design variations on structural integrity, particularly in resisting buckling.

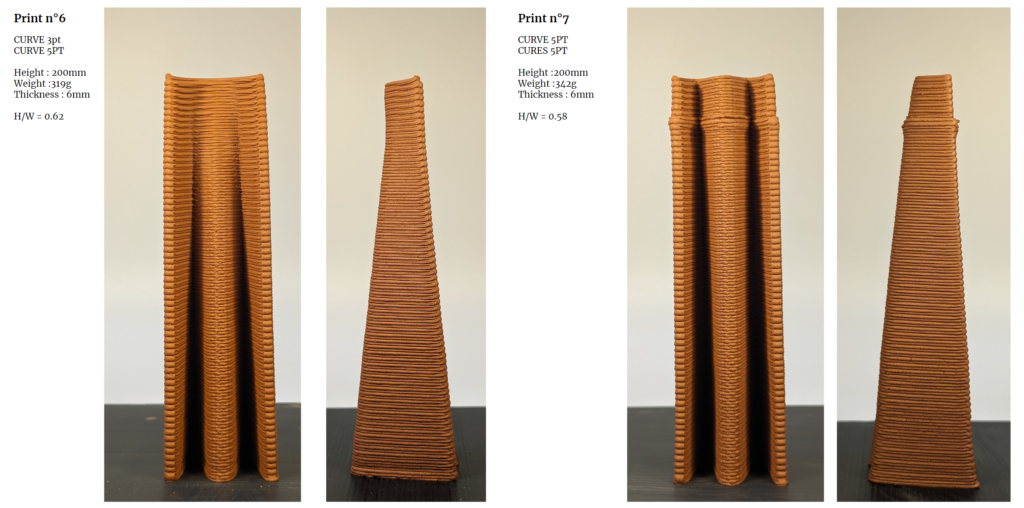

Day 2: Delving Deeper with Selective Improvement

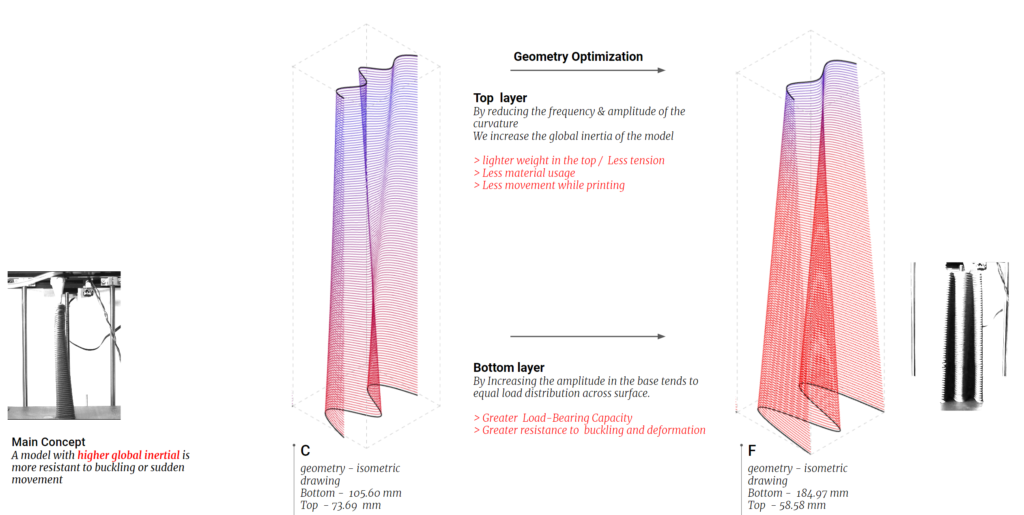

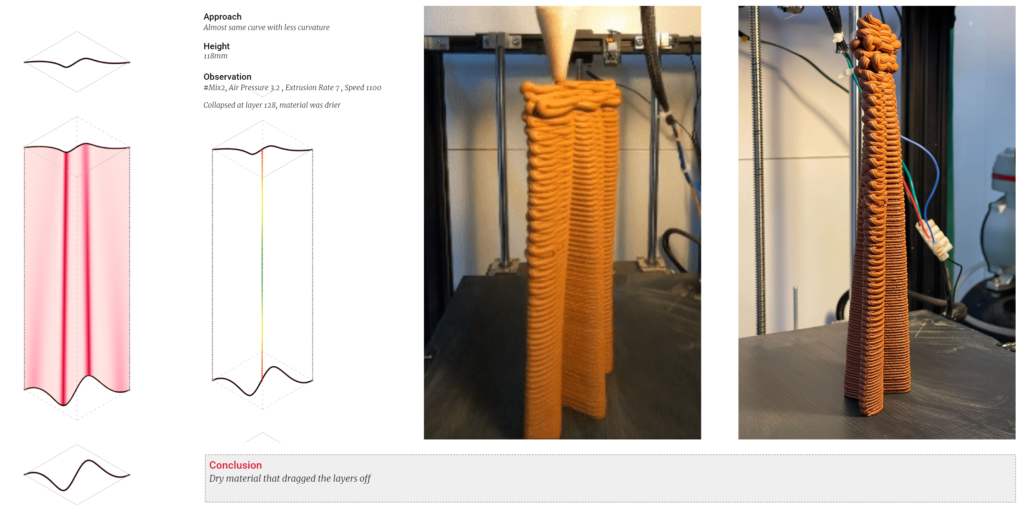

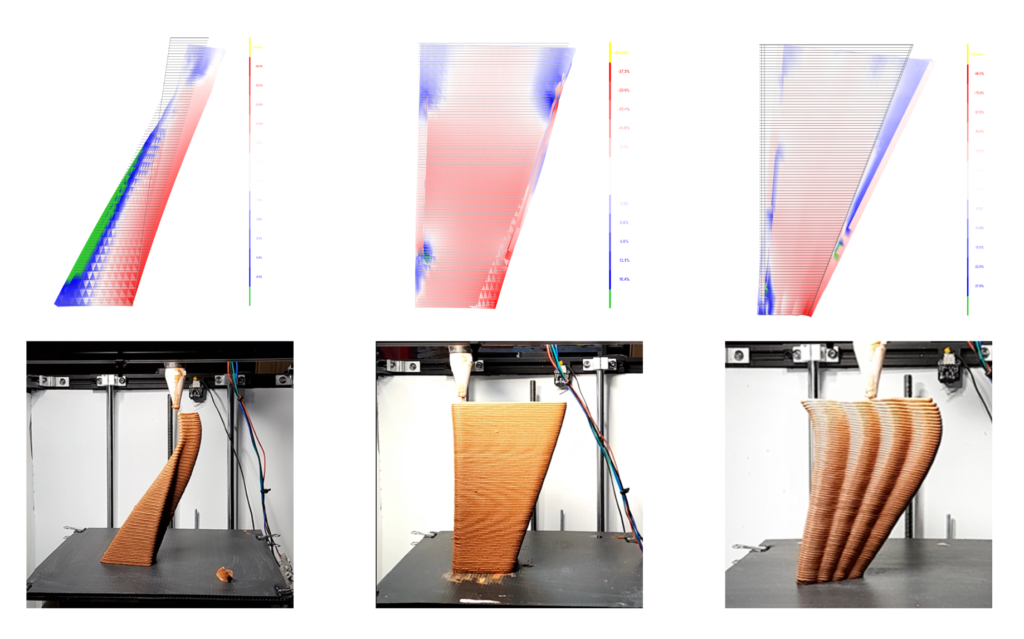

Day two deepened our exploration into structural concepts identified in the first catalogue, employing the 3DPA toolbox for analysis and iterating on previous designs to further understand their structural behaviors. Participants wrestled with the balance between geometric intricacy and structural soundness, pushing the boundaries of what was achievable with desktop 3D printing technology. Through analysis and physical testing unto failure, every collapse and success brought invaluable insights.

Day 3: The Art and Science of Cantilever Columns

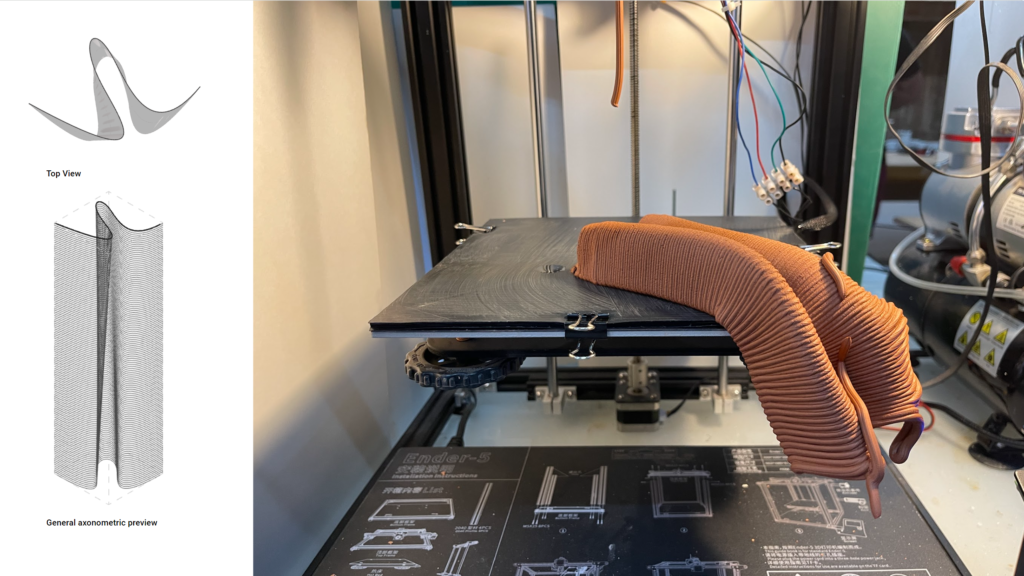

With a shift towards the study of cantilever structures on the third day, participants engineered designs to stretch the boundaries of what is possible within a new bounding box. The approach demanded an understanding of tension and compression within the structures, utilizing closed or self-intersecting curves to enhance strength and durability. The exercises intricately wove theoretical knowledge with practical applications, ensuring a grounded understanding of material behavior during and post-printing.

Day 4: Scaling Heights with Large-Scale Printing

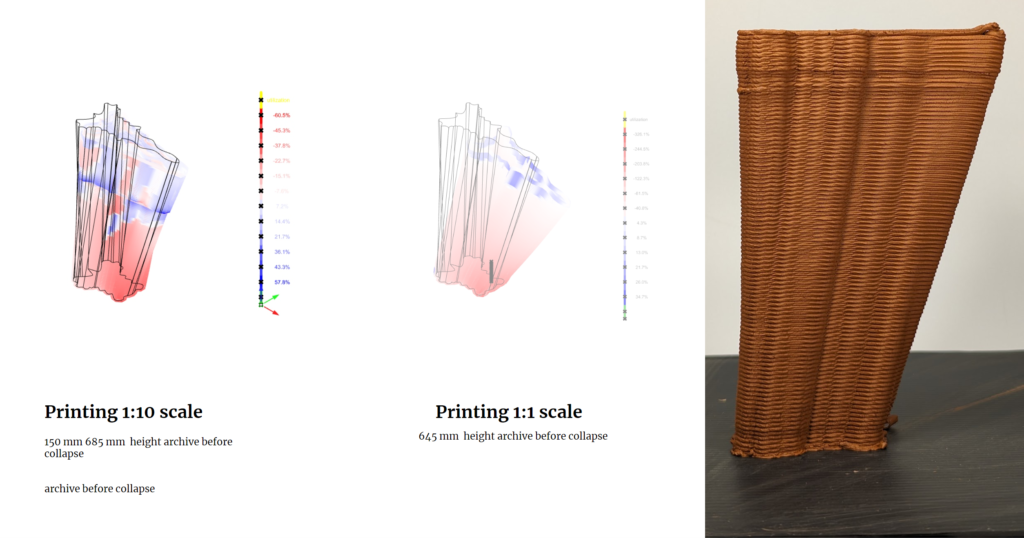

Stepping into larger territories, day four presented the exhilarating challenge of translating our small-scale designs into larger structures utilizing On-Site 3D Printers. The nuances of preparing homogeneous and consistent material, ensuring flawless printing processes, and foreseeing potential extrusion defects were brought into sharp focus as groups navigated through the complexities of large-scale 3D printing.

Wrapping Up a Week of Discovery

This enthralling week not only enriched our technical prowess but also honed our abilities to perceive, adapt, and innovate within the rapidly evolving world of 3D printing in architectural applications. From conceptualizing in the virtual space of design software to witnessing the physical collapse of structures, every moment was a step towards understanding and respecting the profound relationship between design, material, and structural behavior in 3D printing.

As we close this chapter, the insights gained promise to seed future explorations and innovations, propagating the knowledge acquired through failures and successes alike in the vast field of 3D printed architecture.