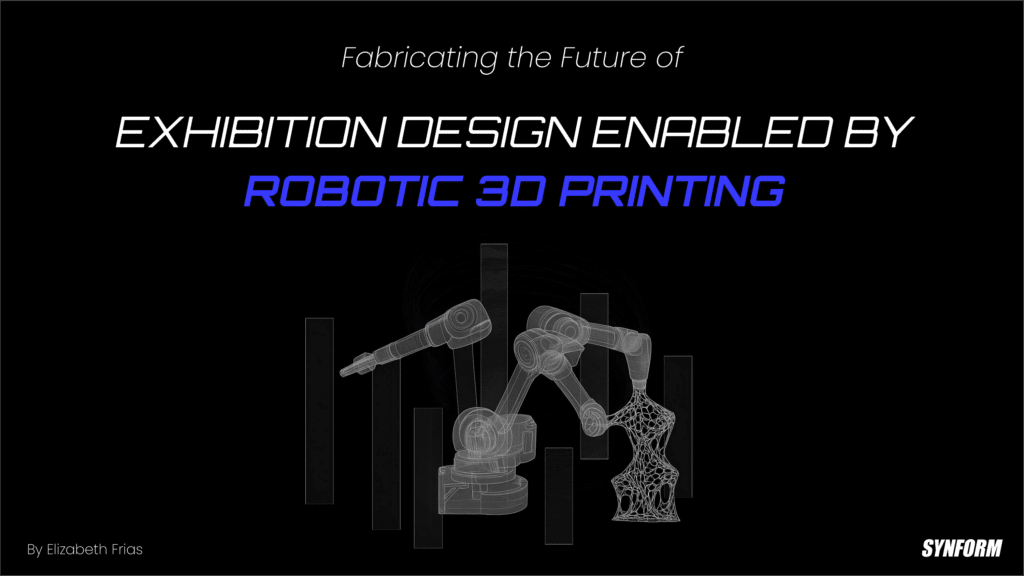

SYNFORM is a design-to-fabrication studio that fabricates luxury scenography and architectural surfaces that are parametric, modular and reconfigurable through large-scale 3D printing using recyclable plastics.

Market Context

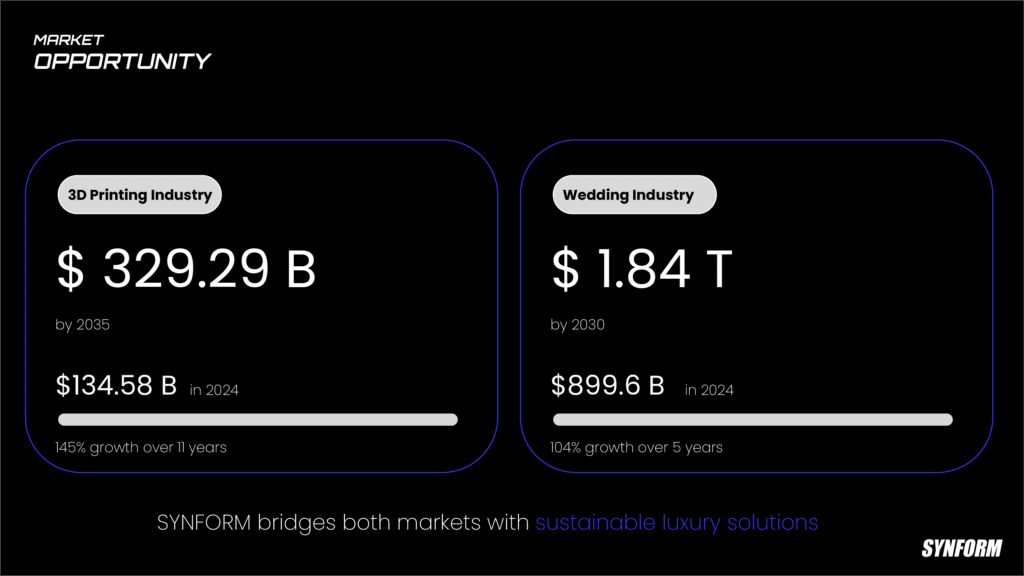

According to Precedence Research, the global 3D printing market is estimated at around USD 29.29 billion in 2025 and is projected to grow to USD 134.58 billion by 2034, with an annual growth rate of about 18.5%. Within that, the construction and infrastructure segment – including interior panels, façades, modular components and structural elements, is still relatively small (about USD 18.2 million in 2022), but it’s one of the most promising areas because more companies are starting to explore robotic additive manufacturing for architecture.

Robotic additive manufacturing has some very clear advantages:

- it allows mass customization instead of mass production,

- it can work on demand,

- it supports different materials,

- it scales up to architectural sizes, and

- it can drastically reduce waste compared to traditional fabrication.

Within this universe, I’m particularly focused on pellet-based 3D printing (FGF – Fused Granulate Fabrication). Instead of printing with expensive filament, FGF uses plastic pellets, the same format used in the conventional plastics industry. That means:

- I can use low-cost pellets instead of premium filament,

- I can work with recycled industrial polymers like PETG, PP, HDPE and ABS,

- I get very high deposition rates, so I can print large elements fast,

- I can produce complex sculptural geometries that are perfect for ephemeral or modular systems.

Mexico is an ideal place to do this. The country is Latin America’s leader in PET recycling, with a collection rate of around 64% in 2024, about 578,000 tons per year, and the capacity to process up to 81% of all PET generated nationally. Recycled PET is already being transformed into sheets, bottles, textiles and pellets in large facilities such as the Apan, Hidalgo plant, one of the biggest in the world for food-grade PET. This means I have local access to cheap, high-volume, recycled feedstock ready to be extruded into new spatial experiences.

Conclusion: Many temporary architectural elements with virgin materials and disposable techniques, drywall, wood, foam and single-use structures that end up in landfills after a single weekend.

If we can redirect even a fraction of that recycled plastic back into modular, reusable spatial systems, we can simultaneously address plastic waste and wasteful construction practices in events and architecture.

Problem

In the events, hospitality, retail and experiential architecture industry I consistently see the same issues:

Massive waste, time-intensive fabrication, geometric and creative limitations and lack of modularity and reuse. These problems generate environmental impact, push budgets up, and still fail to deliver the level of innovation and uniqueness that high-end clients expect.

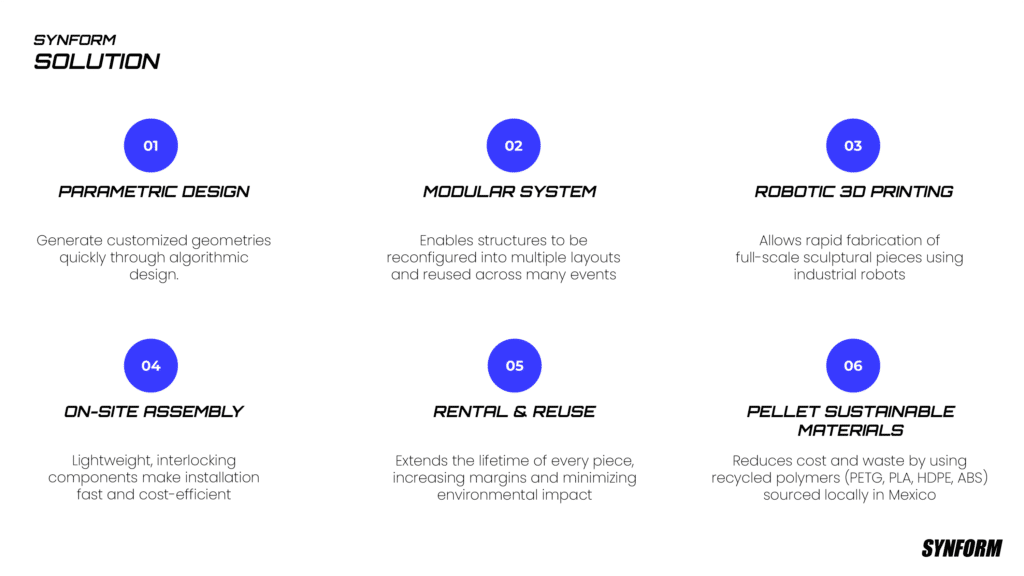

Solution

SYNFORM proposes a different model: robotic, circular scenography and architectural surfaces.

The result is:

- lower material waste,

- faster production and iteration,

- more expressive geometries than traditional methods, and

- a business model based on renting and reusing assets, not throwing them away.

Market: Why now?

Several trends converge right now:

- The 3D printing industry is scaling fast, and construction-related applications are moving from experimental to commercial.

- The experience economy: Weddings, concerts, festivals, exhibitions and brand activations is huge and growing, particularly in Mexico’s major cities and tourist destinations. In many high-design weddings and events, scenography accounts for a significant share of the budget.

- Mexico’s role as a PET recycling leader creates a reliable supply of recycled plastic pellets, enabling large-scale, low-cost production with a credible sustainability story.

This makes 2025–2030 the right window to build a robotic fabrication studio that connects these dots.

Competition

My main competition today is not other robotic studios; it’s traditional set builders and fabricators:

- carpentry and metal shops,

- companies focused on truss + LED staging,

- decor rental firms with conventional inventory.

Internationally, studios like Nagami or La Maquina are pushing robotic fabrication for design and architecture, but in Mexico and Latin America the field is still almost empty, especially for large-format, pellet-based printing targeting events and experiential architecture.

SYNFORM aims to become the first mover and reference studio in this niche.

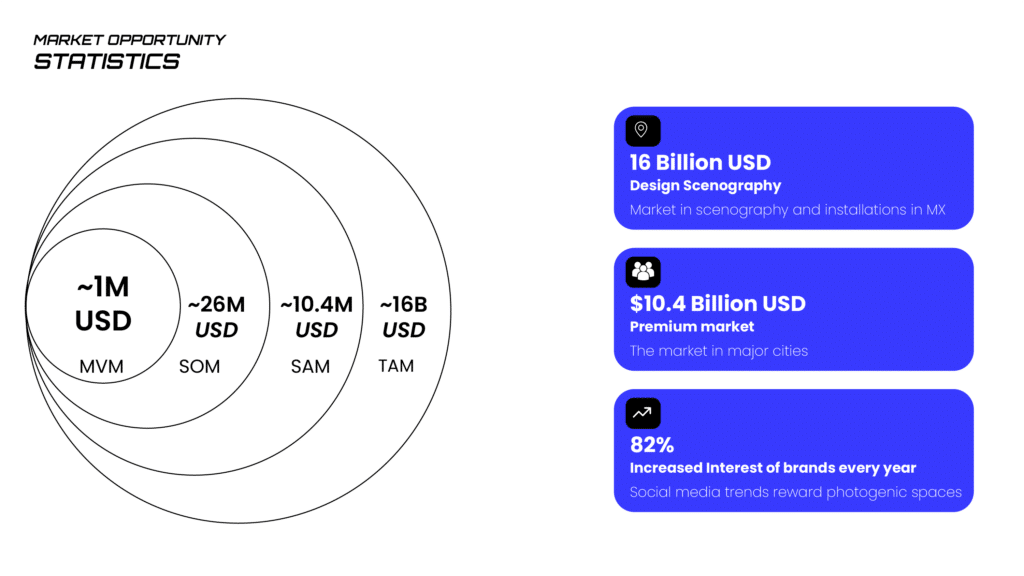

Market Opportunity

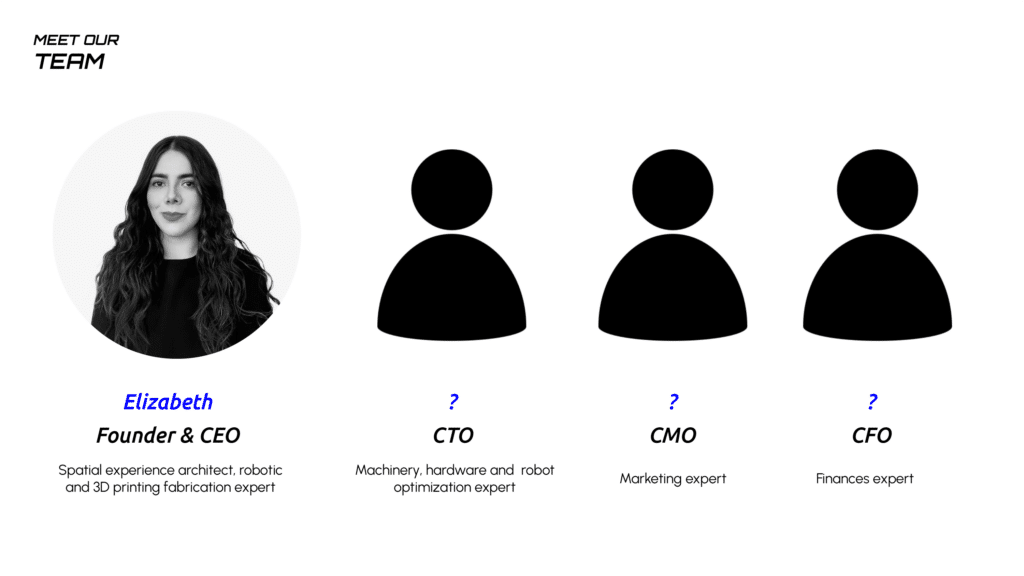

Team

Funding Need

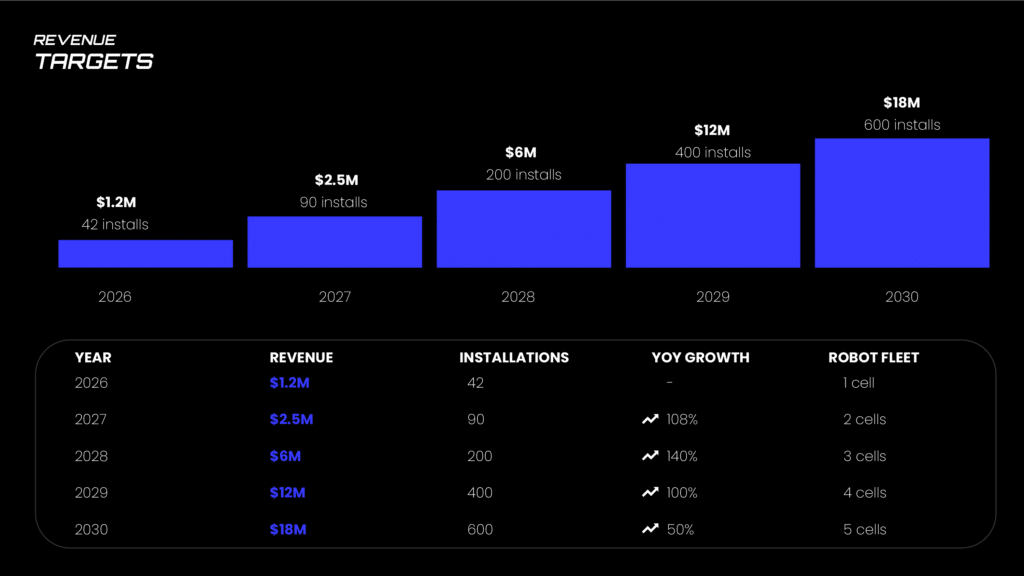

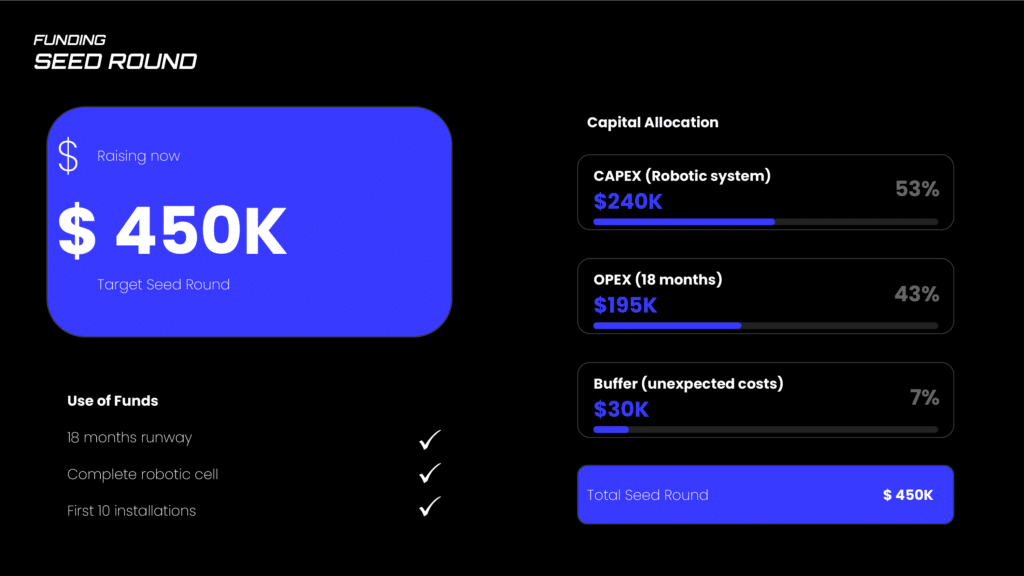

To fully deploy SYNFORM’s first phase, I am raising a seed round in the range of USD 450,000–500,000.

This capital will fund:

- acquisition and commissioning of the first robotic cell (ABB robot + pellet extruder + control system),

- a logistics vehicle for transporting installations,

- 18 months of operating runway for a small core team,

- development of a modular product catalog and key pilot projects,

- and initial investments in marketing and partnerships with planners, brands and architecture studios.

The objective is to reach around USD 1–1.2M in annual revenue and prove the model strongly enough to justify a second robotic cell and regional expansion.

SYNFORM exists because I believe we can use robots and recycled plastic to transform how we design and build temporary spaces, making them more expressive, more efficient and dramatically less wasteful.

If you are:

- an investor interested in robotics, circular materials or the experiential economy,

- a planner, brand or festival searching for a new kind of scenography partner,

- or an architecture studio exploring complex surfaces and modular systems,

I’d love to connect.

Let’s turn Mexico’s recycled plastic into the next generation of sculpted spaces—and prove that technology, design and sustainability can truly align.