THEORETICAL LENSE

Util_huts examines the ubiquities of traditional concrete design, construction and supply chain methods through the research and development of a design tool for backcountry safety huts in Iceland. This tool uses techniques in machine learning, parametric design and structural simulation to explore the architectural possibilities of cement mortar mixtures with basalt aggregates, also known as Volcanic Pozzolan Iceland (VPI). By using the aforementioned methods, the study examines both the material and form’s performance in Iceland’s environmental context, and explores ideas of adaptable and more efficient fabrication workflows

The project was inspired by a line in the Centre for Information Technology and Architecture (CITAS) manifesto;

By understanding materials not as static or inanimate, but as engaged in complex behaviors and performances, new dimensions of design potential are unleashed, innovating structural thinking and creating better and more sustainable material usage

The project operates at two scales:

- On the macro it engages in the global conversation of concrete’s sustainability and it’s effects on green house gas emissions. Learning from best practices in pre-cast concrete production and advancements in cement 3d printing.

- While also harnessing the wealth of knowledge found at the micro (local) scale. Drawing inspiration from vernacular form, material and construction practices.

This micro+macro theoretical leanse coupled with parametric and machine learning techniques has produced a pre-fab and mass customization workflow that strives to reduce energy consumption and material waste.

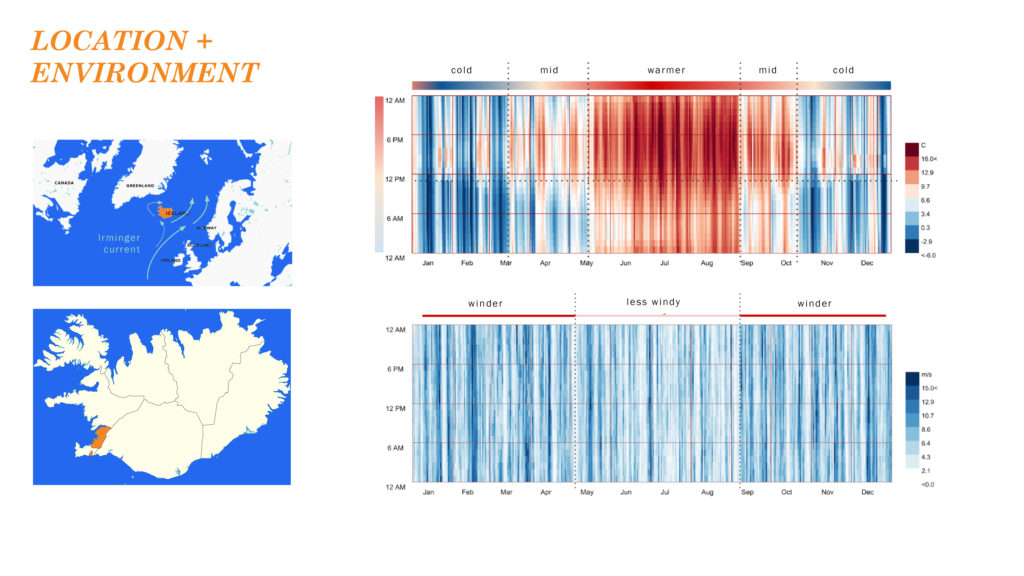

LOCATION

The project is located in Iceland, and more specifically the country’s capital region which, despite it’s location in the North Atlantic, is surprisingly temperate, with the average temperature ranging from 16 to -6 degrees celsius, thanks to the warm air carried up by Irminger’s current.

That said, it is incredibly windy. Often receiving winds up to 25 m/s. This is the environmental element most are concerned with. The majority of the time architects avoid placing openings at the SE aspect of their projects.

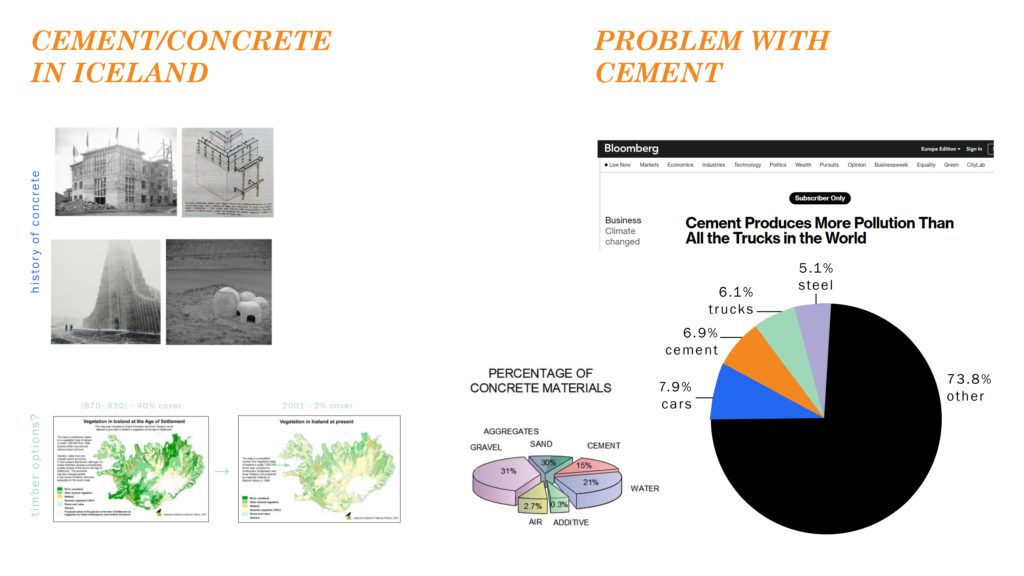

CEMENT IN ICELAND

The concrete and cement industry has particular importance within Iceland´s architectural vernacular – it can withstand the country’s high levels of moisture, extreme wind and seismic activity. Additionally, having rapidly developed in the post WWII era, during the height of brutalism in Nordic countries, concrete and cement are well understood and deeply ingrained within the country’s AEC industry. However, this widely used material has a massive carbon footprint, emitting 5-8% of global greenhouse gases (GHG). The importance of finding a more sustainable material in Iceland is increasingly acute. The country currently imports its cement from Denmark, and produces all other concrete components domestically.

While wood is a more “sustainable” option, it too has massive ecological and environmental impacts and is a far less viable option for Iceland, which has only 2% tree cover, and cannot produce it’s own lumber, meaning the material would have to be imported – adding to the carbon footprint. Therefore a more sustainable and localized version of concrete is preferable.

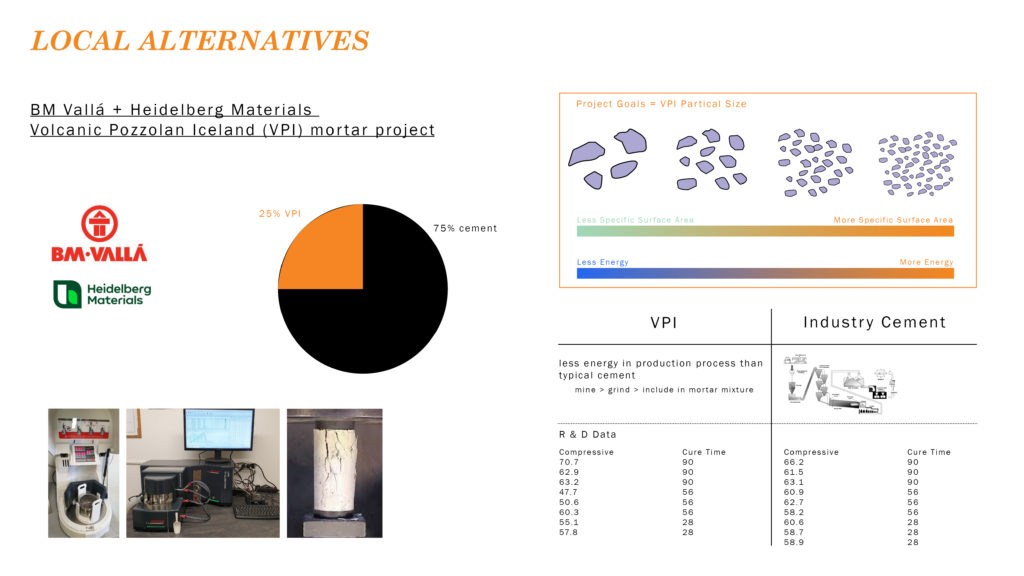

VOLCANIC POZZOLAN ICELAND (VPI)

The VPI cement mortar is still in it’s research and development phase, however Dr. Børge Johannes Wigum, from Heidelberg Materials, who is overseeing the project at BM Valla, a local cement and concrete manufacturer here in Iceland, has been kind enough to share the data from their testing for the UTIL_HUTS project.

The VPI mortar project replaces 25% of cement in the mortar with VPI. The variable in the study is the particle size. The smaller the particle the better, as it enables higher specific surface area (ie more surface area for water to mix, the faster the reaction occurs and the mortar settles). A finer VPI means less water needed (opposite of cement). However smaller particle, means more grinding time, which means more energy used in production.

The attraction to VPI is that it is mined locally and requires dramatically less energy in the production process than typical cement. Which is simply mine > grind > include in mortar mixture. Unlike cement requires a complex process that consumes massive amounts of energy.

Comparing the compressive strength between VPI and typical cement we can see that VPI mortar takes longer to cure but is catches up in strength in longer cure times.

SEARCH AND RESCUE HUT

The material is tested through the architectural context of search and rescue huts, due to their small size, location a long the shoreline and highlands. The majority of the existing huts are in poor condition; and last but not least the research and rescue team (who run the huts) is a deeply ingrained and important institution within Iceland´s culture.

MASS CUSTOMIZATION WORKFLOW

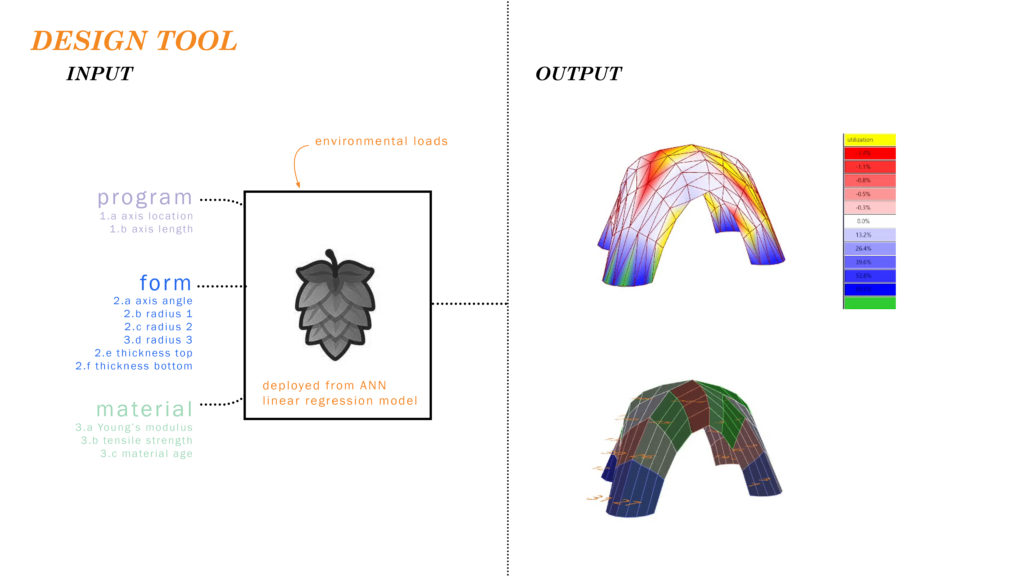

Through a machine learning model, deployed through the hops component in Rhino´s Grasshopper, users can adjust pre-defined parameters to find a form which adheres to the programmatic, environmental and topographic conditions, while gaining real time feedback on the material usage (ie utilization). Utilization is the percent of material mass that is being used structurally. For cement and concrete this should be around 70%, more than that that it’s structurally incompetent, less means the structure is over designed.

The parametric output of of the design tool is a self supported, vaulted dome, that is broken down into 3d printable modules, which are pre-fabricated, driven and assembled on site.

The parameters of the this workflow have been thoughtfully considered, and the next part of the booklet will walk you through their details.

MATERIAL – 3D PRINTED CEMENT MORTAR

As mentioned, this project utilizes material properties of the VPI cement mortar project. While this material is not suitable to traditional cast in place concrete, it is ideal for 3D printing, as it can be pumped and is able to sustain its shape with little or no deformation after extrusion. It also disposes of the need for conventional molds by precisely placing, or solidifying, specific volumes of material in sequential layers by a computer controlled positioning process.

In 3d printing concrete we are able to keep the best practices of pre-cast concrete, which reduce waste from bracing and formwork, excessive concrete, packaging and debris that builds up on-site when from cast in-place. 3D printing also increases material performance because it is fabricated in a controlled environment. It also goes a step further by negating the need for molds.

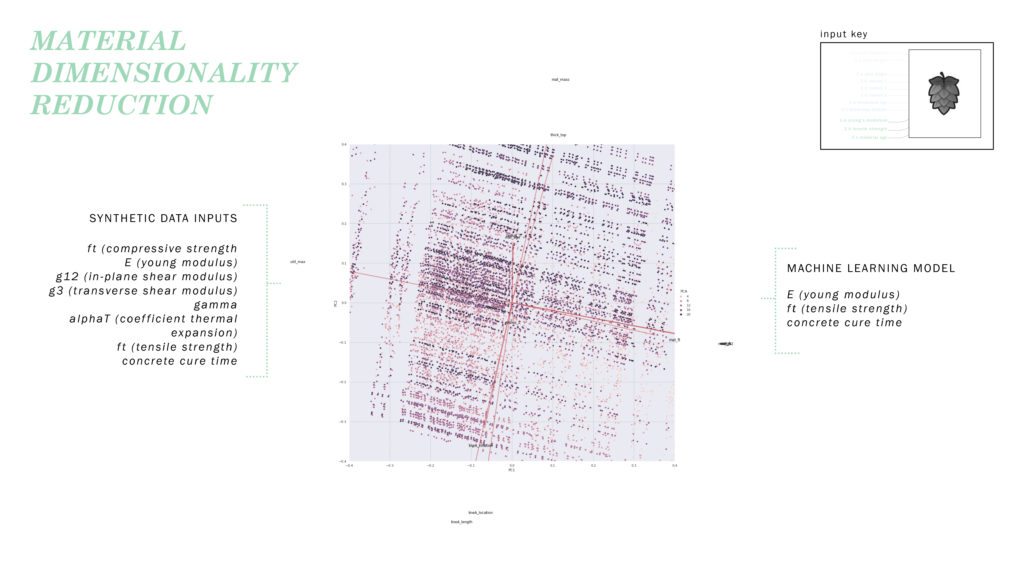

Users of the tool are able to input the material properties to see how they perform. While Karamba requires eight material property inputs, the model only needs three. This is the product of a dimensionality reduction exercise while building the machine learning model, a process which is explained on page 13 of the booklet.

PROGRAM

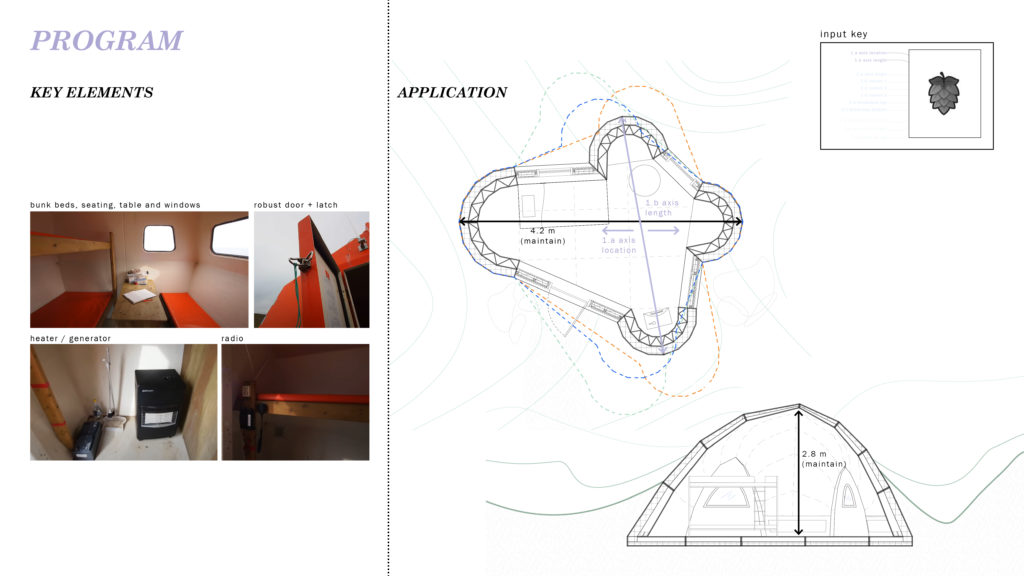

The S&R huts have a simple program. They need to accommodate a bunk bed, seating area, radio, heater, generator, a door and a couple windows. Therefore the length of the huts is maintained at 4.2m while the length and location of the axis can be changed depending on desired capacity and site conditions.

FORM

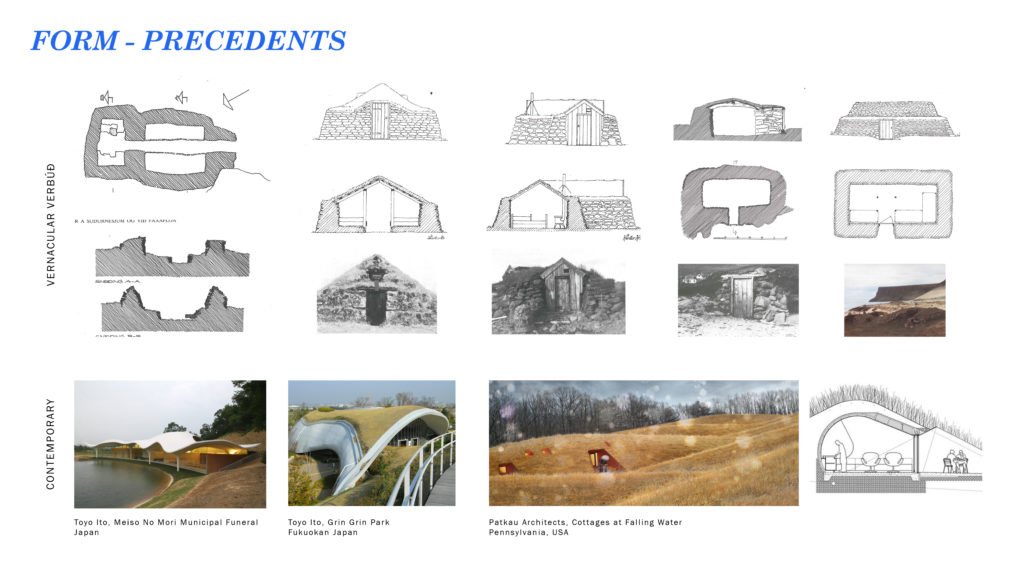

Traditional Icelandic turf huts provided formal and tectonic inspiration. For centuries these structures used the landscape as shelter and insulation. They move with and from the land, made of stacking self similar elements to create an enclosure

Contemporary interpretations of this formal strategy provided further inspiration, as many utilize the self supporting, vaulted forms.

The outcome of this exploration was a self supporting vaulted form, made from stackable modular elements, whose curves nestle within the landscape.

The radius’s that define the form can be changed by the user, along with rotation angle of the axis, and the thickness of the shell walls.

A domed form also creates less resistance to high winds, than a more rectilinear form would.

It should also be noted that these parameters were established to accommodate the blocking of the ever prevailing SE wind, and all where tested in an simulated environment with 20m/s winds from the North and SE, as well as a temperature of -6.

WORKFLOW SCHEMATIC

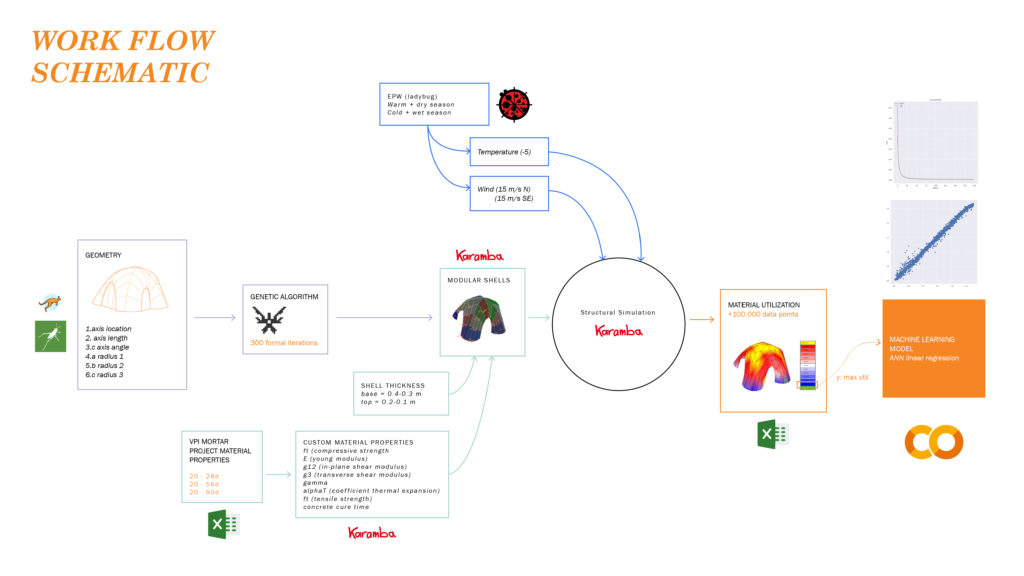

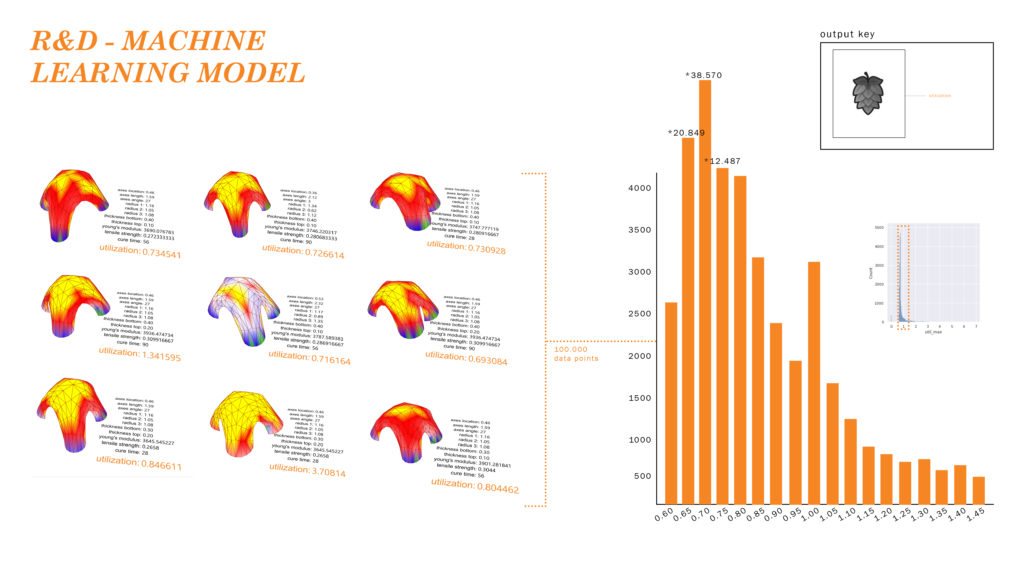

In order to shortcut the costly and time consuming set up of fabrication workflows a machine learning model was created to see if utilization of the VPI cement mortar mixture can be accurately predicted given specific environmental, formal and material parameters.

In order to build the model I first produced a large set of synthetic data. The phases of this process are as follows:

Geometric inputs are fed into biomorpher (which is a genetic algorithm tool), which output 300 varying formal iterations.

These 300 iterations where then fed into karamba, a structural engineering environment, where the shells where given material properties (provided to me by BM Válla), thickness and the environmental conditions are also introduced. All the parameters are analyzed by Karamba which outputs the maximum utilization percentage

The result this exercise was over 100,000 data points, with the y factor being the maximum utilization.

An ANNLinear regression model was then constructed based on this data.

ANN LINEAR REGRESSION

The data cleaning and binning process was very insightful. It showed that there was an incredibly high count of designs with utilization around 70%. Which demonstrated that the material and form where performing well in this environment.

Due to the massive over representation, the data has to be dramatically reduced from +100,000 points to 11,000 which was still a sufficient sample number. After some dimensionality reduction, which caused the removal of several material properties. I was able to get a model with a nice linear trajectory with a loss rate of .00043.

Which can be seen in the original output vs. machine learning output where the majority of predictions are about 1-2% off.

CONCLUSION

While the machine learning model results where quite successful, the project still functions at a higher, more conceptual scale. The next step would be to examine the performance of the 3d printed shells, testing the output performance of the VPI mortar. Environmental conditions in other parts of the country should also be tested, along with the material’s performance under seismic events, which are a regular occurrence in Iceland

Other aspects for improvement in the project include the formal strategy. While the vaulted modular form performs it’s desired effect, it could be further refined, smoothed and optimized. At present it is a is too faceted and is likely skewing the utilization metrics.

Ultimately this project sought to contribute to the conversation of sustainability in concrete, and more specifically the role machine learning plays in architectural fabrication and digitally integrated workflows. Advocating for a localized approach, facilitated by global concepts in computation, fabrication and design.

Util_Huts is a project of IAAC, Institute for Advanced Architecture of Catalonia developed in the Master of Advanced Computation in Architecture and Design 2021/22 Student: Zoe Lewis Thesis Advisor : David Andres Leon

BIBLIOGRAPHY

Andreolli R. 2016. Form Optimization with a Genetic Algorithm [Research Project]. [Stockholm(Sweden)]: KTH Royal Institute of Technology. http://raphaelandreolli.com/form-optimization-genetic-algorithm/

Buswell, R.A. W.R. Leal de Silvab, S.Z. Jonesc, J. Dirrenberger. ‘3D printing using concrete extrusion: A roadmap for research’. Cement and Concrete Research. 112 (2018) 37-49.

Dezem. Vanessa. ‘Cement Produces More Pollution Than All the Trucks in the World´. Bloomberg. (June 23, 2019) https://www.bloomberg.com/news/articles/2019-06-23/green-cement-struggles-to-expand-market-as-pollution-focus-grows?leadSource=uverify%20wall

Guðmundsdóttir AB. 2020: Classification of Icelandic Aggregates and Effect on Concrete Properties [Master’s thesis in Geology]. [Oslo(Norway)]: Norwegian University of Science and Technology.

Nguyen. Hoang, Thanh VuThuc, P. VoHuu-Tai Thai. ‘Efficient machine learning models for prediction of concrete strengths’. Construction and Building Materials. 266 (2021) 1-17.

Sigfusson T and B Johannesson. Sustainable Fibres from Basalt Mining. Paper presented at: unknown; 2016; Helsinki, Finland.

Striatus.2021. Venice. ETH Zurich and Zaha Hadid Architects Computation and Design Group (https://www.dezeen.com/2021/07/28/zaha-hadid-architects-block-research-group-straitus-3d-printed-concrete-bridge/?li_source=LI&li_medium=bottom_block_1)

Sveinbjornsson S, GJ Einarsson, Þ Björnsdóttir and ER Þórhallsson. Elastic Modulus of Concrete with Icelandic Basalt Aggregates. [Reykjavik(Iceland)]: University of Iceland; 2014.

Thomsen, Mette Ramsgaard. Thomsen, Paul Nicholas, Martin Tamke , Sebastian Gatz, Yuliya Sinke and Gabriella Rossi ´ Towards machine learning for architectural fabrication in the age of industry 4.0’. International Journal of Architectural Computing, 18.4 (2020) 335-352. DOI: 10.1177/1478077120948000

Wigum. Børge Johannes. VPI Cement Mortar Project Data. Distributed Oct 26th by email.