| INTRODUCTION |

Learning Structures: From Parametric Rules to Machine-Made Forms.

In this project, we explored the interplay between parametric design, machine learning, and robotic fabrication. Starting from Kapla block assemblies controlled by simple deformation rules, we trained a GAN to reinterpret and generate new structural variations. The process concluded with robotic pick-and-place construction, closing the loop between human logic and machine creativity.

| CONCEPT DESIGN |

From Woven Wall to Deformed Nest: Evolving Structures with Kapla Blocks

Our design concept began with the idea of creating a woven wall using Kapla blocks, exploring patterns of density and transparency. As the project evolved, the logic of deformation and stacking led us to reinterpret the structure as a deformed nest. By adjusting top and bottom geometries, spacing, and rotation, we shaped a porous, dynamic form that set the foundation for machine learning exploration and robotic fabrication.

| WORKFLOW |

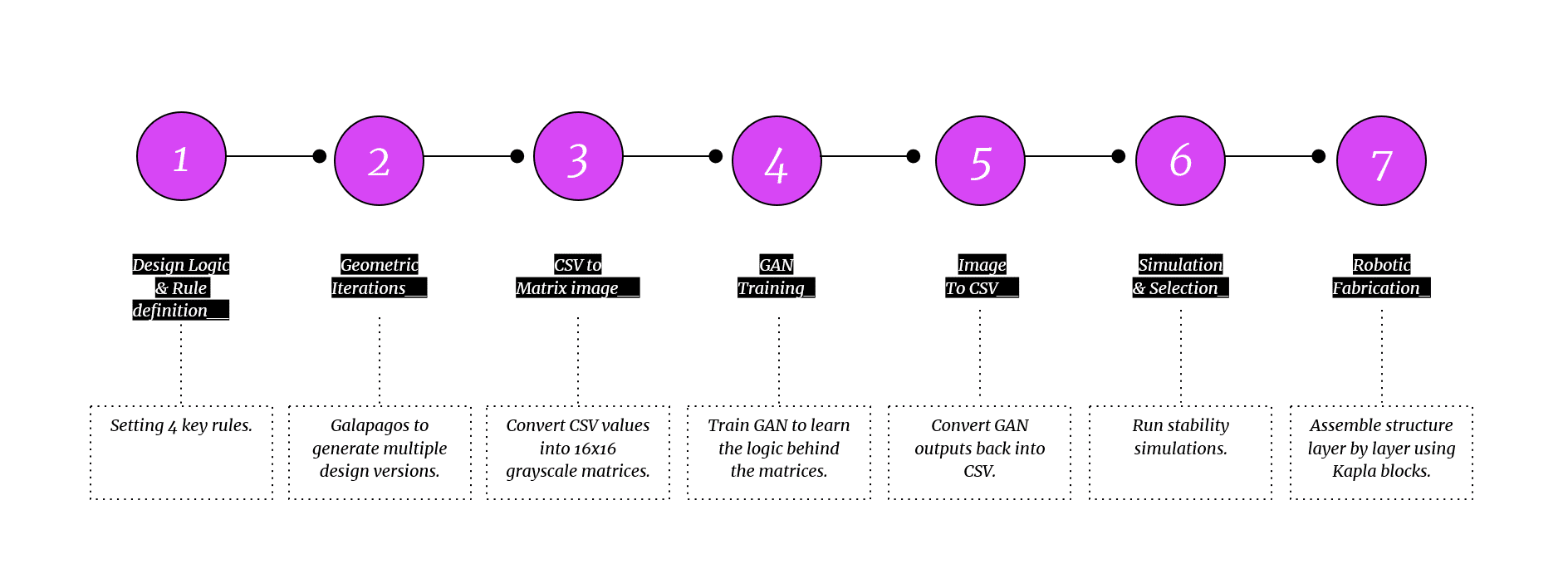

General Workflow: From Parametric Rules to Robotic Fabrication

Our workflow started with parametric modeling of Kapla block assemblies in Grasshopper, generating variations through Galapagos. These were abstracted into CSV matrices and used to train a GAN, producing new design possibilities. The AI-generated outputs were re-materialized in Grasshopper and fabricated through robotic pick-and-place, completing a full loop from rules to machine invention.

| WORKFLOW

| 1. DESIGN LOGIC & RULE DEFINITION |

Design Process Definition: Structuring Variation

Our project began by establishing a design logic based on stacking Kapla blocks along two deformed circular profiles (the bottom and the top). We introduced four key parameters to define the system: deformation of the bottom circle, deformation of the top circle, distance between each block, and rotation of each block to control transparency. These rules allowed us to generate a wide variety of structured forms while maintaining material and geometric coherence. Through this parametric system, we could systematically explore complexity, density, and spatial porosity within the design. This logic served as the foundation for both the dataset creation and the subsequent machine learning processes.

| 2. GEOMETRIC ITERATIONS |

Iterating: Parametric Exploration through Evolutionary Variation

Geometric variation was explored by manipulating the deformation of the top and bottom circular profiles, the spacing between Kapla blocks, and their rotational angle. These parameters were encoded into a parametric Grasshopper script, allowing systematic iteration using Galapagos. Through this evolutionary solver, hundreds of variations were generated, each defined by a unique combination of input values. All configurations were exported as grayscale matrix images and stored in CSV format, forming the structured dataset required for machine learning training and later design reconstruction.

| 3. CSV TO MATRIX IMAGE |

Learning the Logic: GAN Training with Design Matrices

The grayscale matrices generated from parametric iterations were used to train a Generative Adversarial Network. The GAN learned to replicate the underlying spatial rules and design intent embedded in the data. Over multiple epochs, it produced novel 16×16 matrices that followed the learned logic. These outputs suggested new configurations of spacing, deformation, and rotation. This process expanded the design space beyond the original rule set, enabling generative design guided by machine interpretation.

| 4. GAN TRAINING |

Decoding the Machine: Matrix-to-Geometry Translation

The grayscale images were used to train a GAN model, enabling the generation of new design variations based on the learned distribution of the original parameter space. The network was exposed to hundreds of matrix samples encoding deformation, spacing, and rotation rules. Over time, the GAN internalized the spatial logic embedded in the dataset. The output matrices captured this learned structure while proposing novel configurations. This stage marked the shift from manual rule-making to machine-driven design speculation.

| 5. IMAGE TO CSV |

From Pixels to Parameters: Rebuilding Design Data

The GAN-generated images were converted back into CSV files, which were then imported into Grasshopper to reconstruct and visualize the new design variations in 3D. These files encoded values for deformation, spacing, and rotation, allowing each matrix to be translated into a spatial configuration of Kapla blocks. This process reconnected abstract image outputs with the physical design system. It also enabled us to evaluate and compare the machine-generated structures in relation to the original logic.

| 6. SIMULATION & SELECTION |

Simulating Behavior: Structural Testing & Selection

Once reconstructed, the machine-generated geometries were evaluated through structural simulations using PhysX. Each iteration was tested for stability, deformation behavior, and collapse response. This allowed us to identify which outputs were physically viable and which exhibited critical weaknesses. The process acted as a filtering mechanism, selecting designs not only by visual logic but also by performance. These results informed the final choice for robotic fabrication.

| 7. ROBOTIC FABRICATION |

Materializing Code: Robotic Pick-and-Place Assembly

The selected geometry was translated into robotic instructions using a pick-and-place logic tailored to the Kapla block dimensions. Each block’s position and rotation were extracted from the Grasshopper model and formatted as a sequential routine for robotic execution. The fabrication process emphasized precision and repeatability while retaining the spatial complexity of the design. This stage materialized the AI-generated structure through layered, rule-based assembly. It completed the feedback loop between digital logic and physical construction.

| LIMITATIONS & IMPROVEMENTS |

Challenges Encountered and Paths for Enhancement

1. Material Constraints and Assembly Potential

The fixed dimensions and standardized orientation of the Kapla blocks inherently limited the geometric complexity and subtle spatial variations achievable in the assemblies. Expanding the range of allowable block rotations and stacking strategies could enable a richer diversity of configurations, enhancing the architectural expressiveness of the system while maintaining material coherence.

2. Optimization of Design Parameters and Structural Feasibility

The current design strategy, although effective for initial exploration, could be further optimized to align more closely with the physical behavior and tolerances of Kapla blocks. Implementing collision prevention algorithms and allowing for more extreme parameter inputs — such as greater deformation values or irregular spacing — would open possibilities for more radical and unexpected spatial results while ensuring structural feasibility.

3. Dataset Expansion for Enhanced Machine Learning Performance

The training dataset generated through Galapagos was relatively limited in size, which constrained the variety of patterns the GAN could learn and reproduce. A larger and more diverse dataset, incorporating a wider range of parametric mutations, would significantly improve the generative model’s capacity to extrapolate new and more complex design logics beyond the original rule set.