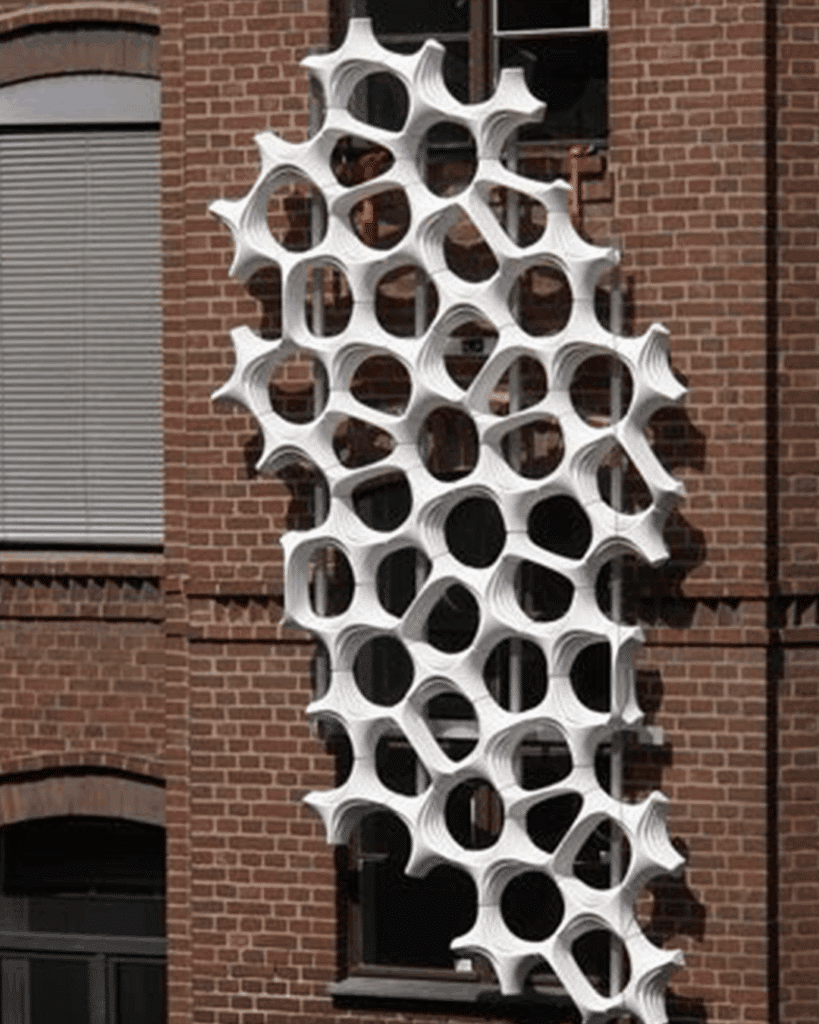

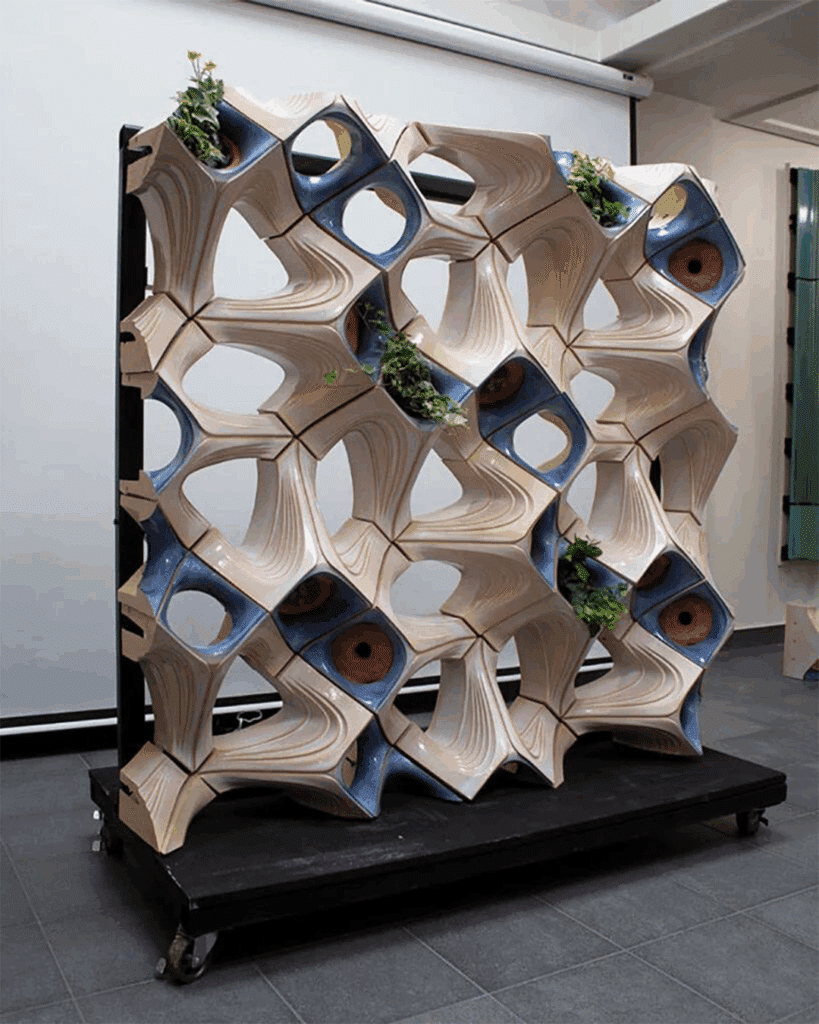

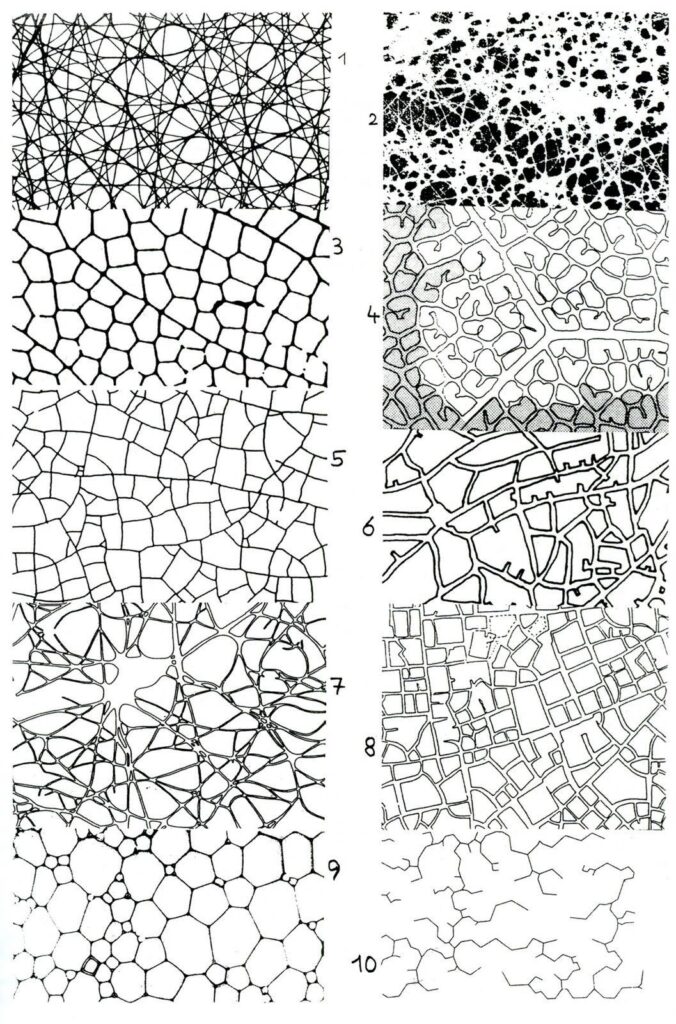

Vertical architectural elements play a defining role in shaping thresholds, filtering light, and guiding how we perceive both interior and exterior spaces. In this project, we explored their spatial and expressive potential through a sequence of hands-on fabrication experiments. Drawing inspiration from natural forms and behaviors, each design aimed to reinterpret organic patterns into façade components. By alternating between 3D printing, laser cutting, CNC milling, and robotic manufacturing, we examined how digital tools can translate natural geometries into architectural systems. Working within a fixed wooden framework, every technique encouraged us to rethink material performance, structural logic, and spatial expression. Through this iterative making process, we gained insight into how fabrication and design can merge to create meaningful façade interventions rooted in natural elements.

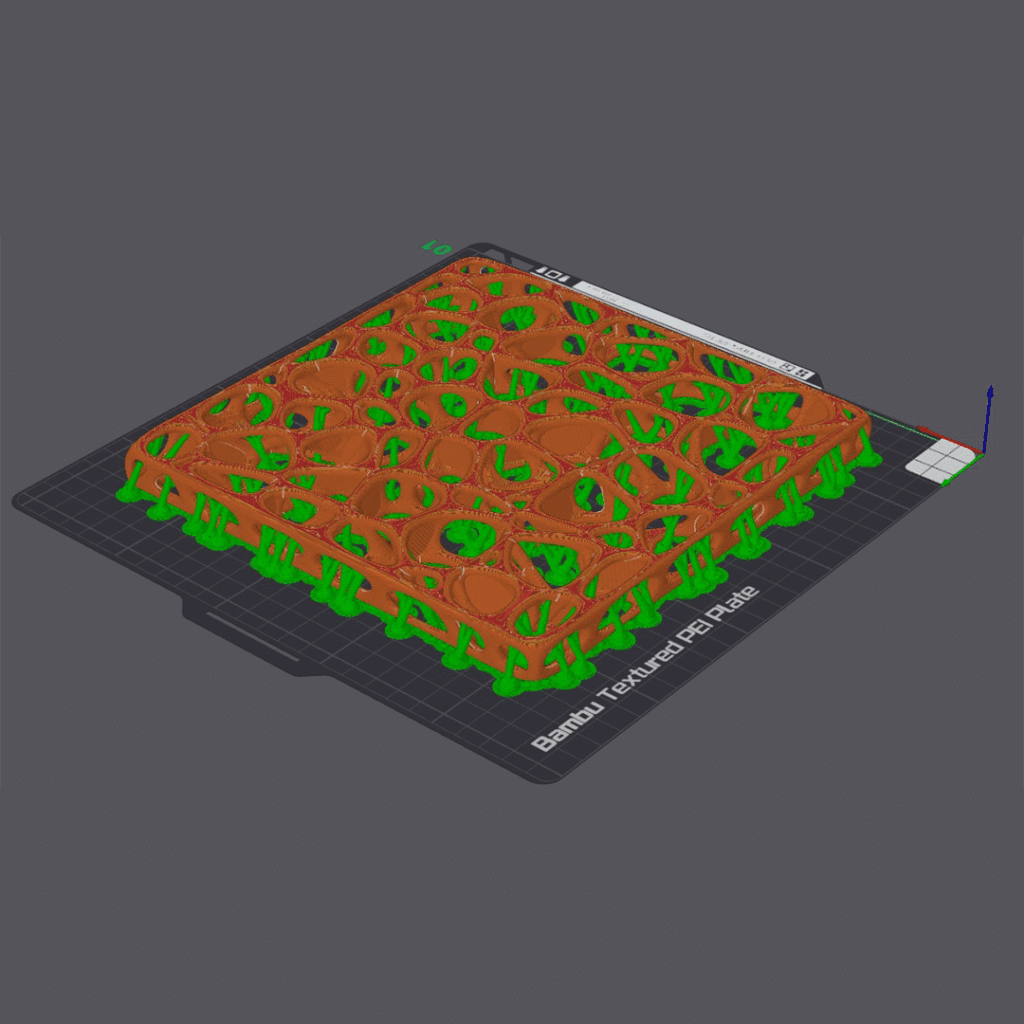

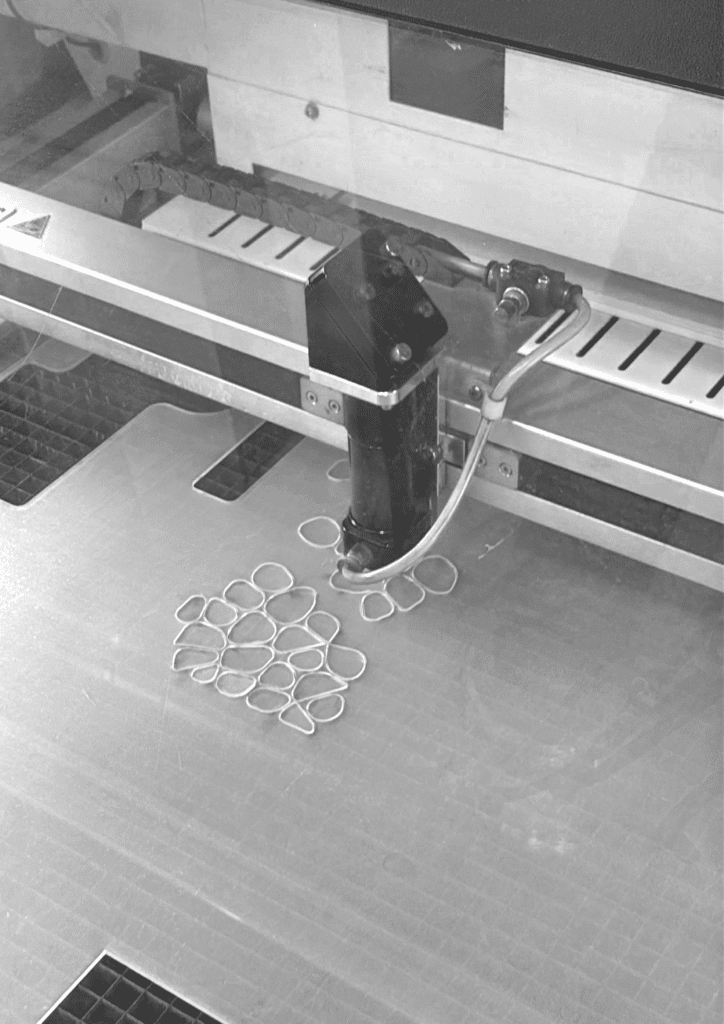

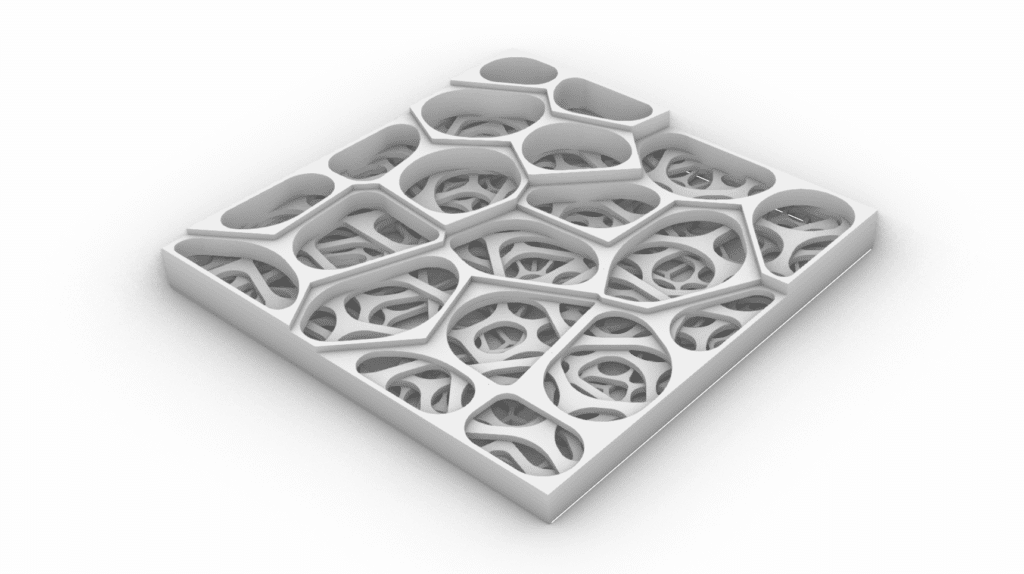

3D PRINTING

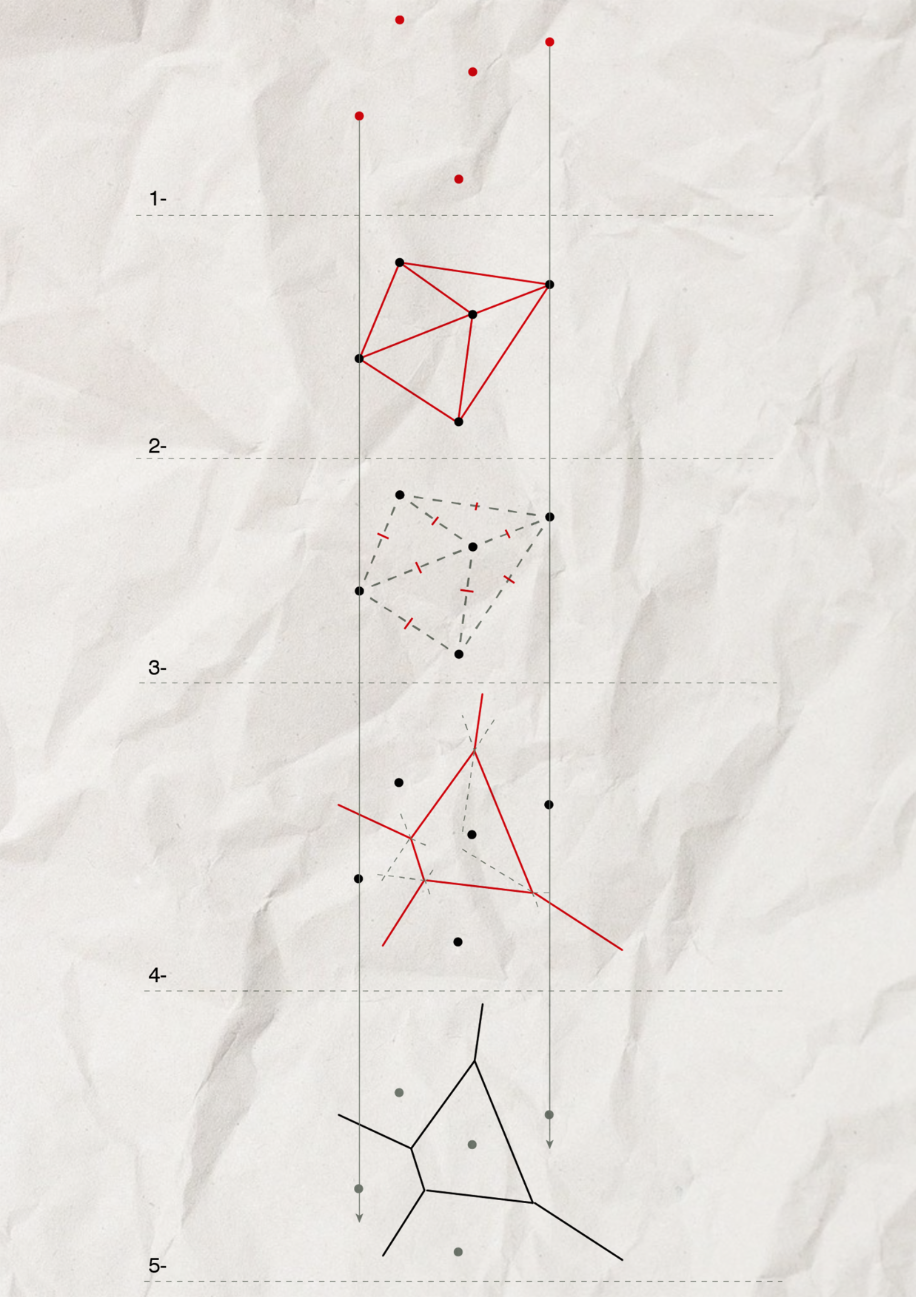

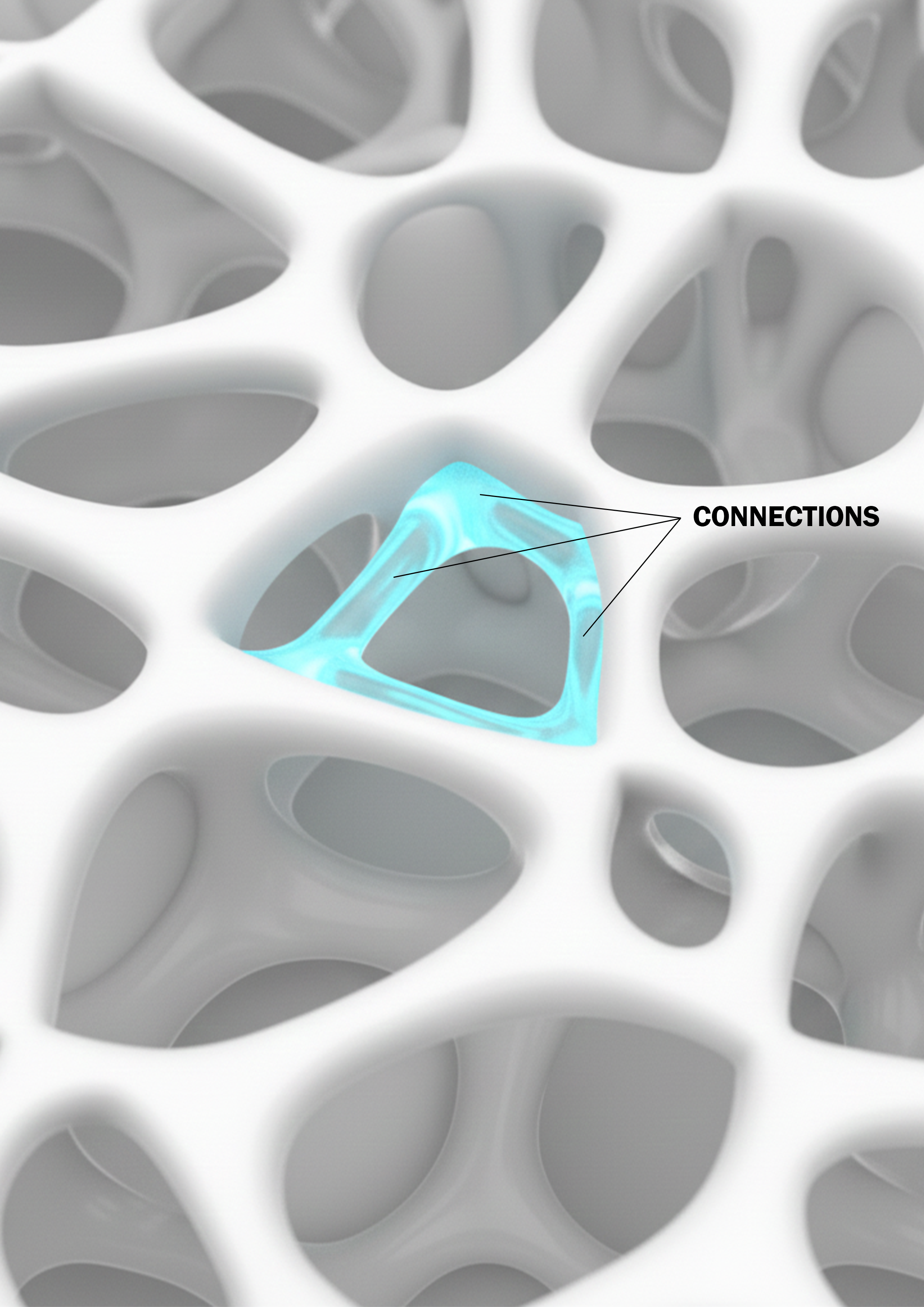

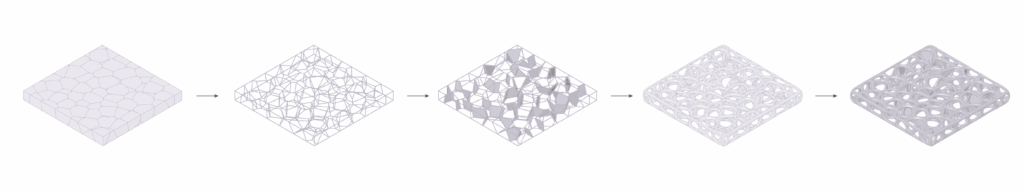

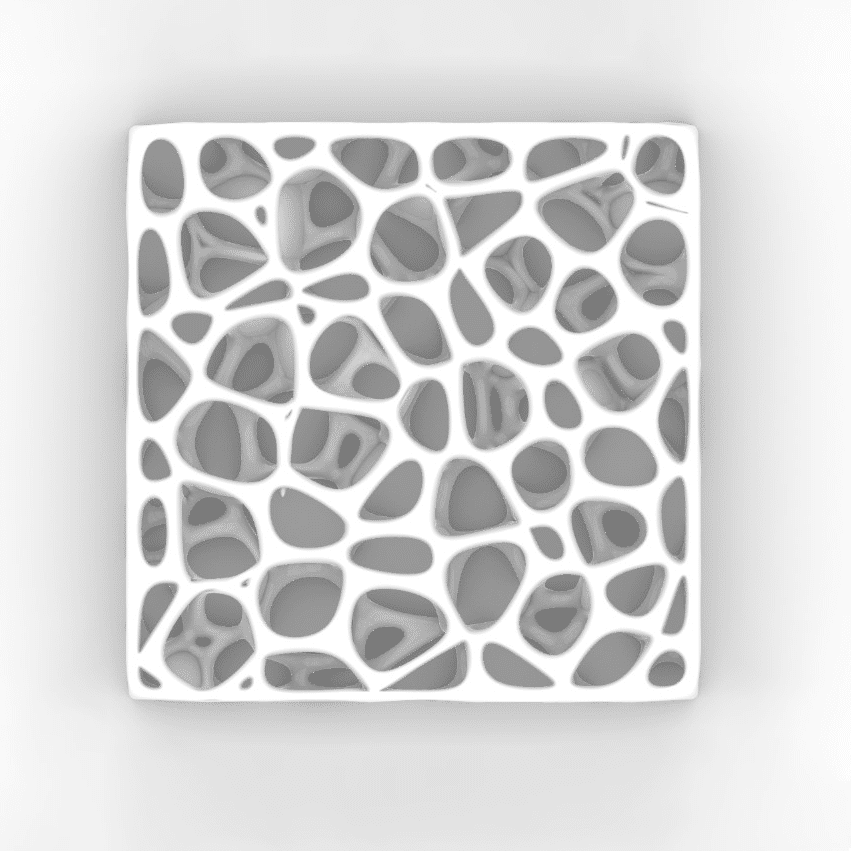

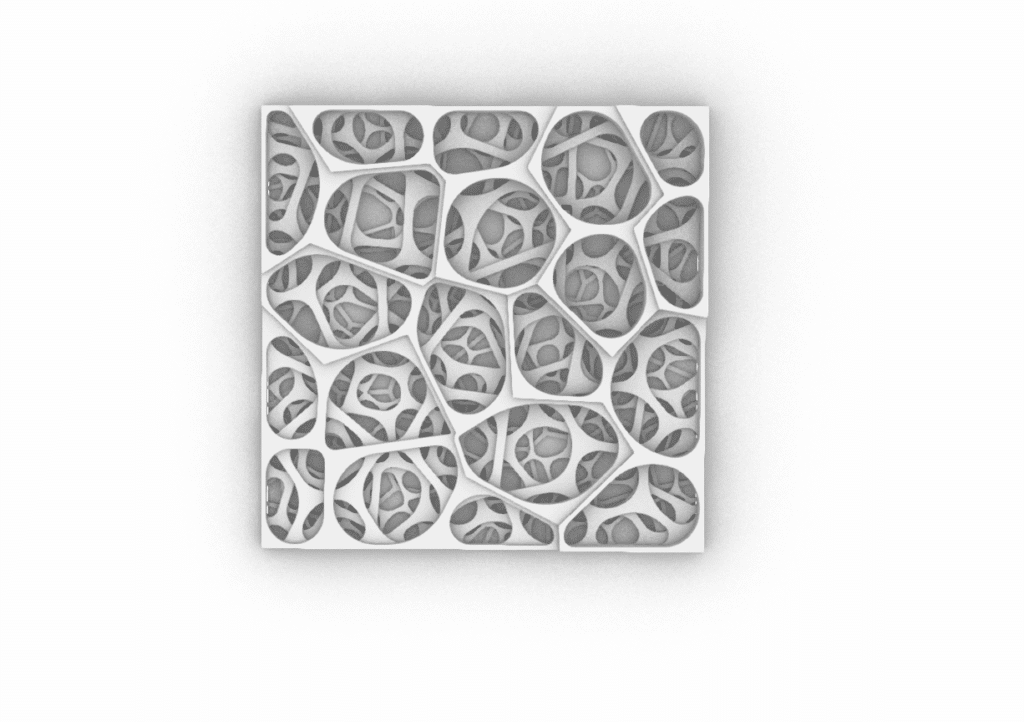

Voronoi Formation

Process & Design

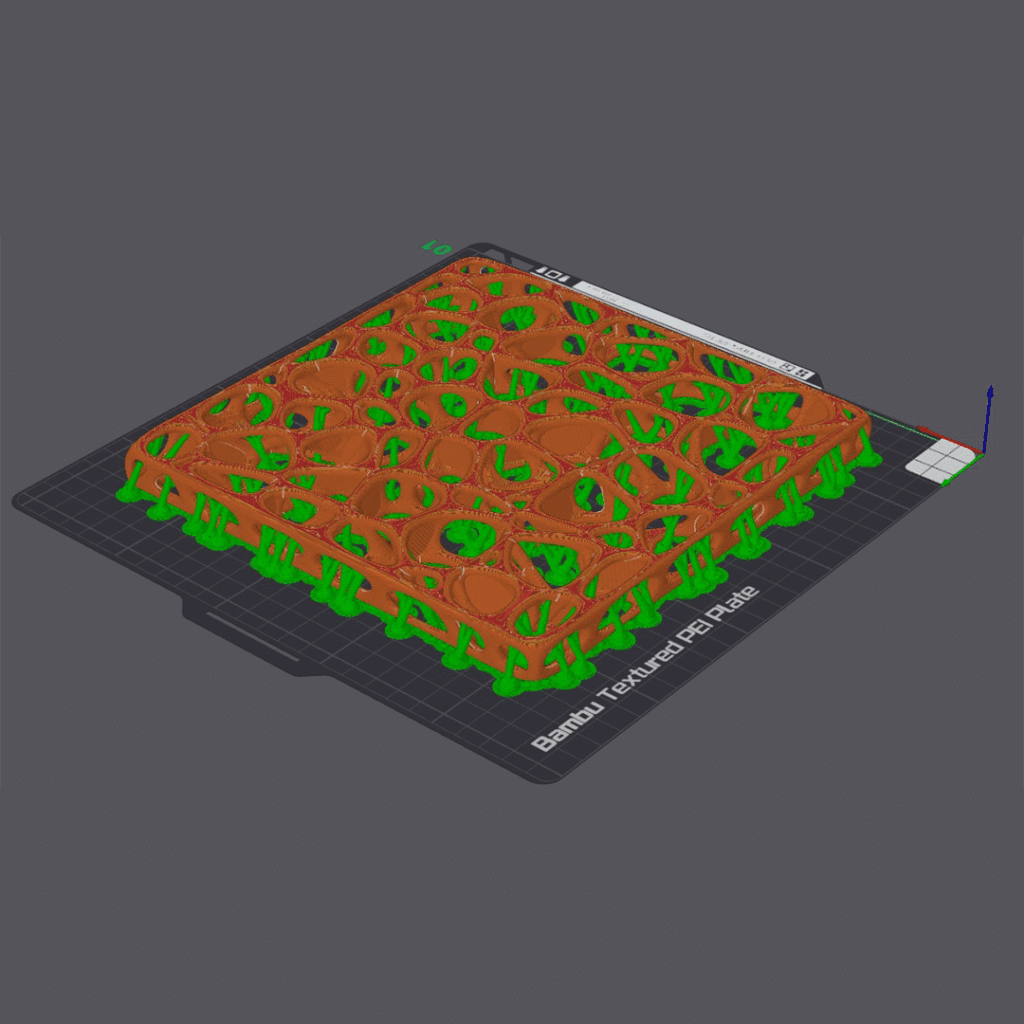

Parameters

Material: PLA

Machine: Bambu Lab P1S

Workpiece volume: 200x200x18mm

Total Filament: 163.39 g

Model Filament: 127.40 g

Support Time: 2h56m

Top Z Distance: 0.12mm

Model Printing Time: 13h1m

Total Time: 13h7m

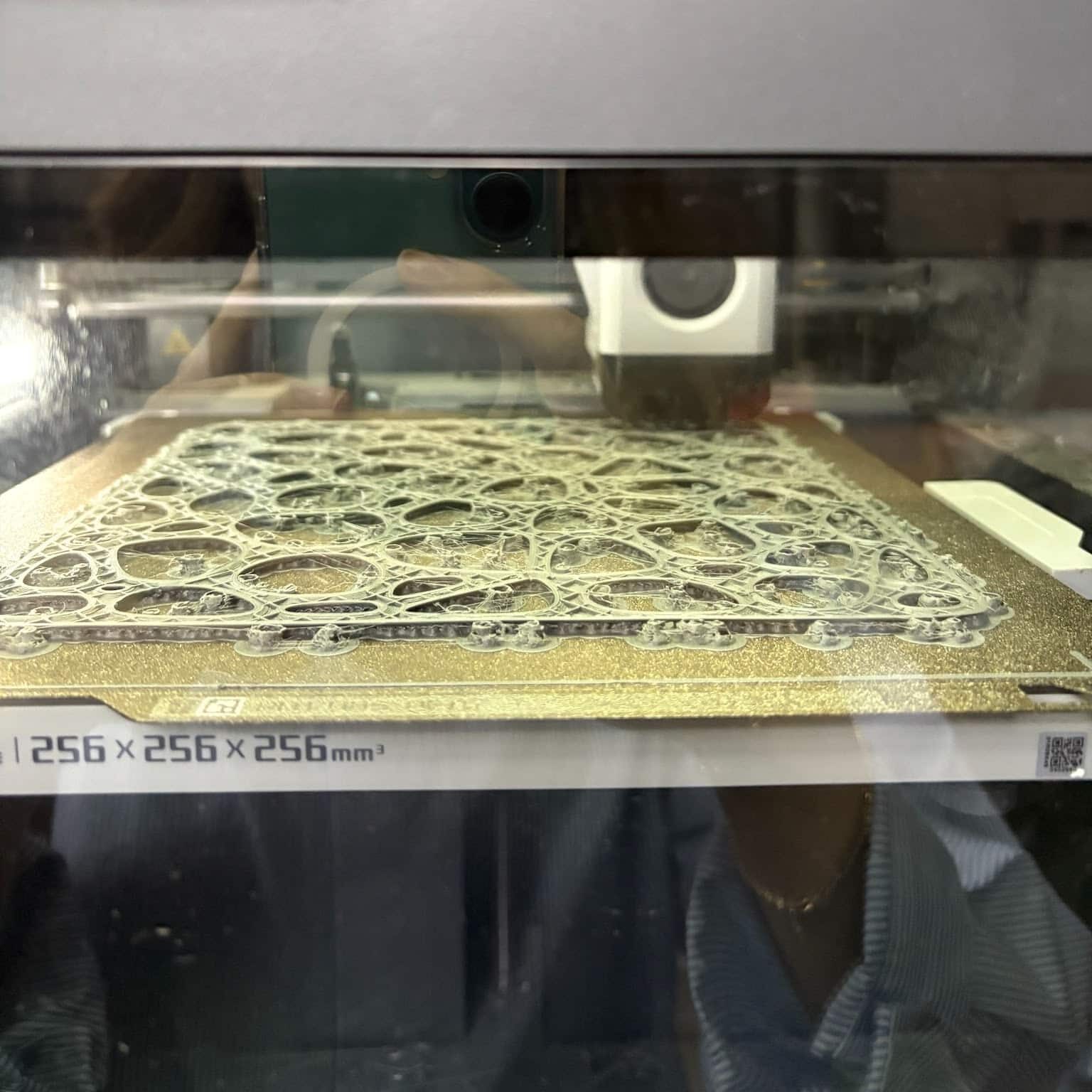

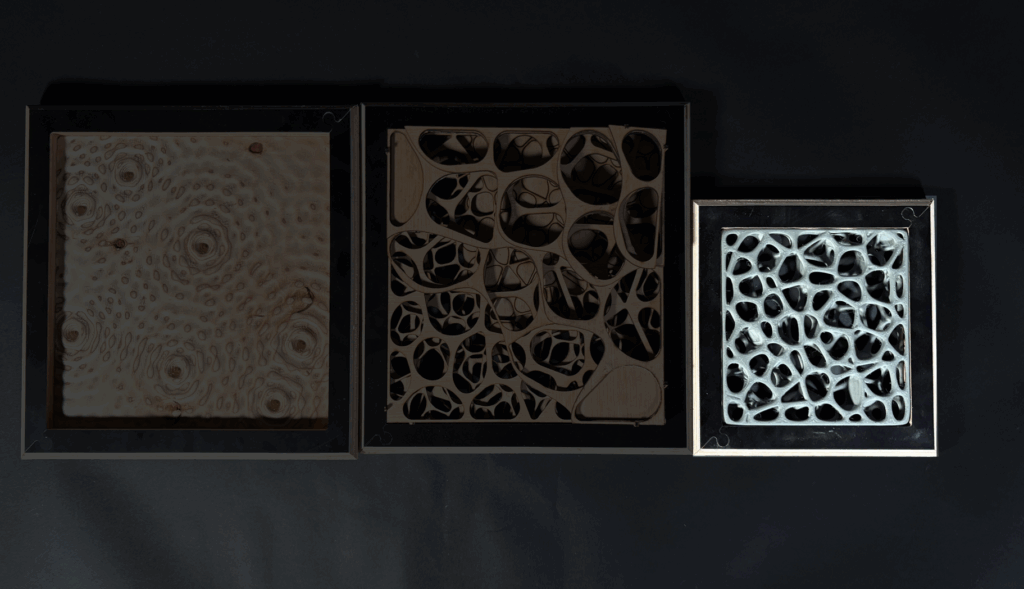

FINAL PRODUCT

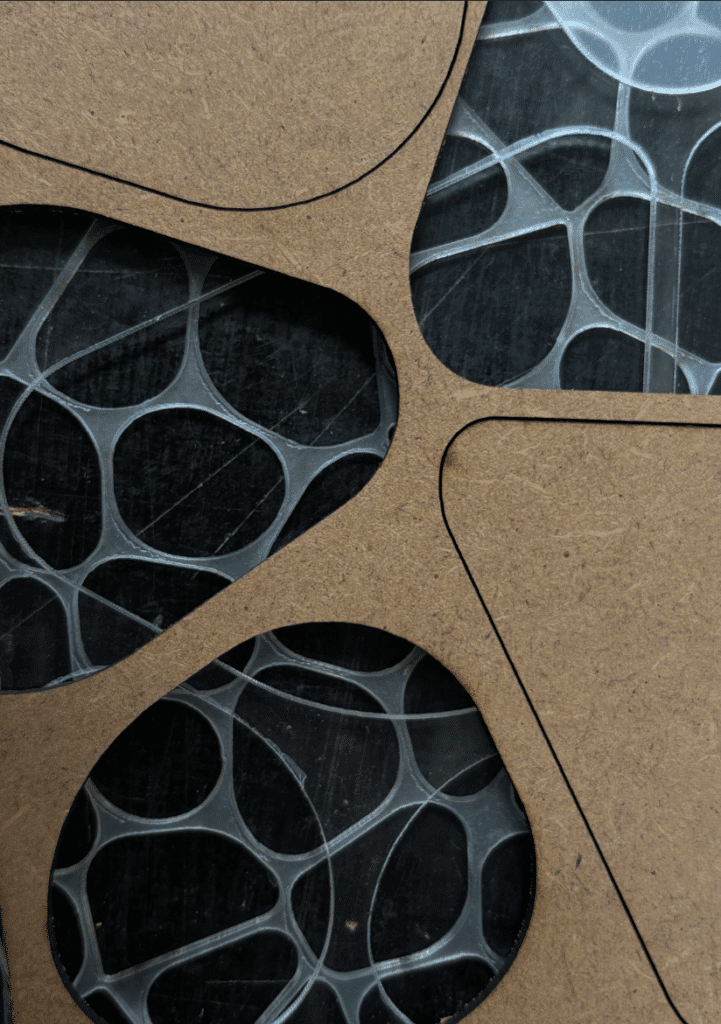

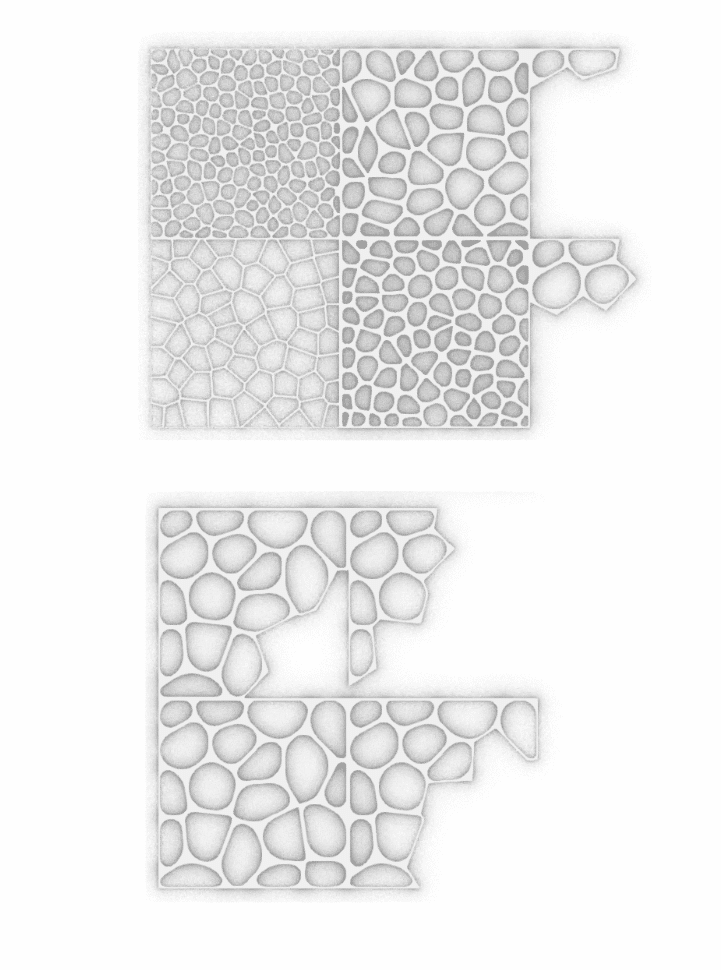

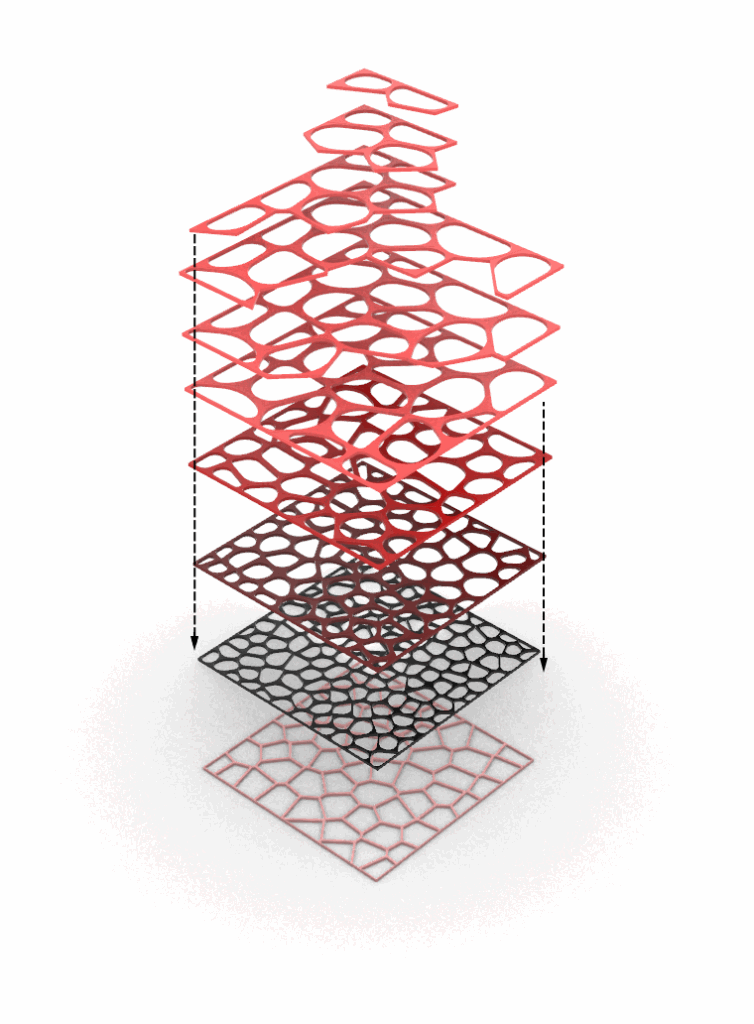

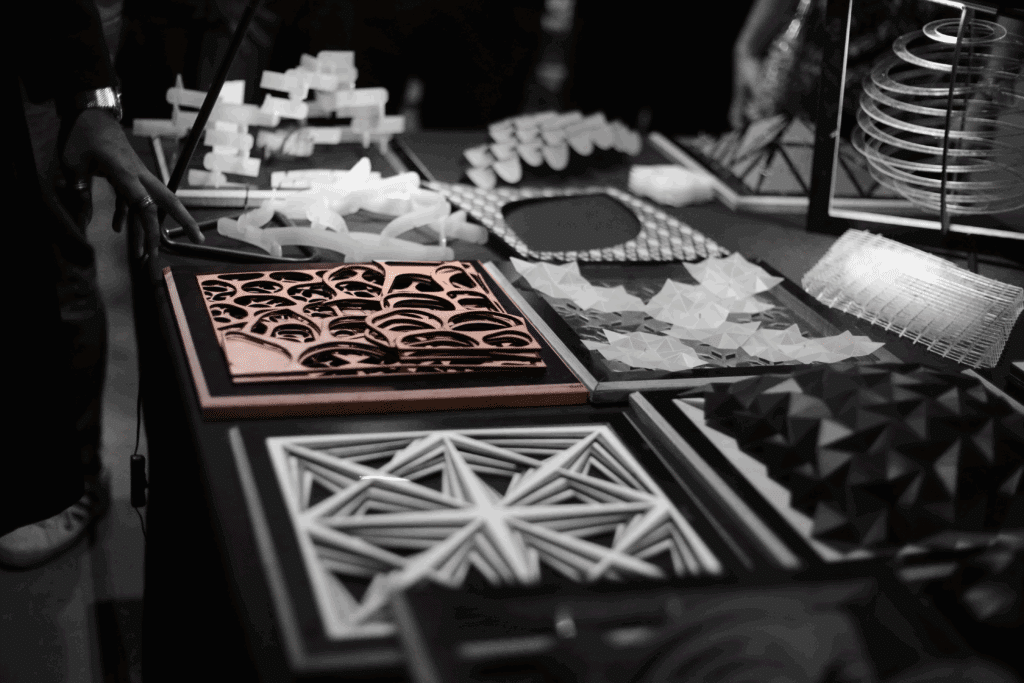

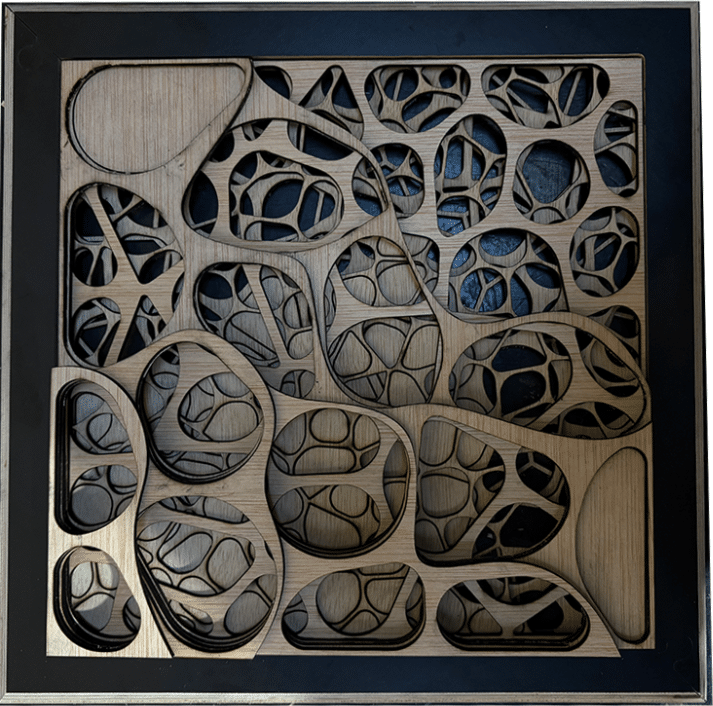

LASER CUTTING

Project Description

This model explores a stacking technique inspired by layered façade systems where multiple patterned surfaces overlap to produce depth, rhythm, and shifting shadows. We began by testing different materials, including acrylic, to understand how translucency and density affect the perception of the openings. In the final version, we chose wood for its warmer visual quality and more tactile presence, intentionally closing some apertures to create a controlled gradient of transparency. The result is InterLayered, a study of how patterned layers can be composed to generate a richer spatial experience and a more expressive play of light.

MATERIAL SELECTION

LAYERS

FINAL DESIGN

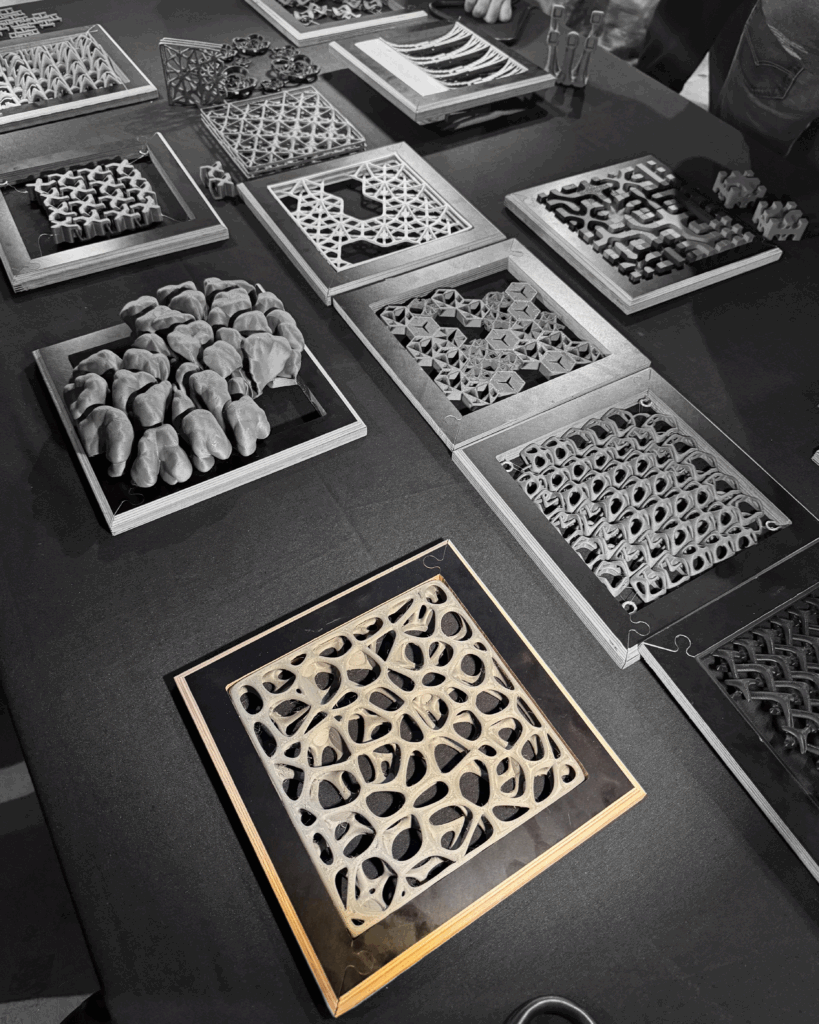

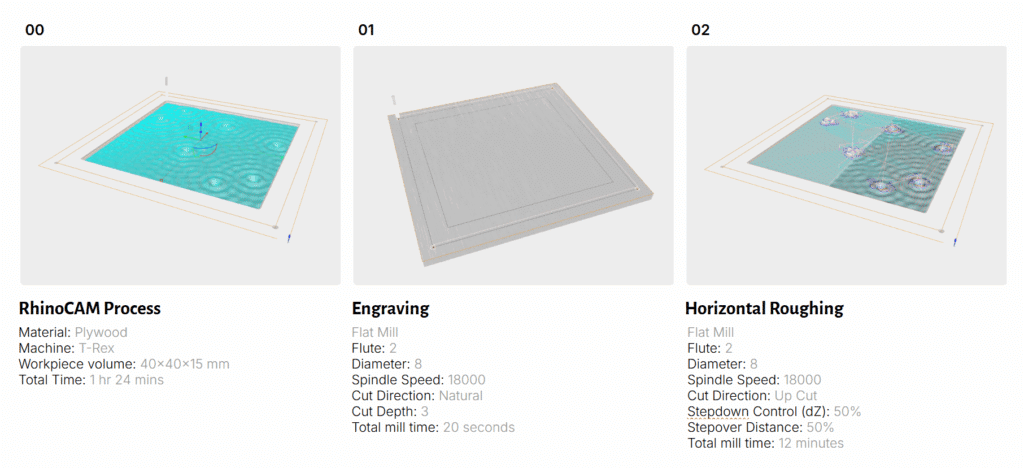

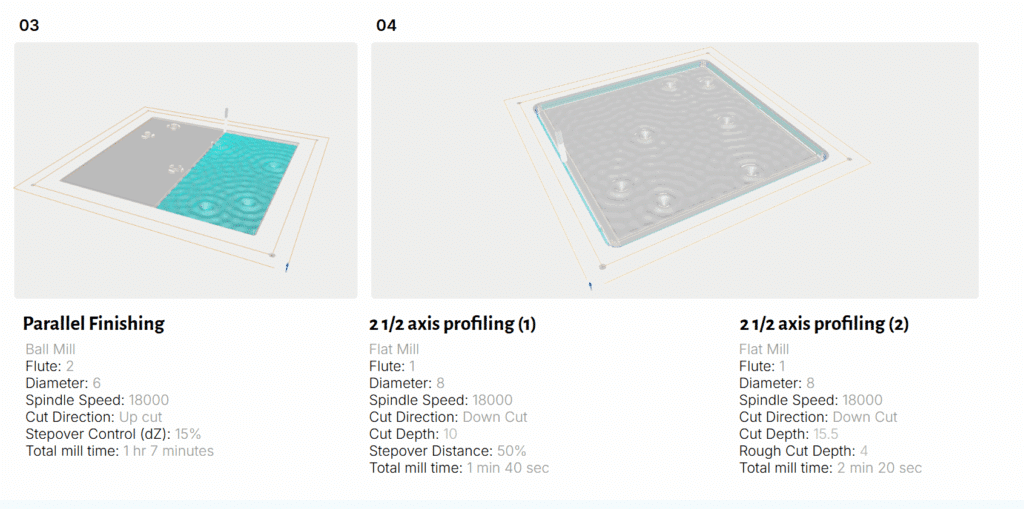

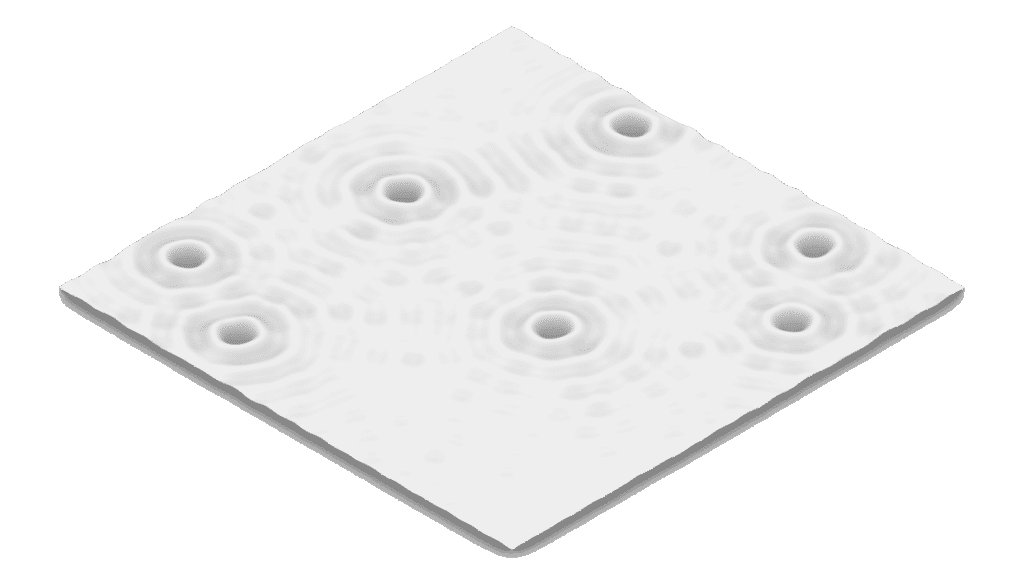

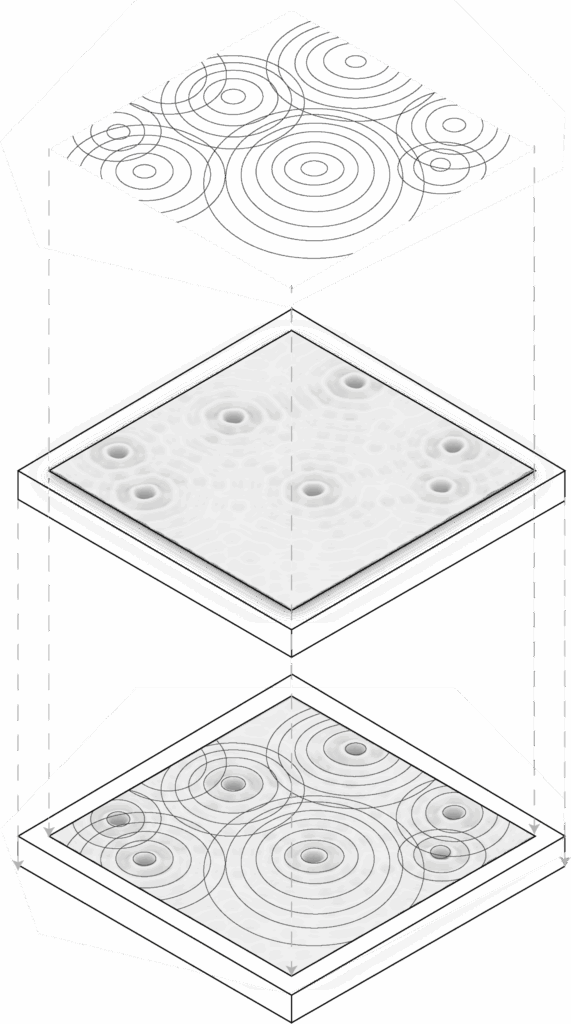

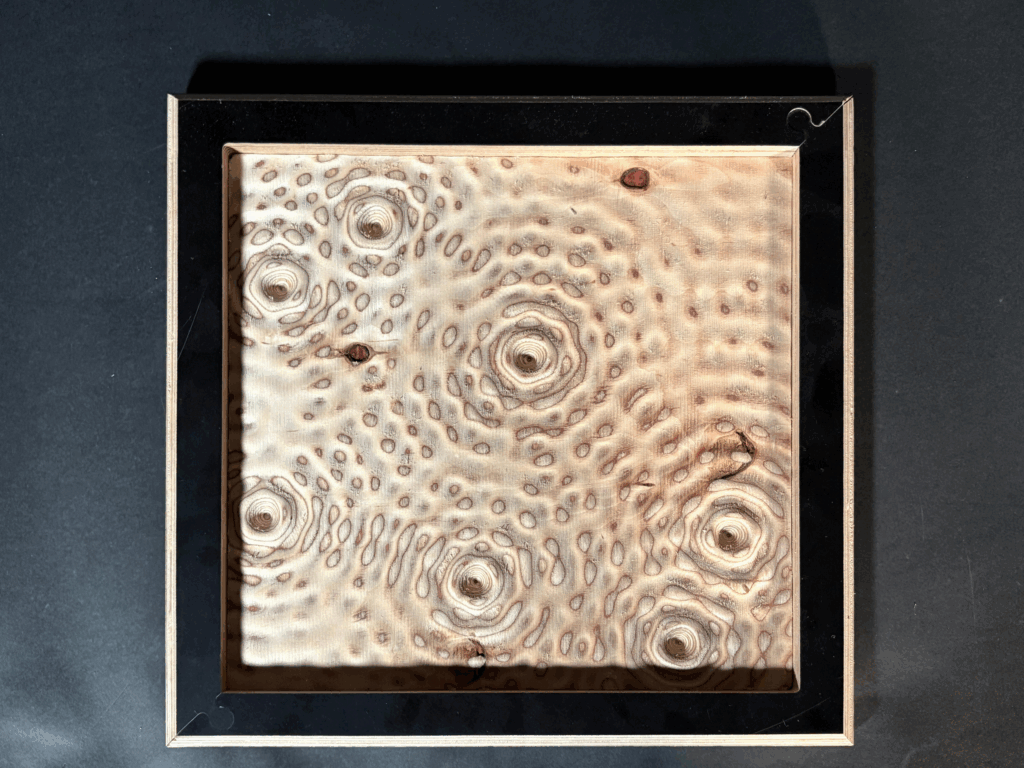

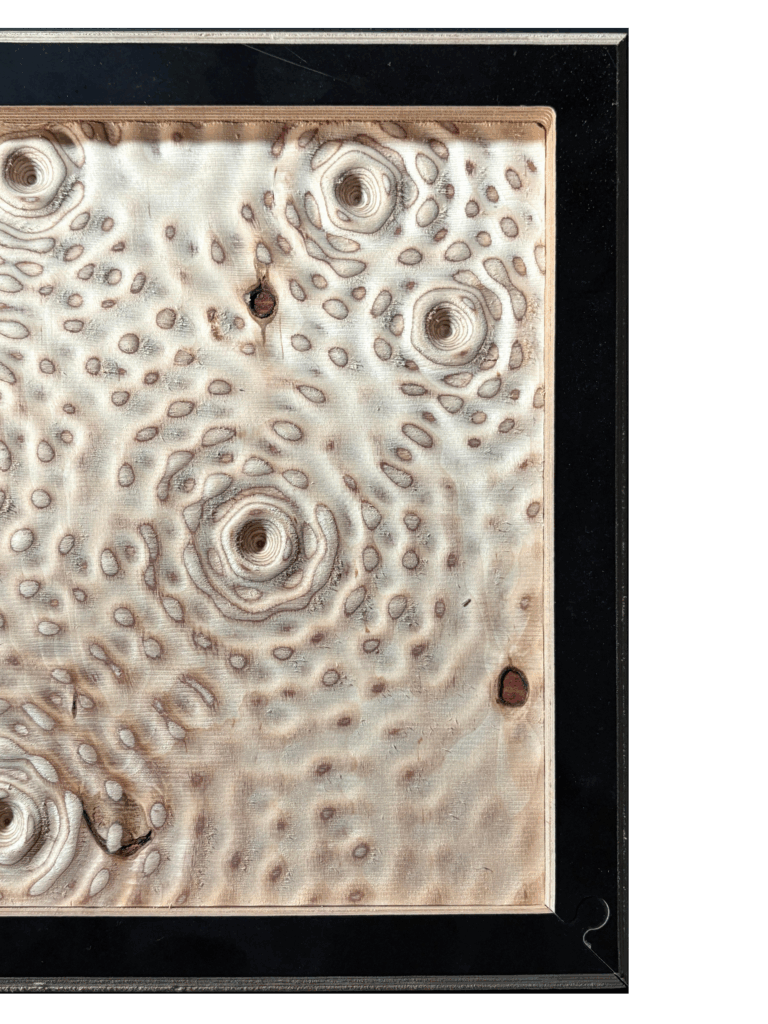

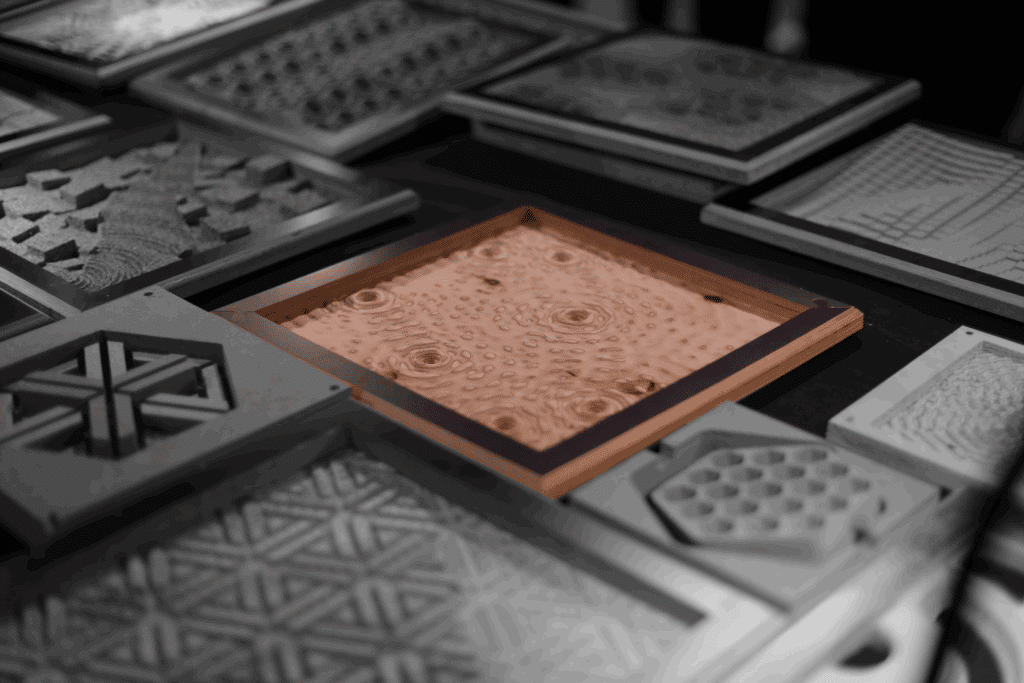

CNC MILLING

Project Description

Our inspiration came from the patterns formed on the water during rainfall, the delicate ornaments created by the drops. After a series of experiments and iterations, we decided to invert the model and design a surface with openings that allow light to pass through.

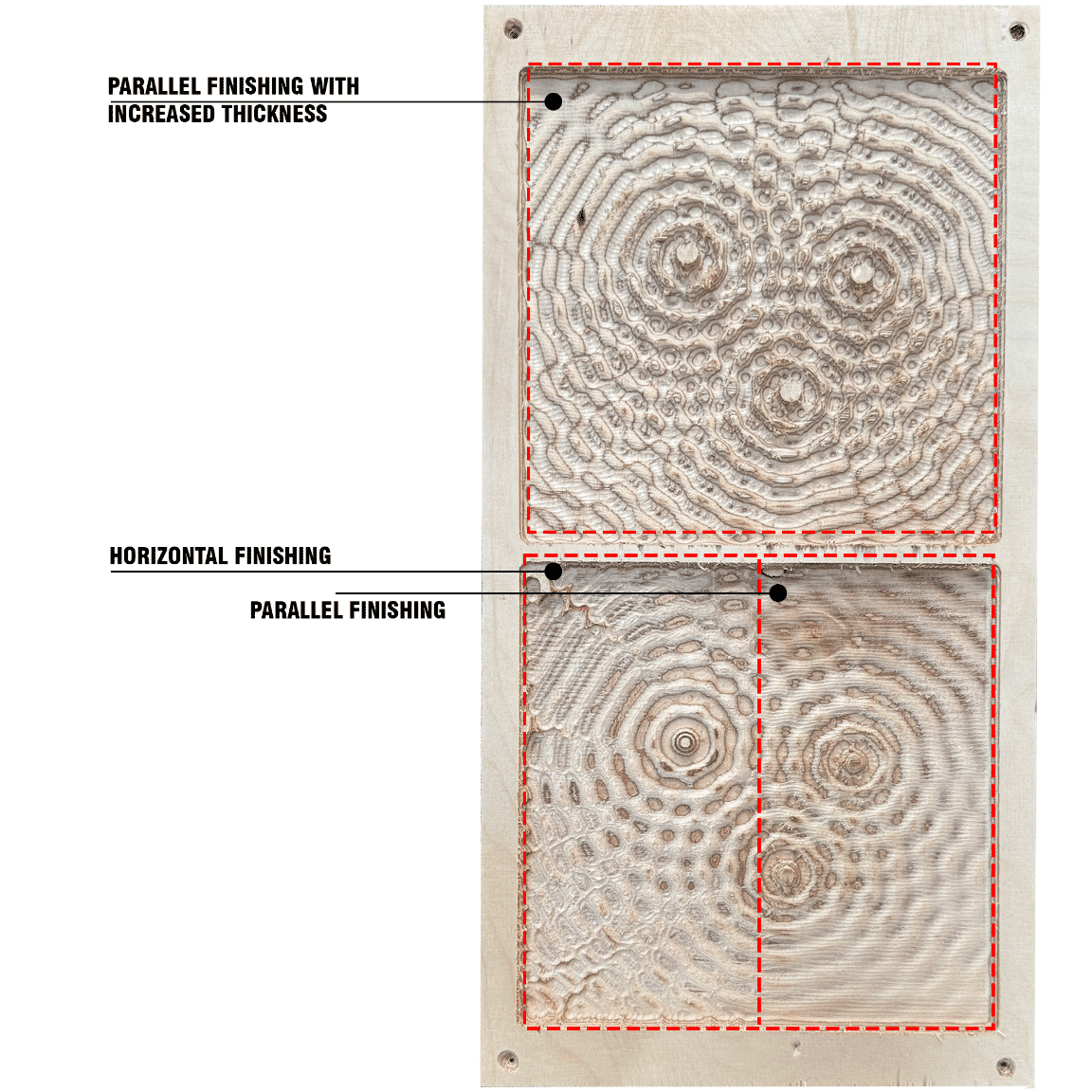

TRIAL

Two main methods were applied: parallel finishing and horizontal finishing. Additionally, one area was machined with increased thickness, allowing us to observe how depth variation affects the surface texture and visual outcome.

Fabrication Strategy

FINAL DESIGN

FINAL PRODUCT

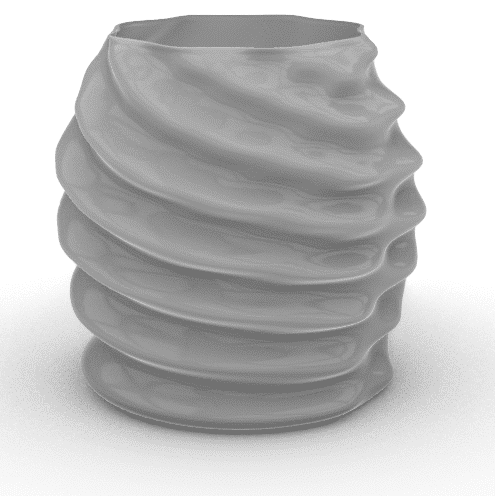

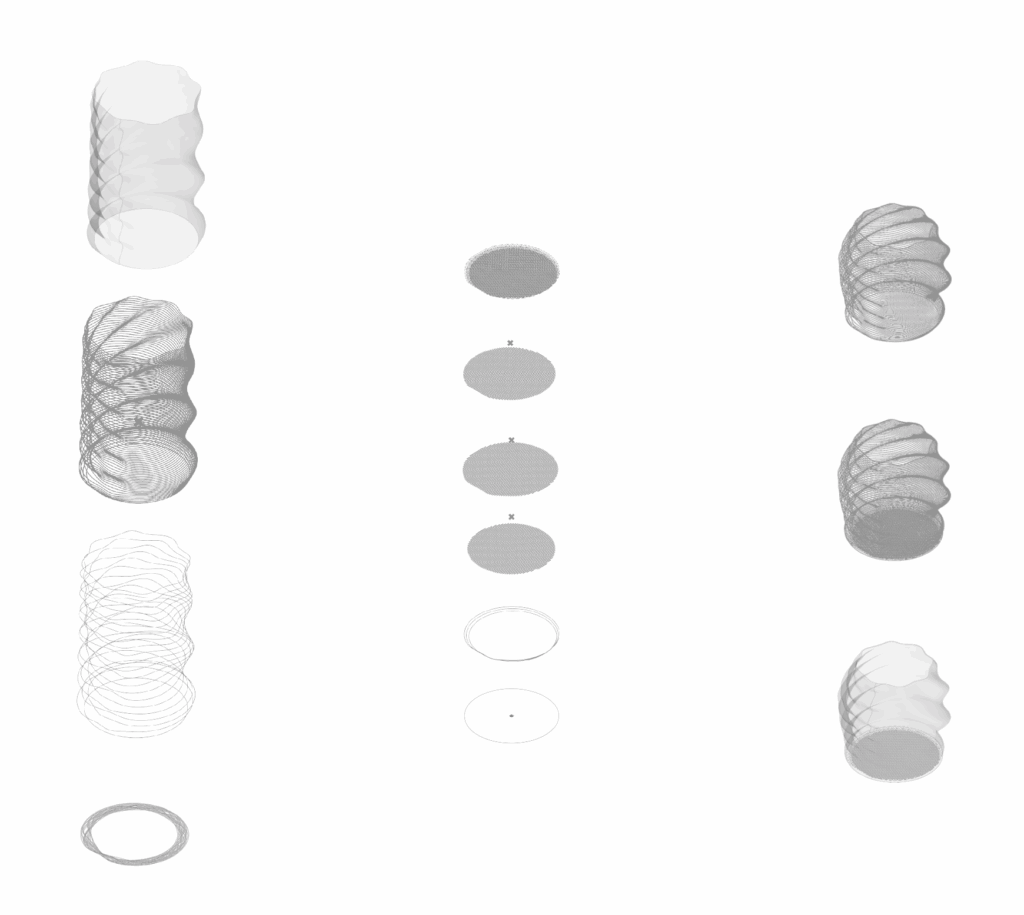

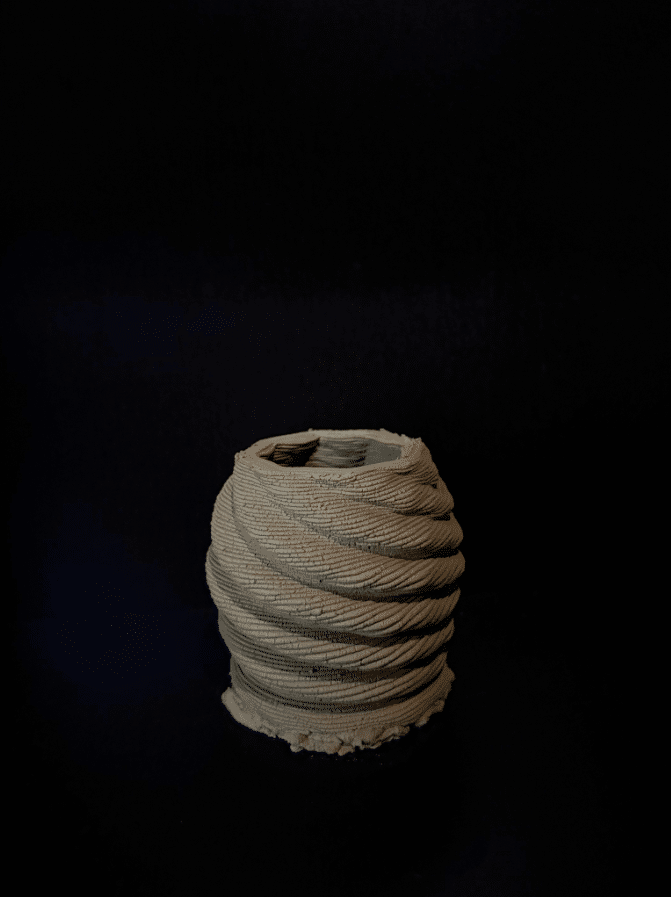

ROBOTIC MANUFACTURING

This project investigates the expressive potential of robotic clay extrusion by exploring how motion, material behavior, and geometry interact during fabrication. The final cup is generated through a continuous, spiraling toolpath that twists around its axis, producing a fluid, wave-like surface. Driven by principles of material responsiveness and controlled irregularity, the design embraces the natural sag, compression, and deformation of wet clay. Instead of forcing geometric perfection, the robotic process amplifies these material tendencies to create a unique, organic form.

Design Generation

THE PROCESS

FINAL PRODUCT

FABRICATION VIDEO :

https://drive.google.com/file/d/1B5hhzhTCbtD_L5Js_fhb0SdQPOFHnUlr/view?usp=sharing