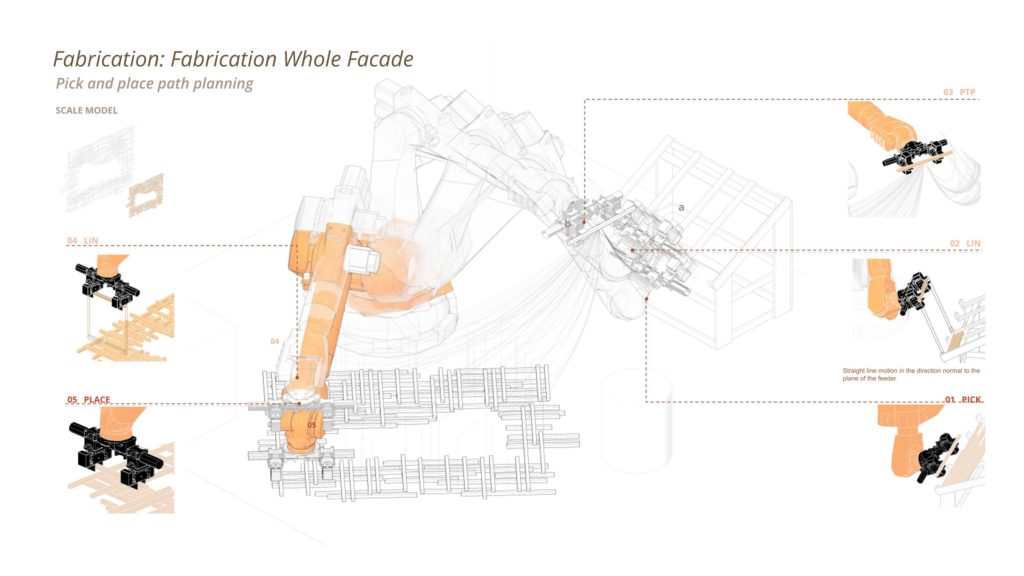

Our Aim Is To Design a Robotic Manufacturing System using Wood Offcuts for Prefabricated and Customized Self Shading Facades

CONTEXT

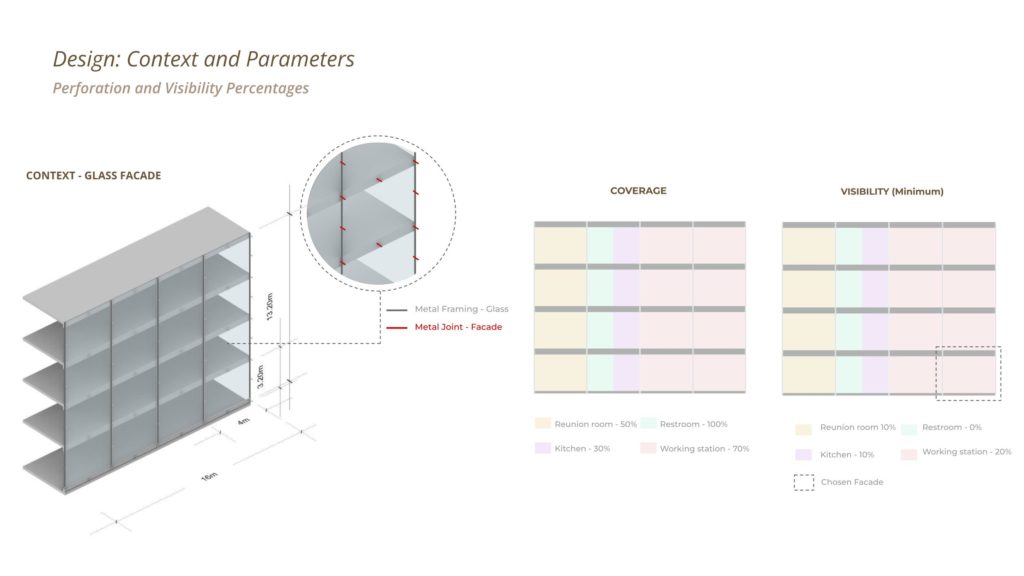

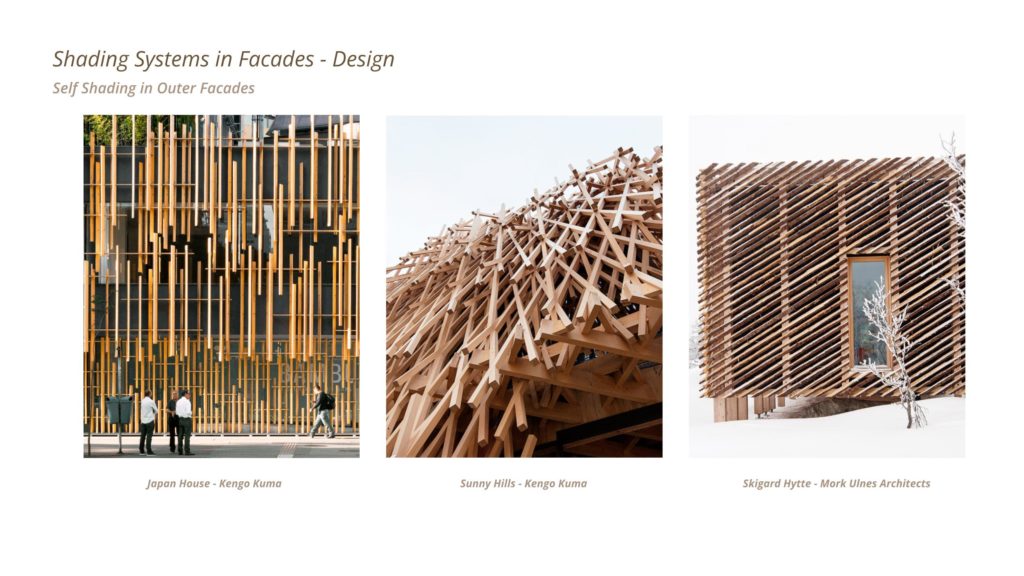

In the realm of mass timber production, a staggering 40% of a wooden log goes to waste, with an additional 25% arising from trimming and edging processes. Despite this substantial waste, innovative approaches have emerged to extract value from these byproducts. Wood waste is repurposed through chipping for applications such as biofuel and gardening, offering an environmentally friendly alternative. However, it is essential to consider the environmental impact of burning wood, which results in carbon emissions 2.5 times higher than natural gas and 30% higher than coal. As an alternative, redirecting these offcuts towards architectural applications presents an intriguing solution. Glass facades, a common feature in modern architecture, contribute to rising temperatures and the heat island effect in cities, posing environmental challenges. In contrast, traditional wooden facades, with their historical significance, offer a more sustainable option. Wood serves as a self-shading system, possesses thermal properties, and contributes aesthetically to a space. Nevertheless, contemporary wood facades often rely on mass standardized pieces, missing an opportunity to utilize the discarded wood. To address this, incorporating robotic procedures in the creation of mass-customized facades using wood offcuts can revolutionize architectural practices, maximizing the value of this abundant but underutilized resource. This innovative approach not only minimizes waste but also aligns with sustainable design principles, fostering a more responsible and environmentally conscious architecture.

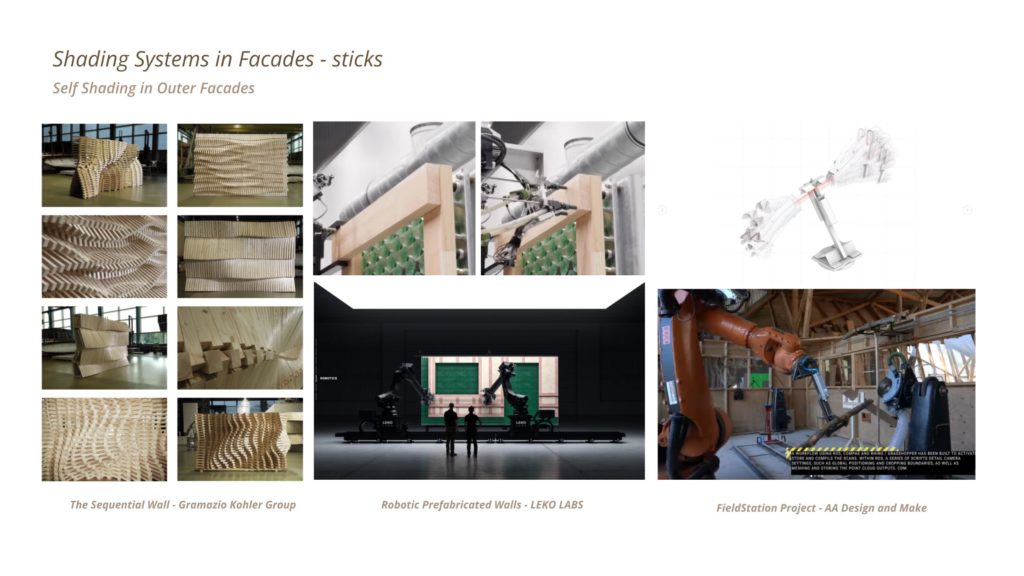

STATE OF THE ART

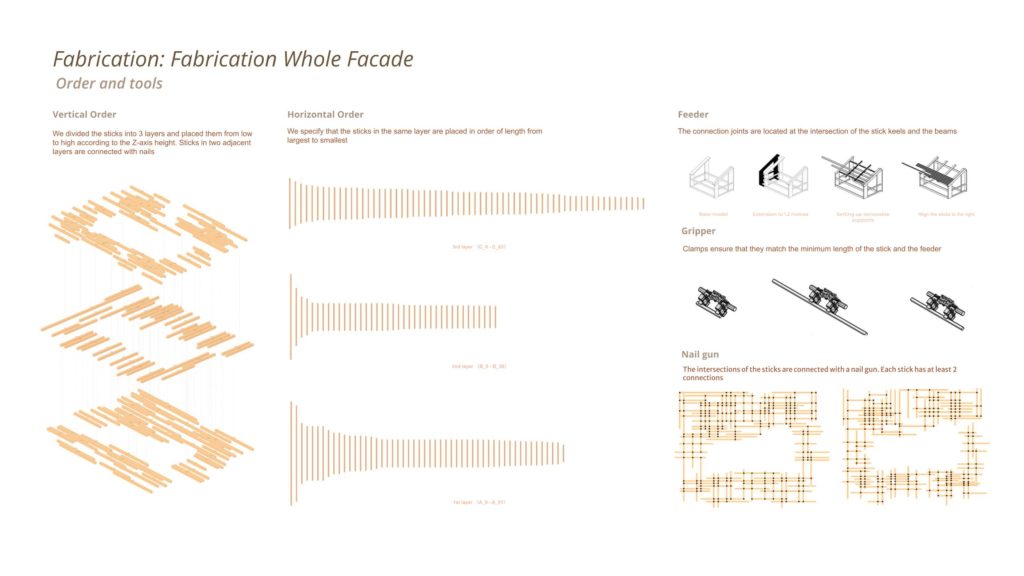

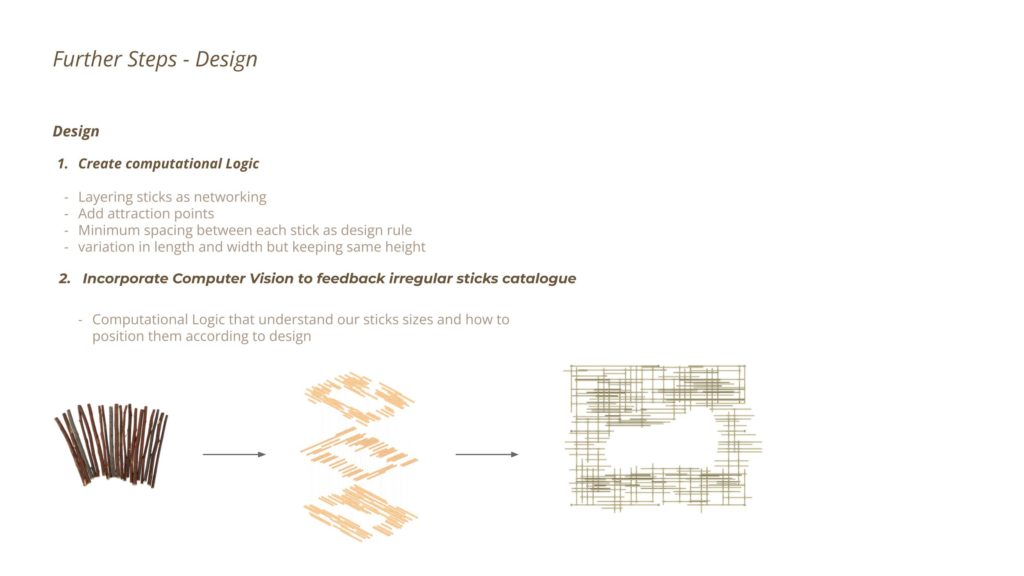

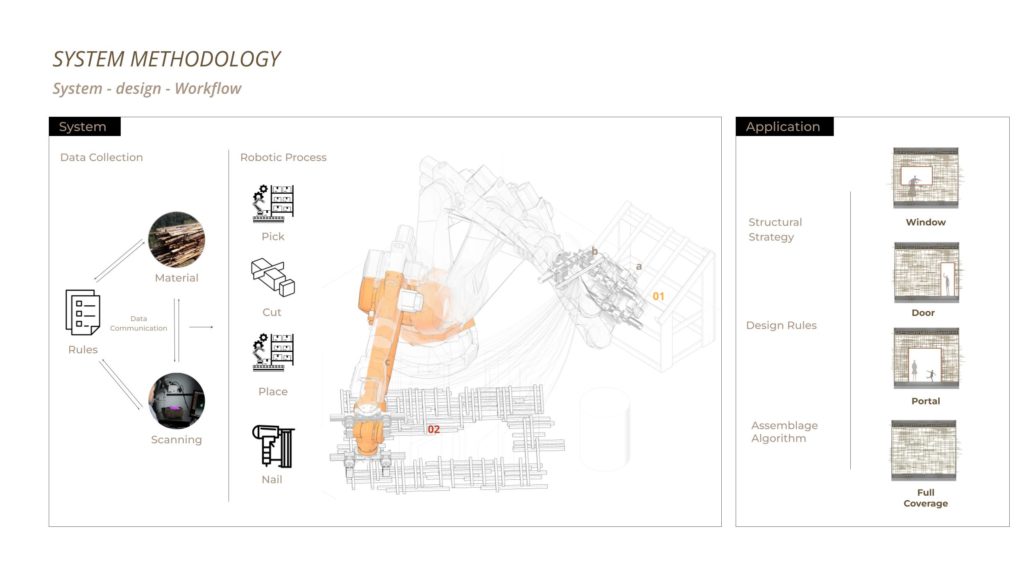

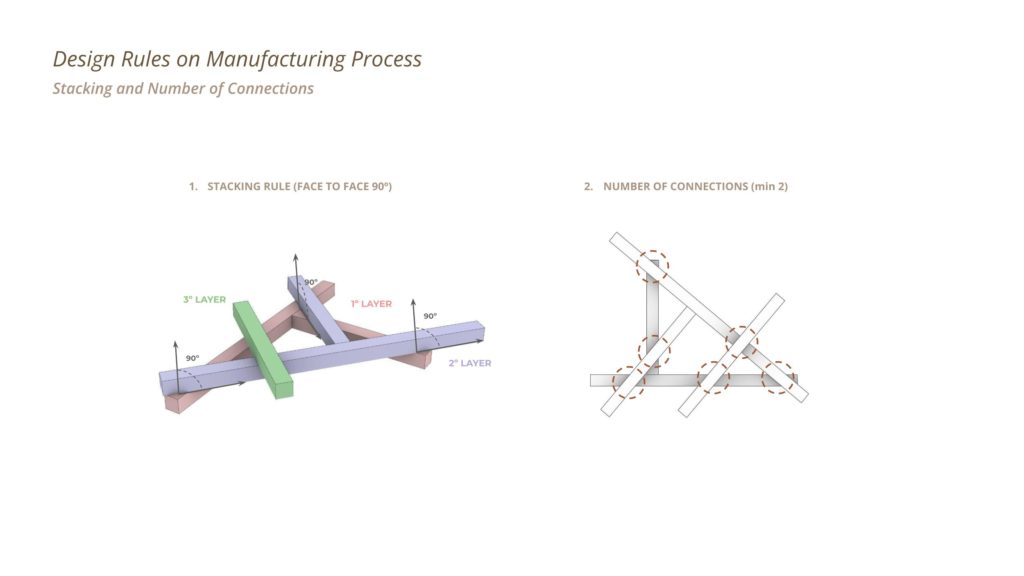

SYSTEM METHODOLOGY

Fig.2 : Slab Wood cutting

Fig.3 : Photos of labeled Cut Sticks

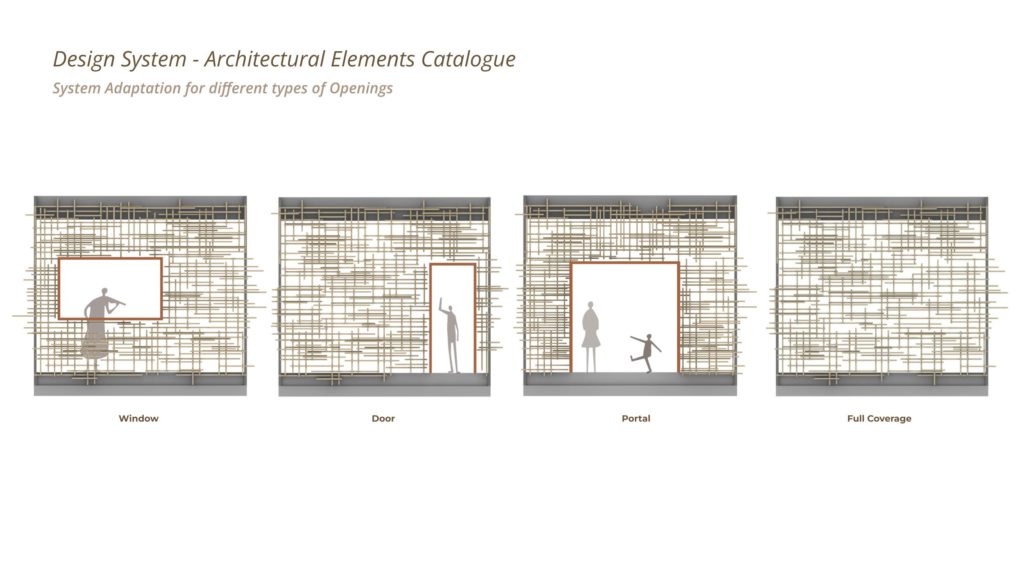

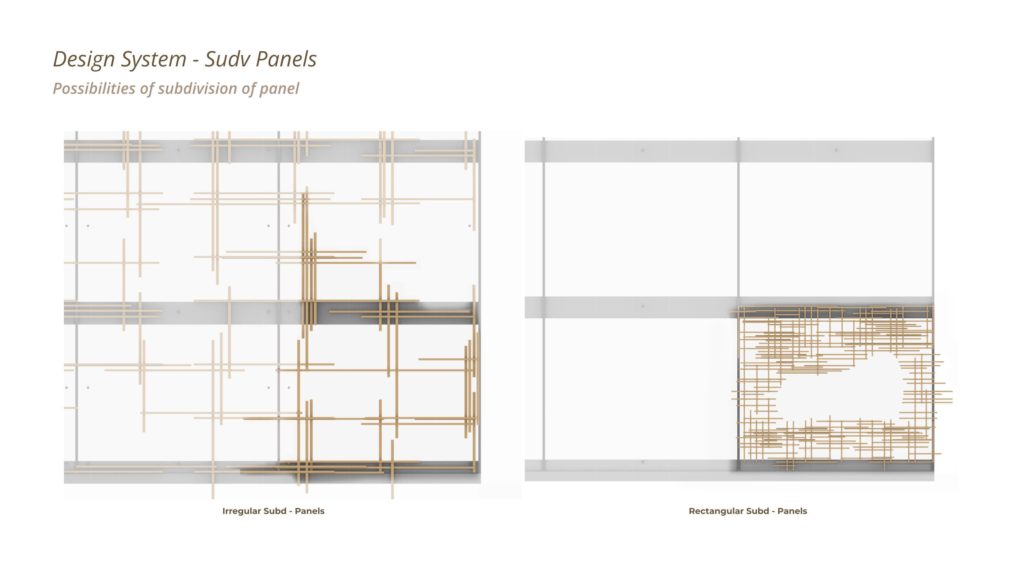

SYSTEM APPLICATION