Context

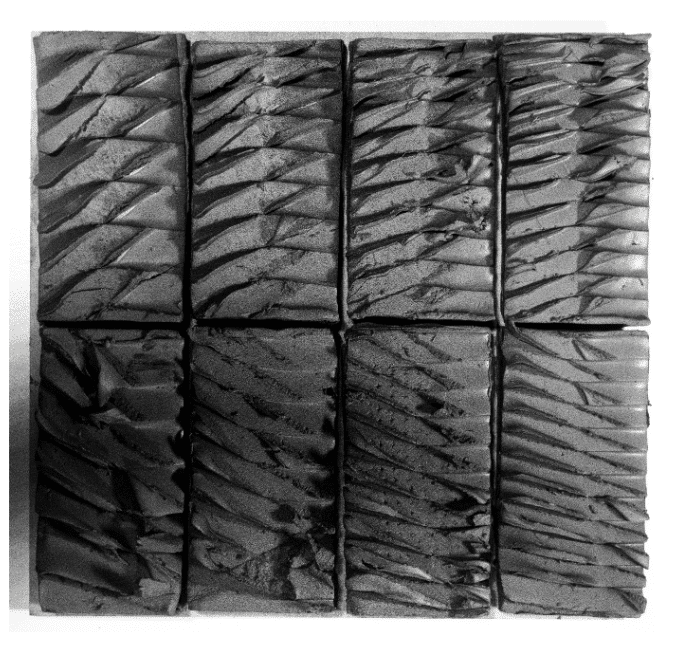

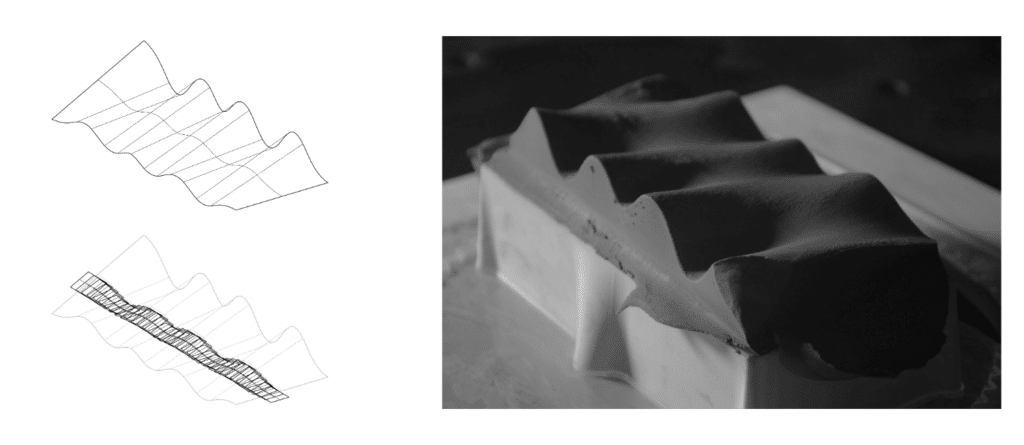

This exercise explores robotic fabrication processes through the direct manipulation of malleable materials. The assignment consisted of producing a 2.5D clay piece, measuring 40 × 40 cm with a maximum height of 5 cm, understood as a physical result of a robotically applied force on soft matter.

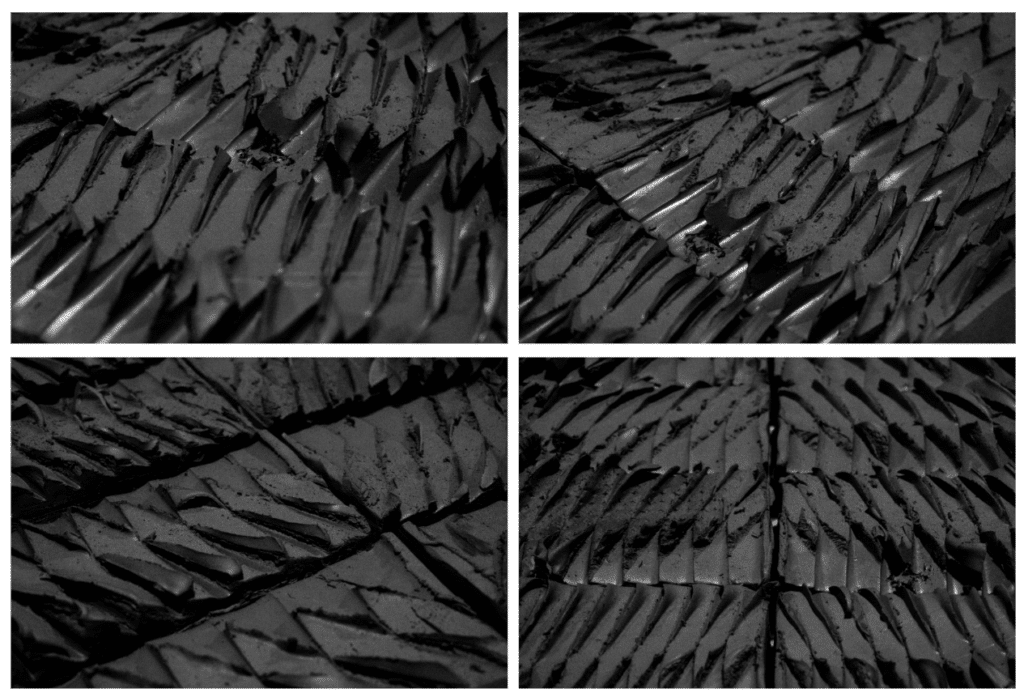

Rather than designing a predefined form, the goal was to understand how robotic movement, tooling, and material behavior interact to reveal the anatomy of the machine through the marks it leaves on the clay.

The material used was black clay, selected for its deformability and direct response to cutting forces. The dimensions of the piece were strictly defined by the brief, constraining the exploration and shifting the focus toward the quality of movement rather than volumetric complexity.

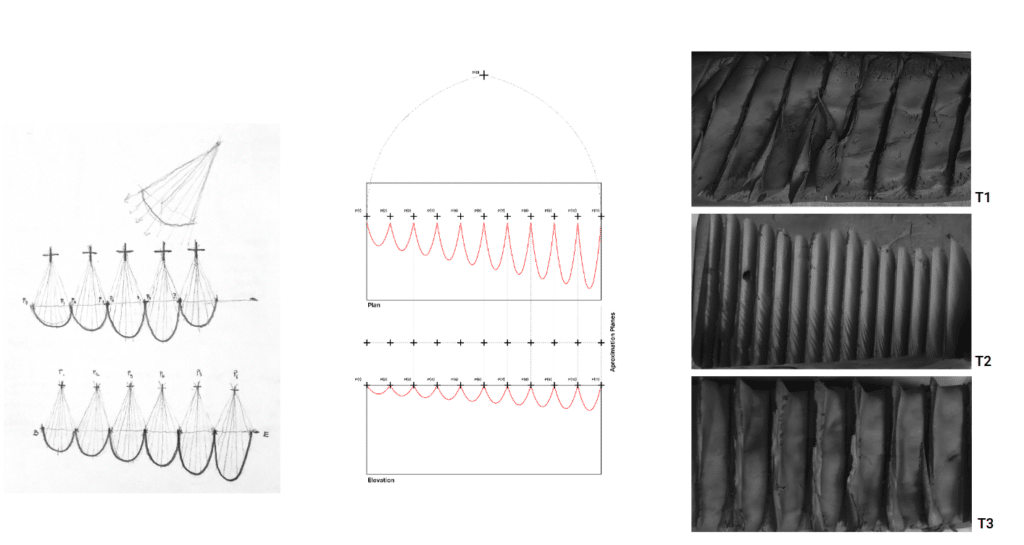

Phase 1 – Manual Exploration

Before working with the robot, a phase of manual exploration was conducted using the wire-cutting tool on small clay samples. This step was essential to understand the real behavior of the tool: how it responds to applied force, how moisture levels affect the cut, and which gestures produce clean cuts, deformations, or collapses.

From this exploration, the group made a clear conceptual decision: to prioritize the creation of a series of movements capable of generating unexpected geometries, rather than attempting to replicate a specific shape. The focus shifted from formal control to studying movement as a form-generating agent.

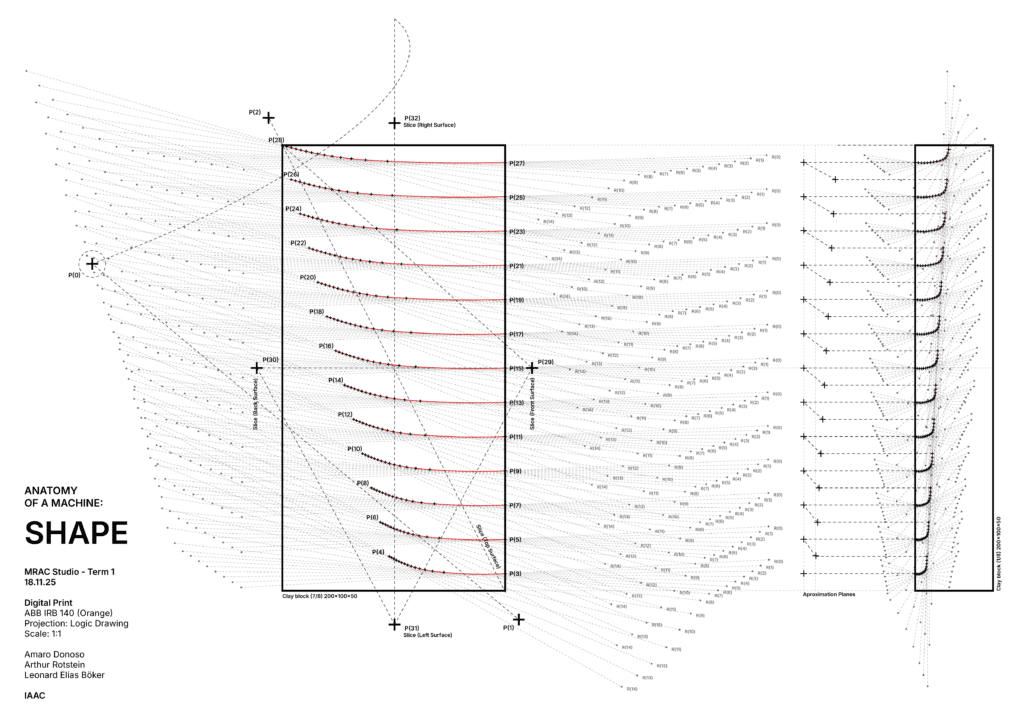

Phase 2 – Digital iterations and movement programming

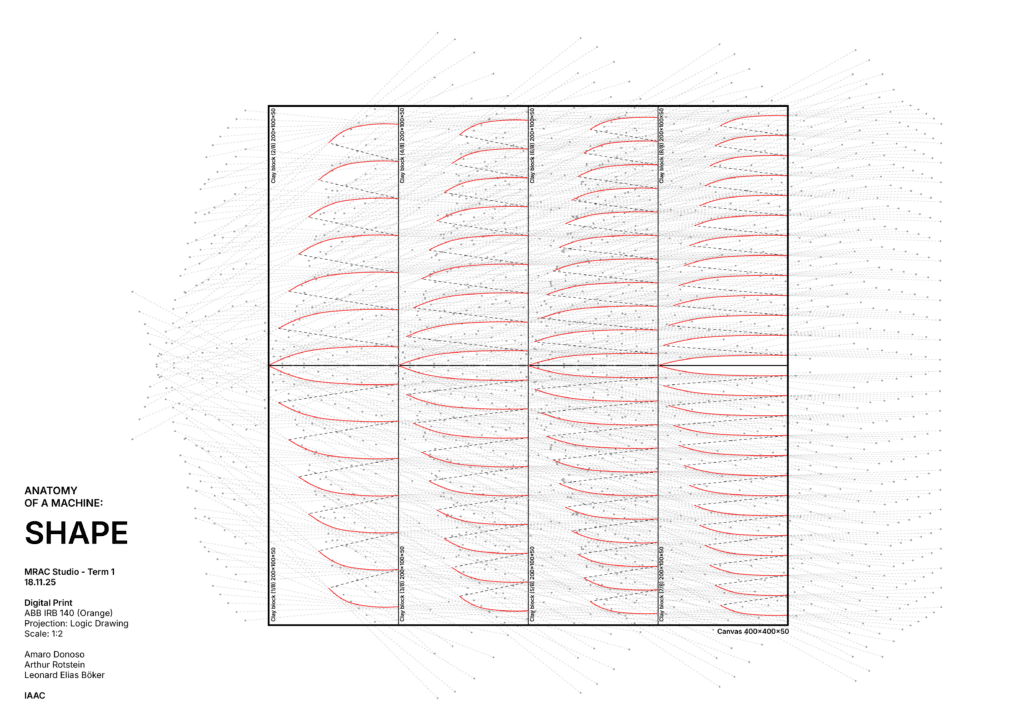

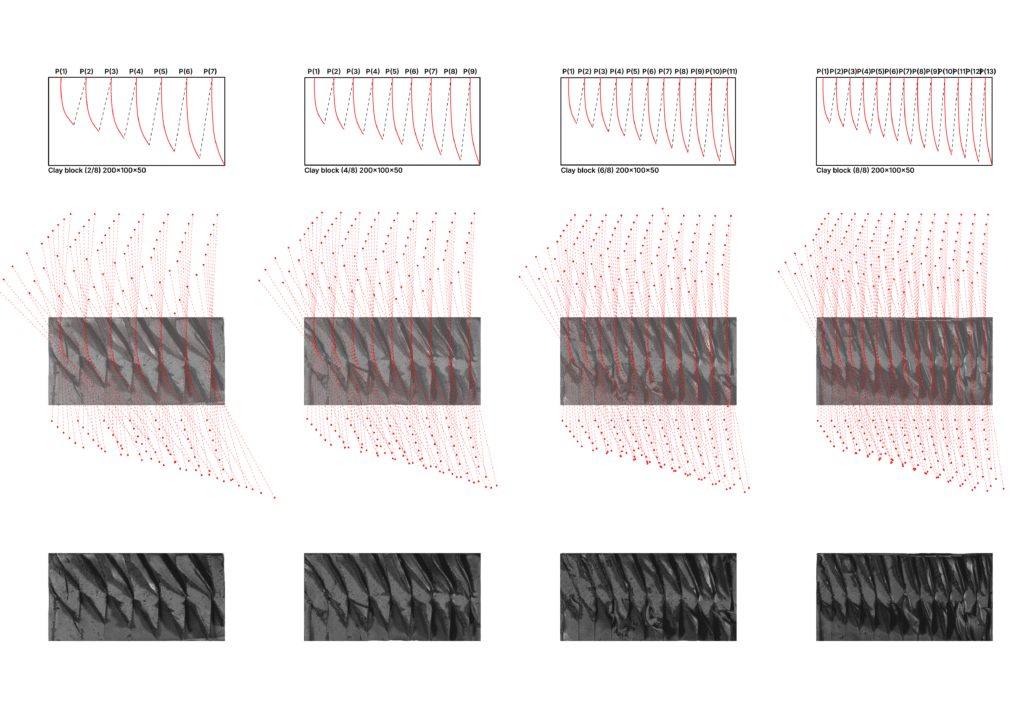

The next phase translated these material insights into a digital programming workflow using Grasshopper. Instead of designing a final geometry, the process focused on imagining how the robot moves through space and anticipating how those movements would affect the clay.

The code functioned as an operational blueprint, defining trajectories, sequences, and TCP orientations, with the understanding that small variations could produce significantly different material outcomes. Early digital iterations explored simple, linear, and repetitive gestures that would later be tested against the material’s real behavior.

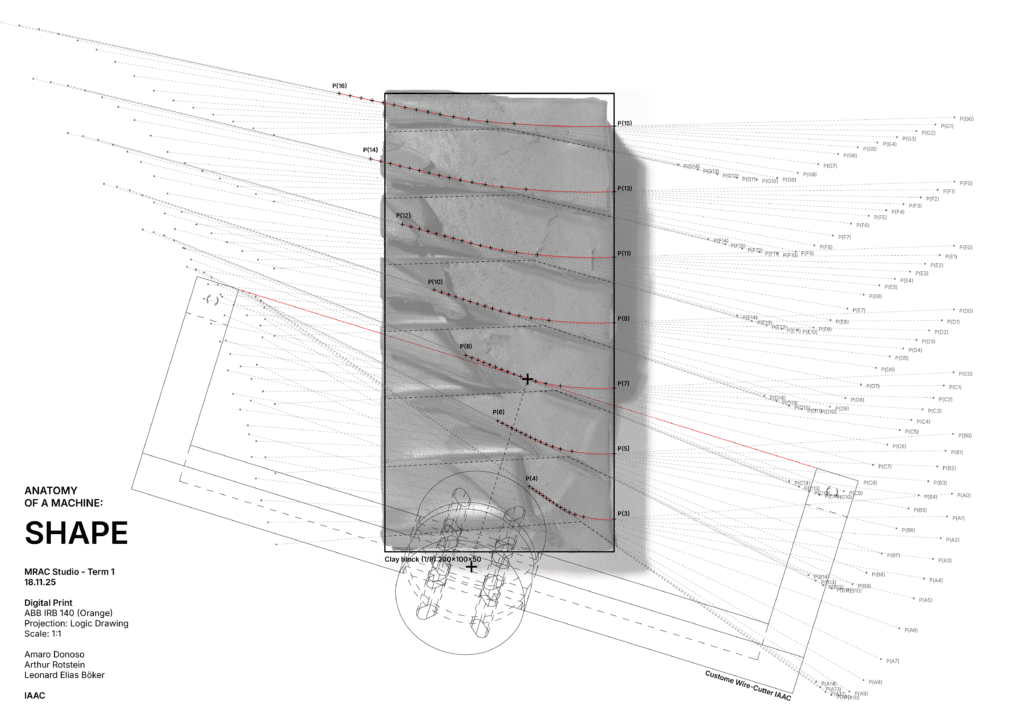

Phase 3 – Final robotic test

In the final phase, the programmed trajectories were executed on the ABB IRB-140 robot to perform cutting tests on the clay block. This required fine calibration of key parameters such as cutting heights, depths, speeds, and movement sequencing.

These tests revealed clear differences between digital trajectories and physical results, particularly due to wire bending and material resistance. Continuous calibration allowed the process to be refined, resulting in a coherent movement logic where the final piece is not a predetermined form but a material record of a controlled series of robotic actions.