INTRODUCTION

In today’s construction industry, a large portion of timber is discarded due to its non-standard shape, curvature, or internal defects. Un_Log Factory challenges this paradigm by proposing a digitally augmented fabrication system that embraces the natural irregularity of timber. Instead of seeing bent or cracked logs as waste, our process redefines them as raw material for design innovation.

Through a hybrid workflow that combines human intelligence, robotic precision, and computational analysis, we developed a pipeline that scans, classifies, kerf-cuts, reshapes, and delivers timber components tailored to both structural and aesthetic goals. This project doesn’t just explore how to reuse what is typically rejected—it proposes a new material language and a scalable production method that aligns with circular economy principles and adaptive design thinking.

OUR AIM

Transformation of discarded tree logs into unique applications for structural and design purposes

Extend the life and utility of irregular logs through reshaping. By comparing raw logs to their transformed counterparts, this slide illustrates how natural material imperfections can be integrated into controlled, purposeful design outcomes using kerfing and bending techniques.

OUR PRODUCT

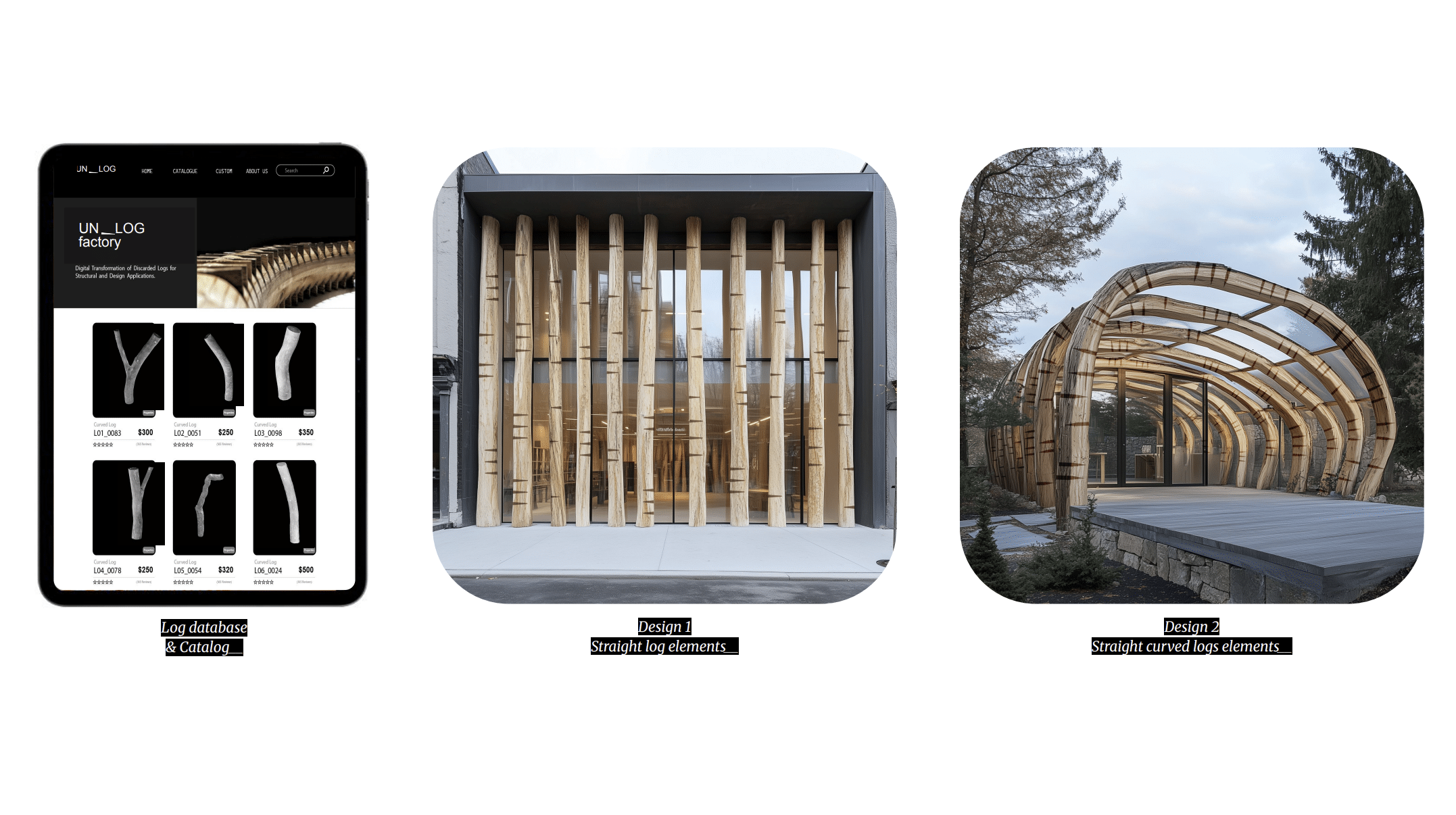

Architectural applications

We offer a full and diverse catalog of different types of transformed logs, ready for implementation in design and architectural projects. Each transformed log becomes part of a growing catalog of design elements. This log library functions as both a physical and digital inventory, categorizing logs by geometry, curvature, and usability for further design deployment.

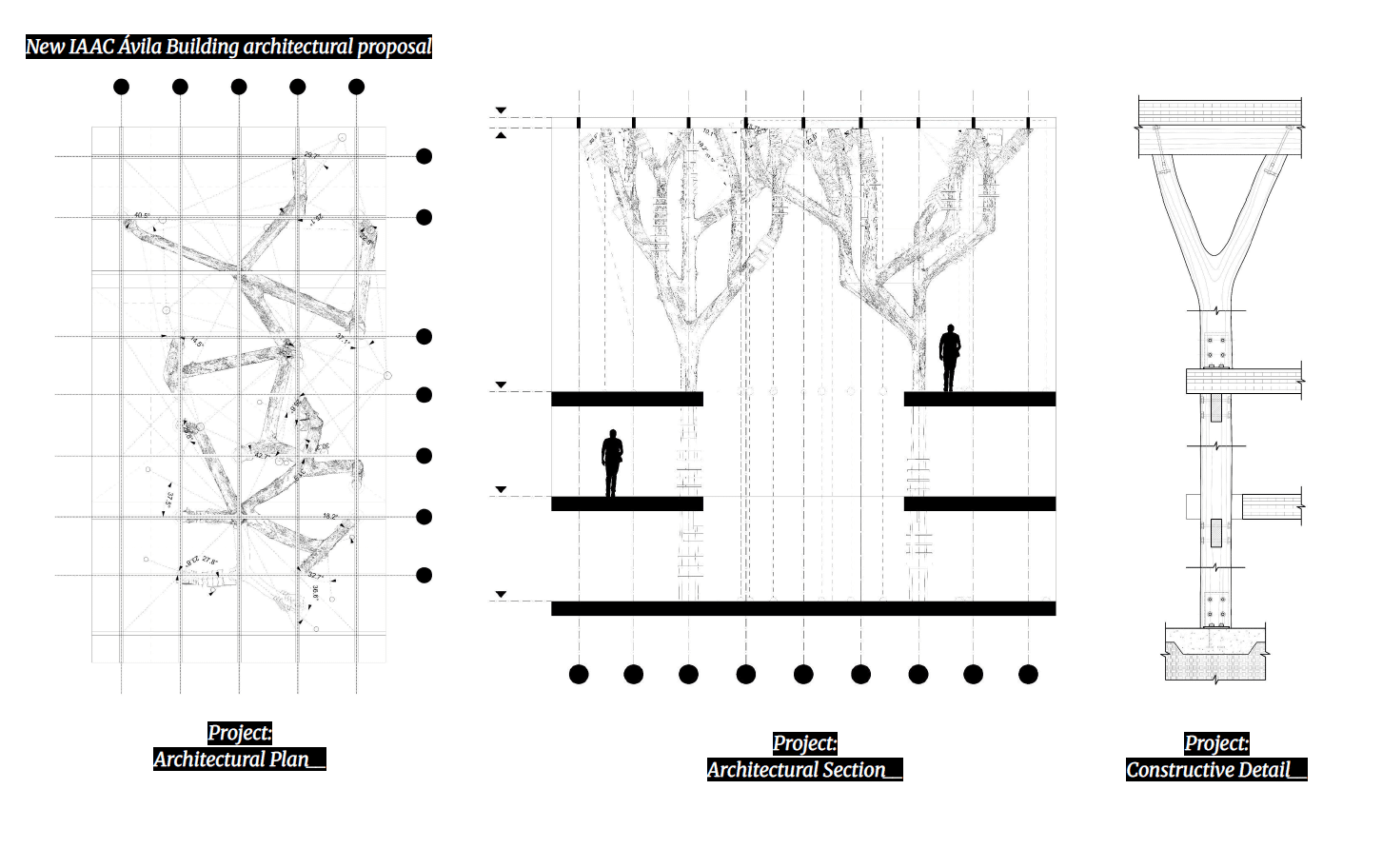

Architectural customized systems

We also offer architectural solutions for customized constructive application. Thereshaped logs are not just conceptual—they are integrated into architectural structures. Detailed plans and sections from a real architectural proposal demonstrate the structural and expressive potential of these modified components.

WORKFLOW

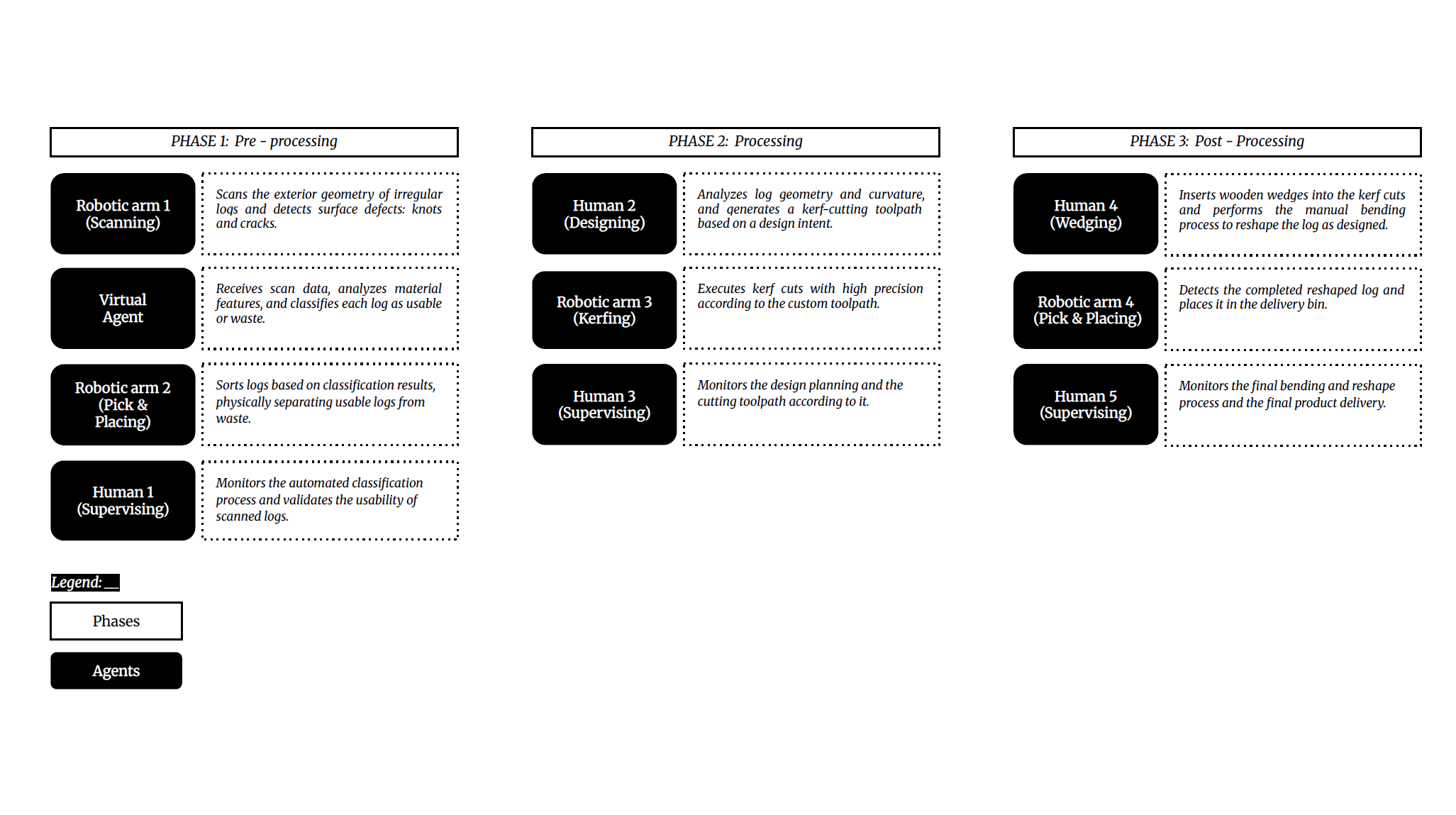

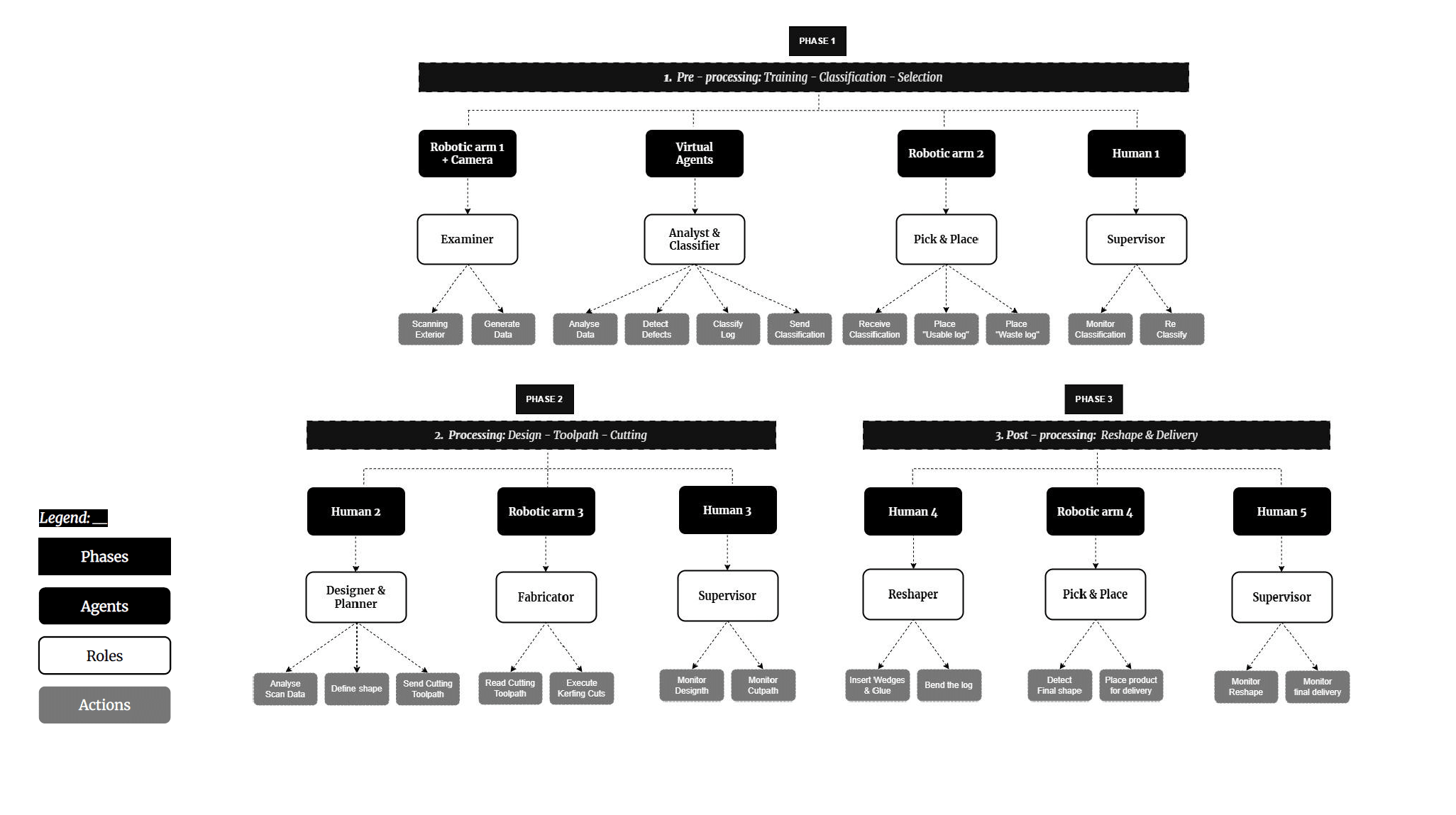

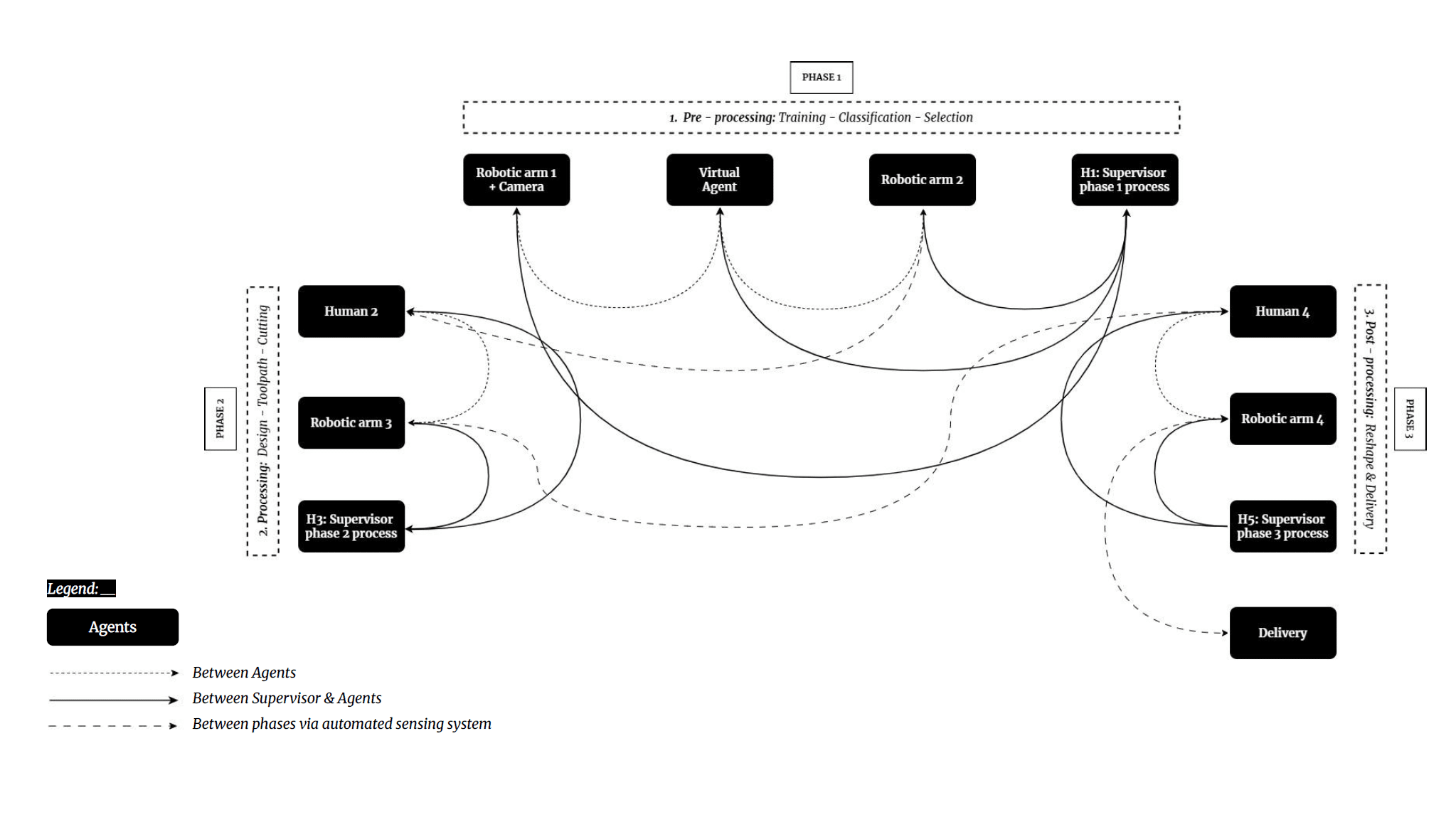

Hybrid Human–Virtual–Robot collaborative production line for reclaiming irregular timber logs

The system is organized into a three-phase workflow: Pre-processing, Processing, and Post-processing. Each phase is managed by a combination of human, robotic, and computational agents, working in sequence through a coordinated fabrication pipeline.

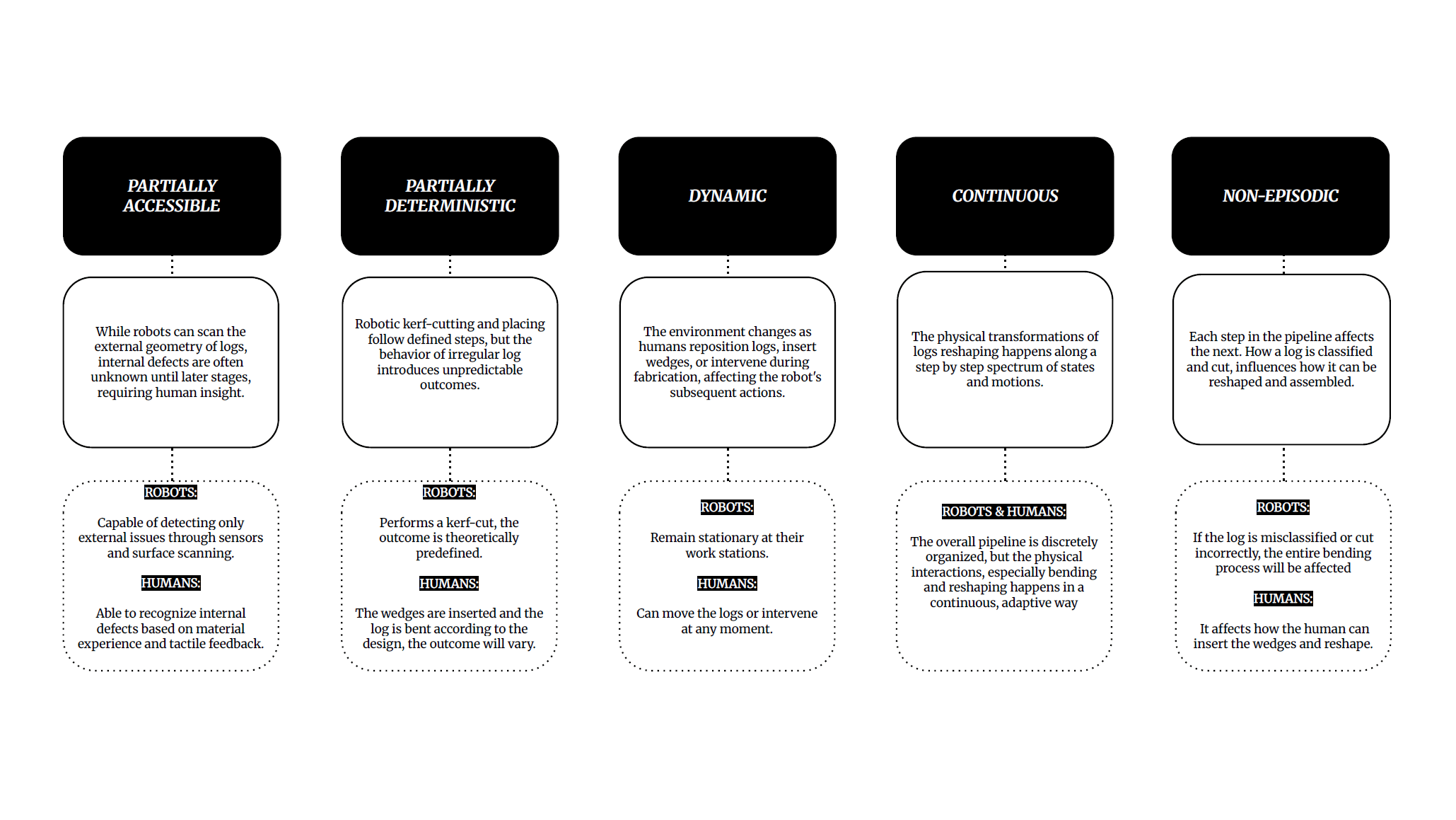

ENVIRONMENT

Characterizing the collaborative Environment within Human, Virtual Agent & Robot

The environment in which this process occurs is defined as partially accessible and partially deterministic. While robots handle predefined tasks, the unpredictability of timber requires human supervision, making the context dynamic, continuous, and adaptive.

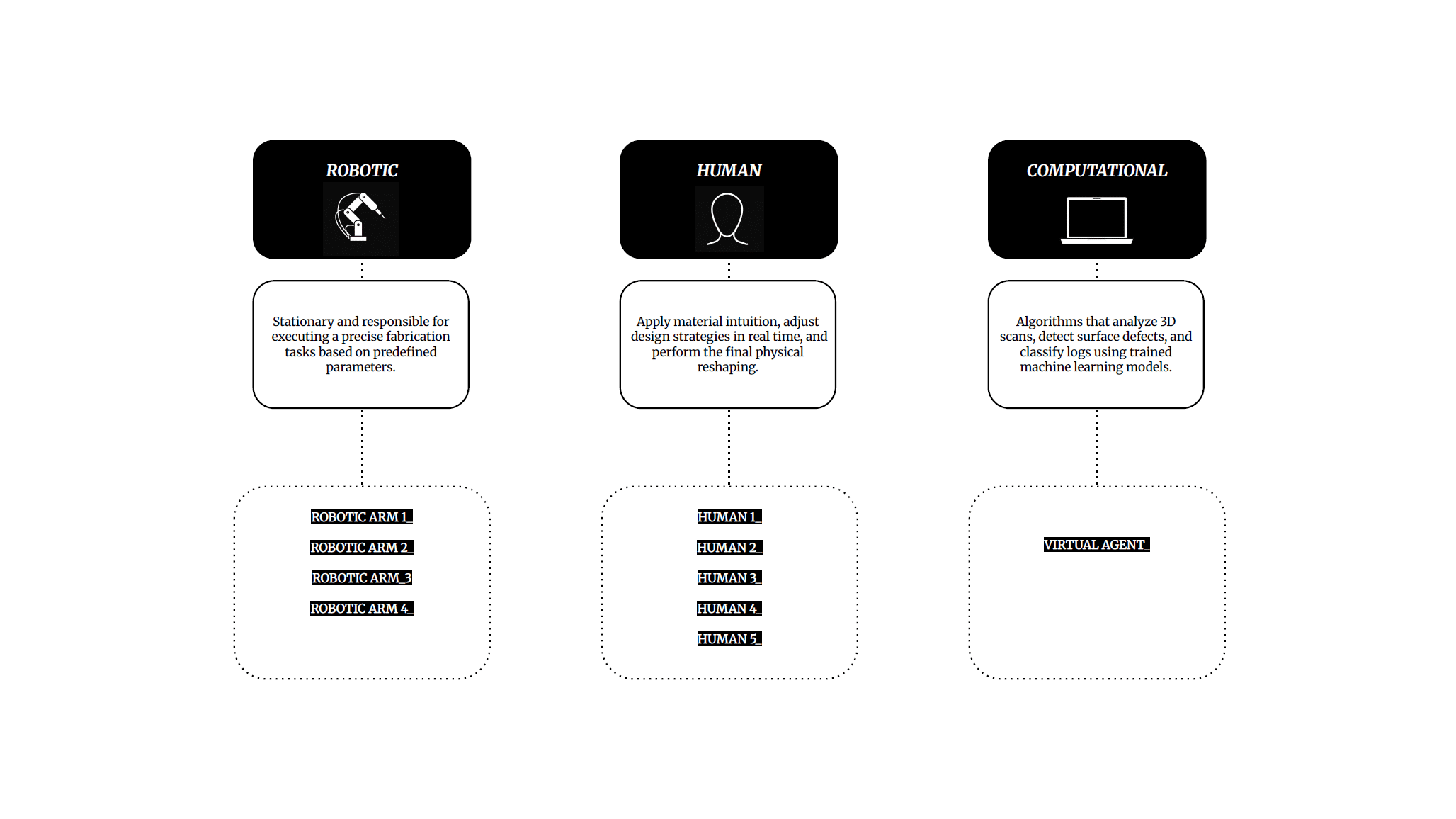

AGENTS

Collaborative production environment in which decision-making and action are distributed across physical and digital

A variety of agents drive the system: robotic arms responsible for scanning, sorting, cutting, and delivery; human agents supervising, correcting, and shaping; and a machine learning classifier that interprets scan data and makes decisions.

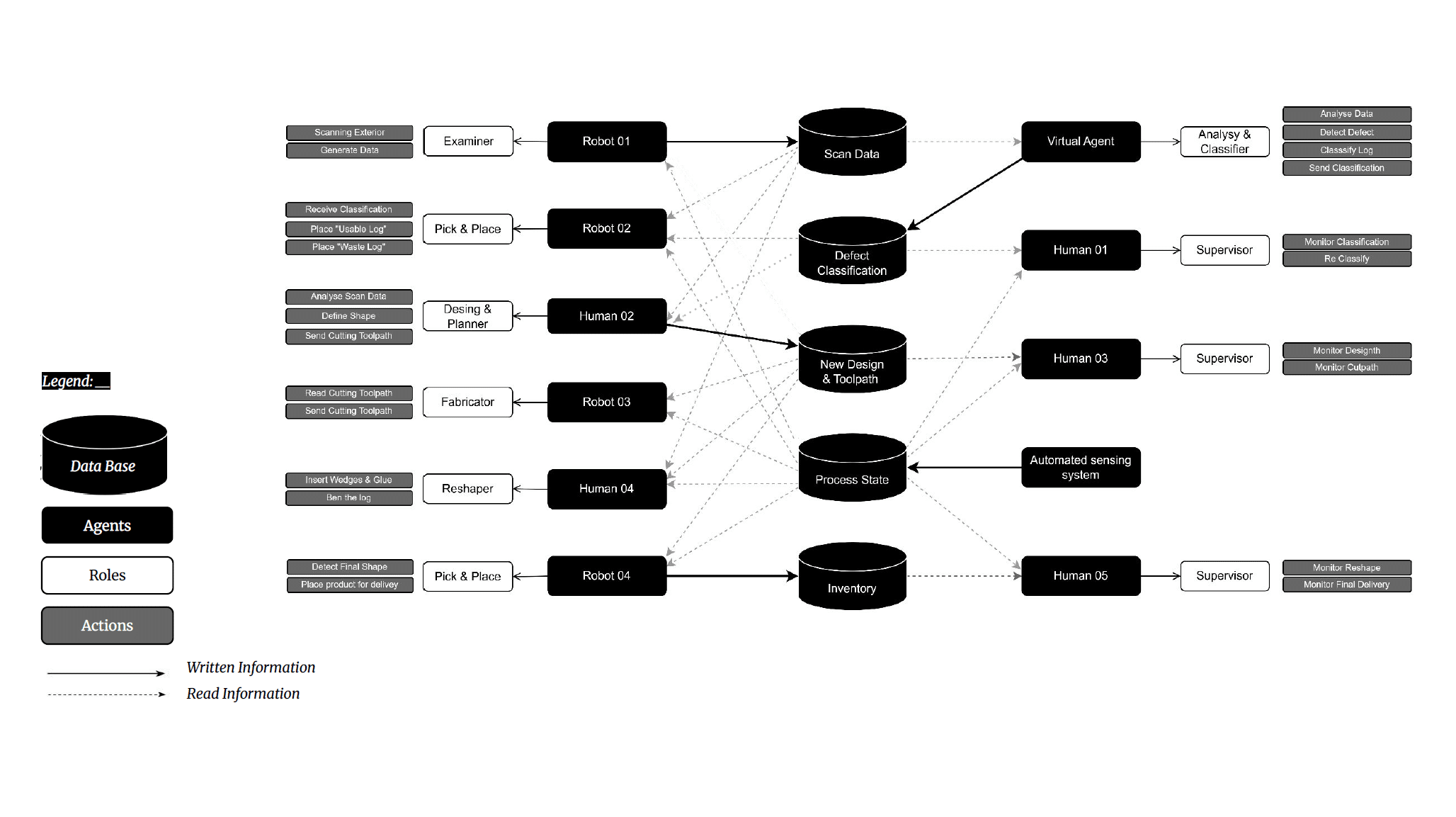

List & responsibility

Agents, Roles & Actions

Each agent fulfills a specific role within the system. Robotic arms perform physical actions like scanning or cutting, while humans intervene in creative and corrective tasks. The division of labor reflects the complementary strengths of each type of intelligence.

ARCHITECTURE SYSTEM

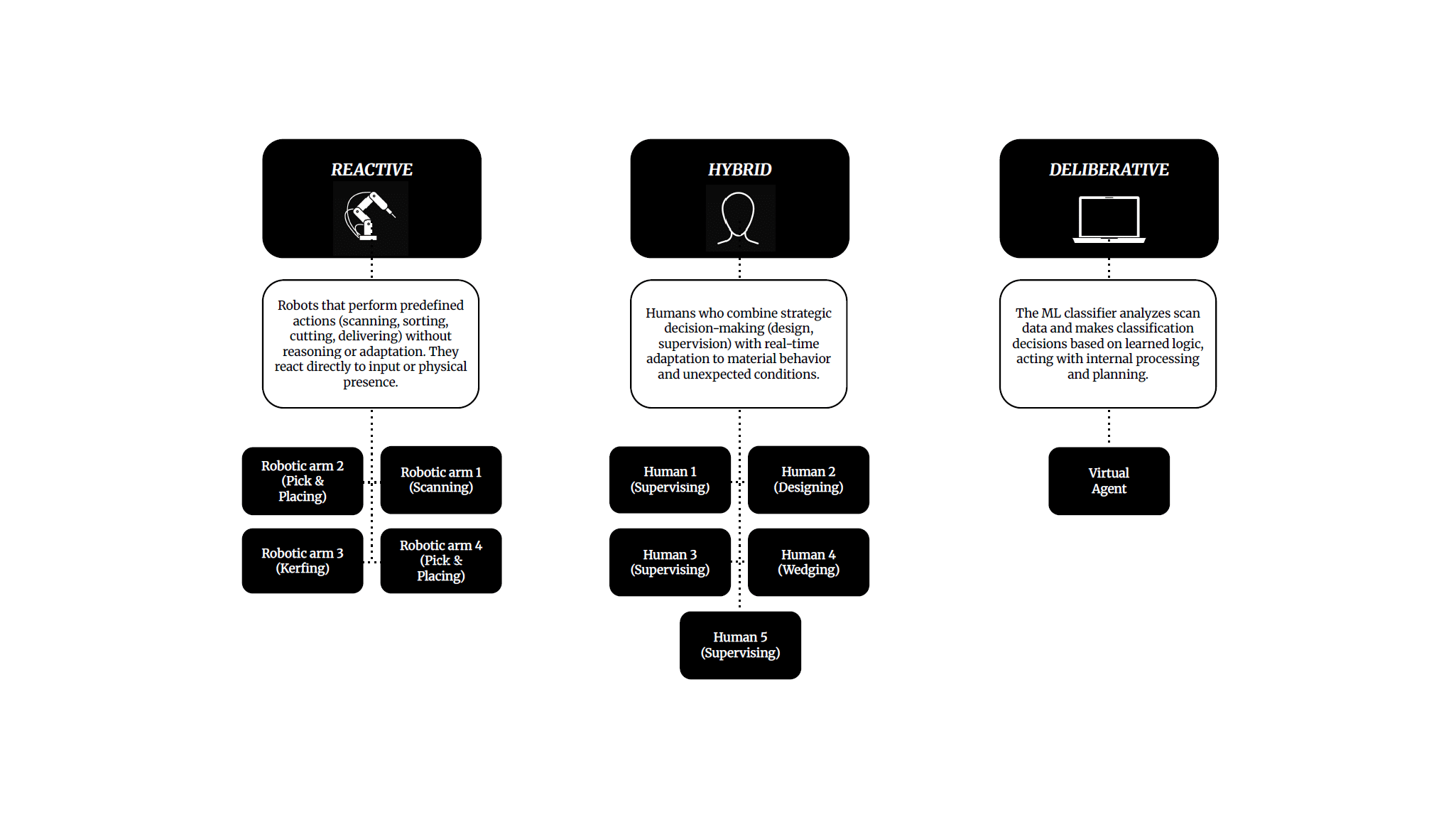

Combining reactive and deliberative agent behaviors across different stages of the pipeline

Agents are classified by behavior: robots operate reactively, responding to direct stimuli; software acts deliberatively, analyzing and planning; and humans function as hybrid agents, balancing real-time reaction with long-term planning and judgment.

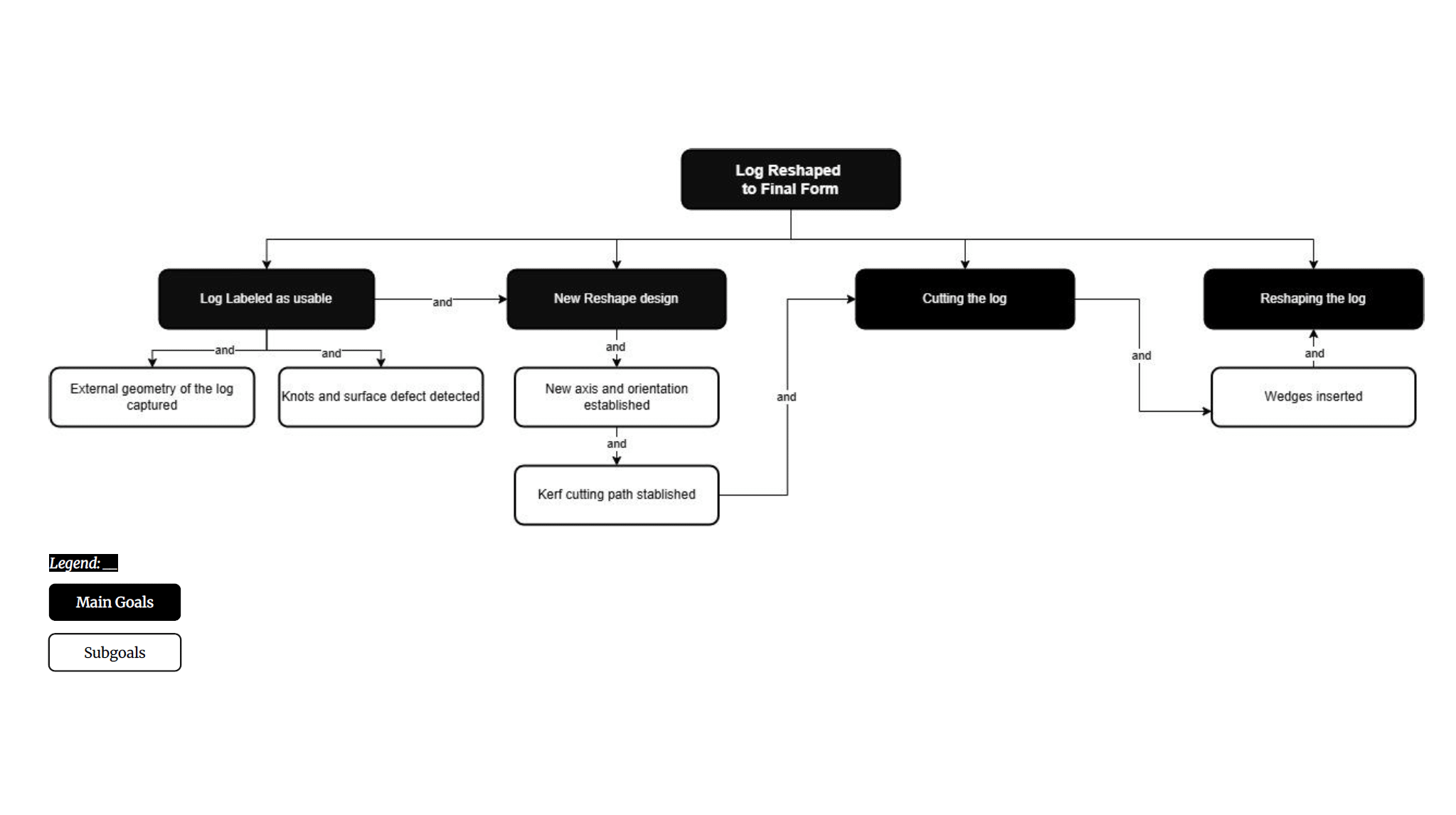

GOALS & SUBGOALS

Every action taken in the system is aligned with a set of goals—from identifying usable logs to reshaping them for delivery. This structure ensures that the entire process remains purposeful and outcome-driven.

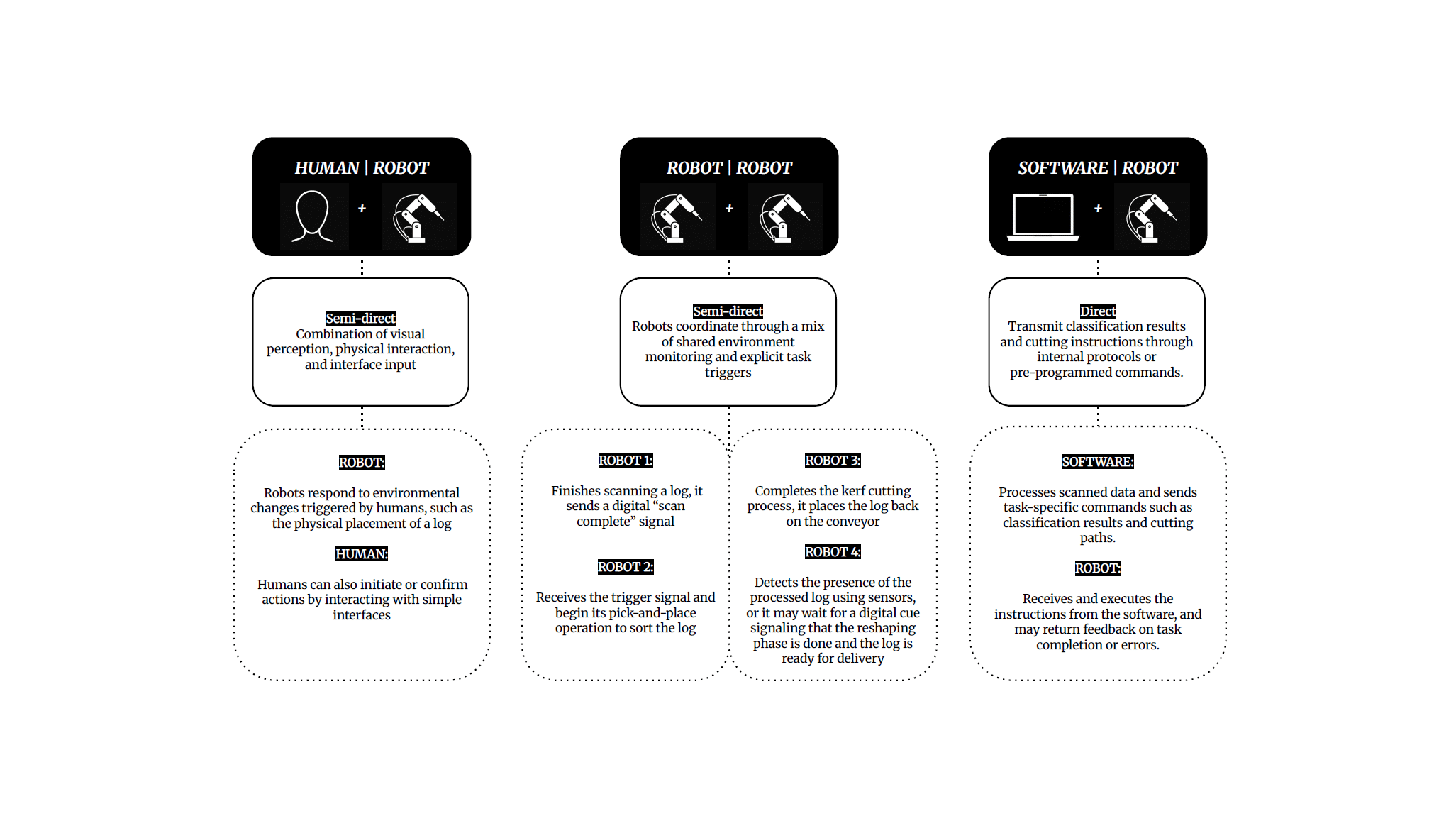

COMMUNICATION EXCHANGE

Hybrid communication system that combines sensor-based and interface-mediated interactions.

Across all agent types, communication ranges from direct commands to semi-direct signals and indirect coordination. Effective operation depends on seamless communication between agents. This includes software sending instructions to robots, humans interpreting sensor feedback, and physical signals triggering the next step in the sequence.

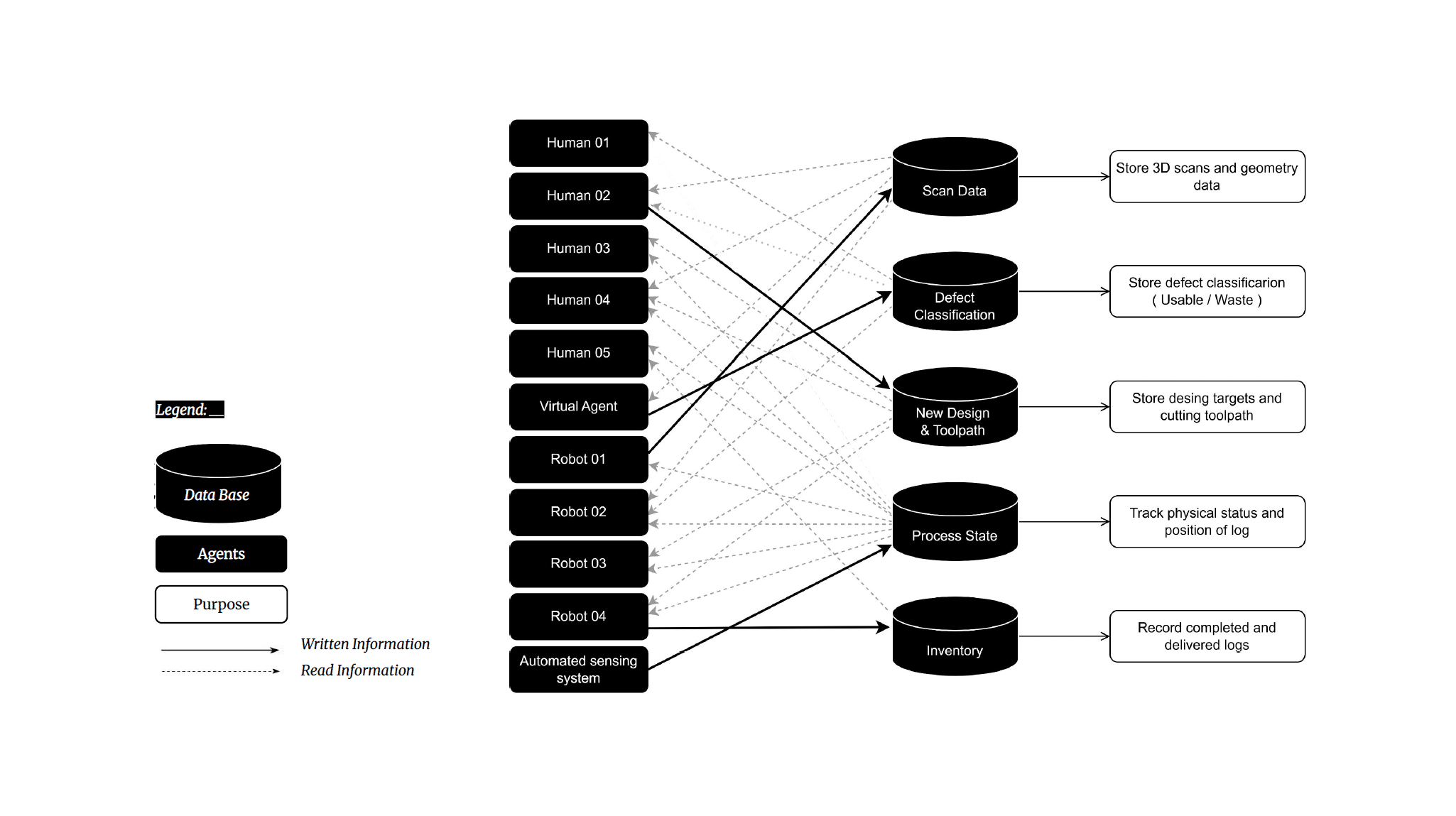

DATABASE

Database Communication between Agents

A centralized database serves as the shared memory of the system. All agents read from and write to this repository—storing scan data, classification outcomes, toolpaths, and reshaping parameters to ensure continuity and traceability.

SYSTEM OVERVIEW

Un_Log Factory operates as an interconnected and collaborative system

Each agent—robotic, human, and computational—plays a defined role within a continuous feedback loop. Data flows through each phase, from scanning and classification to reshaping and final delivery. The system integrates sensory input, real-time decision-making, and physical execution in a tightly synchronized pipeline. By connecting actions, data streams, and communication pathways, the factory functions as a cohesive organism—resilient, adaptive, and capable of transforming unpredictable materials into precise architectural components.

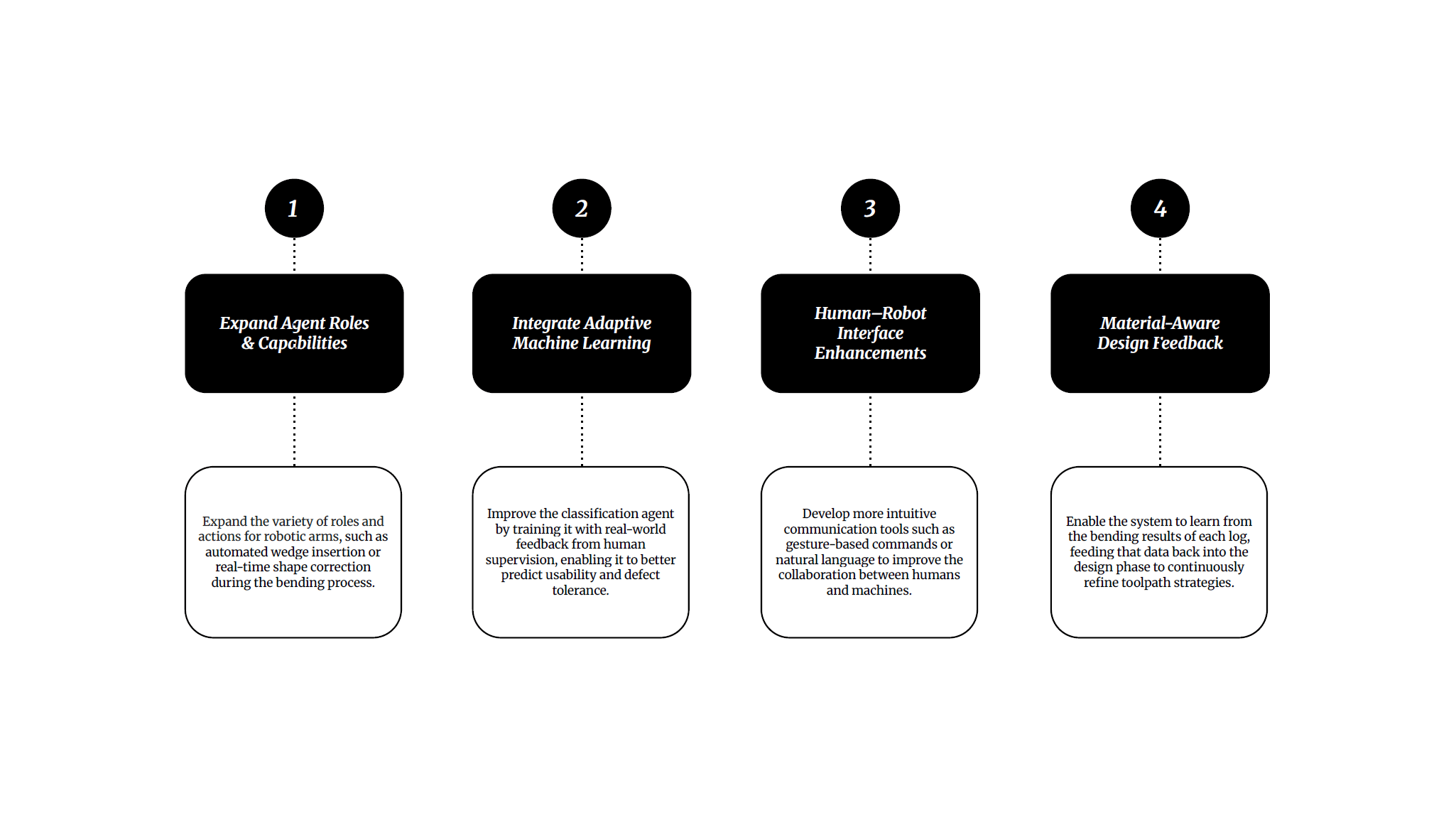

FURTHER STEPS & IMPROVEMENTS

Conversion into an intelligent and scalable fabrication system, capable of responding in real time

The Factory will evolve by enhancing its machine learning accuracy, agent diversity, and real-time human–robot interaction. Simulations and adaptive feedback loops will make the system smarter, more scalable, and resilient to material variability.