INTRODUCTION

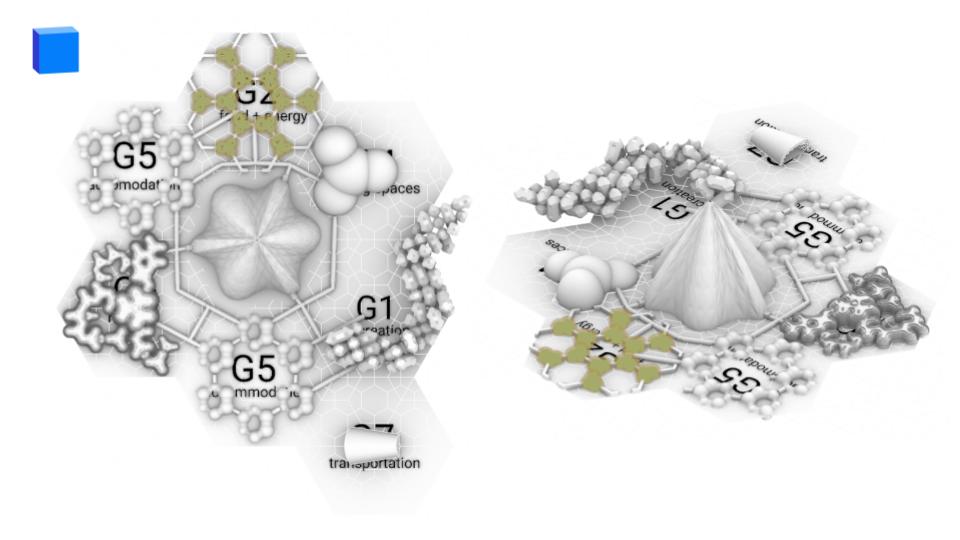

The project entails establishing a self-sustaining and productive colony on Mars through a collaborative effort among seven remote groups from across the world. The primary goal of the project is to develop a colony that can adapt to the harsh Martian environment and sustain itself over an extended period. To accomplish this feat, the groups had to collaborate through various platforms and establish workflows for effective communication and software integration between members and teams. The teams employed advanced techniques to interact seamlessly and leverage their unique expertise towards the project’s success.

FOOD AND ENERGY PRODUCTION

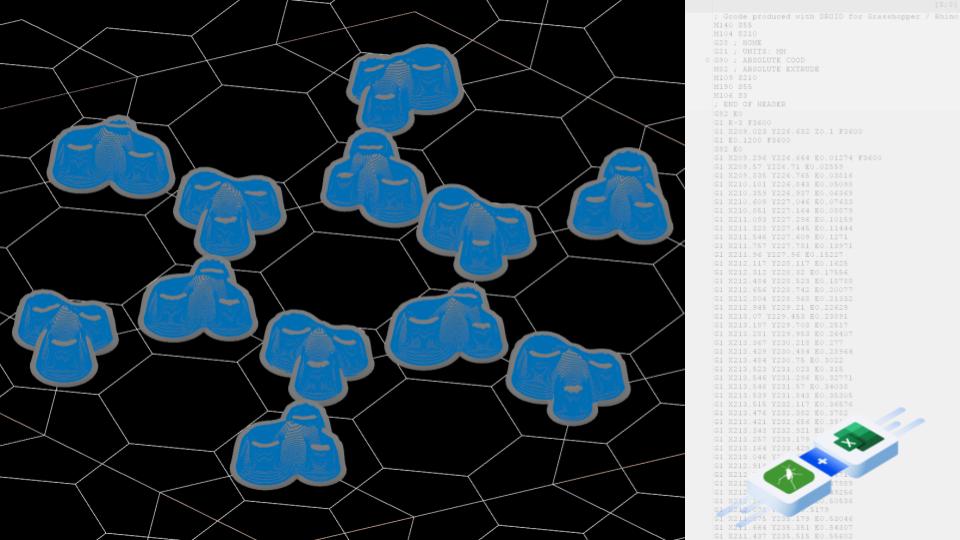

The Food and Energy production project is a crucial aspect of our colony’s design, as it serves to optimize space utilization and meet the diverse needs of the other groups. At its core, the project revolves around a series of interconnected 3D printed capsules that function as food production columns, which are stacked in a space-efficient manner. These capsules are equipped with advanced technologies that enable efficient and sustainable food cultivation, including automated irrigation systems, optimized lighting, and controlled temperature and humidity levels. Additionally, the roof of the capsules is utilized for the production of solar and wind energy, which further enhances the self-sustainable nature of the project. By utilizing these cutting-edge technologies and design principles, our team has developed an innovative and effective approach to food and energy production that is tailored to meet the unique challenges of life on Mars.

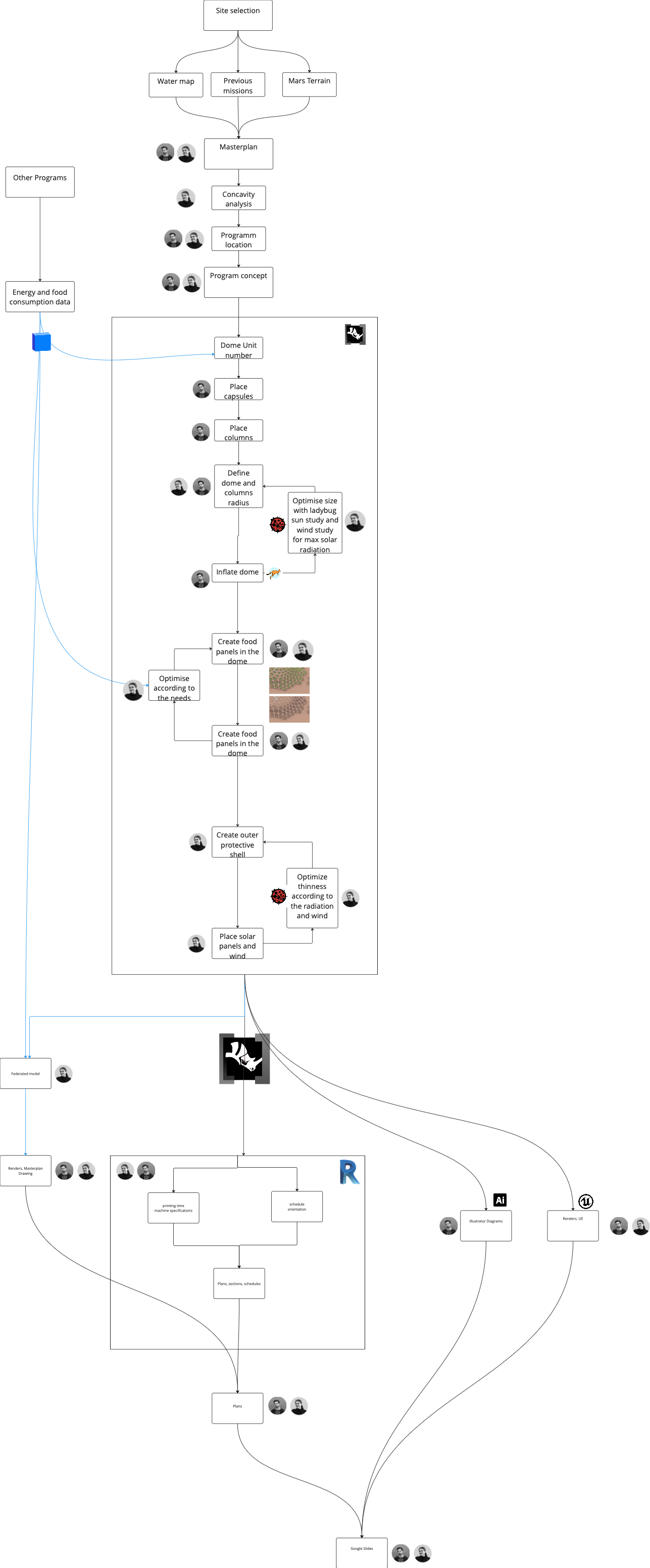

WORKFLOW

SHARING AUTOMATION

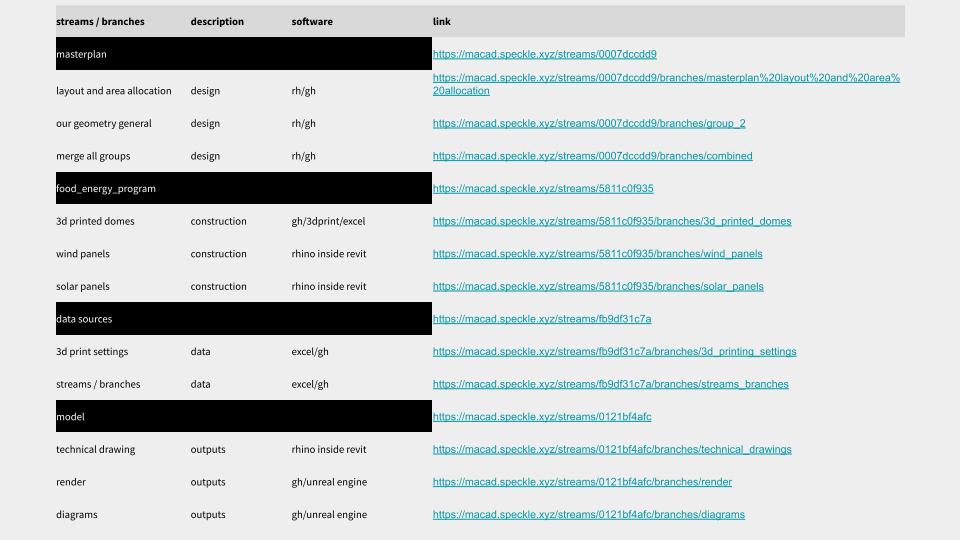

SPECKLE proved to be an invaluable tool for sharing information and geometries among the team members. To maintain a streamlined workflow and organized information flow, the team used an Excel document that contained the branch and sub-branch names of the streams, a detailed description, the software used, and the relevant stream. This document served as a reference point for the team to ensure that all members were on the same page and had access to the necessary information. By utilizing these tools and techniques, the team was able to maintain a high level of collaboration and effectively share information and geometries to advance the project.

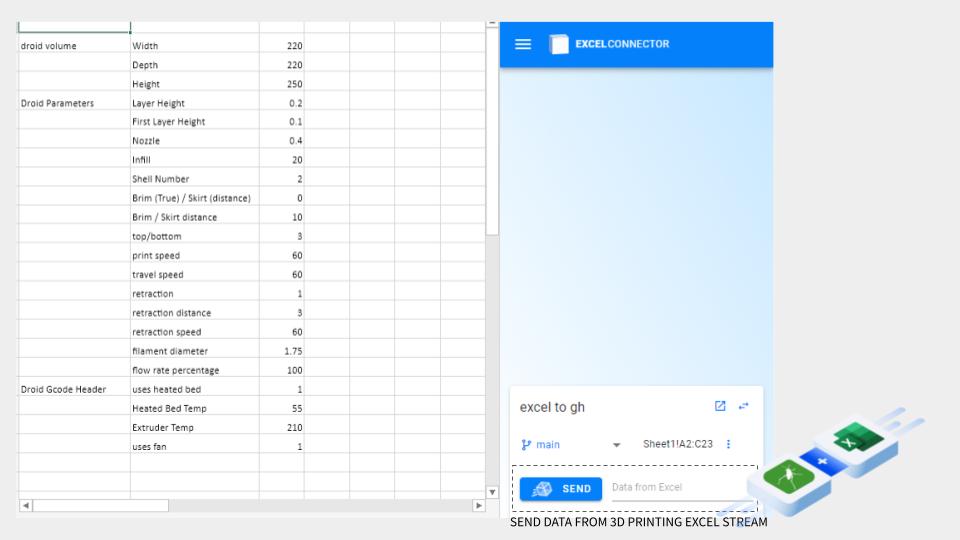

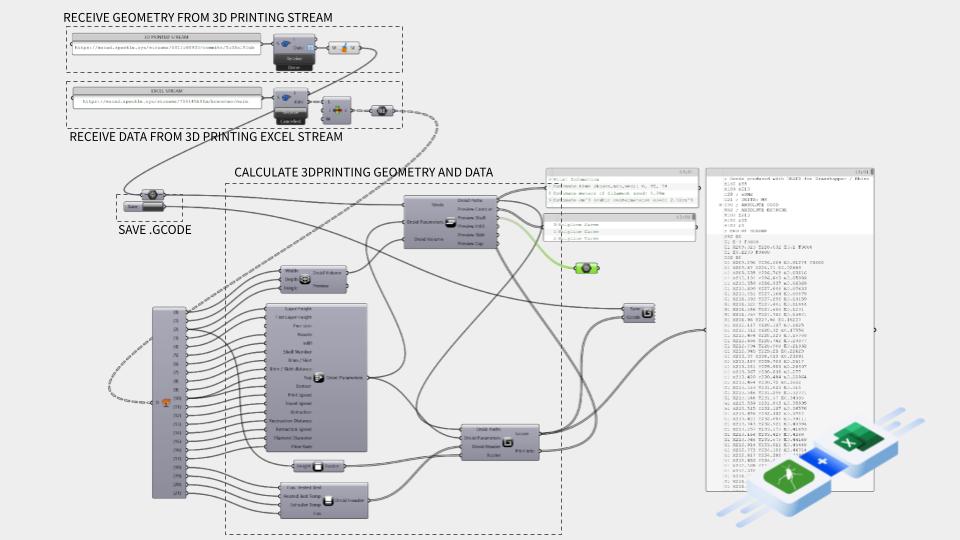

Through the integration of Speckle streams with Excel and Grasshopper, the team was able to automate the 3D printing process of the capsules for the Food and Energy Production project. Excel, being a widely used software, enabled experts from various fields to access and input information related to the unique 3D printing machines used on Mars, which were unlike any on Earth. Grasshopper, in turn, connected the streams of 3D parametric geometries generated in the main file with the machine data, producing G-code files and precise 3D geometries with accurate measurements for printing. The seamless flow of information between these tools allowed the team to streamline the 3D printing process and produce capsules that were optimized for the harsh Martian environment.