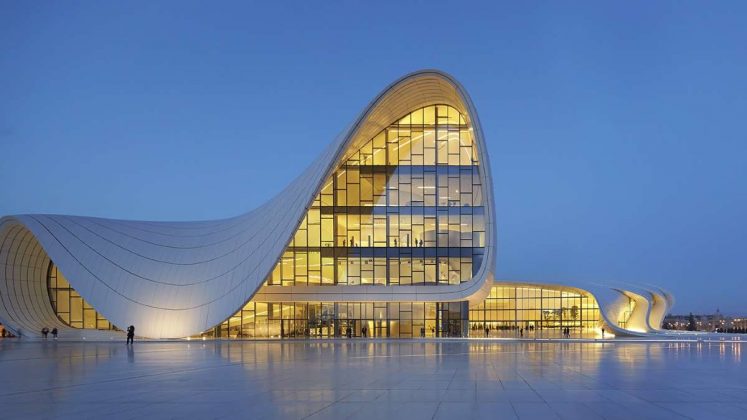

The last 10-15 years of development in computers and software have given most engineers and architects the capacity to self-resolve every kind of problem with complex structural forming in a short amount of time. This has allowed them to break the calculability paradigm. Where what was not able to be calculated, or even understood, was not able to be built. This has freed architectural firms (even small ones) from the necessity to have an extremely high level of technical knowledge. All this is exactly the opposite of what was the case until the late 2000s.

«Computational design and fabrication are at the focus of advanced pratiche and researcg in architecture. They allow for local differentiation of building components that enable buildings that were untinkable a few years earlier. »

Jan Knippers, The limits of Simulation:Towards a New Culture of Architectural Engineering.

The capacity to easily resolve that problem has caused a rush to find the most complex shape possible. Strongly related with with the 3d printing field, this has stimulated a lot of structural and material engineers to invest in research and experiment with new structures and new ways of creating them Instead of letting them continue using the large amount of already existing structural systems that they learned at university.

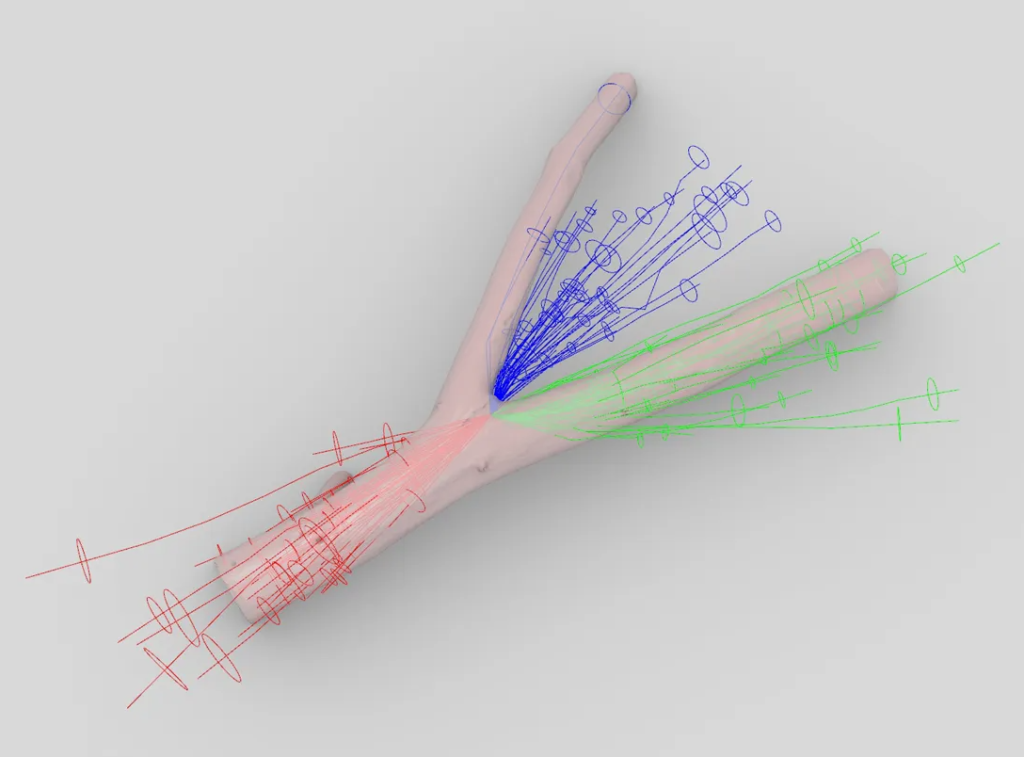

Some examples of the fascinating change that this approach can bring into the architectural field are related to the fibrous materials. The potential of which right now is still limited by the fact that we don’t have an already secure calculating approach. At the present moment, the only secure way of calculating fibrous structural material into the architectural application, is to consider them like a unidirectional layer and add their individual properties into a stiff matrix of the laminated panel.

But of course this limits the possibility to form fibre material into a shape where a single layer has a different orientation and direction.

As have been anticipated before the second part of the new structural Computational design approach is straight related to new high-performance material, nanomaterials or Nanoparticles. This is the reason that these new kinds of materials are so expensive and all the producers look always for some iconic project or contest to make their marketing investment. Even when some of these materials are more suitable for use in a spaceship than to build a house.

silhouetted within the polymer skin. Photo: RMIT University. Resource

New ways of calculating in addition to new knowledge about how to craft old materials can itself influence some shapes. That is what is happening with wooden structures. Due to the fact that we have program that are describing not only the geometry and the structural performance and limits of wood but even calculating the most efficient way of producing and fabricating the wooden elements, this material has had a renaissance in the building industry. Right now, we are even able to think a structure starting from the materials characteristics. Using generative algorithms provides us with the right result or at least a useful one, by using the specifications of the material, and specifications about load and other properties like structural limits, to input data that the algorithm needs to generate the structural system.

The change that this new way of understanding structures could produce in the architectural field looks similar to what happened between the first and second industrial revolutions in terms of new material innovation.

CONCLUSION

- COMPUTATIONAL DESIGN APPROACH IS ACCESSIBLE TO ALL.

- COMPUTATIONAL DESIGN APPROACH IS THE RIGHT INSTRUMENT FOR FINDING THE CORRECT STRUCTURAL SYSTEM FOR EACH PROJECT.

- COMPUTATIONAL DESIGN APPROACH IS FREQUENTLY RELETED TO NEW HIGH-TECH MATERIAL.

- THERE ARE ALREADY EXISTING MATERIALS THAT CAN TAKE ADVANTAGE OF THIS APROCH.

- THERE ARE INSTRUMENT THAT CAN HELP US TO FIND THE OPTIMAL SOLUTION FOR EACH CASE.

MY PERSONAL REFLECTION

Most research involving parametric design is almost always about finding the most complex shape as possible. Or using evolutionary algorithms to help find a structural system that works. Only a few results created with this process have te potential to produce a good impact to the environmental. Even when we speak about a new Bio-based or organic material we can’t say celery that is something good for the environmental.

Bio-based and organic are not the same.

«The prefix “bio” means “life” or “living organisms”. It is generally used to indicate biological or natural materials as opposed to synthetic raw materials such as crude oil or natural gas. Instead, the term bio-based refers to the type of raw material used to manufacture a product, and it does not relate to the materials produced. Which means that if a product is bio-based, it is partly or wholly made from biomass, i.e. renewable materials of plant or animal origin. Being labelled as “Bio-based” however, says nothing about how such feedstock has been produced (for example, how plants have been cultivated). Not every bio-based product is organic. It’s a fact. A product can be “bio-based” and “organic”, but it does not have to be. Bio-based simply describes the fact that a product or material is of plant or animal origin. “Organic” means that the cultivation of the plants or the keeping of the animals complies with requirements of the European organic farming standard. Bio-based is always (per definition) more environmentally friendly. It’s a myth. Bio-based products are not automatically more sustainable than fossil-based products. When it comes to greenhouse gas emissions and fossil resource consumption, bio-based materials usually perform better than fossil-based ones. Conversely, they mostly do worse in the acidification and eutrophication categories. In addition, factors such as environmental damage from oil drilling or disruption of the ecosystems in mining areas contribute to increasing the environmental impact of oil-based resources. Bio-based means a product is always biodegradable. It’s a myth. Biodegradability is often discussed for plastics, but not all bio-based plastics and products are biodegradable. Biodegradation is the naturally-occurring breakdown of materials by microorganisms such as bacteria and fungi to water and gases such as carbon dioxide (CO2) and methane (CH4) or also new biomass. There is no official definition of biodegradable, in contrast to the term compostable…………»

Resource https://cordis.europa.eu/article/id/125396-factormyth-biobased-organic-biodegradable