INTRODUCTION

The Design and Fabrication course’s main objective is to orient us towards learning and gaining experience in the use of tools and machines in relation to fabrication. Through designing, manufacturing and prototyping the models we were able to gain hands-on experience on how to fabricate and construct our projects. Valldaura Green FabLab provided us with all the tools and machinery that were necessary to learn the standard techniques of woodwork.

Our project, “Mil Ramas”, consisted of fabricating techniques that required the use of several different machines. Our mentor, Bruno Ganem, instructs us on the use of the machinery and provides us with the tools and safety gear required to begin work.

Prototype 1

1. Process: Cleaning of Wood | Tool used: Chisel

2. Process: Cutting the branches to the desired lengths | Tool used: Table Saw

3. Process: Drilling of holes | Tool used: High Impact Drilling Machine with 10mm drill bit

4. Process: Cutting Of Wooden Dowels | Tool used: Hand Saw

5. Process: Hammering the wooden dowels | Tool used: Metal Hammer

6. Process: Cutting off the extended branches | Tool used: Chainsaw

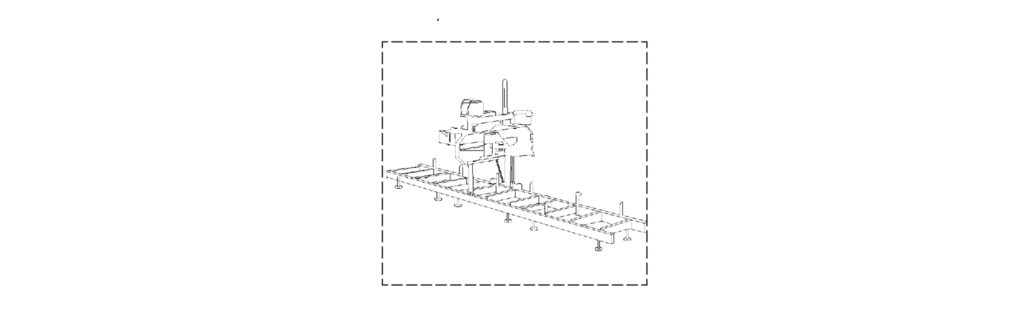

7. Process: Cutting the top portion | Tool used: Saw Mill

8. Process: Treating the branches | Tool used: Blow Torch

9. Process: Shaping the seating | Tool used: Sanding Machine

The tools used the most in our project were the high-impact drilling machine and sanding machine as these tools were what helped shape our project into the design we wanted to achieve. Our main aim was to limit the amount of metal usage to almost completely depend on wood to build our seats. Using wooden dowels to hold the branches to one another, we were able to achieve this target.

Prototype 2

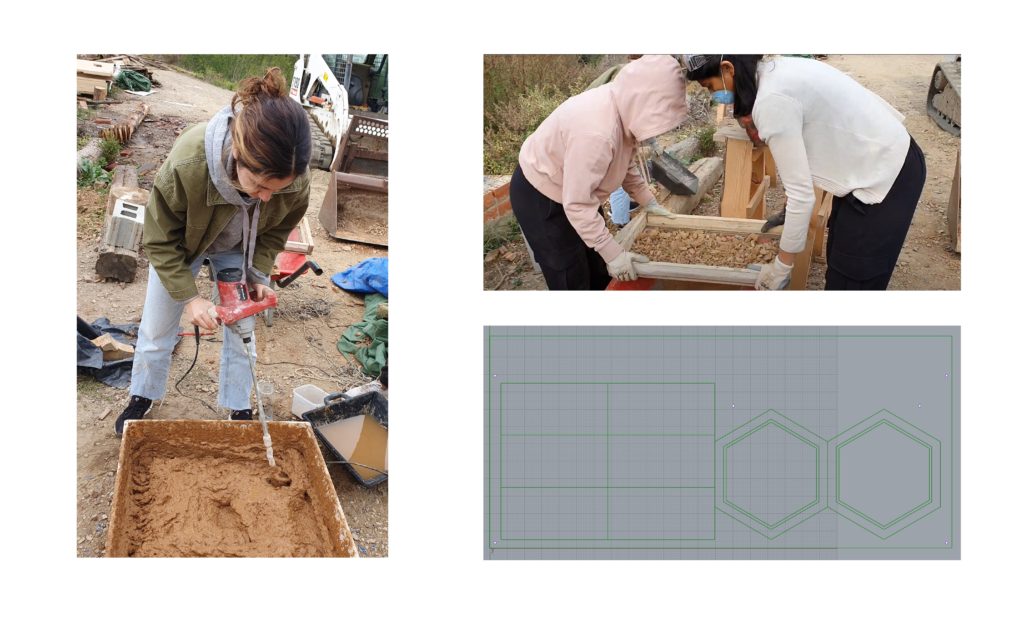

A. Process: Making of Mould and the Poured Earth Mixture | Tool used: CNC Machine, Sieve and Mixer

Although Mil Ramas was a small-scale project, the use of machinery to cover the scope of the project was not any less. The fabrication course gave us the opportunity to experiment with many more techniques such as the making of poured earth as an alternative base to our seat. Through our prototyping, we were able to use CNC, sanding and drilling machines. The learning experience was fruitful and inspiring as we not only learned from our mentor but from each other as well. The Valldaura Green FabLab is not only a space for work but also a space of enlightenment, inspiration and hard work.