Computational Fluid Dynamics for Natural Ventilated Systems primarily located within the United States

The Problem within Context:

Sears Catalogue from 1930s to 1950s United States.

The American Dream is a phrase that has taken meaning in the ownership of a home with a white picket fence. The phrase was popularized in the 1930s after WWI with the surge of young families moving to the suburbs. This created a housing boom that resulted in Sears catalog-homes, being fully designed and shipped to your door. However, what was not pre-planned within these homes was how they functioned within their environment.

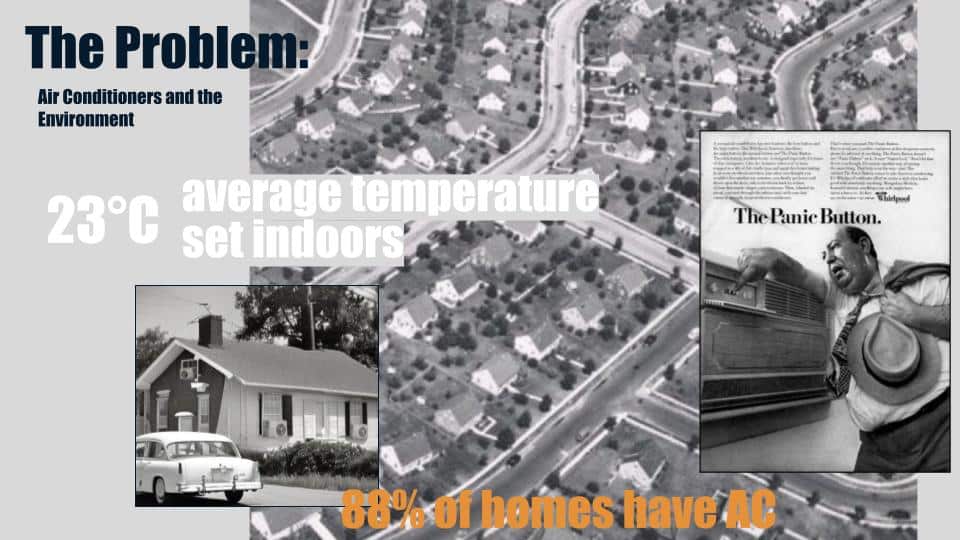

40% of all homes in the United States were built after the birth of the Air Conditioner in the 1930s, meaning homes no longer needed site specific design, but could be picked out of a catalog and function anywhere. Baseboard heating and Central AC became important and required elements of every home, with up to 88% of homes having air conditioning units, according to a survey by the Energy Information Administration in 2020, erasing the need for functionality of windows. This is a huge issue, as with rising energy costs on the consumer and the environment, homes cannot meet the needs of the inhabitants. AC is also incredibly hard on the human body, and has caused up to a “200% increase in sick building syndrome in the buildings with air-conditioning systems when compared with natural ventilation systems” according to a Review of research on air-conditioning systems and indoor air quality control for human health.

___________________________________________________________

Vernacular Studies

People have been living on earth for many years and have methods of controlling interior climates without the need for electricity. Instead this came through design, something that now is only being used in the US for looks.

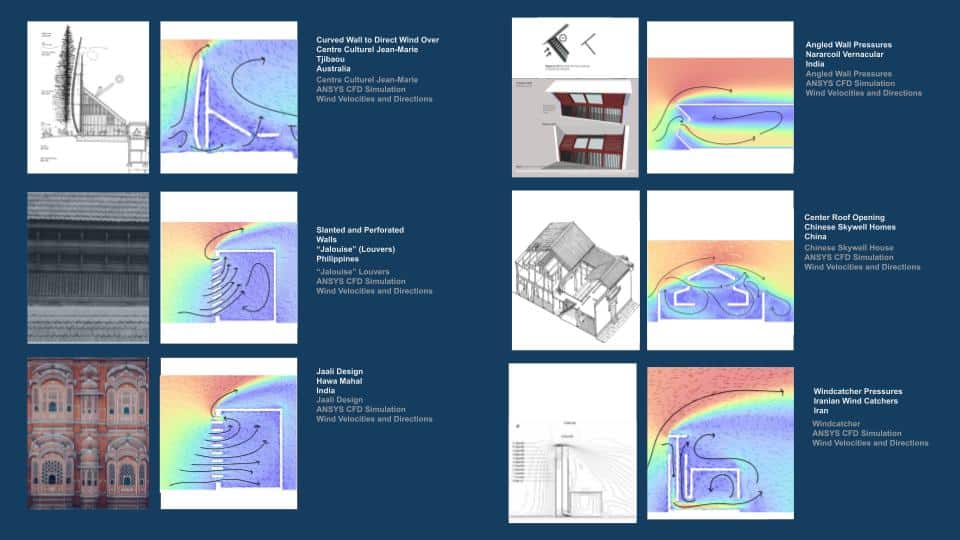

ANSYS CFD Analysis of Vernacular Design.

Homes used to be more than a trend. They functioned alongside inhabitants as mechanisms to enhance the environment. Across the globe in hot and humid climates, examples of manipulation of windflow have cooled buildings in many different ways, including material use, such as stones that help cool air, operable designs such as louvers or shutters, and the tapping of wind to bring more airflow into the home. Even here in Barcelona, cross-ventilation was designed into apartment buildings with the chamfered blocks.

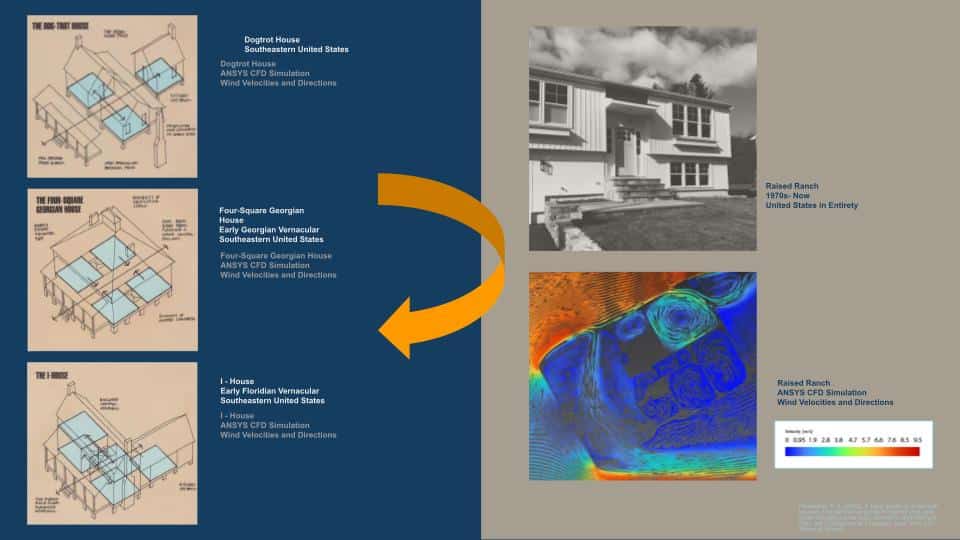

In fact, even within the early United States, homes were also built that functioned in their environment. The Dogtrot, Georgian four-square and early Floridian House all used the wind to move humidity and warm air through, and out, of the home. In comparison to homes that are found today, they are vastly more prepared for the climate they are in, as they were built in reaction to it.

ANSYS CFD Analysis of Raised Ranch, typical American Home. Looking at windflow patterns in existing homes.

___________________________________________________________

Research Question:

Which begs the question;

Through the examination of vernacular architecture within the United States and other parts of the world through the lense of CFD Wind Analysis, can one utilize airflow to cool a modern home in the Southeastern United States?

Can we create a new vernacular for the United States which is better suited to its place in history and climate.

___________________________________________________________

Site leading to Specific Design:

Airport Runway Directions as indicators of prevailing wind patterns across the United States.

The United States hosts a multitude of Climatic Zones however, the South of the United States hosts an interesting mix of fluctuating wind patterns and an abundance of warm and humid days.

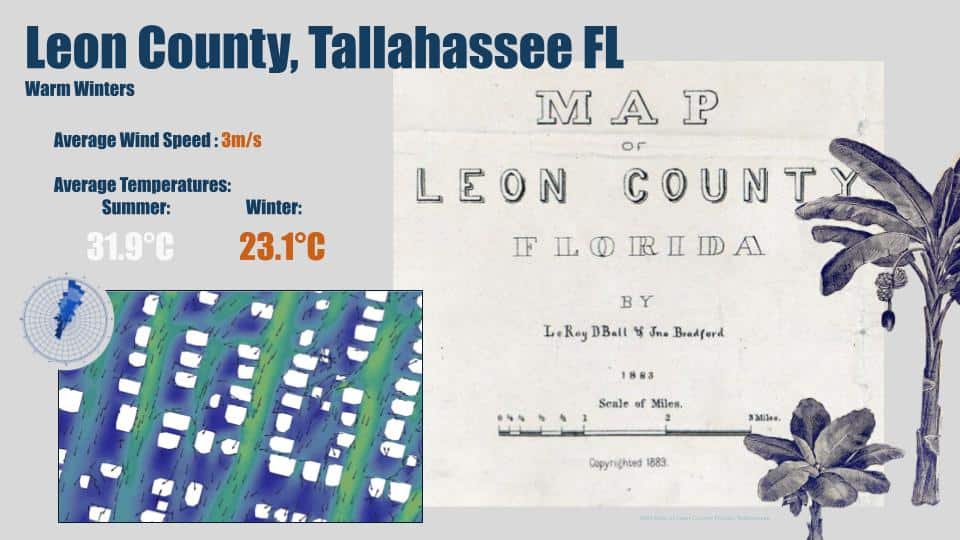

Within Leon County in Florida, the average temperature reaches 23c within the warm winter months, the average temperature that people set their AC to. At this time this is being met with AC all year round. However, the average wind speed of 3m/s, would offer cooling without cost, but is not being utilized.

___________________________________________________________

Design

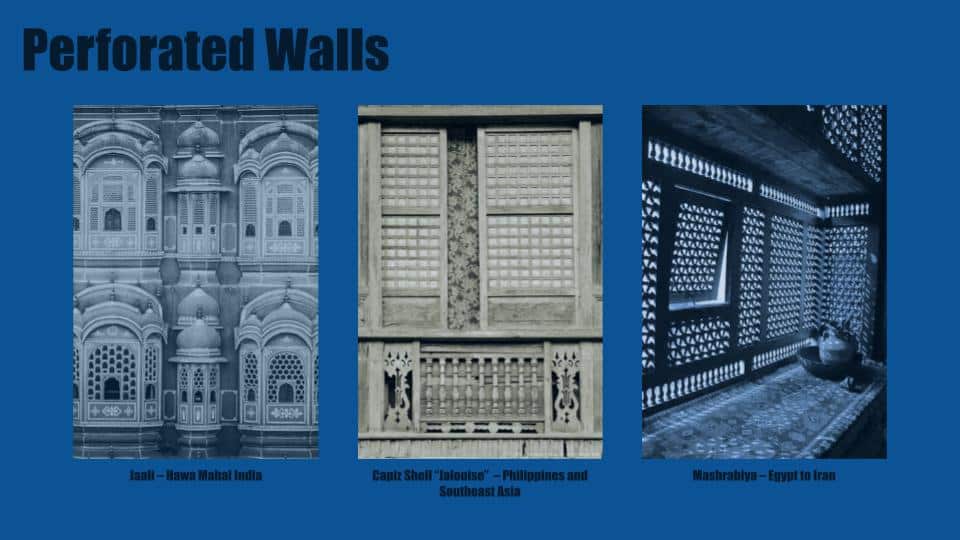

In other areas of the world with similar warm and humid climates this problem is tackled with an increase in perforated surfaces, angles, and channeling, which create pressure zones that pull air inside. This is combined with a wooden material choice to ensure constant fast moving air which acts as a natural Fan.

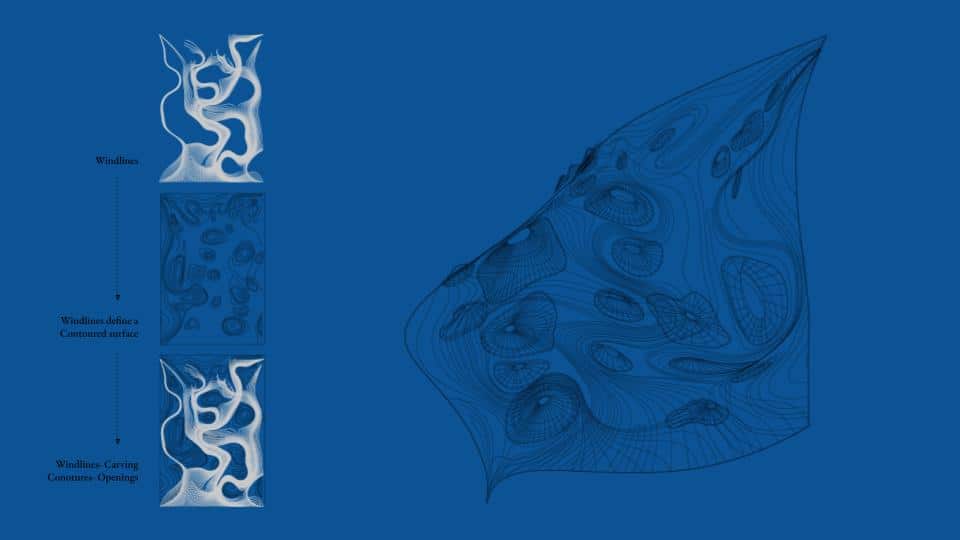

The design comes from an exploration of wind moved through different pressures along with texturing for plant growth which aids in cooling the wind slightly before it enters the home.

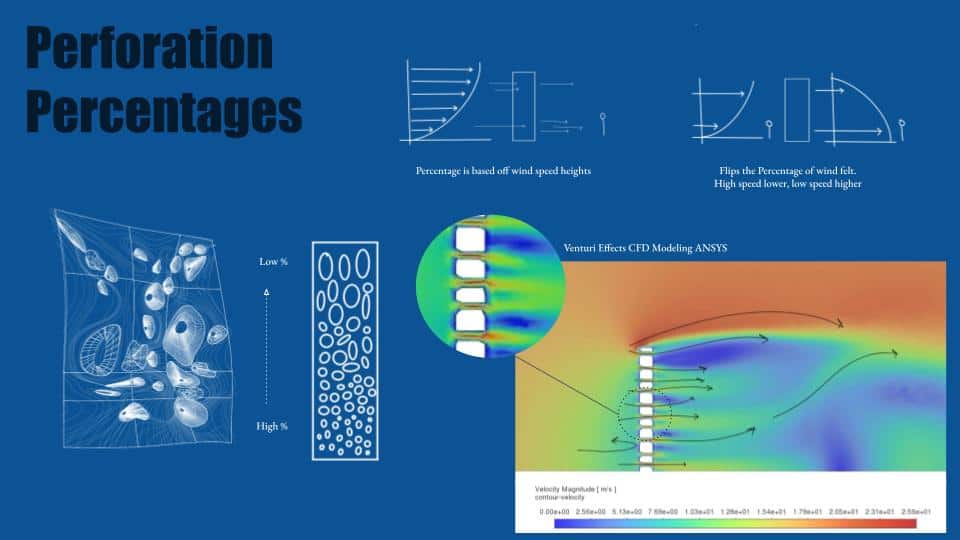

These pressure zones are created in three ways. The first and most notable is the percentage and size of the perforations, which use the Venturi Effect to increase the velocity of the air entering a space. Since the wind is faster at higher altitudes due to less obstacles, more perforations appear on the bottom, speeding up the slower air found there. At the top, where the air is already moving a bit faster, larger openings keep this air from increasing in speed. This also matches with the human body as faster air cools the body, while the face receives a gentler breeze. Prioritizing an air current where humans and furniture are placed.

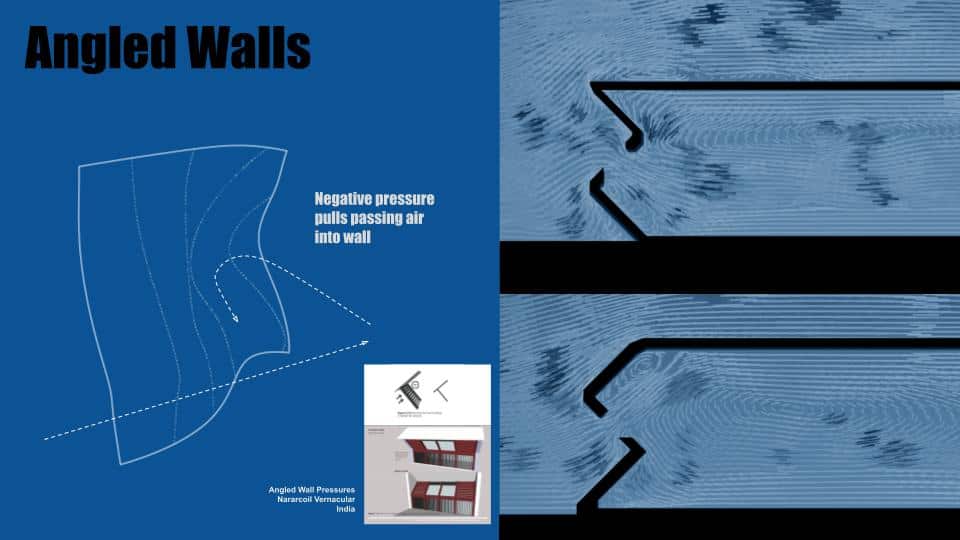

Angles are utilized to create a difference in pressure. This pulls air into the space as airflow travels from high to low pressure. This translated into an undulating facade system which could host many pressure “pockets” where air is pulled inside.

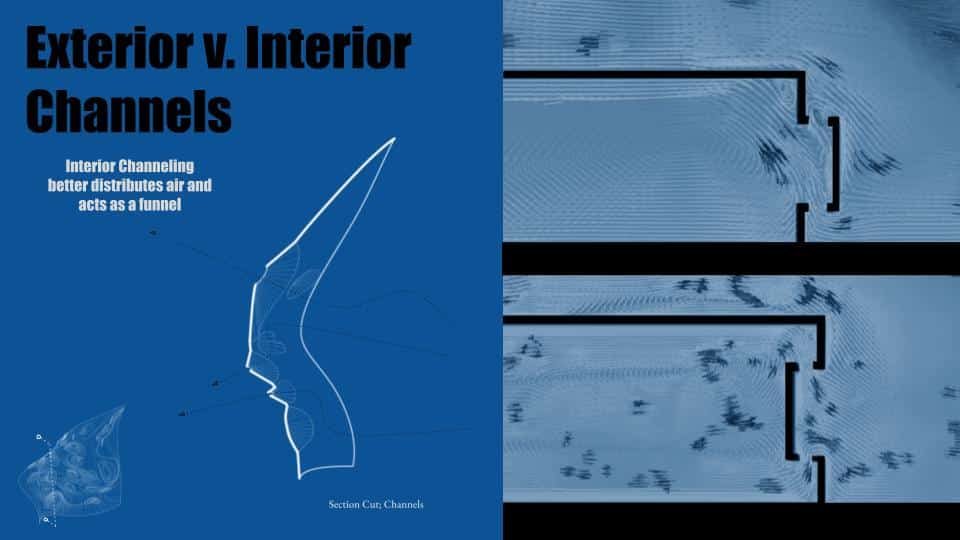

An inward facing channeling system was also used as air is funneled to the interior. Since wind likes to move in a straight line, allowing for the fastest motion from one place to another, it is more beneficial to catch air than it is to redirect via “pushing” it outwards or to the side.

This system then works similarly to how one would cool a cup of coffee. By blowing away the top layer of heat, it allows for faster cooling through the faster release of the trapped heat, in our case, sweat.

___________________________________________________________

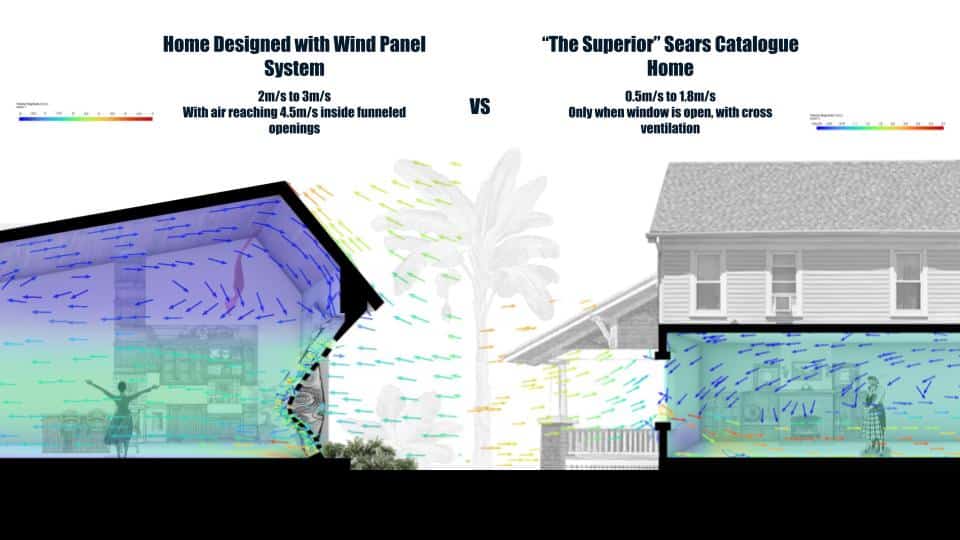

Since maximum airflow velocity is desired, these methods are crucial elements in the design of the facade window system of a building and resulted in the design of a wind-conscious facade system. Through the application of these undulating perforations, a significant increase in airflow can be felt.

This against the model of an existing home, the ventilation inside rises from an average of 0.5-1.8m/s to 2-3m/s, successfully doubling the ventilation rates of that of a standard home, such as one built in the time of the Sears Catalogue.

ANSYS Fluent CFD Wind Modeling overlayed on render of home, showing increased ventilation from facade system.

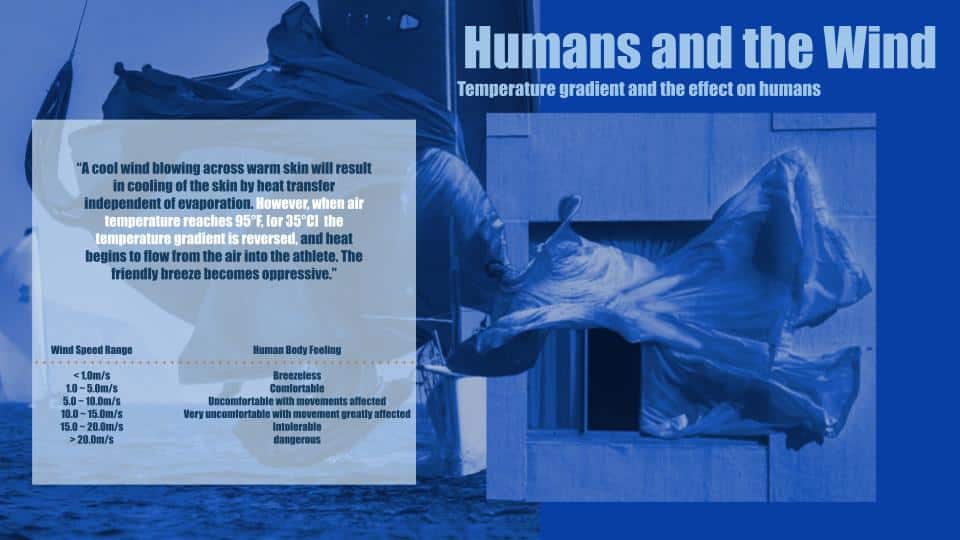

Therefore, With an airflow velocity of upwards of 2-3m/s, if assuming that wind velocity and cooling have a more linear correlation, the perceived cooling felt by the inhabitant also drops 1 degrees Celsius or about 2 Degrees F. This is due to the increased evaporation of sweat due to the increase in windflow.

It’s an important distinction that it is not necessarily the temperature of the air that realizes this drop in temperature, but the sensors within our skin. Therefore, while the increase in airflow may not physically cool the space, due to the higher evaporation rates of sweat, we feel cooler and therefore more comfortable. It is the same ideology used in the winter where wind-chill is used to predict how the speeds of wind affect the perception of coldness on the human body, and how the feel-like temperature in the summer is much higher than the air temperature due to the sun.

To combat this even further, the undulations and curves allow for shading of the facade and a texture has been applied to the surface which can allow for plant growth. The small “pockets” of air that form due to low pressure also slow the air down slightly before it speeds up again when it enters the home through the channels. Here the air briefly lingers in the shaded regions and passes over the plant growth giving it a chance to cool slightly before entering the home, suggesting an even cooler perception once inside.

Rendered Application into Home or as a screening device to combat bugs and weather from entering the home. Background render Image from Pintrest; SelfBuild Ireland.

___________________________________________________________

Fabrication

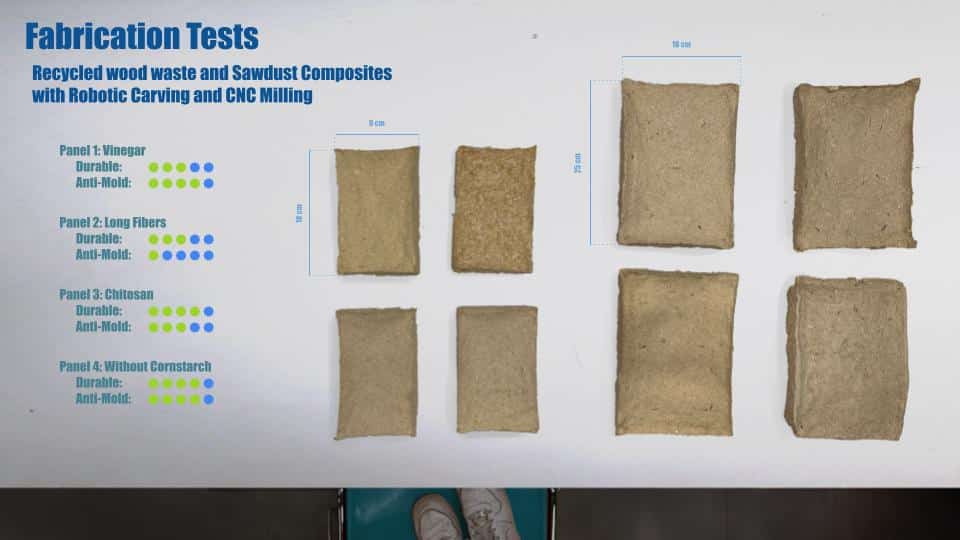

The texture of the panel, which holds spaces for plant growth, called for specific fabrication processes and material studies.

A bio-composite panel made with recycled sawdust was chosen as it not only allows a moldable body for texturing and a host for plant life, but also nods at the wooden vernacular that exists in the United States. Wood also is able to absorb moisture, which later can be evaporated and carried inside by the wind, improving interior conditions.

A robotic fabrication technique was adapted to carve the panels creating grooves and channels that will inform spaces for small plants such as mosses to grow. This Texturing also resembles the grooves and wrinkles of an elephant’s skin, which creates small shadows that shade the elephant even when in full sunlight. This micro-shadowing as well as the increase in surface area for plant growth work in tandem to cool air slightly before being sped up to enter the home.

This technique was tested with a variety of panels, testing if the state of drying influenced the carving texture. It was found to work best when the material was completely wet, reducing the risk of collision, ripping, or damage to the pieces. This, however, also reduced the accuracy of the carves, increasing the level of complexity to the piece.

It was decided that a more precise measure of carving was desired and so this technique was then mimicked with the CNC Milling machines, since more accurate depths of grooves could be achieved. This translated itself to engravings that could follow more complex lines and contours, while still creating micro-shadows and giving small grooves for plant growth.

Photographs of CNC Milling “carving” process.

Fabrication Process, from creation of material to casting and drying to engraving.

Plant applications lead to a retainment of moisture and water on the panels to allow for growth. The grooves double as channels that move the water off the panel, restricting the pooling of water that could contribute to the decomposition of the panels. A waterproofing coating of Tung Oil which supports the shedding of excess water on the surface acts as a natural polyurethane without harmful chemicals and microplastics that could be carried inside from the windflow.

Ensuring that the interior space remains healthy as well as cool.

___________________________________________________________

Final Photographs of Material Prototype.

___________________________________________________________