Introduction

Welcome to an exploration of Hyperbuilding B’s structural innovations, brought to life by our dedicated structural team—Erva, Renuka, and Ernesto. Our journey was guided by Japanese design philosophies, advanced structural strategies, and meticulous collaboration with the design teams. This blog delves into our approach, workflow, and key performance metrics that shaped the Hyperbuilding B’s resilient and efficient framework.

Understanding the Concept

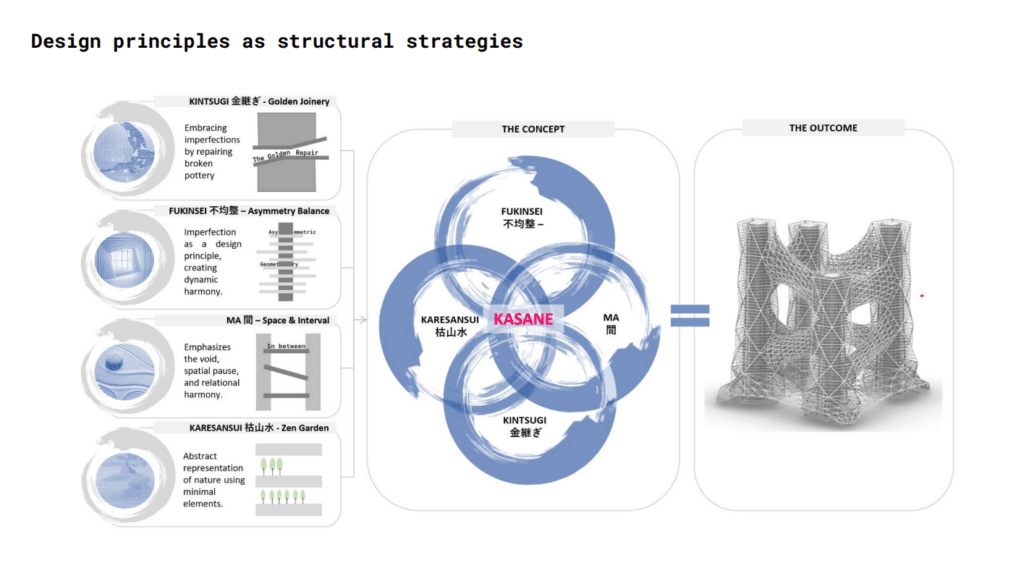

Our structural approach is deeply inspired by Japanese principles such as Kintsugi (embracing imperfections), Fukinsei (asymmetry), Ma (spatial intervals), and Karesansui (minimalist stone gardens). These ideas were not just aesthetic choices but influenced our structural decisions to ensure sunlight access, ventilation, flexibility, and seismic resilience.

Iterative Design and Development

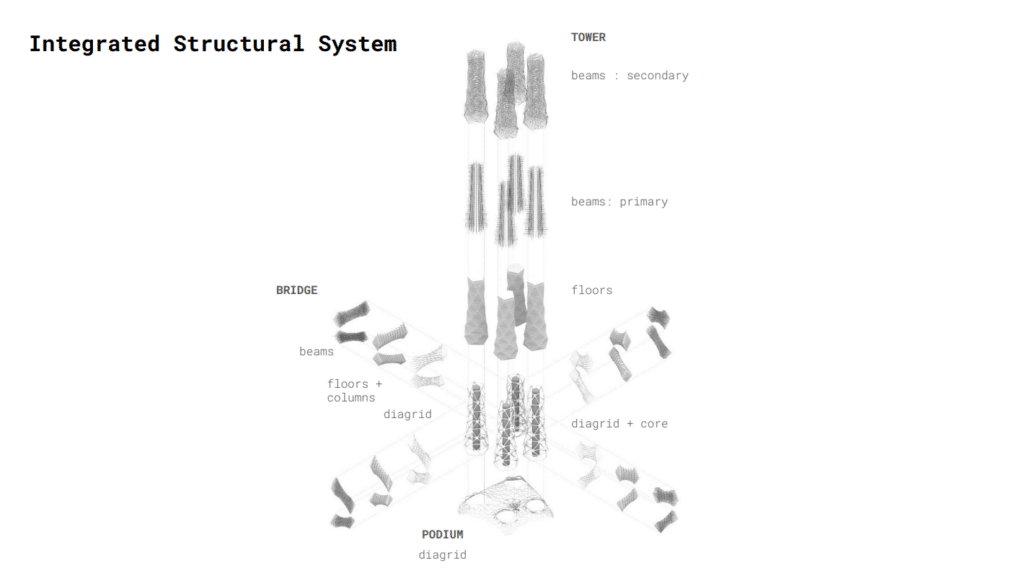

The development of the Hyperbuilding B involved multiple iterations to refine the structural elements. We explored different core placements, diagrid patterns, and load distributions to optimize stability and efficiency. Each iteration provided valuable insights into how the towers, bridges, and podium interact structurally.

The design process of Hyperbuilding B’s structural system stemmed from a set of team design requirements, including:

- Maximizing sunlight and airflow

- Ensuring operability and functionality

- Creating internal layout flexibility

- Developing a site-responsive structure

- Making it cohesive for multipurpose use

To address these needs, we tackled structural challenges such as high lateral loads, wind-induced displacement, and seismic resilience. Our design approach drew inspiration from natural forms and engineering efficiency, which led to the Core & Outrigger Structural System.

This structurally efficient system ensures high lateral stability while allowing architectural flexibility. The combination of a central core and strategically placed outrigger elements distributes loads effectively, optimizing both safety and spatial adaptability.

Unifying Structural Design Through Japanese Concepts

In shaping Hyperbuilding B, we embraced Japanese design philosophies to guide our structural approach. Principles such as Kintsugi (embracing imperfections), Fukinsei (asymmetry), Ma (spatial intervals), and Karesansui (minimalist stone gardens) were not just aesthetic inspirations but fundamental to our structural strategy.

Our design journey began with key requirements from the design team, including access to sunlight and airflow, functional adaptability, and spatial flexibility. These aspirations, however, introduced structural challenges such as wind loads, seismic resistance, and lateral stability—each demanding innovative solutions.

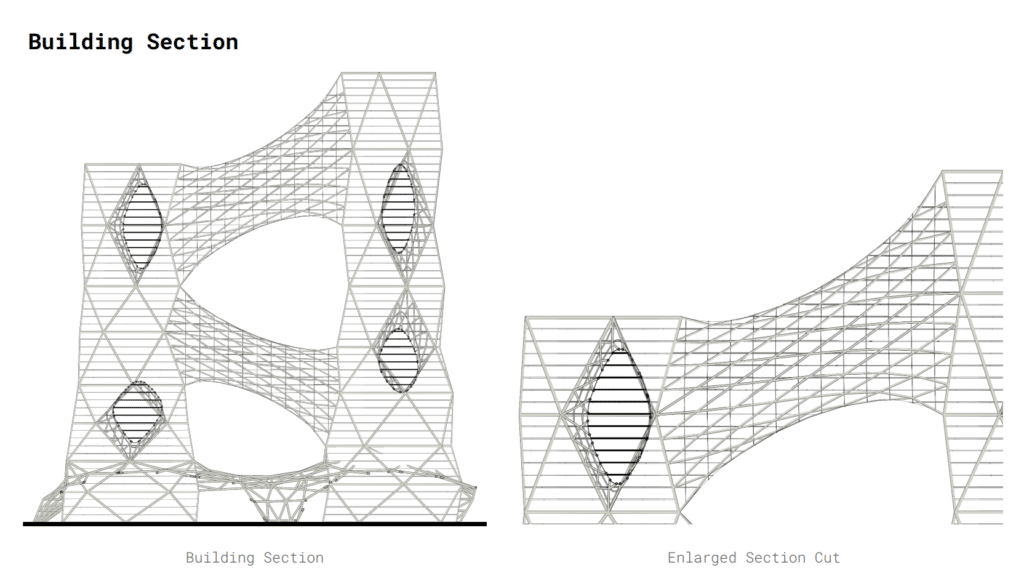

Through extensive explorations and iterations, we arrived at a comprehensive structural system that integrates a podium, towers, and bridges. Each component was carefully allocated to different design teams, and our structural framework was developed to unify these elements into a cohesive and resilient whole.

STRUCTURAL SYSTEM

The towers use a combination of diagrids and core structures, allowing for higher load distribution efficiency and providing open floor plans. The interplay of horizontal, vertical, and diagonal elements creates a strong yet flexible framework capable of handling wind and seismic forces.

Bridge Structures

The bridges presented unique challenges as load transfer was not direct to the ground. We tackled this by:

- Placing rings of columns at strategic intersections

- Using primary beams along perimeters to distribute loads

- Incorporating secondary beams and diagrids to complete the structural integrity

These sky bridges do more than connect structures—they redistribute weight, improve aerodynamics, and enhance accessibility.

KPIs

Wind Load Reduction Strategies

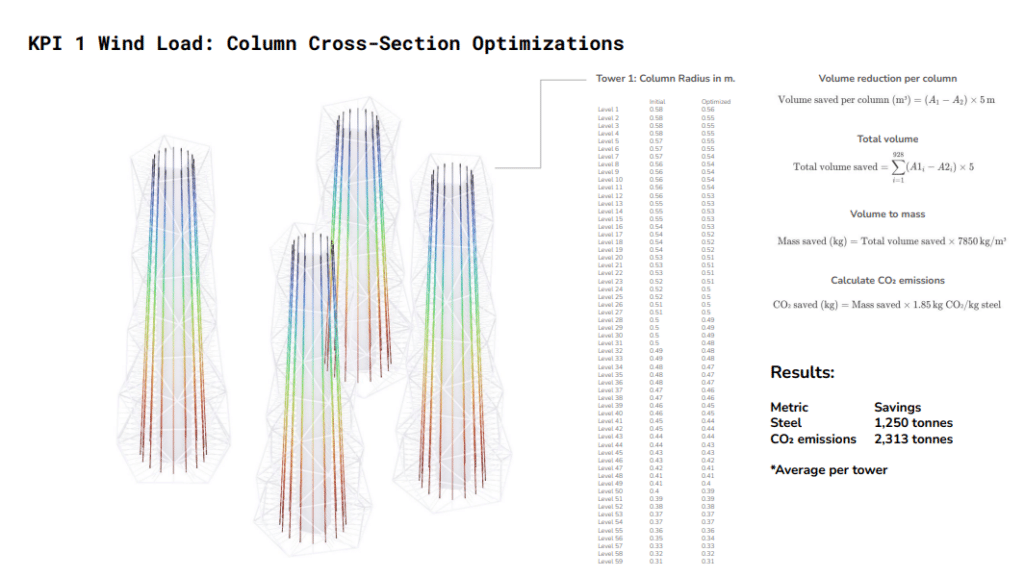

Wind loads were a key factor in our optimization. We tested different geometries to reduce wind resistance through tapering and roundness.

- Bridges: Achieved an average 26% reduction in wind loads

- Towers: Attained a 16.5% wind load reduction

By applying this optimization, we enhanced material efficiency, reducing 1,250 tonnes of steel per tower and lowering CO₂ emissions by 2,300 tonnes per tower.

KPI 1 – Wind Load Optimization

With a defined structural system in place, we established key performance indicators (KPIs) to evaluate its efficiency. Our first KPI focused on wind load reduction for both towers and bridges.

We started by testing rough geometric shapes with no tapering or roundness, measuring their baseline wind load performance. Then, we applied profile tapering and roundness, optimizing the structures to achieve significant load reductions.

- Bridges: Achieved an average wind load reduction of 26%, improving aerodynamics and stability.

- Towers: Optimized for a 16.5% wind load reduction, leading to enhanced structural efficiency.

The impact of this wind load reduction extended beyond performance improvements. By optimizing the towers, we achieved:

- 1,250 tonnes of steel saved per tower

- 2,300 tonnes of CO₂ emissions reduced per tower

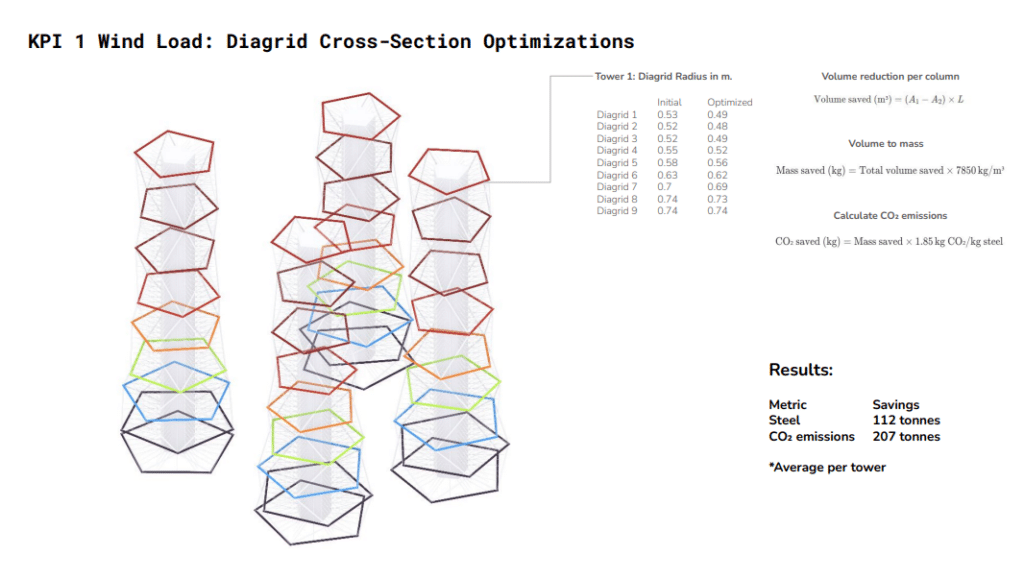

Additionally, we applied this optimization strategy to our diagrid system. Due to their distinct load behaviors, we analyzed the horizontal and diagonal elements separately, ensuring accurate calculations and material efficiency.

Diagrid System: Horizontal & Diagonal Elements

The diagrid structural system, which serves as an exoskeletal framework for the towers, required a more nuanced optimization approach. Since horizontal and diagonal elements function differently in load distribution, we divided the diagrid analysis into two key areas:

- Horizontal elements – optimized to improve structural stiffness and distribute wind forces more evenly across the building envelope

- Diagonal elements – adjusted for better load transfer and minimized material use without compromising stability

This meticulous refinement of the diagrid framework allowed us to further reduce unnecessary structural mass while maintaining high performance, ultimately contributing to the overall efficiency of the hyperbuilding.

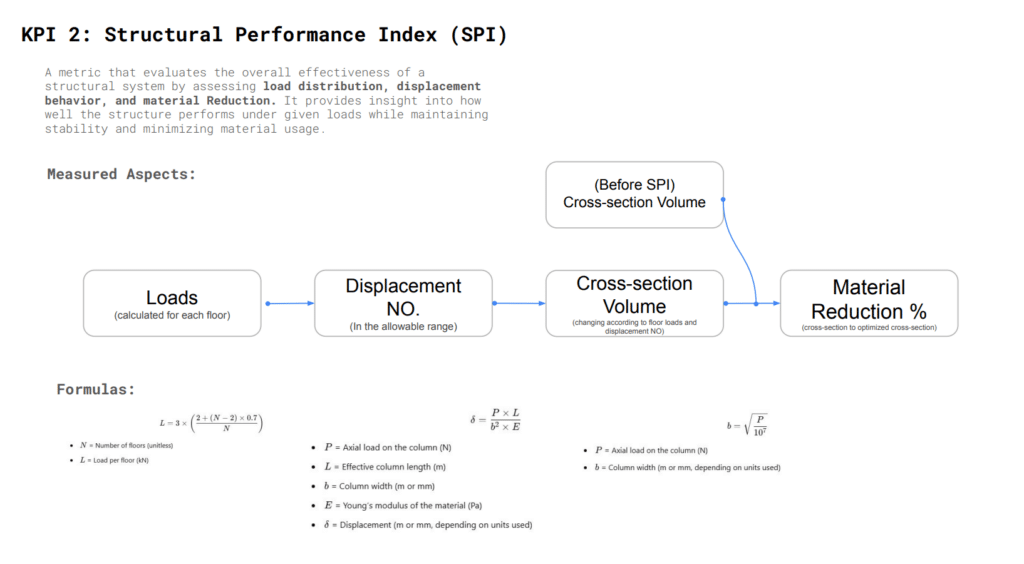

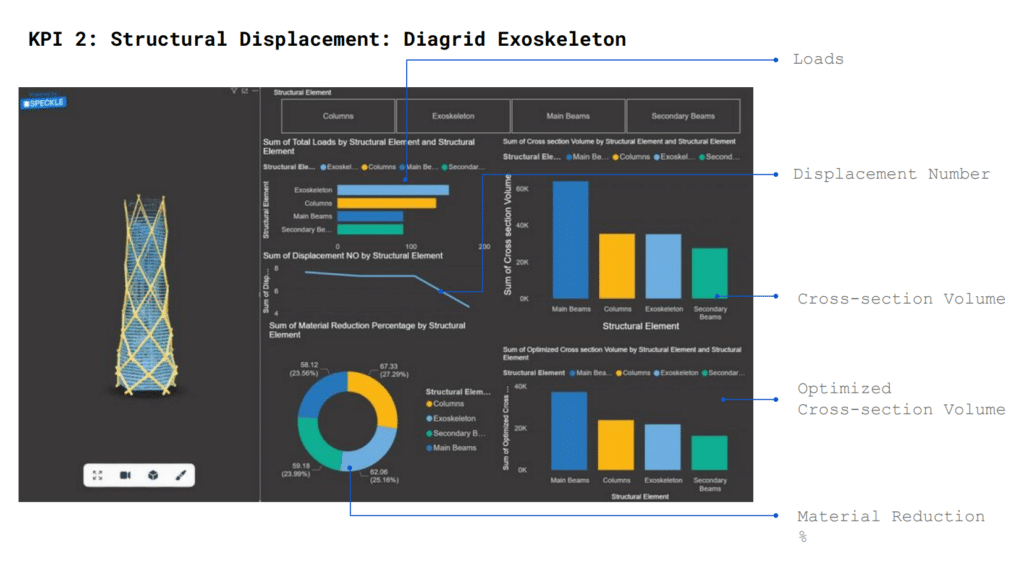

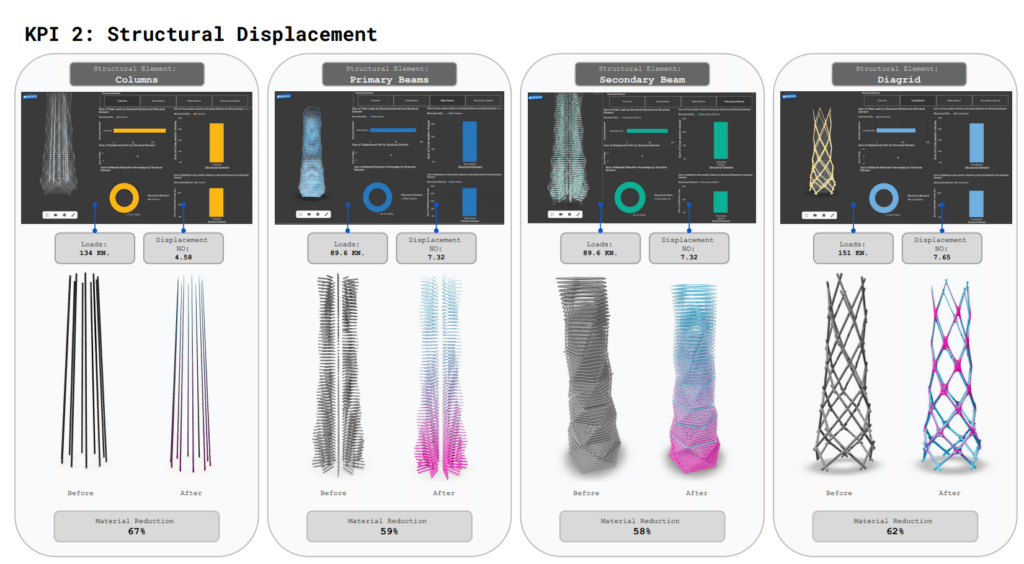

KPI 2: Displacement & Material Reduction

STRUCTURAL DOCUMENTATION

RENDERS