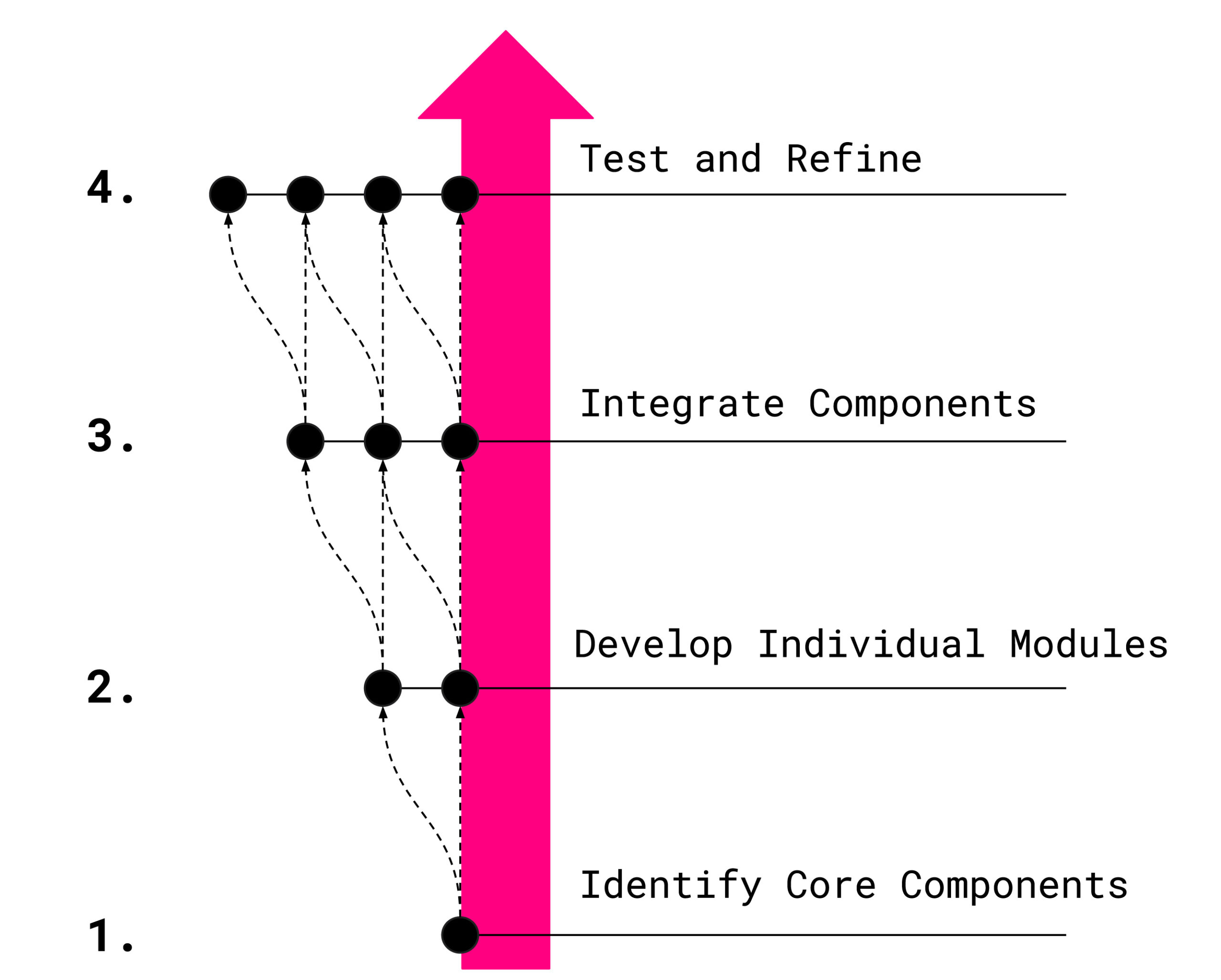

Strategy // Bottom-up Industrial High-rise

4. Adaptability to Change

evolving needs or technological advancements, and allows for easy upgrading or replacement of capsules

3. Prefabrication & Mass Production

Prefabrication and standardization.

2. Central Core Structure

The capsules are connected to a central core the building can grow or contract in response to societal changes

1. Modular Design

concept of replaceable and adaptable modular capsules

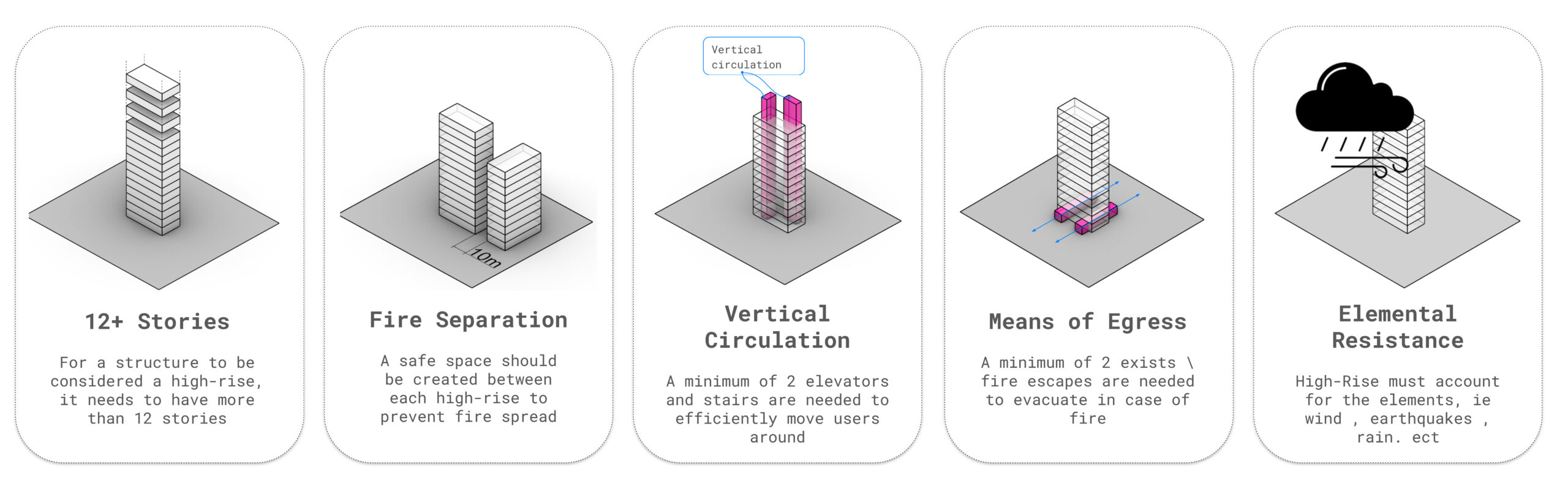

Typology:

A high-rise buildings are tall structures with 12 or more stories. They are often found in urban areas where land is limited, thus more spaces are provided vertically. High-rise structures require specific characteristics and units to support their height, function properly, and ensure safety.

Characteristics:

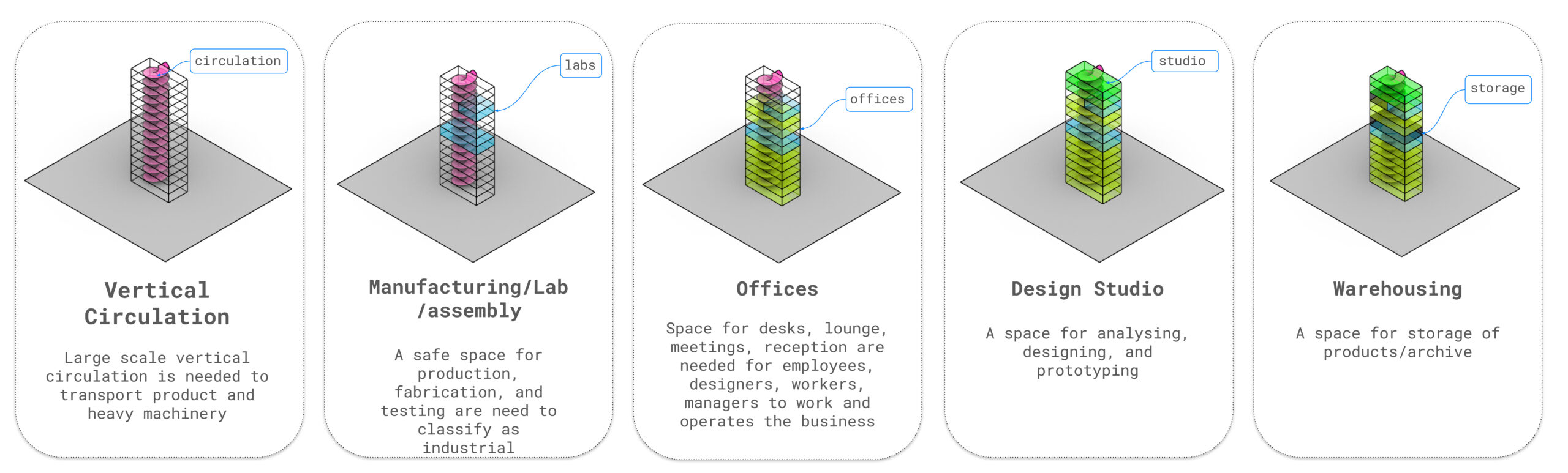

Use Case:

An industrial space operates in manufacturing, production, fabrication, and assembly. While they typically include warehousing, industrial spaces don’t always have to be in warehouse property. Industrial spaces are occasionally where the business/studio operates, so it often has a combination of both office space and manufacturing space.

Key Components:

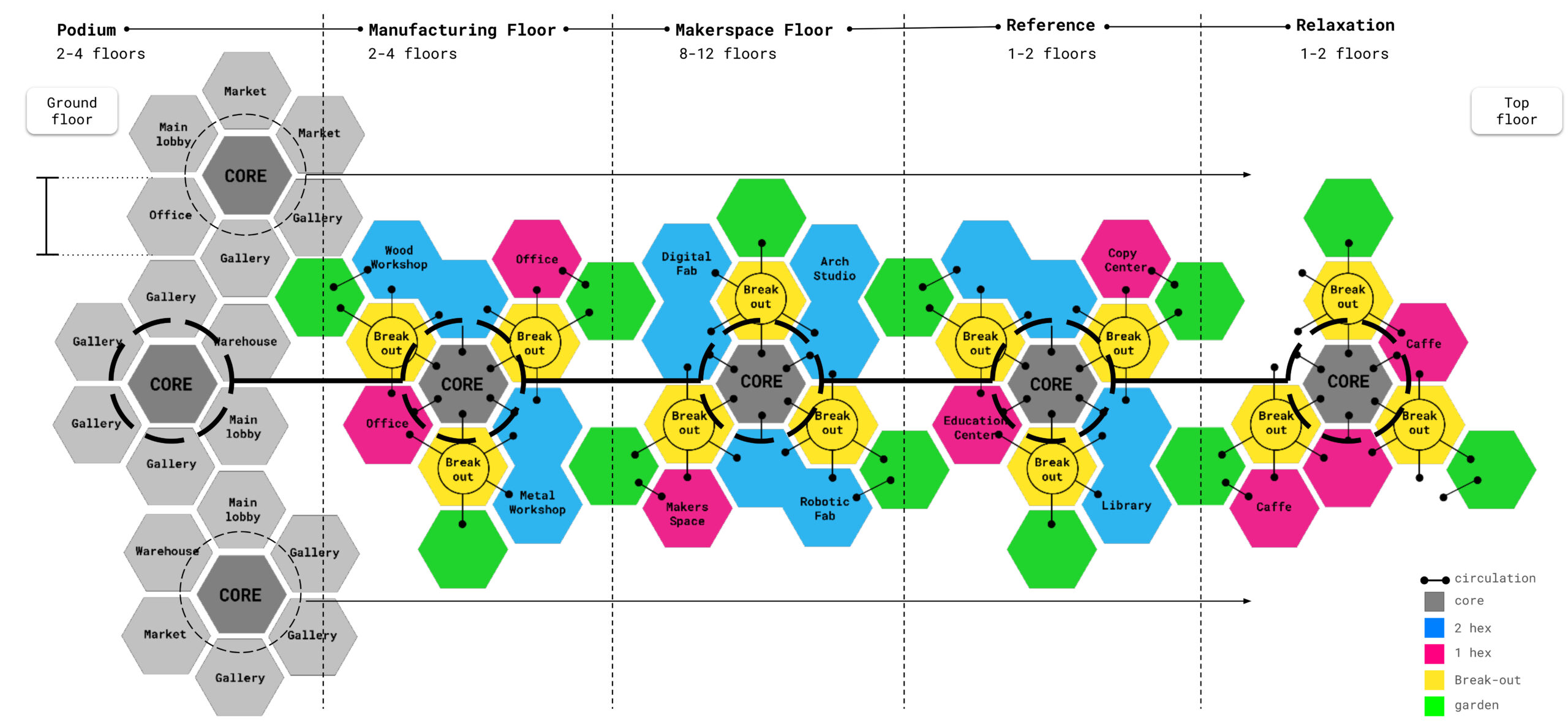

Spatial // Topological Map

The spatial characteristics of the project begin with a ground-floor podium comprising 2-4 levels. Above this, the building includes:

- Manufacturing floors: 2-4 levels

- Makerspace: 8-12 levels

- Reference spaces: 1-2 levels

- Relaxation areas: 1-2 levels

Each floor is organized around a central core, which is connected to a breakout area and surrounded by other functional rooms. Each room is accessible either through the core or the breakout area. Additionally, the building features a garden that provides access to the units and the breakout area, creating a seamless integration between functional and recreational spaces.

Challenges

Common Challenges

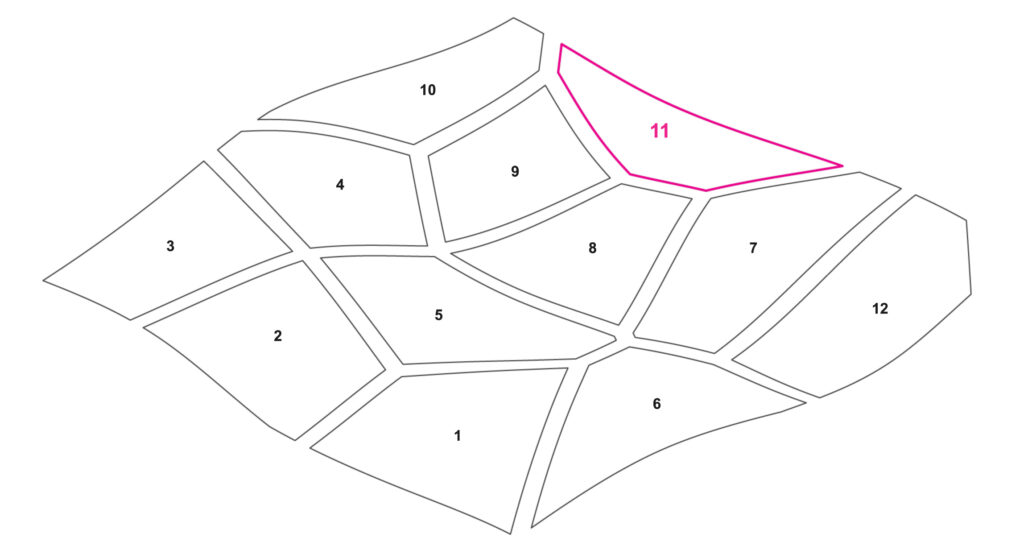

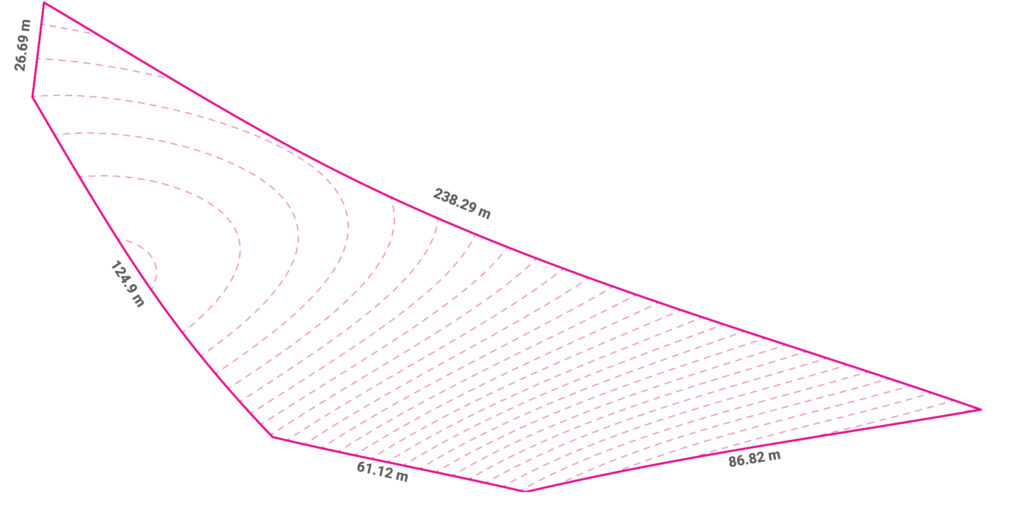

Input Plot \\ Plot 11

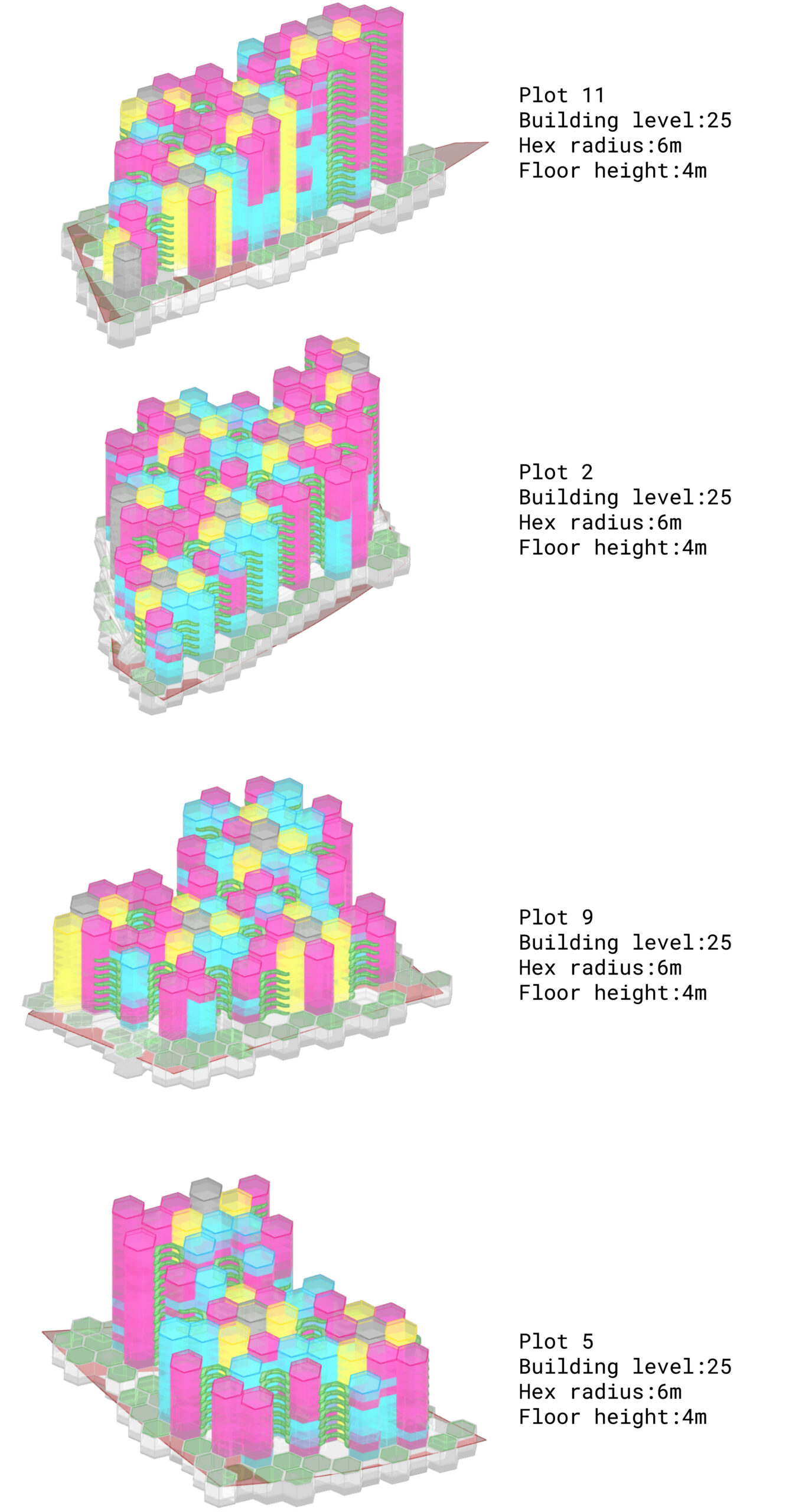

Common Model Plots

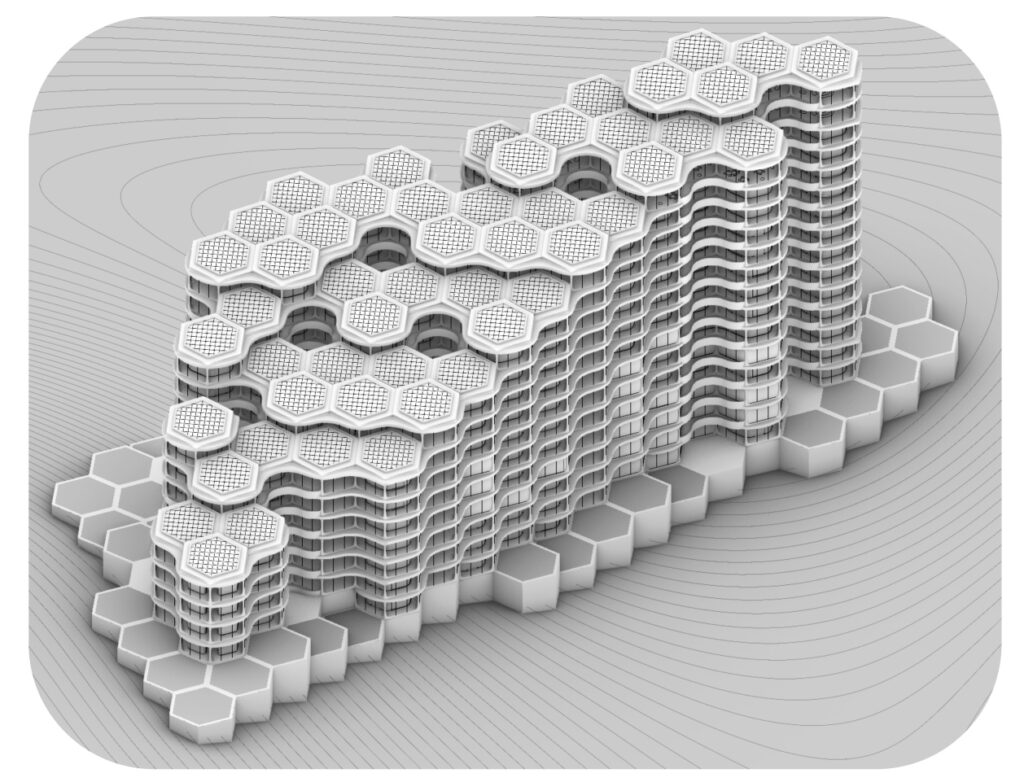

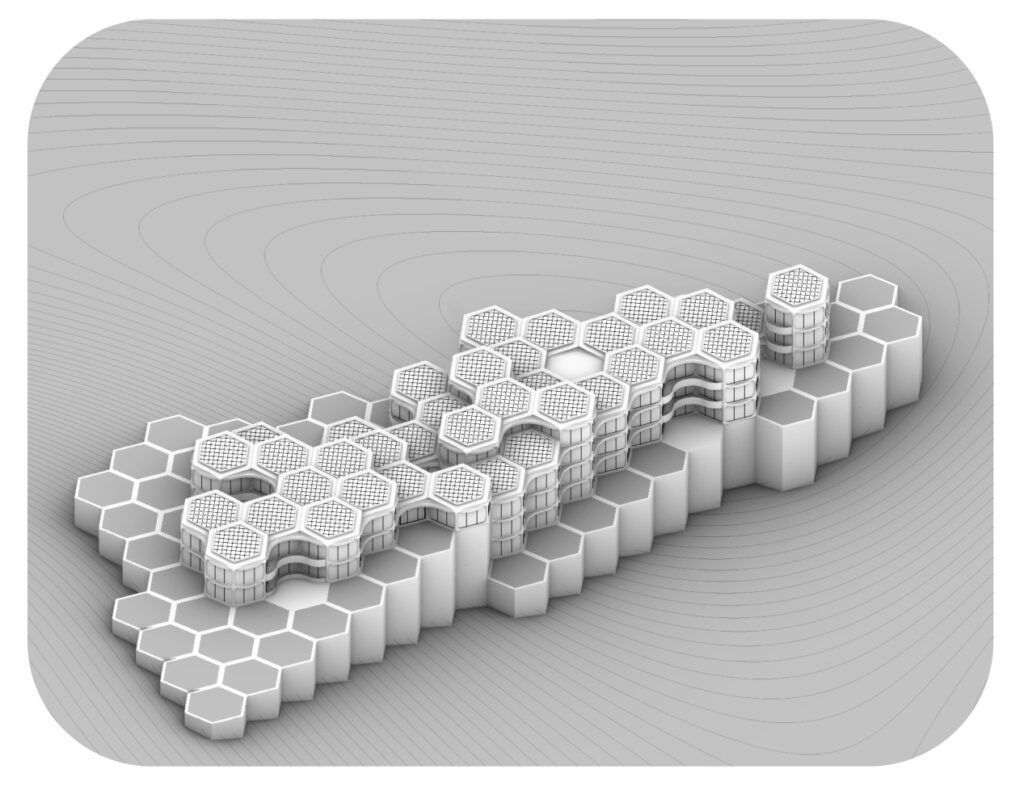

(NW view)

PLOT 11

(NW view)

12041.39 sqm

User Defined Inputs \\ Input Topography

User Defined Inputs \\ Target Function

Target function is determined by modules parts catalog. Each module function type is assigned a value setting it to be a Must function ( value number of 1 ), Primary function ( value number of 0.8 ) or Secondary function ( value number of 0.2 ) . that is fed to Aggregation parts catalog to distribute functions during aggregation

Group Challenges

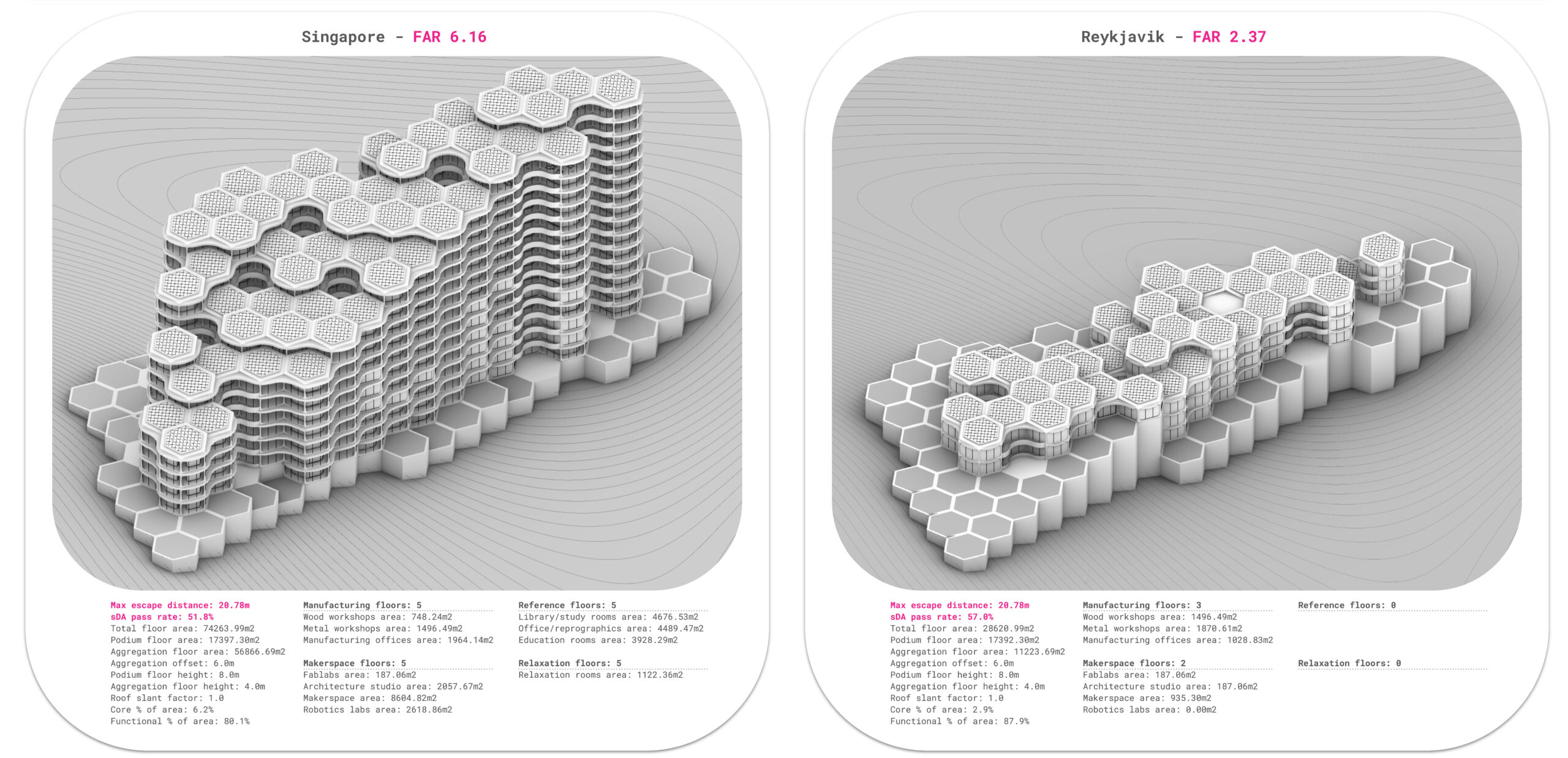

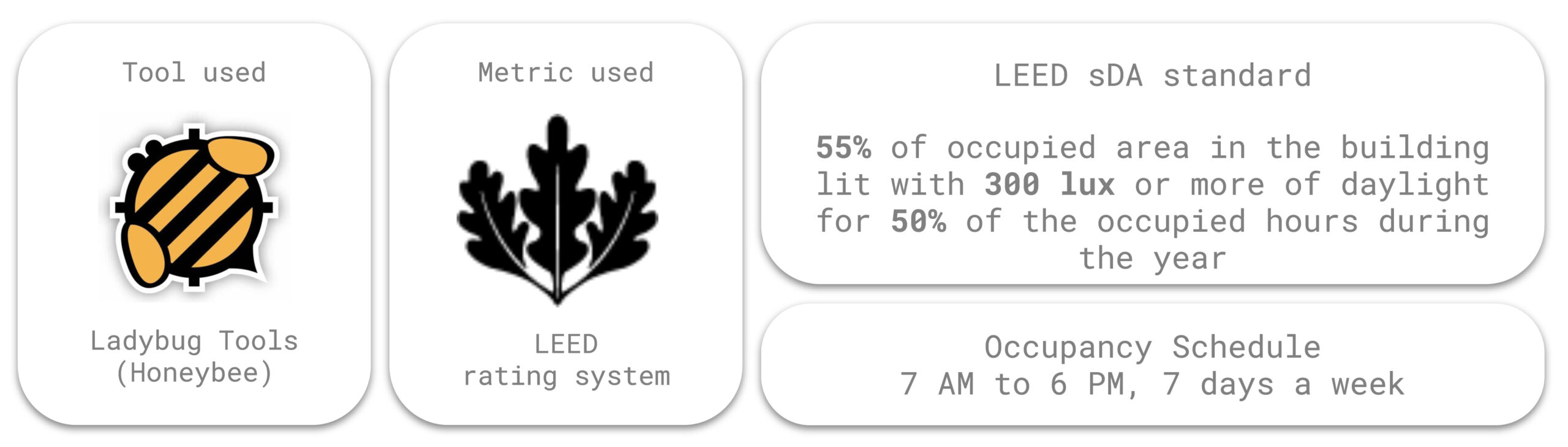

LEED Compliance \\ Spatial Daylight Autonomy (sDA)

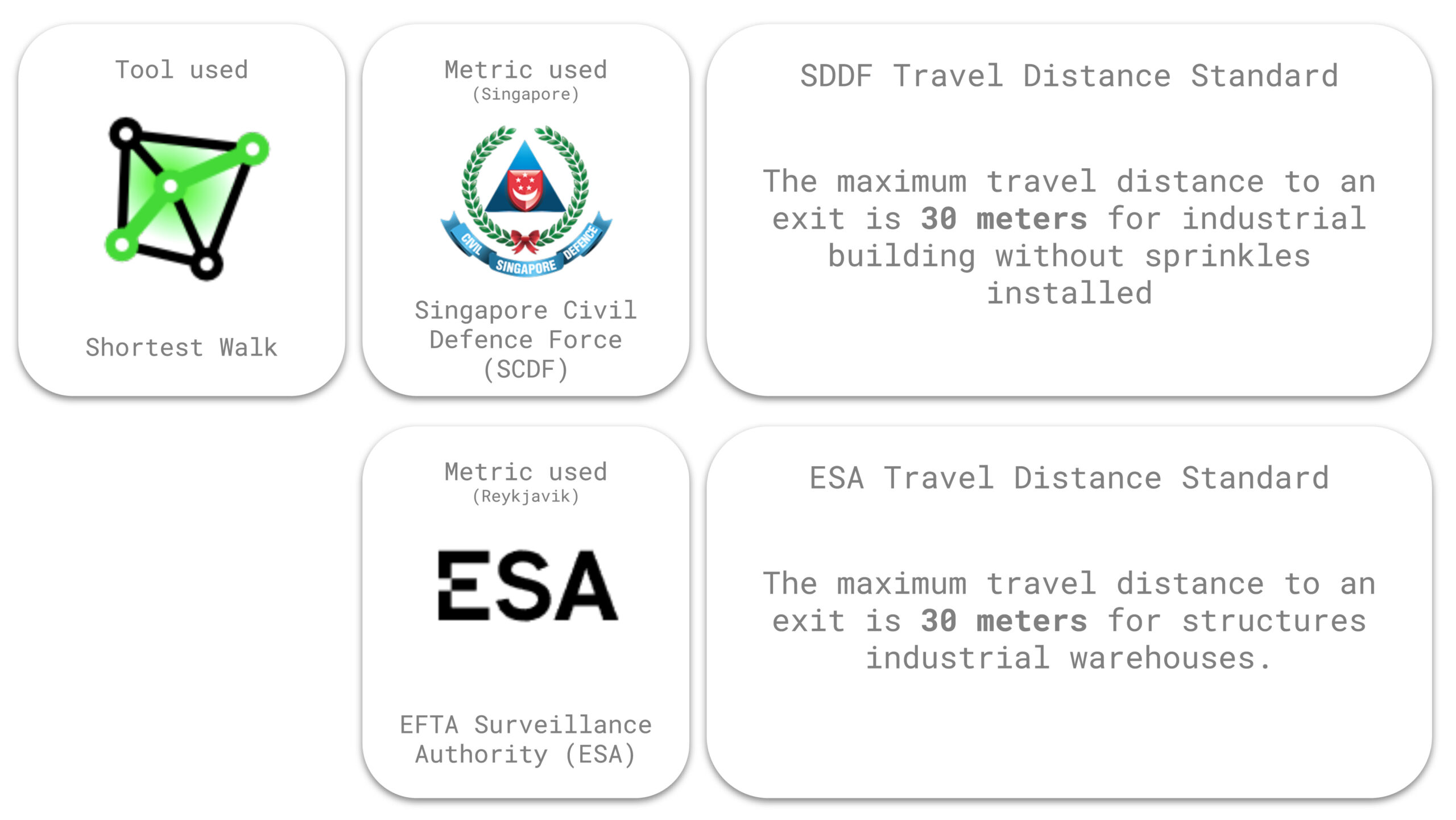

Fire Safety Compliance \\ Travel Distance to Exist

Modules

The modular design is based on aggregating single hexagons with a 6m radius. Functions are distributed across multiple hexagons, with each unit featuring a unique plan and spatial design. The focus is on the single hexagon (50 sqm), highlighted in pink, which accommodates smaller functions. Larger facilities, such as workshops and fabrication spaces requiring more room, are facilitated by combining two hexagons to create expanded spaces

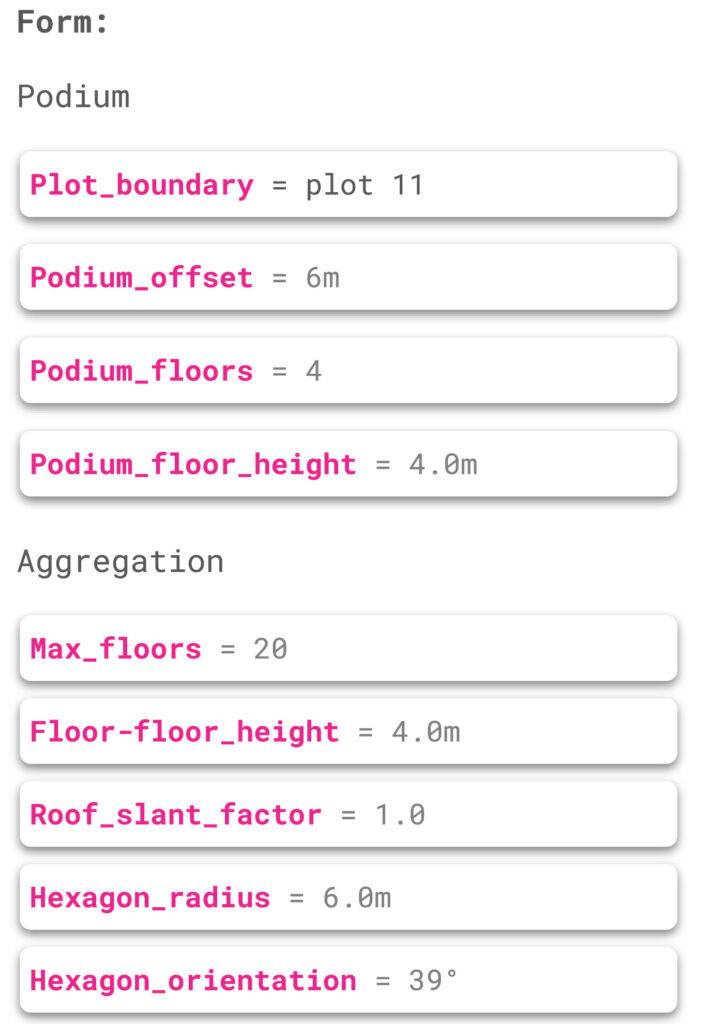

Aggregation Workflow

The computational workflow for the aggregated building form utilizes Wasp by Andrea Rossi and begins with defining inputs such as the site surface, podium height, hexagon radius (fixed at 6m), maximum building levels influenced by topography, and a roof slant adjusted based on aggregation height. Modules are designed as single hexagons (50 sqm) for smaller functions and double hexagons for larger spaces like workshops, with constraints assigning specific functions to different floors and zones. Aggregation starts with core modules, ensuring escape route compliance, while gardens and breakout spaces are strategically positioned for circulation and natural light. Functional modules aggregate between cores and gardens with adjacency to light. After aggregation, additional building elements such as balconies, glazing, shading, and a podium housing shops and storage are incorporated. The form is analyzed for daylight autonomy, escape distances, and functional utilization to ensure efficient, adaptable, and context-sensitive modular design.

Step 1

Inputs:

Aggregation offset from plot: 1.0 – 10.0m

Orientation (north) – 0-90 degrees

Aggregation floor-floor height: 3.0 – 4.5m

Podium floor-floor height: 4.0m – 8.0m

Hexagonal module radius: 5.0 – 7.0m

Roof slant factor: 0.1 – 1.0

Max levels: 5 – 20

Step 2

Modules per floor:

Manufacturing floors

Makerspace floors

Reference floors

Relaxation floors

Step 3

Step 4

Step 5

Step 6

Detailing added:

Balconies (pictured)

Horizontal shading

Roofing and photovoltaics

Glazing

Podium staggering and floors

Step 7

CHALLENGES:

sDA using Honeybee and fire distances using shortest walk

Step 8

OUTPUTS:

FAR

sDA

Escape distances

Functional utilization

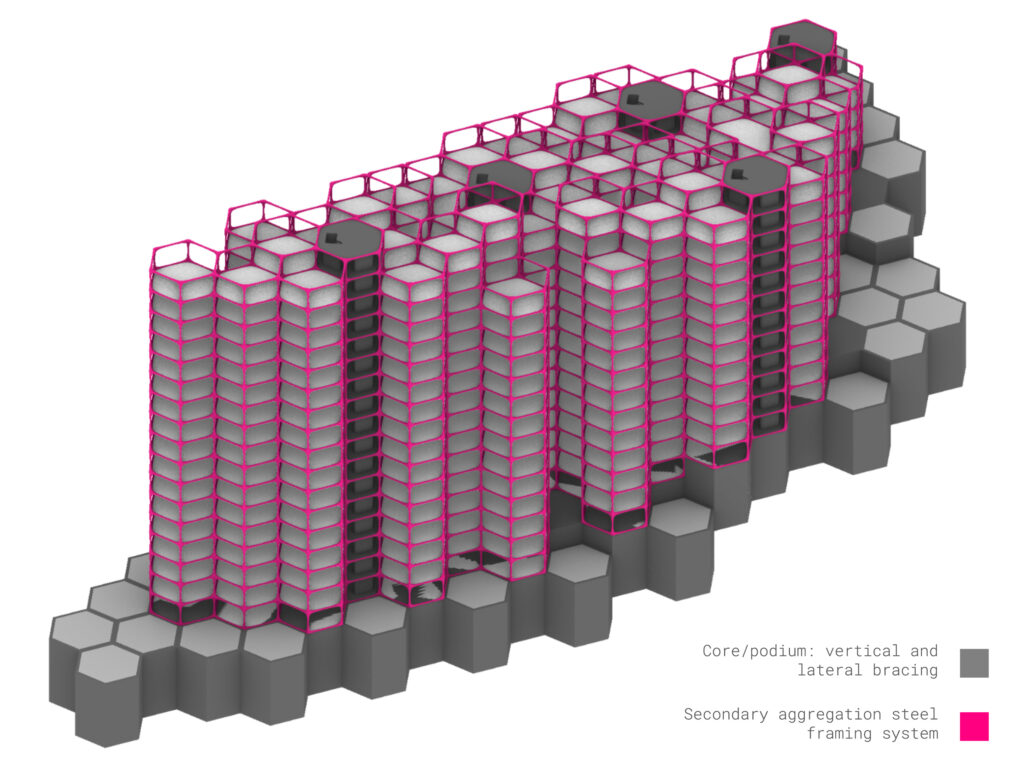

Instantiation

An instantiation of the script illustrates the count and cumulative area of each module type per floor. The accompanying GIF highlights the 1-hexagon and 2-hexagon cluster sizes, along with the functional module types deployed on each floor. In this iteration, the spatial daylight autonomy (sDA) analysis achieved a 51.8% pass rate, with a maximum escape distance of 20.78 meters. The structural diagram showcases the primary concrete core and podium elements in relation to the secondary modular steel framing, while the circulation diagram below outlines the nearest escape routes to a core.

Structural diagram showing primary and secondary hierarchy

Circulation diagram showing escape distances to cores through breakout modules

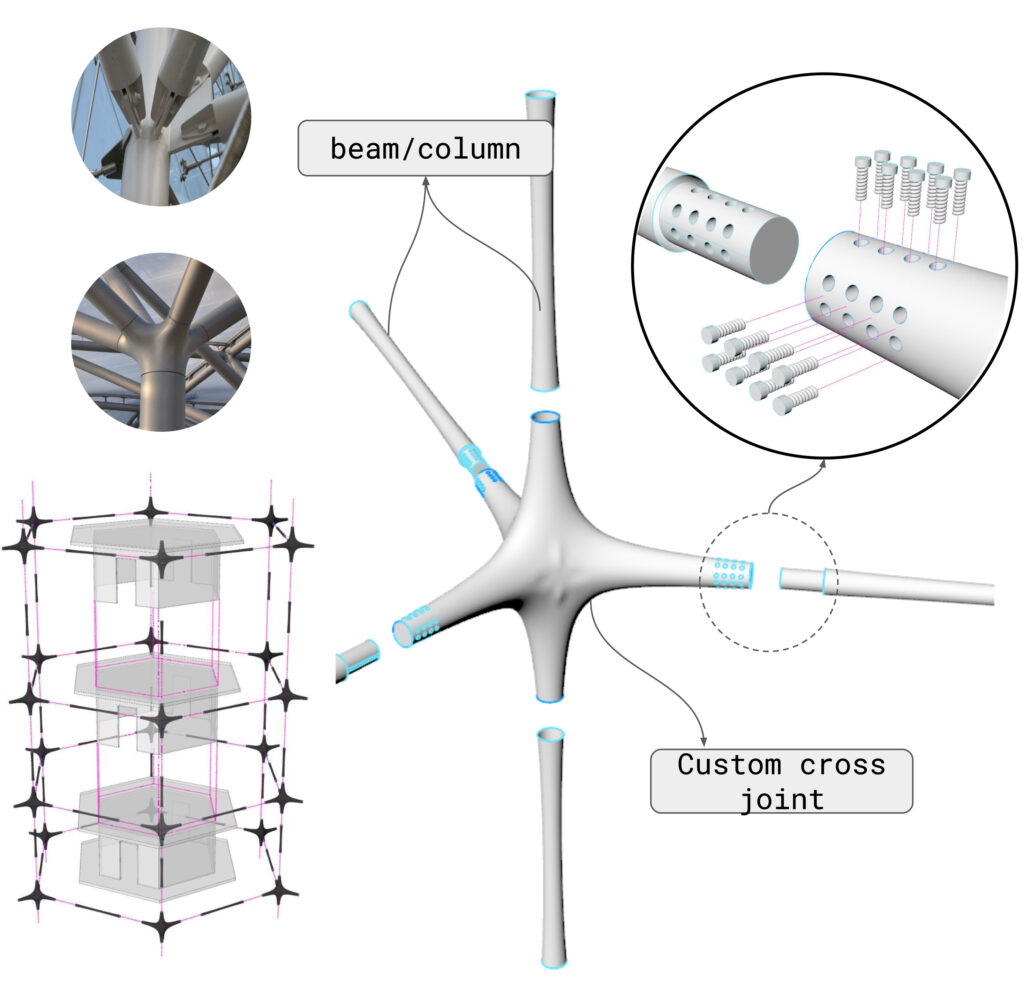

Structure // Concept

Concrete Podium

Concrete core and podium as the foundation. The concrete cores provide vertical support, prevent lateral movement by resisting wind and seismic forces, and act as the central structural elements around which the modular units will be built. The podium distributes horizontal loads and supports the modular units above, creating a strong and stable base for the hybrid system.

Concrete Podium

The structure consists of a modular steel beam system using round hollow sections (O-sections) to form a lightweight yet strong framework. The modular design allows for scalability, enabling the structure to grow and adapt to changing needs over time. Architecturally, the system resembles a multipipe configuration, with interconnected tubular elements creating a visually dynamic and structurally efficient form. This approach ensures flexibility, ease of assembly, and efficient load distribution across the system.

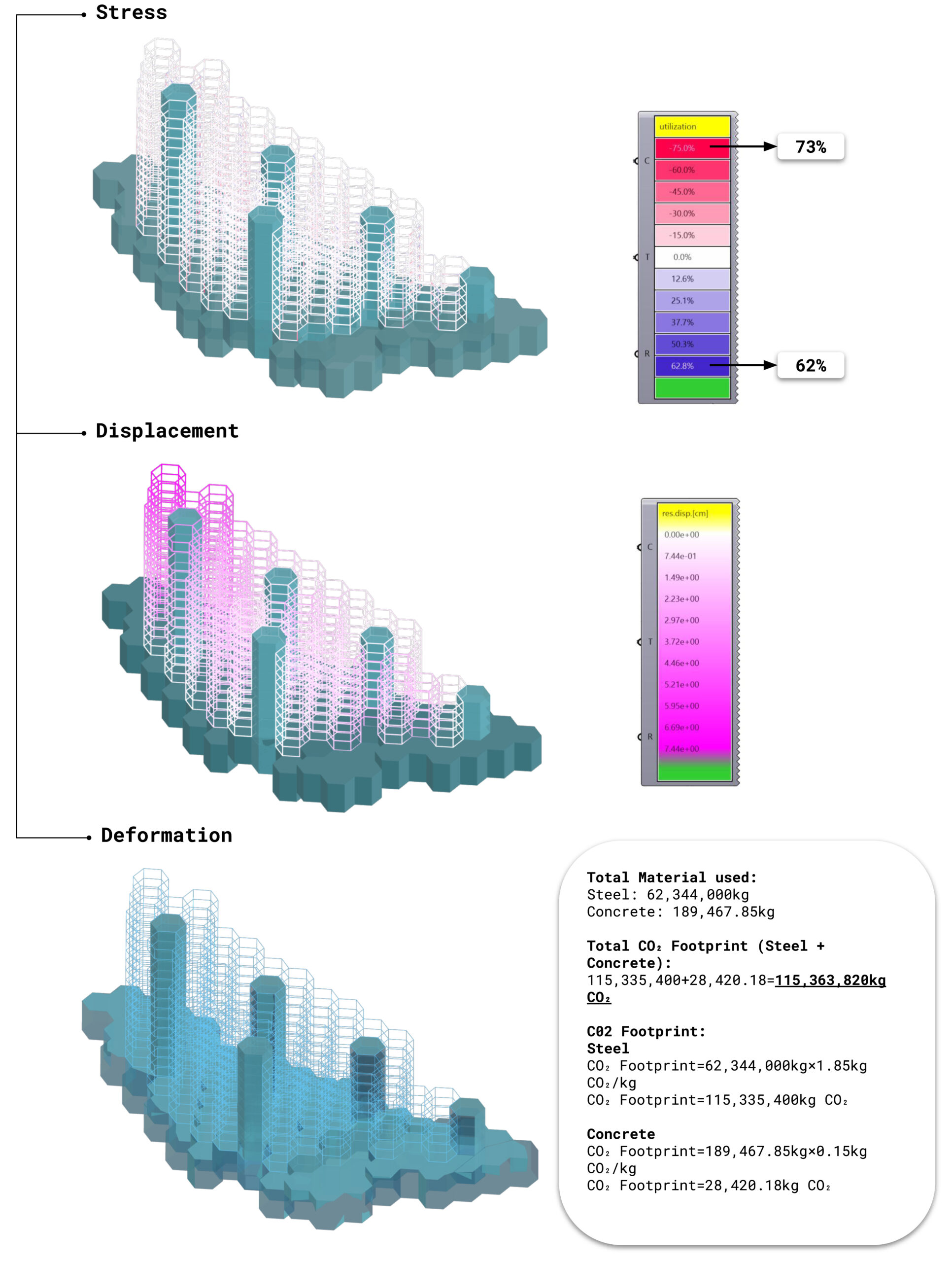

Structural Analysis

Plan//Typical level

Each floor is designed with access to an outdoor garden, ensuring ample natural sunlight and fostering a connection to outdoor spaces. Circulation is primarily facilitated by the central core and breakout units, with select additional units serving as secondary circulation hubs. The hexagonal design posed a unique challenge in creating an efficient and seamless flow, requiring careful planning to optimize connectivity throughout the building.

Section//A-A

Permutations

Recipe Deployment

Common Plot