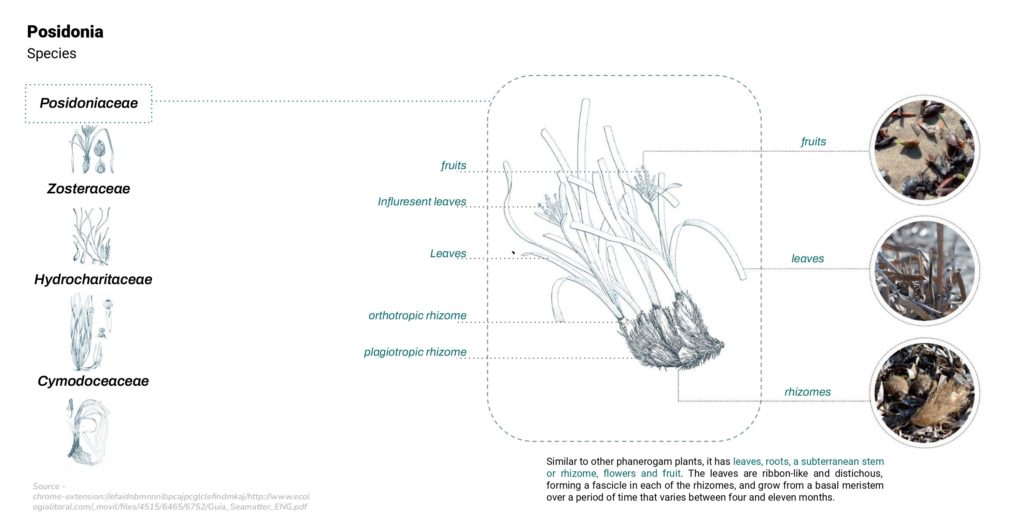

Posidonia Oceanica: The Aquatic Seagrass Species

Posidonia oceanica is a species of aquatic seagrass that belongs to the Posidoniaceae family. It possesses roots, a rhizomatous stem, and ribbon-like leaves, resembling those of terrestrial plants. These features allow it to anchor itself to the seabed and spread horizontally, forming extensive meadows in the Mediterranean Sea. These seagrass meadows provide critical ecological functions and serve as habitats for a diverse range of marine organisms.

The Exclusivity of Posidonia Meadows

Posidonia meadows are a distinct and remarkable feature of the Mediterranean Sea, found nowhere else in the world. These meadows are composed of the seagrass species Posidonia oceanica, which forms extensive underwater habitats. Its presence is a testament to the region’s ecological richness and biodiversity. The meadows play a crucial role in maintaining water clarity, stabilizing sediments, and providing shelter and food for numerous marine organisms. Recognized as a marine treasure, the conservation and preservation of Posidonia meadows are essential to safeguard the unique ecosystem of the Mediterranean Sea.

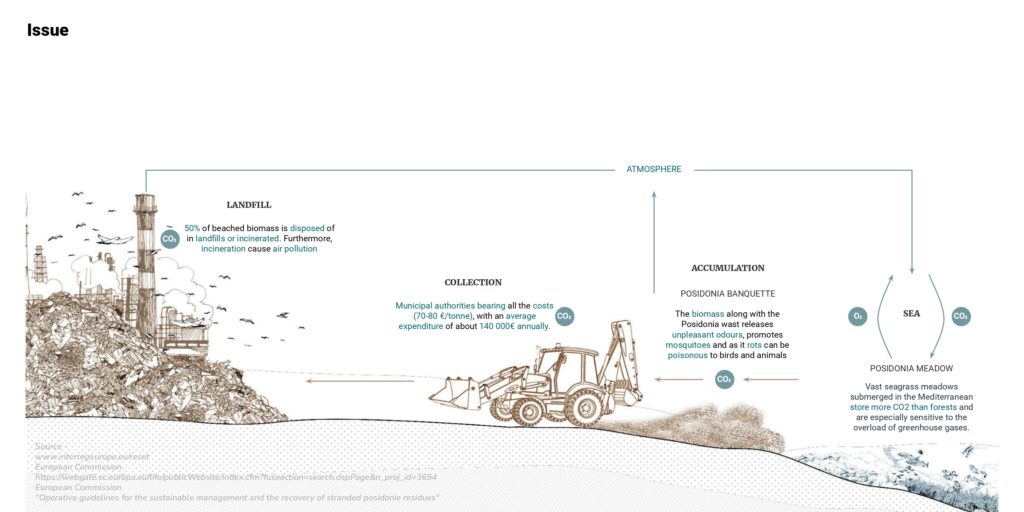

Mediterranean Waste Crisis

Along the Mediterranean coast, there is a pressing issue of massive waste accumulation, which emits a strong odor due to decomposing organic matter. Surprisingly, among this waste, the valuable Posidonia seagrass is treated as unwanted and removed, ending up in landfills. This improper disposal of Posidonia puts a considerable financial burden on coastal municipalities.

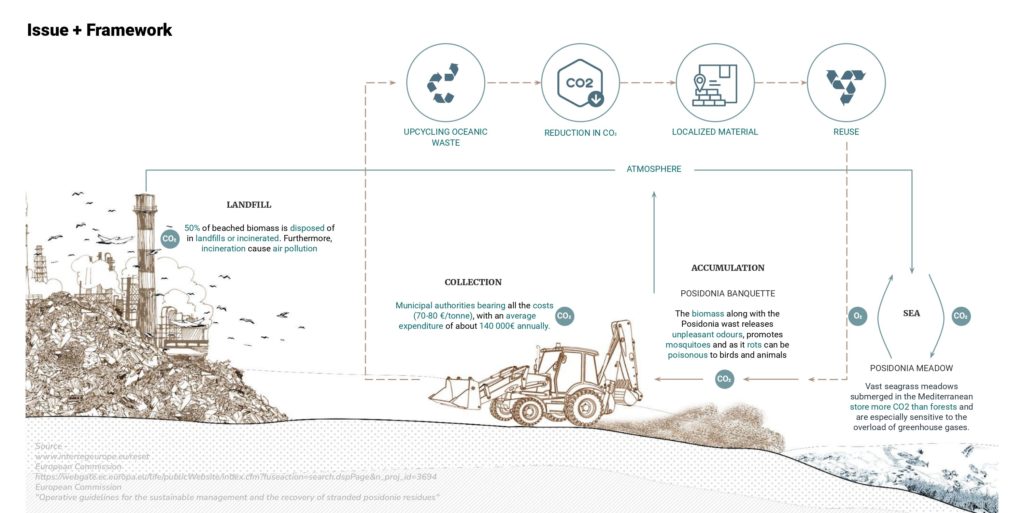

Posidonia Waste: Transforming Environmental Challenges into Local Solutions

By repurposing Posidonia waste, numerous environmental advantages can be achieved, including the recycling of oceanic waste currently relegated to landfills along the Mediterranean coast. Moreover, utilizing Posidonia for the creation of locally-sourced materials can significantly reduce transportation costs, stimulate the coastal economy, and foster community-driven sustainable solutions.

Posidonia: A Multi-Beneficial Resource with Exceptional Properties for Sustainable Construction

Posidonia possesses several advantageous properties that make it a highly desirable resource, particularly in the construction industry. Firstly, it serves as a carbon sink, effectively absorbing and storing carbon dioxide. Additionally, Posidonia is renewable, allowing for sustainable harvesting practices without depleting its population. Its versatility is another asset, enabling it to be utilized in various applications.

Moreover, Posidonia acts as a biofertilizer, enriching the soil and promoting healthy plant growth. As a low carbon crop, it has a minimal carbon footprint, contributing to environmental sustainability. When considering its mechanical properties, Posidonia excels as a construction material. It offers excellent thermal insulation, effectively regulating temperature. It also provides acoustic insulation, minimizing sound transmission. Furthermore, Posidonia exhibits moisture resistance, making it suitable for humid environments, and it is fire-resistant, enhancing safety measures. Its resistance to mold and degradation ensures durability and longevity.

The combined advantages of Posidonia’s environmental benefits and favorable mechanical properties position it as an ideal material for the construction industry, supporting sustainable practices while delivering exceptional performance.

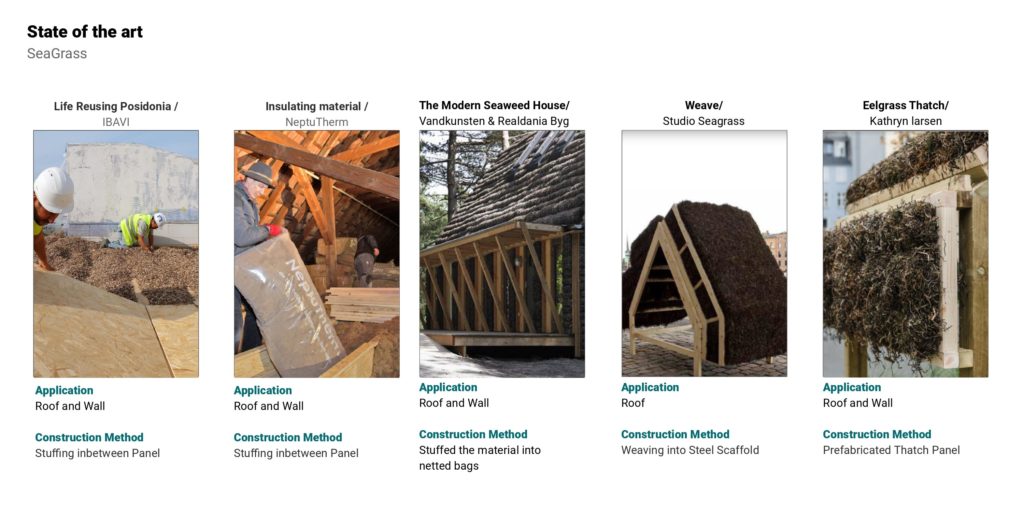

Seagrasses as Sustainable Architectural Materials: Exploring the Potential of Posidonia and Eelgrass

Ongoing research is focusing on the potential of seagrasses, particularly Posidonia and Eelgrass, as valuable raw materials for architectural applications. Posidonia, with its excellent insulating properties and lightweight nature, is well-suited for use in sandwiched panels. On the other hand, Eelgrass has been successfully incorporated into construction systems through innovative fabrication techniques like stuffing into netted bags, weaving into scaffolds, and creating prefabricated thatch panels for interior and exterior walls and roofs. Additionally, ongoing investigations are exploring alternative seagrass species that possess similar characteristics, expanding the possibilities for sustainable and eco-friendly architectural materials.

Seagrass and Additive Manufacturing in Sustainable Architecture

The findings from the reference studies indicate that while seagrass has been repurposed as a building material, its utilization has primarily been limited to traditional methods such as molding and casting. However, there is a significant opportunity to explore alternative fabrication techniques, specifically additive manufacturing, which offers enhanced design freedom and harnesses the potential of new technologies.

By embracing additive manufacturing, architects and designers can unlock a whole new realm of possibilities for seagrass-based materials. This innovative approach allows for intricate and customizable designs, enabling the fullest potential of seagrass to be realized in architectural applications. With additive manufacturing, layers of seagrass-based materials can be precisely deposited, offering precise control over structural properties and geometries.

Additive manufacturing not only empowers designers with greater flexibility but also contributes to sustainability efforts. The process minimizes material waste and energy consumption, aligning with the principles of eco-conscious design. Moreover, the use of seagrass as a renewable and natural material further enhances the environmental benefits of additive manufacturing in architecture.

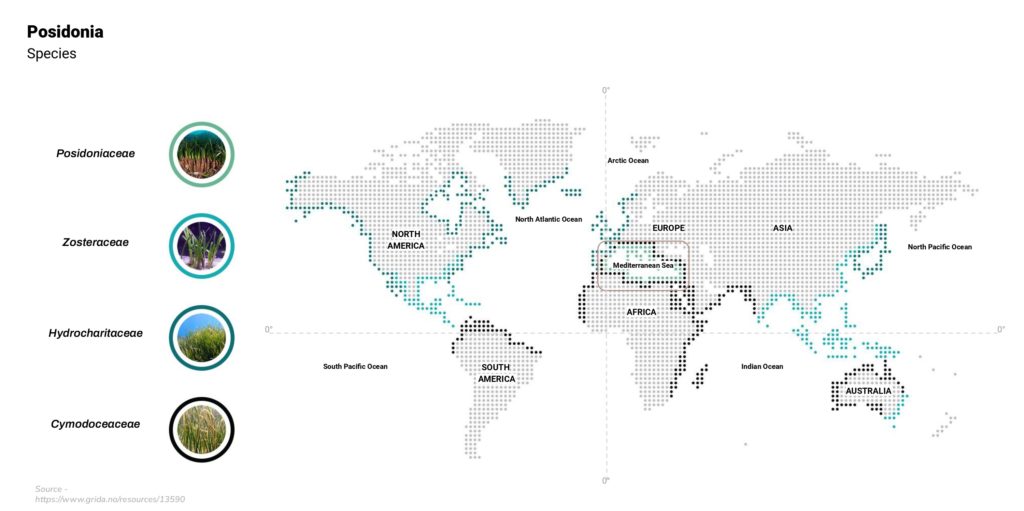

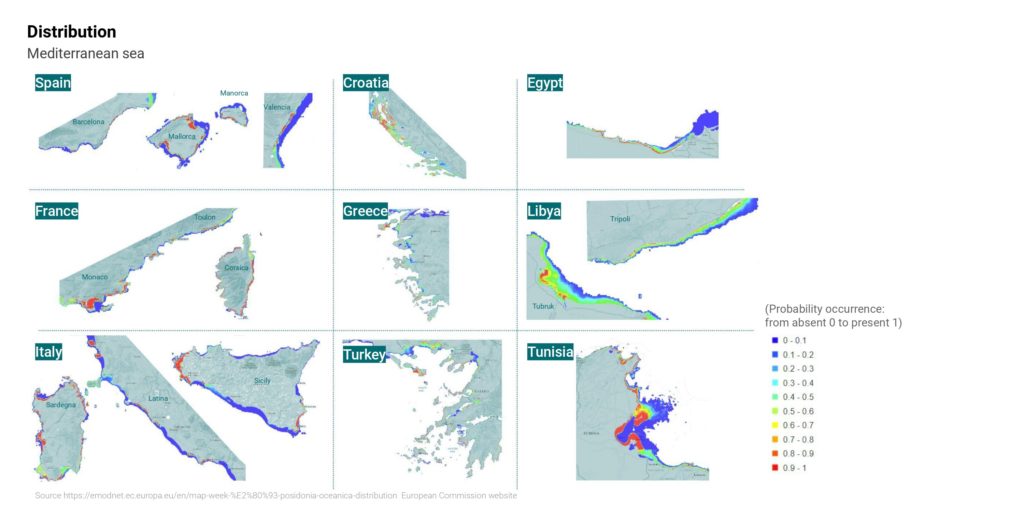

Posidonia Distribution: Mapping Along the Mediterranean Coast

Posidonia oceanica, the most common species of Posidonia in the Mediterranean, is known to form extensive meadows in countries such as Spain, France, Italy, Greece, and Turkey, among others. These countries generally have significant coastal areas where Posidonia meadows can be found.

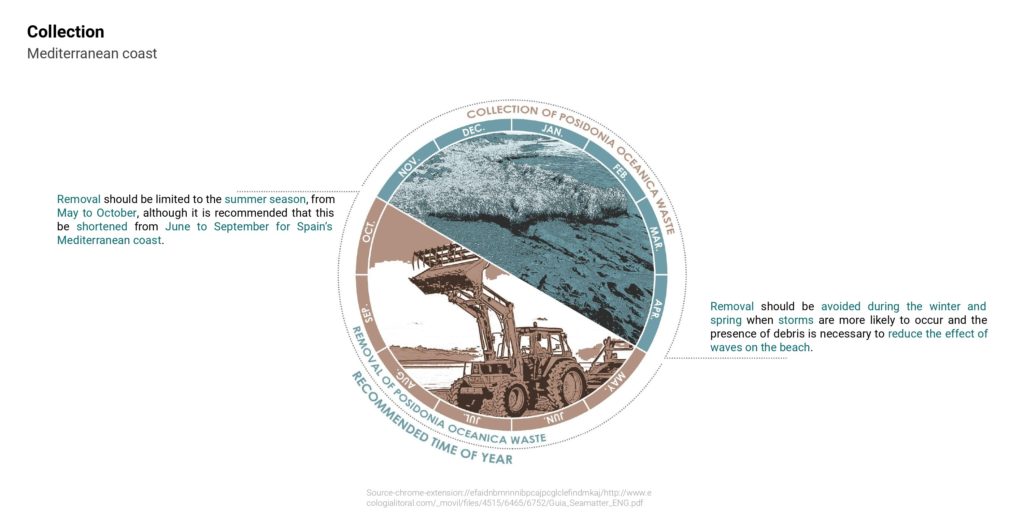

Optimizing Posidonia Waste Removal: Considerations for Timing and Seasonality

Timing and considerations for the removal of Posidonia waste play a crucial role in coastal management practices. It is recommended that the removal activities are limited to the summer season, specifically from May to October. However, for Spain’s Mediterranean coast, it is advised to further shorten the removal period to span from June to September. This timeframe takes into account the specific environmental conditions and requirements of the region.

During the winter and spring seasons, storms and rough weather conditions are more prevalent along the Mediterranean coast. These natural events can lead to increased wave activity and potential erosion. To mitigate these effects and maintain the natural balance of the beach ecosystem, it is important to refrain from removing Posidonia waste during this period. The presence of debris, including Posidonia, helps reduce the impact of waves on the beach, acting as a protective barrier against erosion.

By adhering to a limited removal period during the summer and avoiding removal during the winter and spring, coastal authorities and municipalities can strike a balance between preserving the ecological benefits of Posidonia and managing the aesthetic concerns associated with accumulated waste. This approach allows for the coexistence of a healthy coastal ecosystem and a pleasant beach experience for residents and visitors alike.

Collection and Drying of Posidonia Seagrass

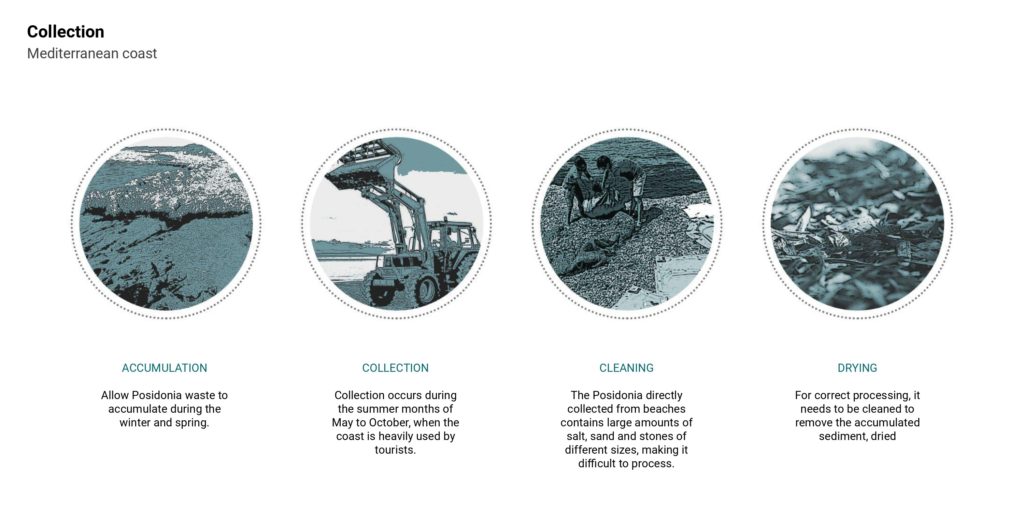

Posidonia seagrass, a remarkable marine plant, possesses a unique characteristic of self-replication, rendering it an abundant and renewable resource along the coast. This seagrass species naturally washes up on beaches without any human intervention, making it readily available for collection. The process of gathering Posidonia seagrass involves a straightforward approach, requiring minimal effort.

Initially, the collection phase involves carefully gathering the washed-up seagrass from the beach. As Posidonia is known to accumulate in large quantities, the collection process can yield a significant amount of raw material for various purposes. The seagrass is then subjected to a simple cleaning procedure, involving the removal of any debris or impurities present within the accumulated mass.

Once cleaned, the next step involves drying the Posidonia seagrass. This can be achieved through natural drying methods, such as exposing the collected seagrass to sunlight and air, or utilizing specialized drying facilities. The drying process helps reduce moisture content, ensuring the preservation of the seagrass while facilitating storage and transportation.

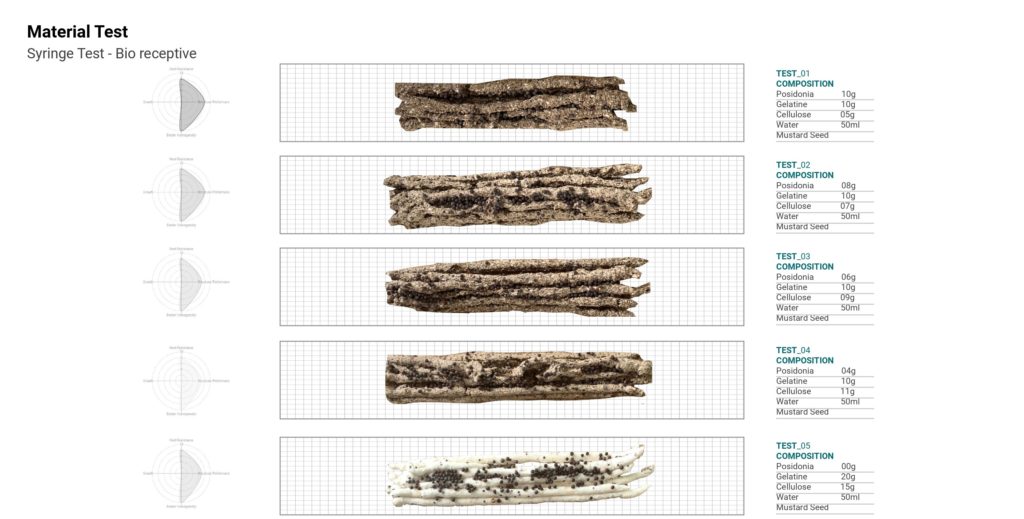

Exploring Binders for Posidonia-Based Mixtures: Enhancing Adhesion and Workability

After sourcing the Posidonia seagrass material, the experimented on a series of initial explorations. The focus was to establish a base mix by utilizing Posidonia and cellulose for their water holding capacity, while introducing different binders to enhance the adhesive properties of the mixture. Sodium alginate and gelatin were chosen as potential binders due to their adhesive qualities

Keeping Posidonia and cellulose as constants, varying amounts of sodium alginate and gelatin were incorporated into the mixtures. The aim was to find the optimal combination that would enhance cohesion, adhesion, and workability. Sodium alginate, derived from seaweed, was selected for its binding capabilities and compatibility with the Posidonia and cellulose components. Gelatin, a natural protein-based binder, was chosen to provide additional adhesive strength and stability.

Bio-composite Material System

Through systematic experimentation, the experimenter carefully evaluated the effects of different binder concentrations on the overall properties of the mixture. Factors such as workability, drying time, tensile strength, and durability were assessed to determine the most suitable binder combination.

These initial explorations served as the starting point for further refinement and optimization of the Posidonia-based mix. By investigating the effects of different binders, the experimenter aimed to develop a formulation that would maximize the material’s adhesive qualities without compromising its desired characteristics.

The gelatin binder proved to be the most effective in terms of maximizing structural strength, adhesion, and homogeneity in the Posidonia-based mixture. Its inclusion enhanced the overall robustness and stability of the material while providing strong adhesion between the Posidonia fibers and cellulose particles. The gelatin binder also contributed to a more uniform distribution of components, resulting in a consistent composition throughout. These findings highlight the potential of gelatin as a key ingredient in creating strong and cohesive Posidonia-based materials for various applications.

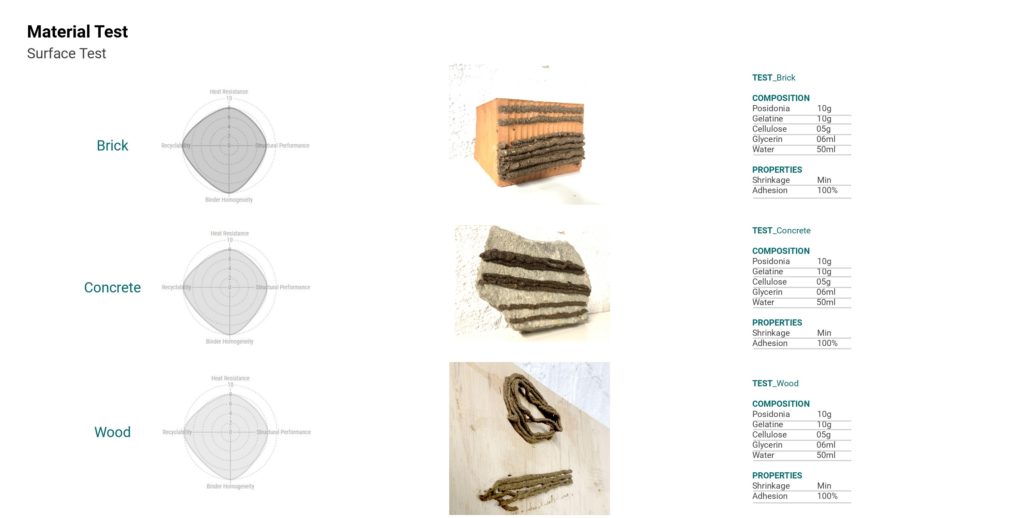

Adhesion Test on Various Surfaces: Assessing the Bonding Strength of Posidonia-Based Mixtures

The Posidonia-based mix was subjected to adhesion tests on various surfaces, including brick, concrete, and wood. The purpose was to assess its bonding capabilities and compatibility with different materials.

During the testing process, the mixture was applied onto the surfaces of brick, concrete, and wood, ensuring proper contact and coverage. Adhesion strength and performance were evaluated by examining the extent to which the mixture adhered to each material.

Remarkably, the Posidonia-based mix demonstrated excellent adhesion on all three surfaces. It formed a strong bond with the brick, concrete, and wood, adhering firmly without any signs of detachment or instability. This result indicated that the mixture possessed versatile adhesion properties, making it suitable for a wide range of construction and design applications.

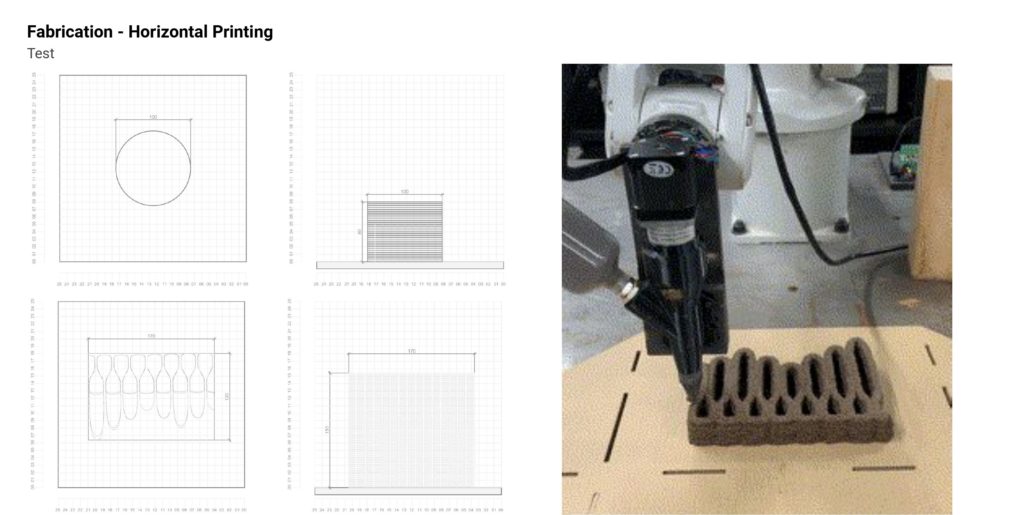

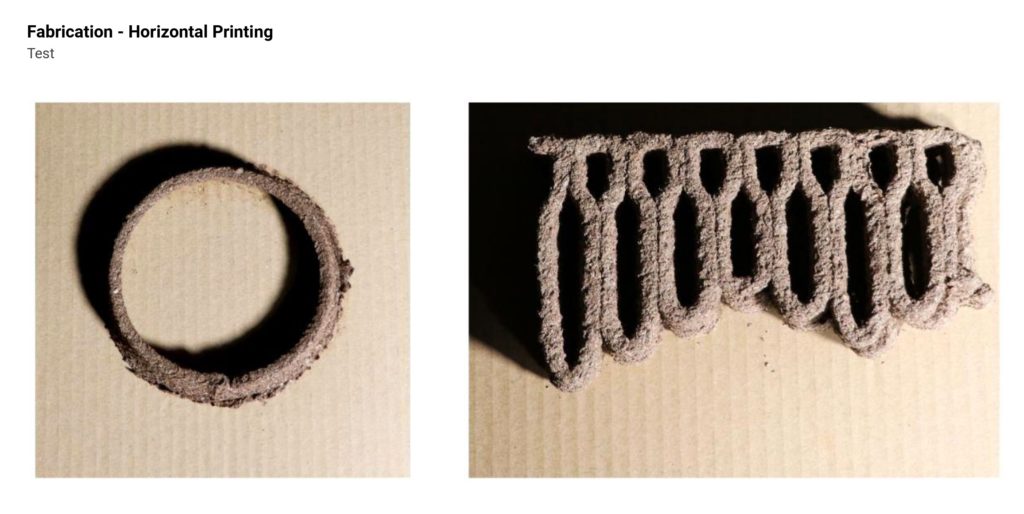

Horizontal – XY Axis Printing

After conducting initial tests with different end effectors, as a peripheral device that was mounted on the robot to interact with its task, both piston-based extrusion and motor-screw-based extrusion, it was determined that the motor-screw end effector yielded the best results for the material mix. Following these findings, a series of basic tests were carried out using the ABB 140 robotic arm equipped with a pneumatic and motor screw extruder setup. The setup featured a 6mm nozzle size and a layer distance of 2.5mm, allowing for precise control and extrusion of the Posidonia-based material during horizontal printing. The tests aimed to assess key parameters such as extrudability, layer adhesion, and suitable slicing distance. These findings provide important insights into the printing parameters that achieve the desired results with the Posidonia-based material, paving the way for further exploration.

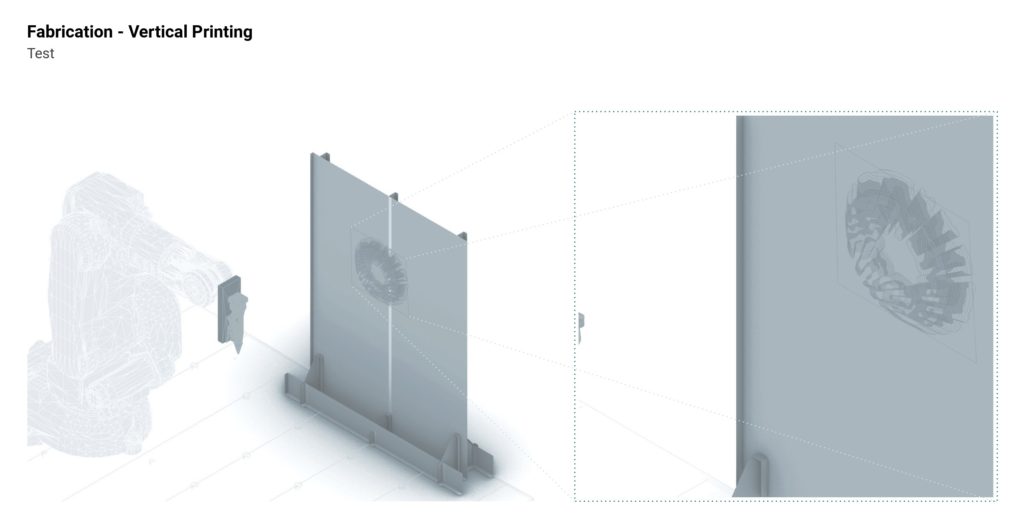

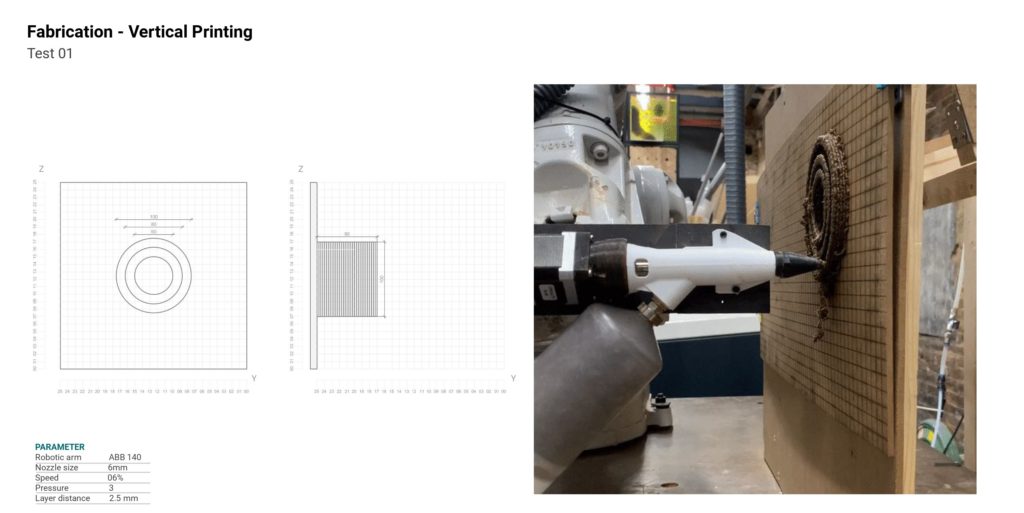

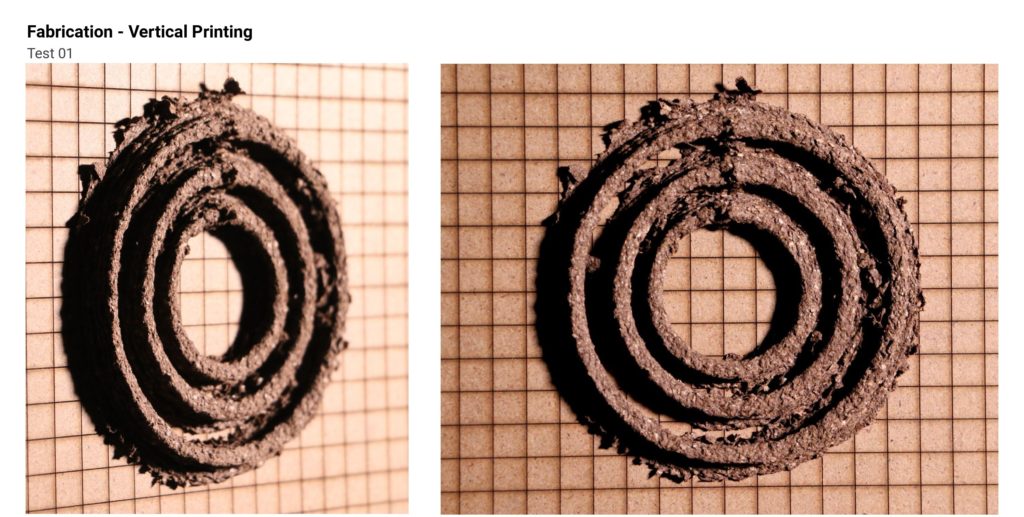

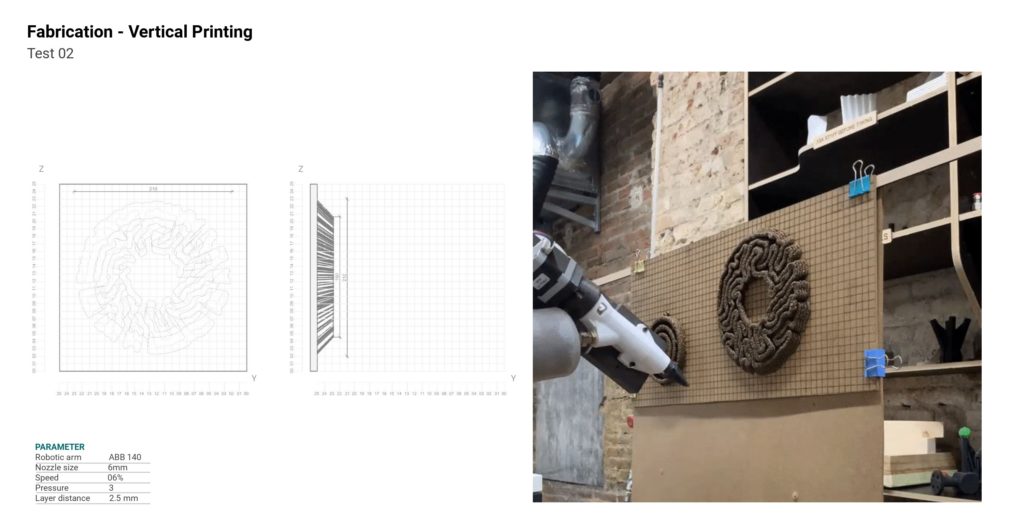

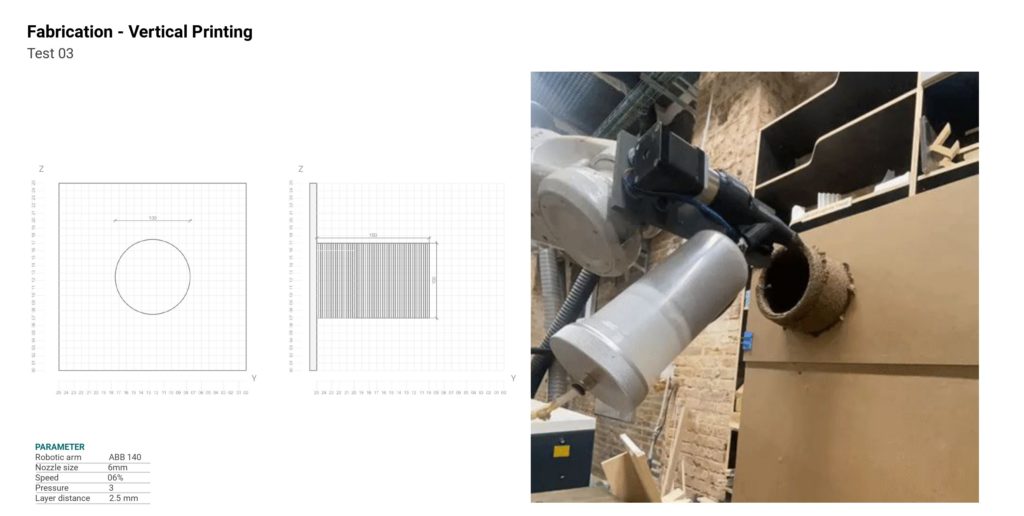

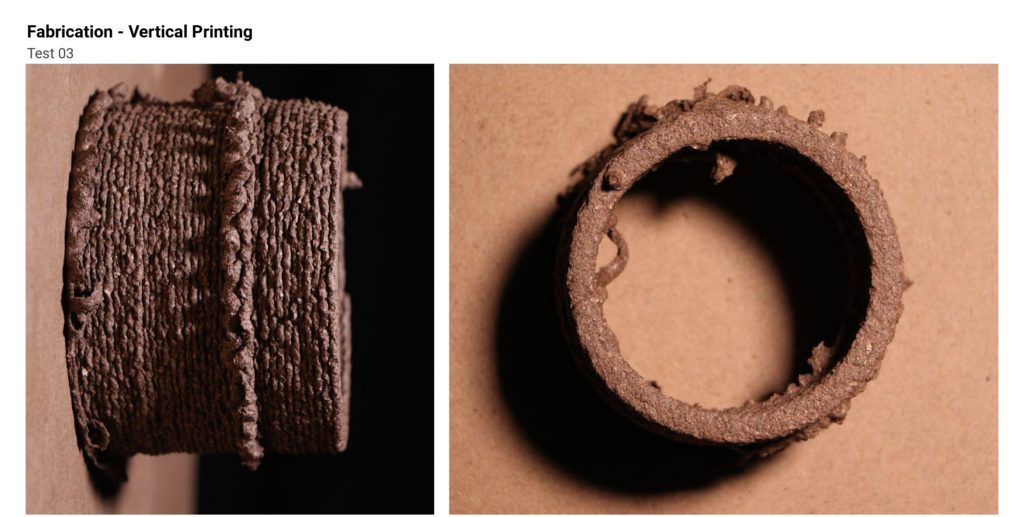

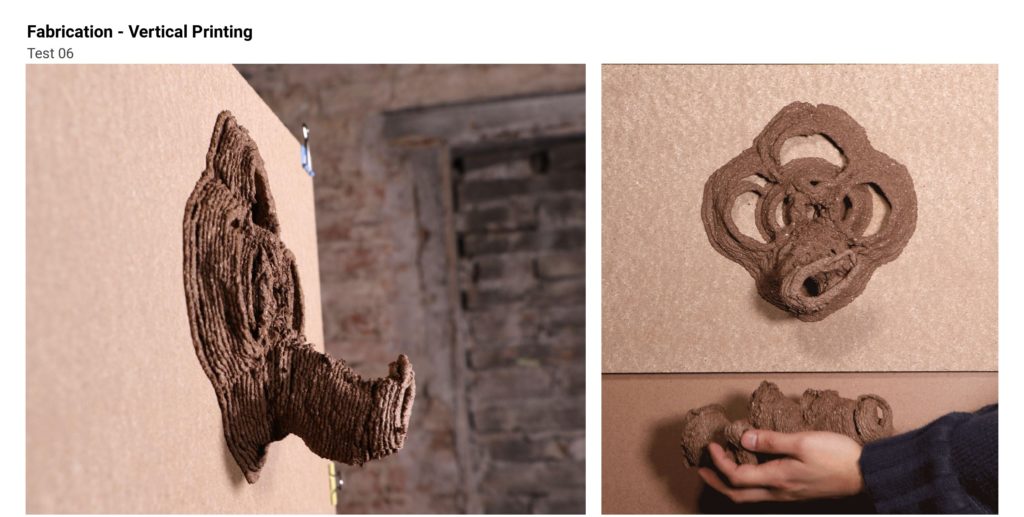

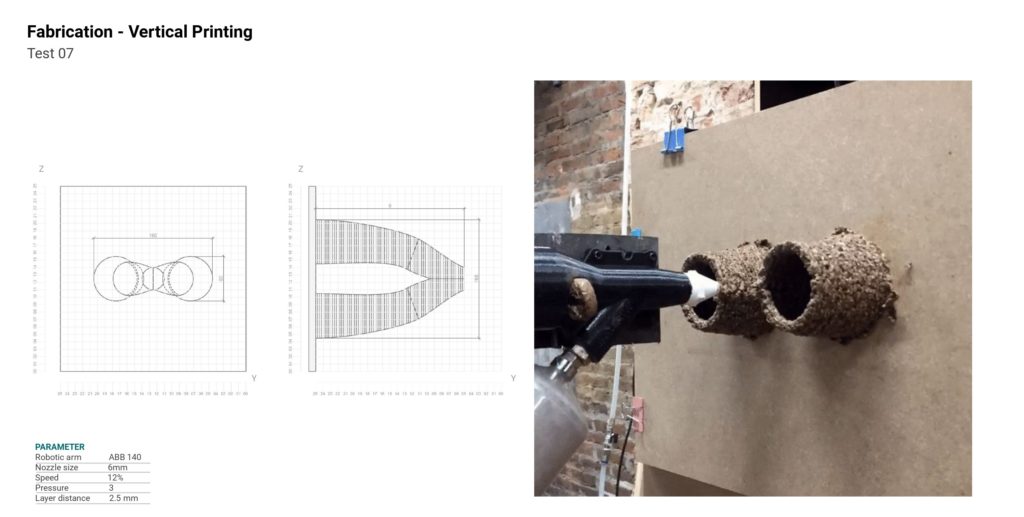

Vertical – XY Axis Printing

A series of vertical printing tests were conducted to assess the behavior and performance of the Posidonia-based material. The material, which had shown promising properties in horizontal printing, underwent evaluation for parameters such as adhesion, printability, and extents during the vertical printing process.

The tests involved printing prototypes using different designs and configurations to determine the material’s suitability in vertical applications. The prototypes exhibited good adhesion to the base, indicating strong bonding between the layers and the printing surface. After the vertical drying process, the prototypes remained intact and firmly adhered to the base, demonstrating the material’s ability to maintain its structural integrity.

Various patterns and designs were tested to assess the material’s performance under different conditions. The prototypes successfully maintained their shape and withstood applied loads, showcasing the material’s stability and structural integrity. However, some challenges were encountered during the tests, such as instances where certain elements failed or deformation occurred due to changes in the toolpath or excessive weight.

Despite these challenges, the series of vertical printing tests provided valuable insights into the behavior and potential applications of the Posidonia-based material. The successful prototypes demonstrated the material’s capability to be effectively used in vertical printing, while the challenges highlighted areas for further improvement and optimization. These findings contribute to the ongoing exploration of sustainable and innovative materials for vertical printing applications.

Integrating Sustainable Materials in Poblenou’s Urban Landscape

Based on previous tests and evaluations, it was established that the Posidonia-based material possessed the capability for multi-surface printing, rendering it well-suited for the creation of façade envelopes.

The selected site for this particular project is Poblenou, which aligns with the Barcelona block system and serves as an innovation center. The choice of this location provides a fitting context for exploring the potential of the Posidonia-based material in architectural applications.

By integrating the material into the façade envelopes of buildings in Poblenou, the project aims to showcase the versatility and sustainable qualities of the Posidonia-based material within an urban setting. The Barcelona block system, known for its characteristic urban morphology, offers an ideal framework for incorporating innovative and environmentally-friendly materials.

Through the implementation of the Posidonia-based material in the façade envelopes, the project seeks to contribute to the aesthetic appeal, energy efficiency, and overall sustainability of the buildings in Poblenou. The innovative nature of the material, coupled with the site’s emphasis on innovation and sustainable development, presents an opportunity to demonstrate the potential of this eco-friendly solution in architectural design.

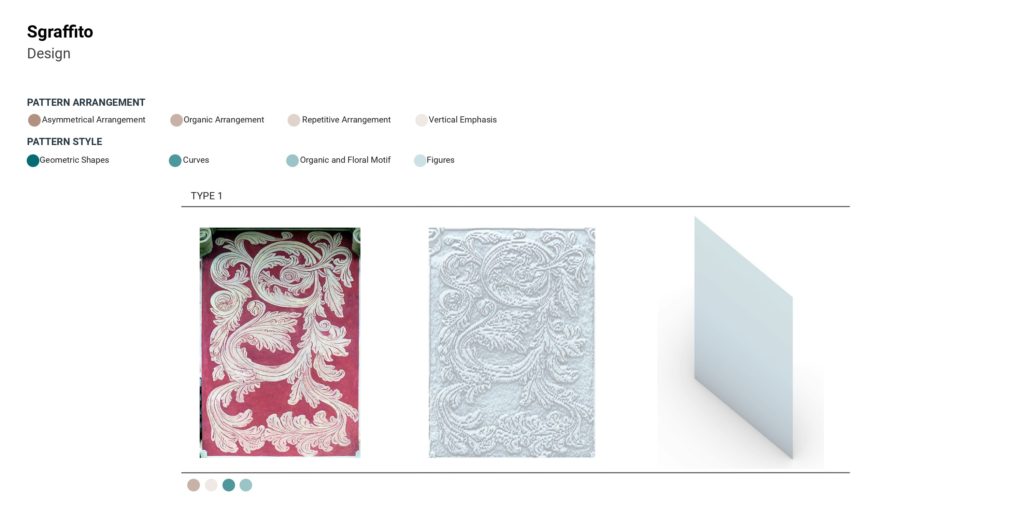

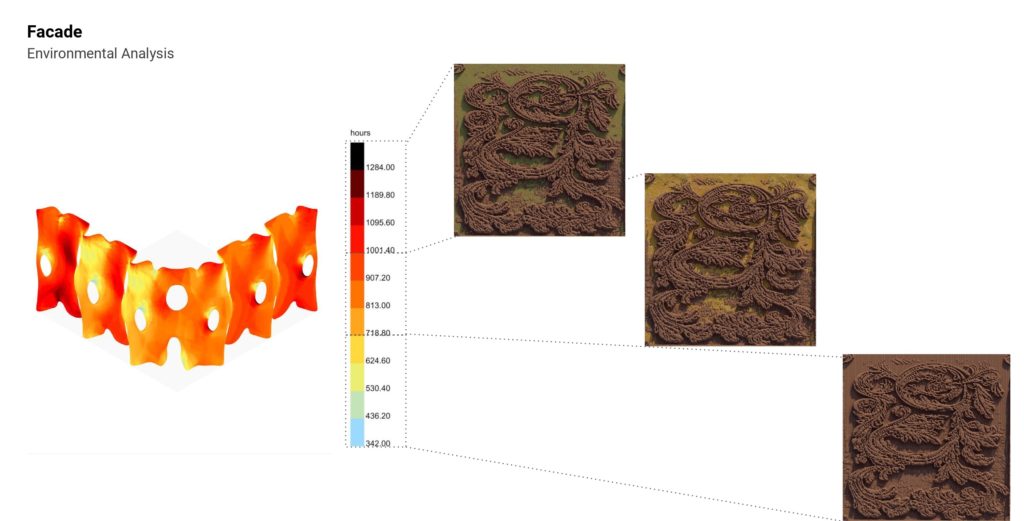

Exploring the Sgraffito Technique for Posidonia-Based Façade Envelopes

The geometries of the design for this project will draw inspiration from the Sgraffito technique, a prominent art nouveau style known as Modernisme in Barcelona. The Sgraffito technique involves carving or scratching through layers of plaster or stucco to reveal contrasting colors and textures underneath, creating intricate patterns and designs.

In the context of the project, the Sgraffito technique will be adapted and applied to the Posidonia-based façade envelopes. The technique will be used to create visually striking patterns and textures on the surface of the envelopes, adding an artistic and aesthetic dimension to the architectural design.

By incorporating the Sgraffito technique, the project aims to pay homage to the rich artistic heritage of Barcelona and its association with Modernisme. The intricate geometries and decorative elements created through this technique will not only enhance the visual appeal of the façade envelopes but also serve as a representation of the city’s cultural identity.

Sgraffito Technique: Exploring Geometry for Posidonia-Based Façade Envelopes

The Sgraffito technique offers a wide range of possibilities for creating captivating and visually striking designs on Posidonia-based façade envelopes. Drawing inspiration from the art nouveau style known as Modernisme in Barcelona, the geometry of the design incorporates a diverse array of elements.

Pattern styles form an essential component of the Sgraffito technique, allowing for the exploration of intricate and ornate designs. From delicate filigree patterns to bold and geometric compositions, the technique offers the flexibility to create visually appealing patterns that reflect the desired aesthetic.

Geometric shapes play a significant role in the Sgraffito technique, providing a foundation for the overall design. Rectangles, triangles, circles, and polygons can be combined and arranged in different configurations, allowing for the creation of dynamic and visually stimulating compositions.

Curves add fluidity and grace to the design, softening the overall appearance and creating a sense of movement. Whether in the form of flowing lines, sweeping arcs, or intricate spirals, curves bring an element of elegance to the façade envelope, complementing the organic nature of Posidonia.

Organic and floral motifs draw inspiration from nature, introducing elements such as leaves, flowers, vines, and tendrils. These motifs infuse the design with a sense of vitality and bring a touch of natural beauty to the façade envelope.

Figures, such as human forms or mythological creatures, can be incorporated into the Sgraffito design, adding narrative and symbolism to the overall composition. These figures can evoke emotions, tell stories, or represent cultural and historical references, enriching the visual experience and creating a deeper connection with the viewer.

The arrangement of these elements offers endless possibilities for creative expression. Asymmetrical compositions can create a sense of dynamism and intrigue, while organic arrangements mimic the flow and harmony of the natural world. Repetitive patterns can convey a sense of rhythm and unity, while vertical emphasis draws the eye upward, accentuating the verticality of the building’s façade.

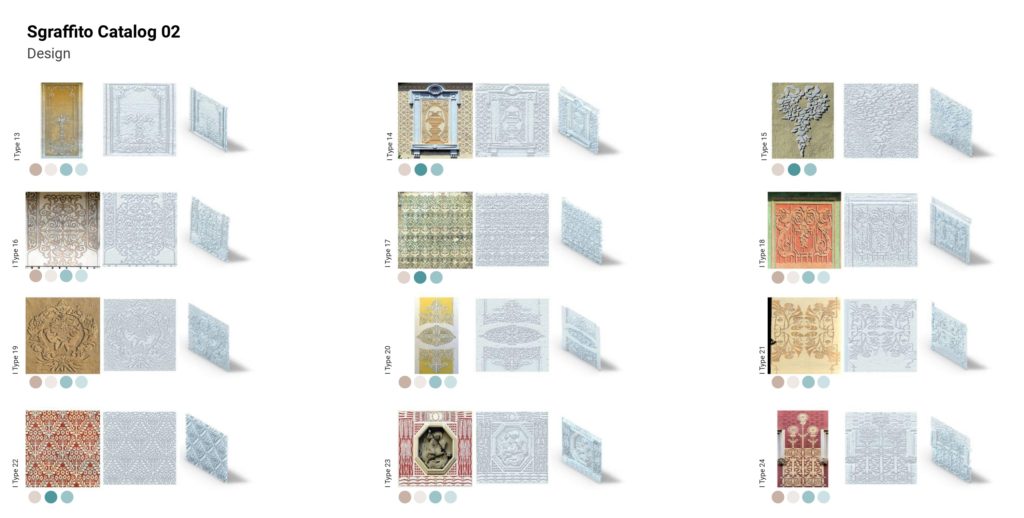

Sgraffito Design Catalog: Patterns and Styles

In order to build a comprehensive catalog of Sgraffito designs, a meticulous process was undertaken. Images of textured surfaces, showcasing a wide range of Sgraffito patterns and styles, were meticulously sampled and documented. The captured images served as a valuable resource for catalog creation, ensuring the inclusion of diverse and visually captivating designs.

The catalog itself became a treasure trove of inspiration, showcasing an array of patterns and styles that are unique to the Sgraffito technique. Each design was carefully categorized and differentiated within the catalog, allowing for easy navigation and exploration. To aid in clarity and visual organization, a color legend was incorporated, helping to distinguish between different patterns and styles.

This catalog of Sgraffito designs became a valuable resource for architects, artists, and enthusiasts alike, providing a wealth of inspiration and reference for future projects. It served as a visual guide, enabling individuals to explore the intricacies of Sgraffito patterns, study their characteristics, and incorporate them into their own artistic endeavors.

Through the creation of this comprehensive catalog, the rich heritage and aesthetic allure of Sgraffito designs were celebrated and made accessible to a broader audience. The catalog not only preserved the essence of this art form but also served as a source of inspiration for future generations, ensuring the continued appreciation and utilization of Sgraffito techniques in contemporary artistic and architectural practices.

Bio-Receptive Surfaces: Integrating Sgraffito Designs for Visually Appealing

The catalog of Sgraffito designs offers a diverse collection of patterns and styles that can be used to create visually appealing building exteriors. These designs can be incorporated into the material, combining Posidonia with a base mix, to enhance the aesthetic appeal of the building while promoting bio-receptivity.

By utilizing the Sgraffito designs, architects and designers can introduce various elements such as geometric shapes, curves, organic and floral motifs, and figures to the building’s exterior. These elements can be arranged in different ways, including asymmetrical, organic, repetitive, and with vertical emphasis, allowing for unique and visually captivating designs.

The catalog serves as a valuable resource, providing a range of options and inspirations for incorporating Sgraffito designs into the material. It showcases the versatility and potential for creating surfaces that are both visually appealing and bio-receptive, fostering a connection between the built environment and nature.

In ongoing tests, the material’s bio-receptive properties are being explored by mixing Posidonia with a base mix in various ratios and incorporating mustard seeds. Mustard seeds are known for their fast-growing and easily extruded nature, making them an ideal choice for testing the material’s ability to support plant growth. These tests aim to evaluate the feasibility and effectiveness of the material as a bio-receptive surface.

Exploring Material Printability: 5-Axis Printing Testing

The testing of materials’ printability in the vertical and 5-axis printing configurations involves evaluating their behavior during the printing process and their ability to adhere to the desired surfaces. Different materials, such as polymers, metals, ceramics, and composites, can be tested to assess their suitability for vertical and 5-axis printing applications.

The transition from horizontal to vertical printing opens up new possibilities for exploring the printability of various materials. By introducing the concept of 5-axis printing, additional degrees of freedom are incorporated into the printing process, allowing for more complex geometries and intricate designs.

Selecting Patterns through Image Sampling and Curve Generation

The process of selecting patterns for 3D printing involves image sampling and curve generation techniques. By utilizing image sampling, patterns can be extracted from various sources such as photographs, illustrations, or digital images. These patterns serve as visual references for the desired design.

Once the patterns are selected, the next step involves generating curves that represent the intricate details of the chosen patterns. This can be achieved using specialized software tools that allow for the conversion of 2D patterns into 3D curves suitable for 3D printing.

During the curve generation process, the software analyzes the selected patterns and converts them into a series of interconnected curves. These curves capture the intricate details, shapes, and contours of the original pattern, ensuring that the resulting 3D print accurately represents the desired design.

The generated curves are then used as a blueprint for the 3D printing process. They serve as the basis for creating a digital model that can be sliced into layers and translated into machine-readable instructions for the 3D printer.

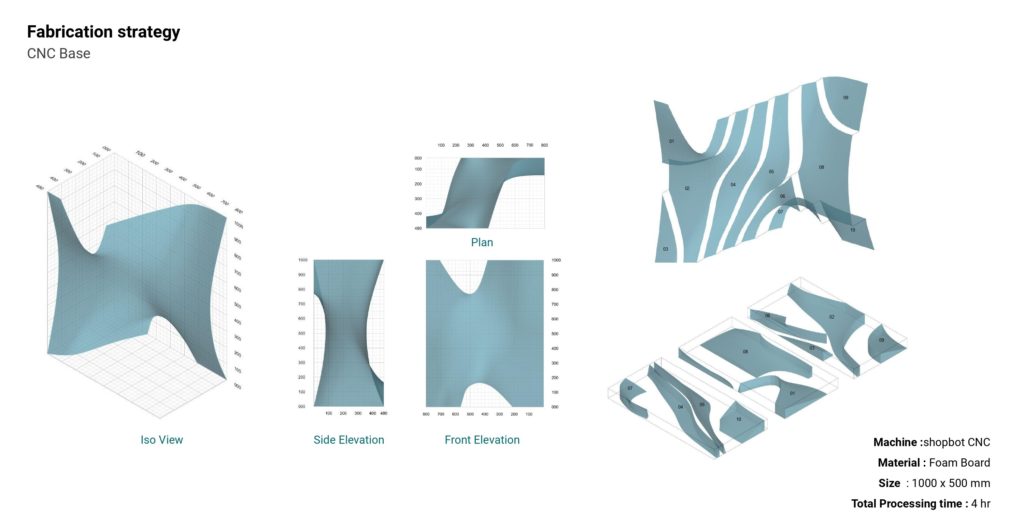

Fabrication of Iso Surface

In order to facilitate the 5-axis printing process, an iso surface was generated as a reference model. The iso surface represents a smooth continuous surface that encapsulates the desired geometry of the object to be printed.

Once the iso surface was generated, it was divided into smaller pieces or sections to be CNC machined from foam board. CNC (Computer Numerical Control) machining involves using computer-controlled cutting tools to precisely carve out the desired shapes from a solid material. By dividing the iso surface into sections, it becomes more manageable for the CNC machining process.

After each section was machined from the foam board, the pieces were carefully joined together, aligning the edges and ensuring a seamless fit. The joining process may involve adhesive bonding or other suitable techniques to securely assemble the individual sections into a complete iso surface.

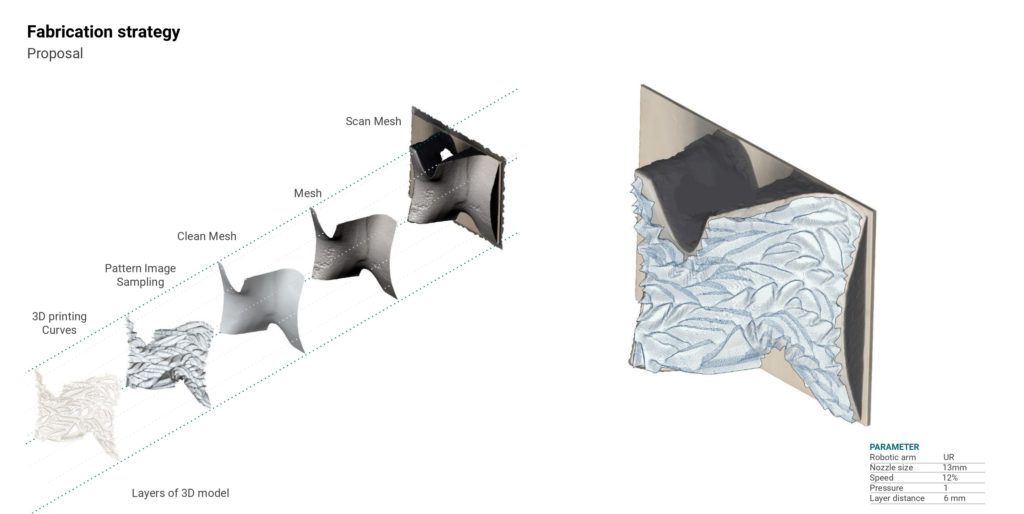

Ensuring Accuracy: Photogrammetry Scanning of Joined Model for Correct Mesh of Physical Prototype

To ensure the accuracy of the physical prototype, a photogrammetry scanning technique was employed to capture the joined model and generate a correct mesh representation. Photogrammetry involves capturing a series of photographs of an object from multiple angles and then using specialized software to stitch these images together and create a detailed 3D model.

In this case, the joined model, which consisted of the various components assembled together, was carefully scanned using a photogrammetry setup. The model was placed in an environment with controlled lighting conditions, and a series of high-resolution photographs were taken from different perspectives. These photographs captured the intricate details and geometry of the model.

The captured photographs were then processed using photogrammetry software, which analyzed the images and reconstructed the 3D geometry of the model. The software utilized advanced algorithms to align and match the features present in the photographs, creating a point cloud that represented the surface of the model. This point cloud was then converted into a mesh, which formed the digital representation of the physical prototype.

The generated mesh was thoroughly examined to ensure that it accurately reflected the geometry and proportions of the joined model. Any discrepancies or errors were carefully addressed, making necessary adjustments to achieve a precise representation. The goal was to create a digital model that faithfully represented the physical prototype, capturing all the intricate details and nuances.

Translating Scanned Mesh to 3D Printed Curves: Replicating the Selected Pattern

After generating the scan mesh of the joined model, the next step involved cleaning the mesh to ensure a smooth and clean surface. This process aimed to remove any imperfections, noise, or artifacts that might have been captured during the scanning process. Various software tools and techniques were employed to refine the mesh and achieve a high-quality representation of the physical prototype.

Once the mesh was cleaned and optimized, the selected pattern was sampled onto the surface of the model. This involved mapping the pattern onto the mesh, aligning it with the desired areas of the prototype. The pattern could be derived from various sources, such as images, designs, or artistic inspirations.

To prepare the model for 3D printing, curves were generated based on the sampled pattern. These curves served as the blueprint for the additive manufacturing process, guiding the deposition of material to create the desired shape and form. The curves defined the boundaries and contours of the pattern, ensuring accurate reproduction during the printing process.

Enhancing Energy Efficiency and Aesthetic Appeal: Bio-Receptive Texture for Sun-Exposed Building Sides

The goal of applying a bio-receptive texture on the sun-exposed sides of the building is to address the issue of heat penetration and enhance energy efficiency. By incorporating bio-receptive elements, such as patterns inspired by natural forms, the building can benefit from their functional and aesthetic properties.

Bio-receptive textures have the potential to minimize heat absorption by utilizing surface patterns that disperse and reflect sunlight, reducing the amount of heat transmitted into the building. This approach aligns with sustainable living principles by employing nature-inspired strategies to mitigate environmental impact.

Additionally, the bio-receptive texture adds an aesthetic dimension to the building’s exterior. By integrating visually appealing patterns derived from natural elements, such as plants, leaves, or organic shapes, the building can harmonize with its surroundings and create a visually captivating facade. This not only contributes to the overall architectural design but also enhances the aesthetic experience for occupants and passersby.

The combination of energy-efficient features and aesthetic appeal makes the application of bio-receptive texture a compelling approach in contemporary architecture. By leveraging natural patterns and materials, buildings can strive for sustainability, visual attractiveness, and improved comfort for occupants.

Ultimately, the integration of bio-receptive textures on the sun-exposed sides of the building offers a holistic solution that addresses both functional and aesthetic aspects, promoting a harmonious relationship between the built environment and nature.

Advancing Fabrication: Large-Scale Printing on Building Facades with Autonomous Robots

In the pursuit of advancing fabrication techniques, the utilization of autonomous robots has emerged as a promising approach for large-scale printing on building facades. This innovative method involves the use of mini bots, compact robotic devices capable of directly printing on the surface of the facade.

The mini bot is specifically designed to navigate complex architectural surfaces, maneuvering seamlessly to reach different areas of the facade. Its autonomous capabilities allow it to operate independently, reducing the need for human intervention and increasing efficiency in the fabrication process.

With the ability to print directly on the facade, the mini bot opens up new possibilities for creating intricate designs, patterns, and textures on a larger scale. This technology enables architects and designers to explore creative concepts and implement unique visual elements that were previously challenging to achieve manually.

One of the key advantages of employing a mini bot for large-scale printing is the precision and accuracy it offers. The robot follows programmed instructions, ensuring consistent and uniform application of the printing material. This level of control results in high-quality finishes and precise execution of intricate designs.

Moreover, the use of autonomous robots in fabrication minimizes the risks associated with human errors and increases productivity. The mini bot can work continuously without fatigue, maintaining a consistent workflow and reducing project timelines.

By integrating this technology into the fabrication process, architects and designers can achieve greater flexibility and customization. The mini bot can adapt to various surface geometries and accommodate complex architectural features, allowing for the creation of bespoke designs tailored to the specific requirements of the building.

Enhancing Urban Biodiversity: Sgraffito Patterns and Bird Habitats in Building Facades

The incorporation of Sgraffito patterns in building facades not only adds visual appeal but also creates crevices and textured surfaces that can serve as potential habitats for city birds. These crevices can provide nesting opportunities for birds, contributing to urban biodiversity and promoting ecological balance within the urban environment.

City birds, such as sparrows, swallows, and pigeons, often struggle to find suitable nesting sites in urban areas where natural habitats are limited. By integrating crevices and textured surfaces into the facade design through Sgraffito patterns, buildings can offer nesting spaces for these birds, allowing them to establish their nests and raise their young.

The presence of nesting birds can bring numerous benefits to the urban ecosystem. Birds play a crucial role in pollination by dispersing pollen as they move from flower to flower. This promotes the growth of plants and enhances the overall bio receptivity of the structure. Increased pollination can lead to the establishment of green spaces, gardens, or even vertical gardens on the building facade, further enhancing the sustainability and ecological value of the structure.

The nesting birds also contribute to the overall biodiversity and ecological balance of the urban environment. They can help control pest populations by feeding on insects, reducing the need for chemical pesticides. Additionally, their presence adds to the beauty and liveliness of the urban landscape, providing an enjoyable and nature-friendly environment for residents and visitors.

By intentionally designing facades with Sgraffito patterns that create suitable nesting spaces, architects and urban planners can actively contribute to the conservation of bird species and the enhancement of urban ecosystems. This approach demonstrates a holistic and sustainable design philosophy that takes into account both aesthetic and ecological considerations, promoting the coexistence of nature and built environments.