Introduction

Intentions

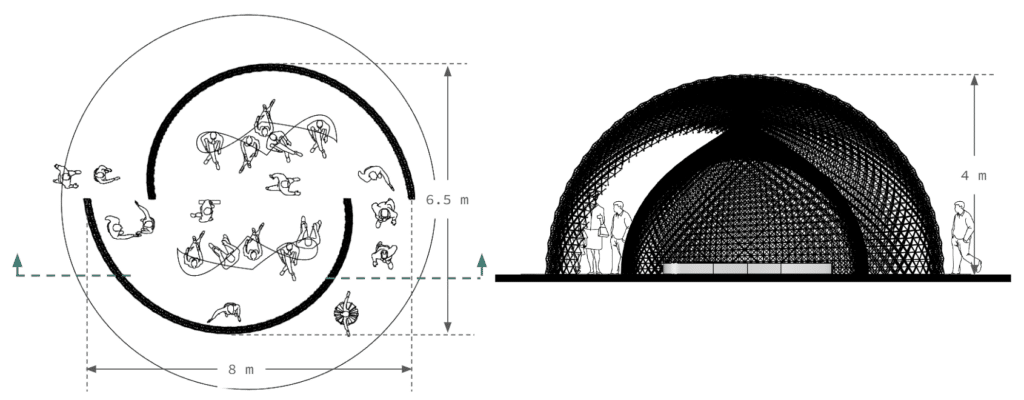

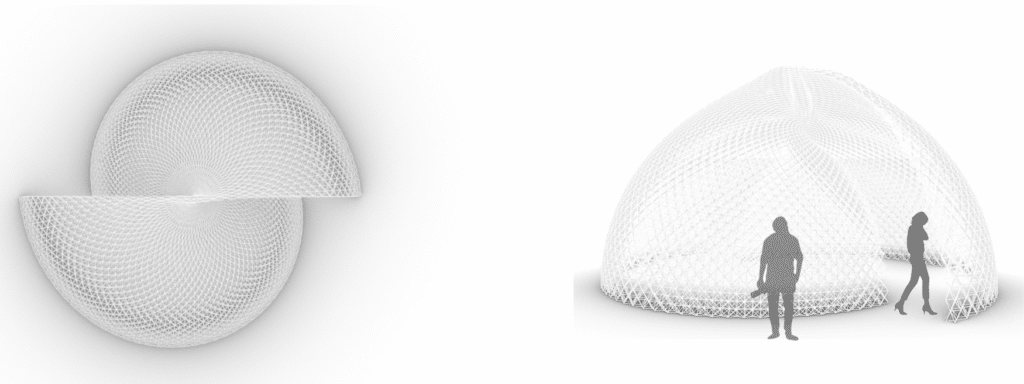

The pavilion was conceived as a flowing spiral, a path where visitors enter without seeing the exit, guided like a wave through the form — much like a shell in the ocean. Our aim was to create a geometry that is neat yet non‑banal: generated by simply rotating a curve, but enriched with structural intelligence and poetic resonance.

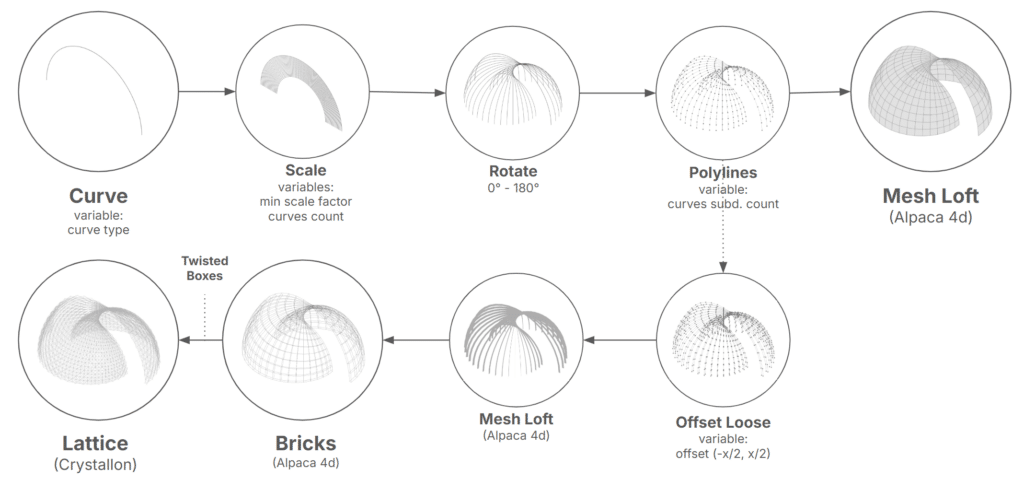

Design Process

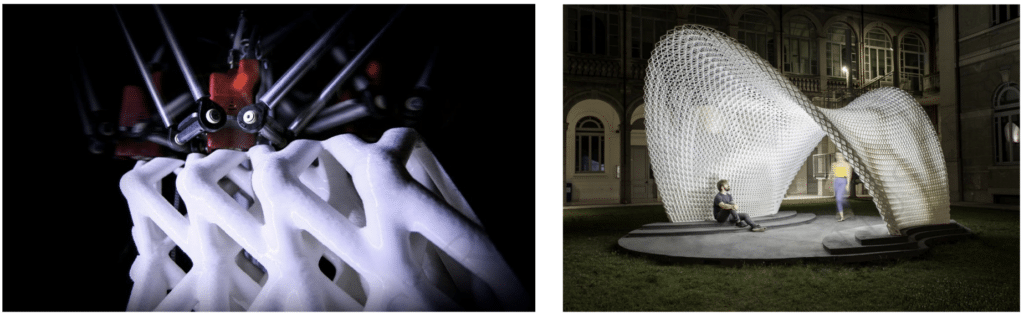

Our starting point was additive manufacturing. After evaluating options, we found Delta WASP printers to be the most effective for large‑scale projects. The design brief specified glass‑reinforced recycled PET as the material, with the following properties:

- Young’s modulus: 9.47 GPa

- Density: 1.71 g/cc

- Yield strength: 116 MPa

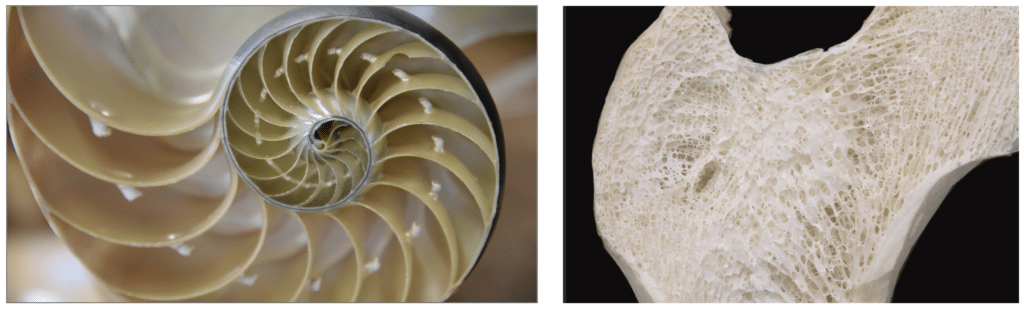

Inspired by biology — the nautilus shell’s logarithmic spiral and trabecular bone’s porous orientation— we developed a pavilion that unfolds as a continuous spiral path.

Computational Design

Form Generation

The design began with a curve that was scaled and rotated, evolving into three explorations: a continuous shell, a brick tessellation and a lattice.

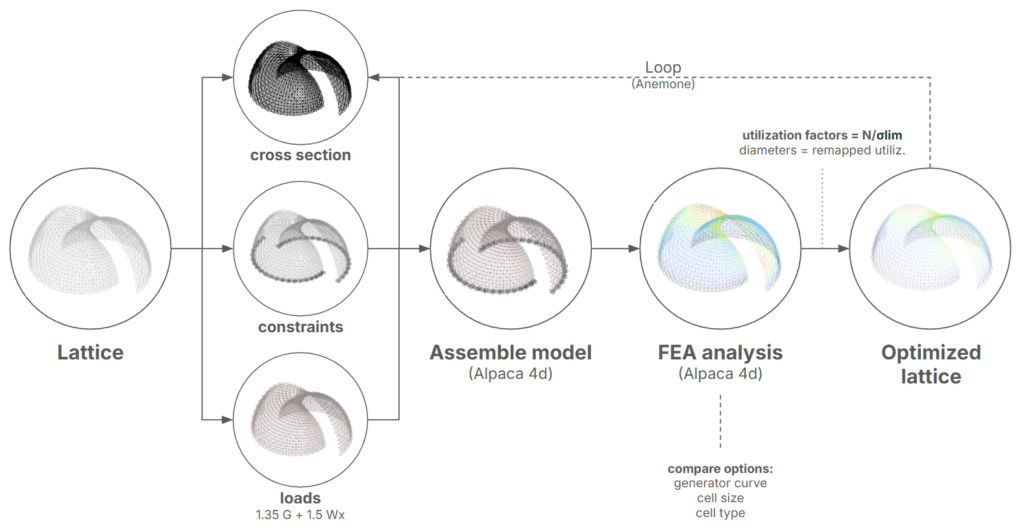

Finite Element Analysis

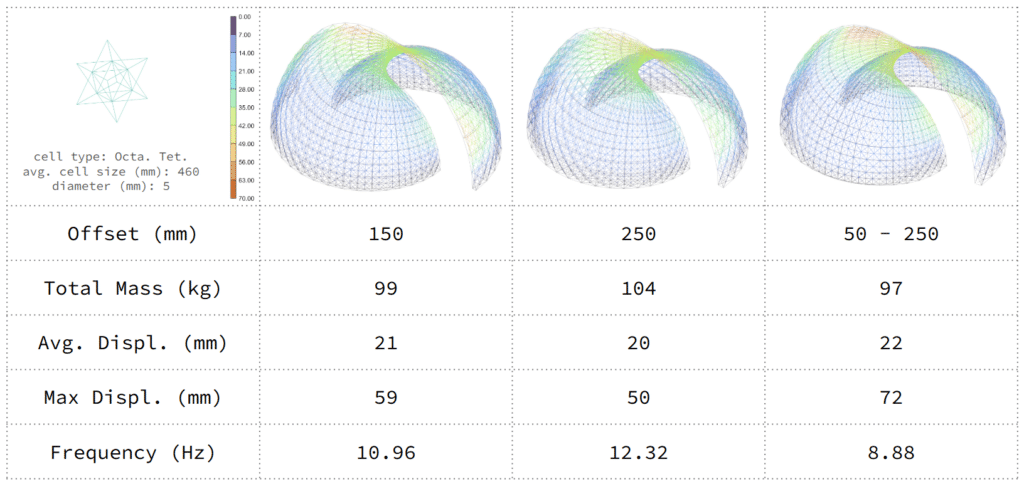

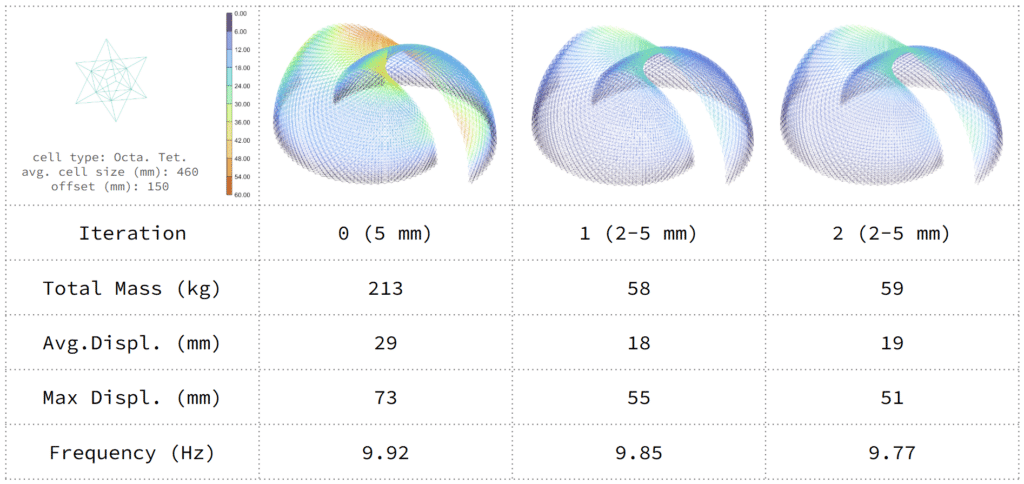

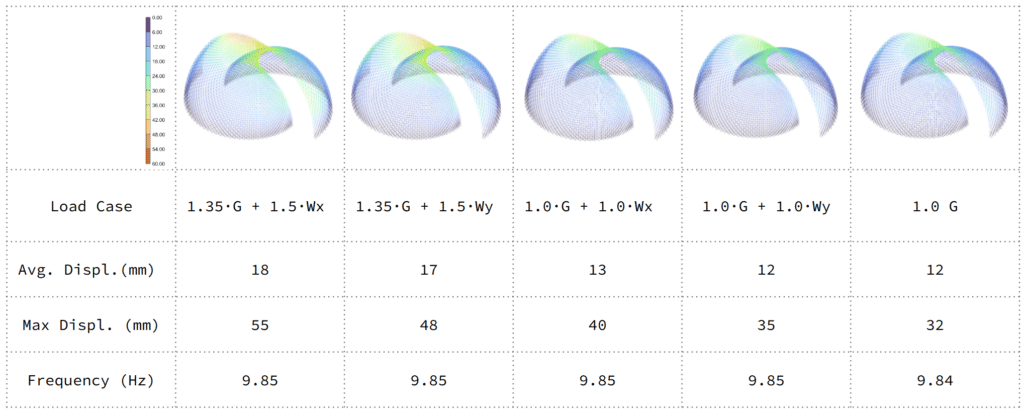

Alpaca4D was employed for finite element analysis (FEA) of the shell, brick tessellation, and lattice. The pavilion was modelled as fully anchored to the ground, with a maximum element diameter of 5 mm. Loads applied included gravity and wind in both the X and Y directions (0.08 kN/sqm). For the design iterations, we focused on the most severe load case.

Design Iterations

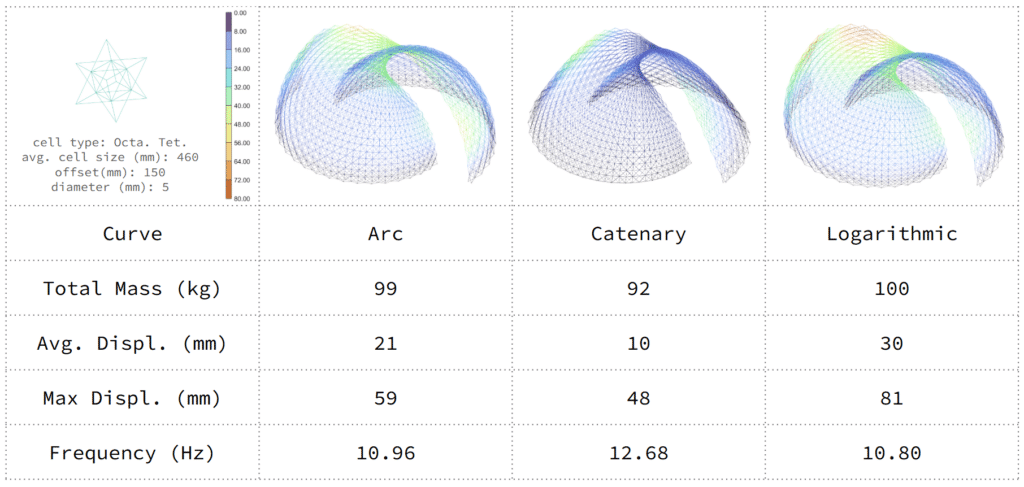

As expected, switching from an arc to a catenary curve improved overall behaviour, while an asymmetrical curve had the opposite effect. However, cross‑section optimization was more beneficial for the arc, so we decided to proceed with the initial geometry.

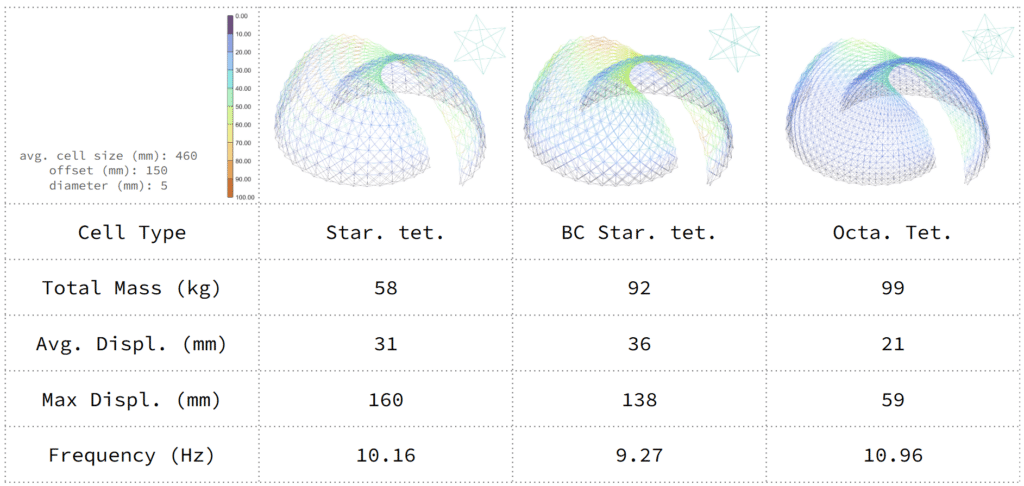

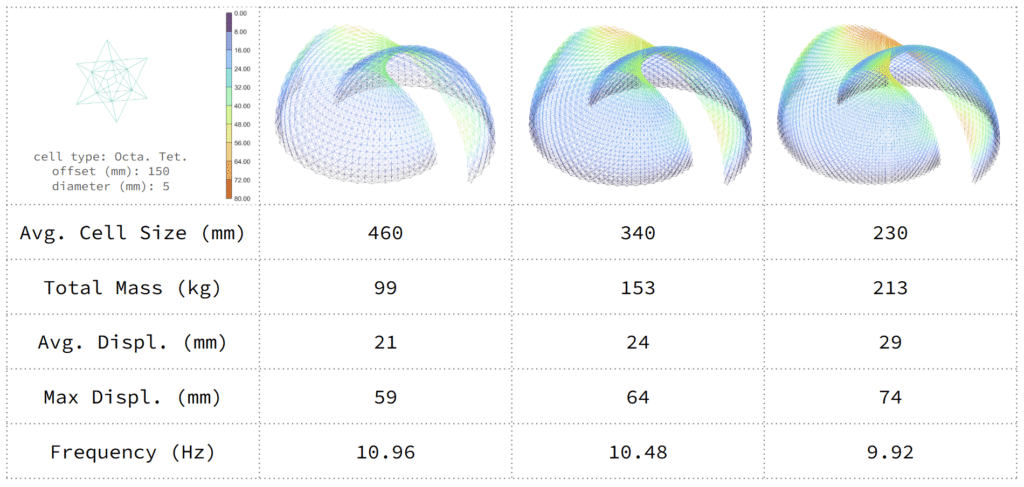

Among the explore cell types, Octa. Tet. showed the best performance in terms of displacement and frequency, even though with almost double mass than Star. Tet. Smaller cells increased both mass and displacement, but fabrication constraints and the small allowable diameters imposed limitations on beam length. Balancing these factors, we selected 230 mm as the cell size, which offered structural reliability while remaining feasible for production.

Optimization Methods

We chose not to use evolutionary solvers, as our aim was to gain a clear understanding of how changes at different scales — from overall geometry to cell topology — affected structural behaviour. Studying parameters independently allowed us to isolate their impact, even if it did not provide a complete picture of how they interrelate. It is also worth noting that the initial form was relatively fixed, shaped both by the brief constraints and by our design intentions.

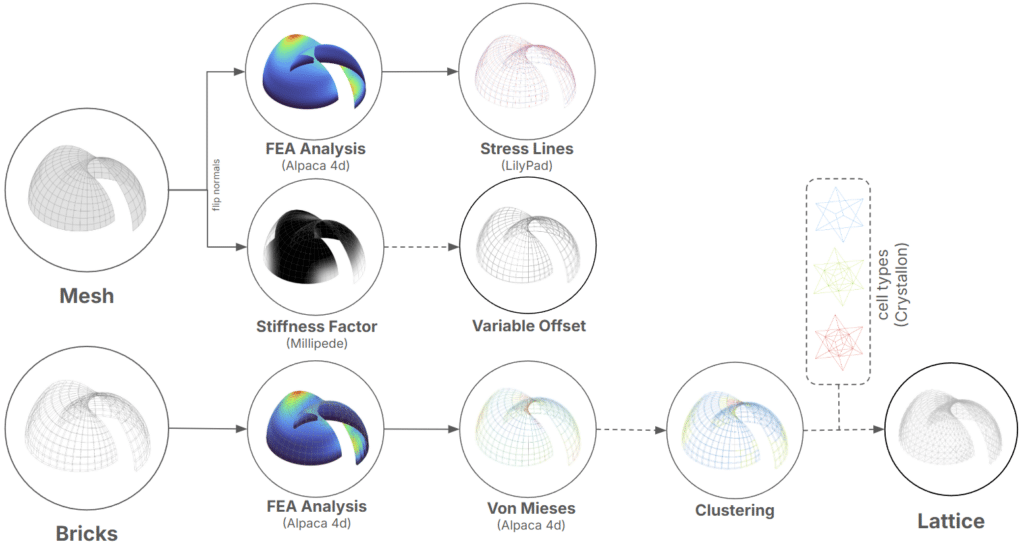

Within this framework, we tested several optimization techniques:

- Shell remeshing along stress‑lines

- Stiffness‑based variable offsets

- Cell clustering and variations based on von Mises stress

- Cross‑section optimization based on utilization factors

Of these, cross‑section optimization proved the most effective, achieving a 73% reduction in mass and a 26% reduction in displacement.in displacement.

Since the original mesh already aligned with stress‑lines, remeshing was unnecessary. Stiffness-based variations in the offset and the cell type depending did not allow to save material without exceeding deflections limits.

Design to production

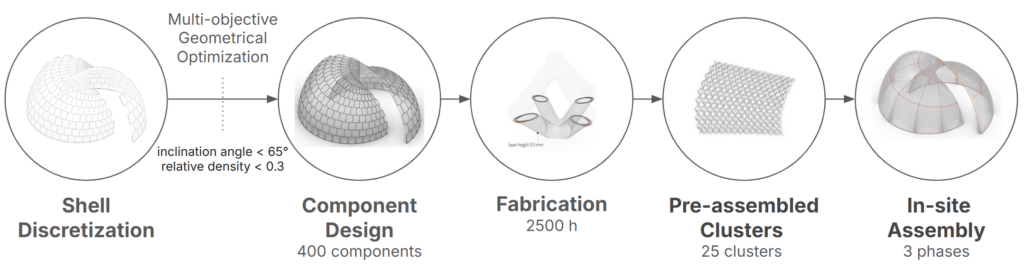

The shell was discretised into 400 components with masonry‑like tessellation, i.e. components of one row are shingled in order to provide a connection discontinuity.

Printing will take about 2400 hours with three Delta WASP 60 × 100 printers. Components are pre‑assembled into 25 clusters, optimised for transportation and then joined on site in three phases. First set of clusters are fixed to the base and the overall structure is fixed to a wooden construction through a set of bolted connections.

Results

Pavilion in Numbers

- Dimensions (m): 8 × 6.5 × 4

- Offset (mm): 150

- Area (sqm): 68.5

- Total Mass (kg): 58

- Elements: 45,120 (avg. length 140 mm)

- Total Length (m): 6350

- Cells: 1,600 (avg. size 230 mm)

- Components: 400

Achievements

The pavilion’s low mass stems from:

- Material efficiency: recycled PET has low density.

- Lattice logic: forces are channelled along stress lines, reducing redundancy.

- Cross‑section optimization: diameters varied only where structurally necessary.

- Biological inspiration: strength achieved through porosity and orientation, not bulk.

Together, these strategies produced a structure closer to textile logic than traditional construction.

Critical Reflections

Despite these promising results, the final weight appears unrealistically low. One likely reason is that buckling analysis was not performed, meaning slender elements may behave less effectively under compression than predicted. Other factors — such as joint stiffness, printing imperfections, or assembly tolerances — could also influence real‑world performance.

Cell size should probably be further reduced, but calculation time limited our exploration. Future work could include multi‑objective geometrical optimization of cells and components for production, with goals such as:

- Inclination angle < 65°

- Relative density < 0.3

This critical perspective highlights the gap between computational models and physical reality. While the lattice logic and material choice are inherently efficient, further validation is essential to ensure that the pavilion’s lightweight elegance can be reliably translated into built form.