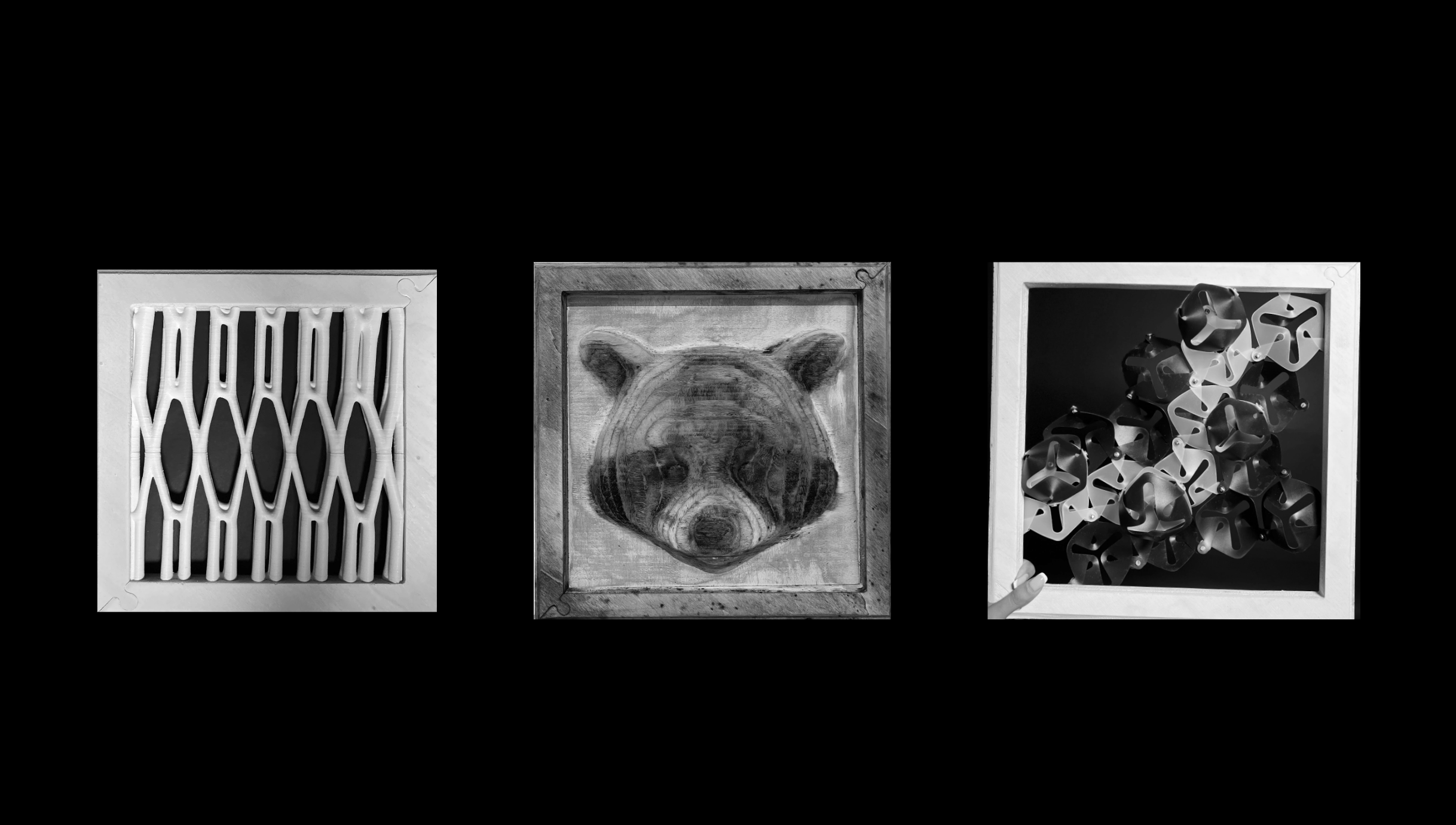

BOUNDARY CRAFT

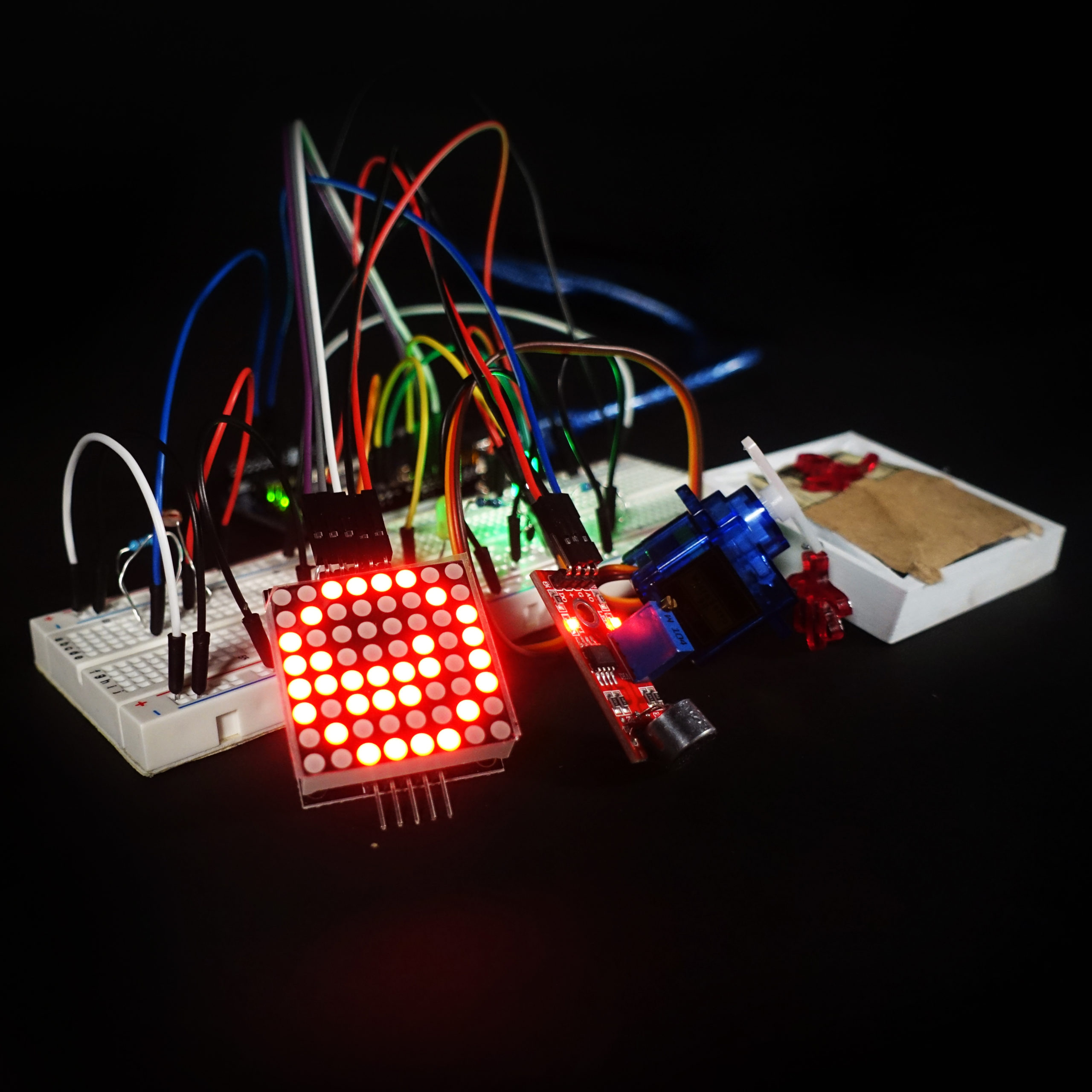

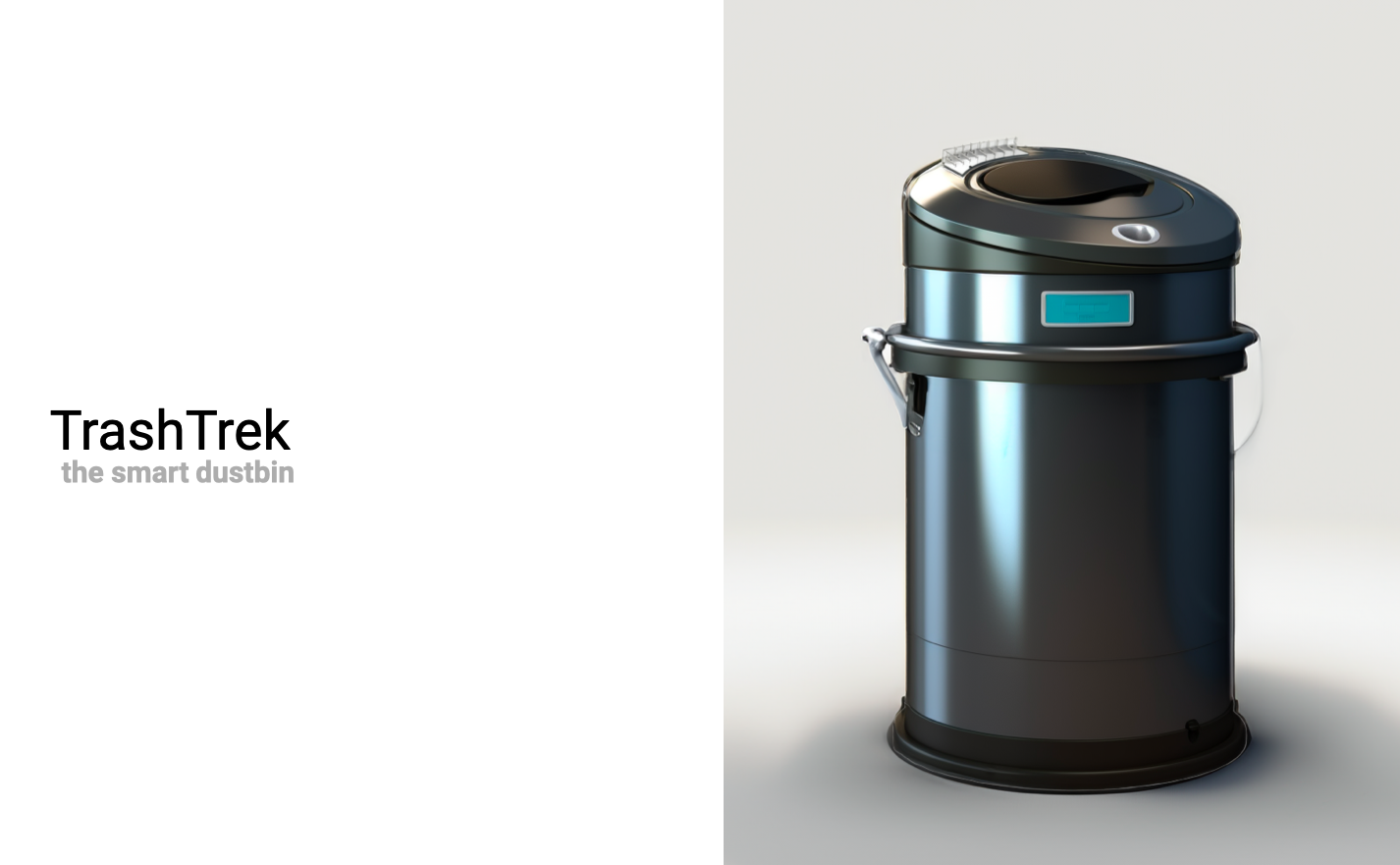

Exploring Dynamic Privacy in Public Spaces through Distance Sensors and Servo Motors This project represents a captivating exploration at the crossroads of programming, physical computing, and spatial design. The central focus revolves around the utilization of cutting-edge technologies, namely distance sensors and servo motors, to craft an interactive partition module. The primary objective is to … Read more