From capturing intricate geometries to enhancing processes, our research emphasizes in innovation in construction and data optimization, showcasing the transformative potential of advanced scanning tools. These technologies not only enhance our ability to capture the intricacies of physical structures but also provide actionable insights for a variety of applications.

Research Topics

1. Fabrication Optimization

We leveraged scanning to improve workflows, enhancing material efficiency in 3D printing, refining timber assembly, and creating sustainable modular systems, enabling precise data acquisition for the enhancement of fabrication processes.

2. Data Optimization

Scanned data is transformed into actionable insights for urban planning, heritage preservation, and real-time monitoring. We focus on creating advanced visualizations and data management systems to tackle complex challenges.

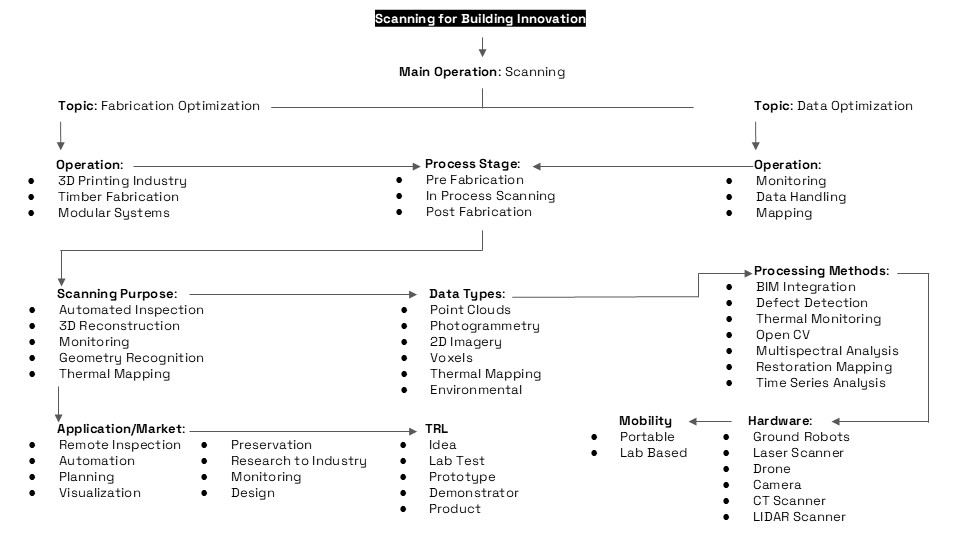

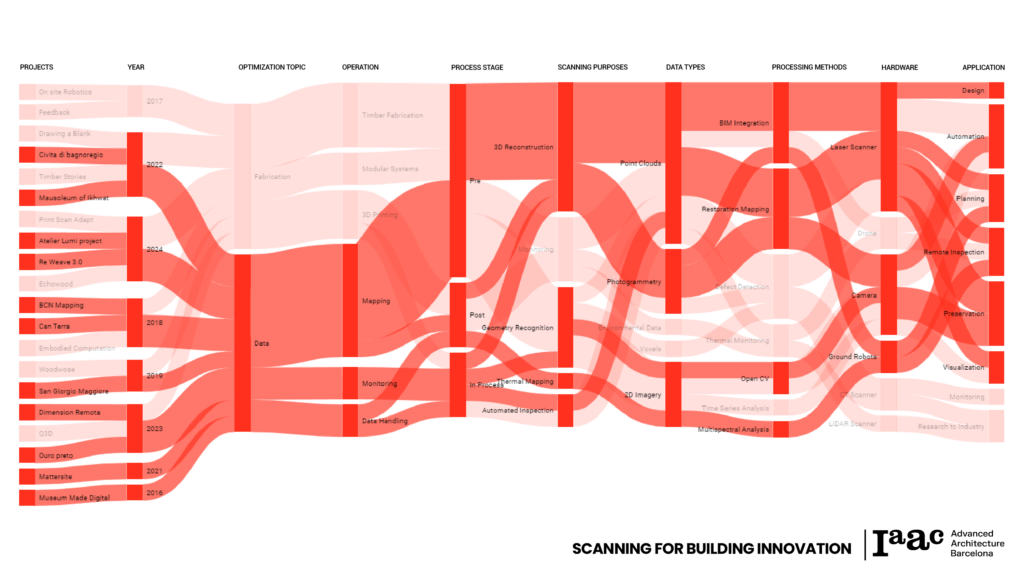

Mapping Structure

We categorized our data visualization framework into 2 topics (fabrication optimization and data optimization) which then we decided to categorize in operations (e.g., 3D printing, monitoring, mapping, etc), process stage in where the scanning is used (e.g., pre-fabrication, post-fabrication), scanning purposes, data types (e.g., point clouds, thermal maps) until the application market of each scanning project. This structure ensures clarity and flexibility for diverse applications.

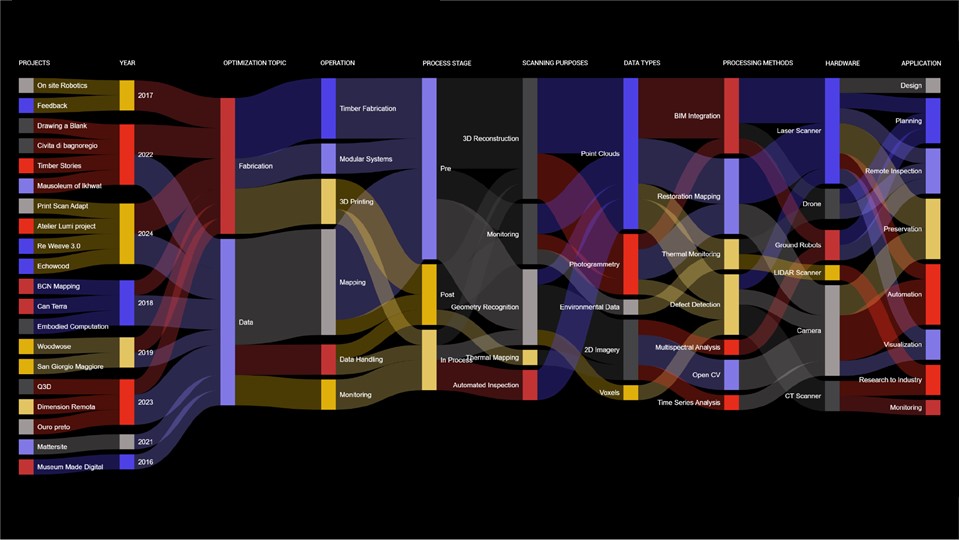

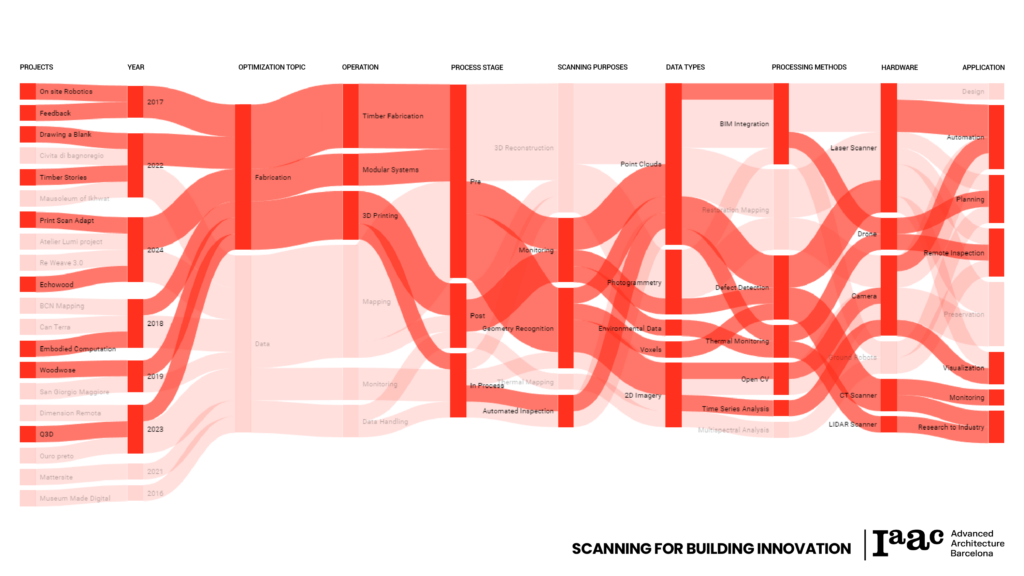

Mapping

Overview of Topic: Fabrication Optimization

We explored how scanning enhances fabrication processes by enabling precision, efficiency, and sustainability. From streamlining timber assembly to real-time extrusion analysis in 3D printing, these projects emphasize the integration of scanning into pre-, in-, and post-fabrication stages, fostering innovative approaches to modern construction.

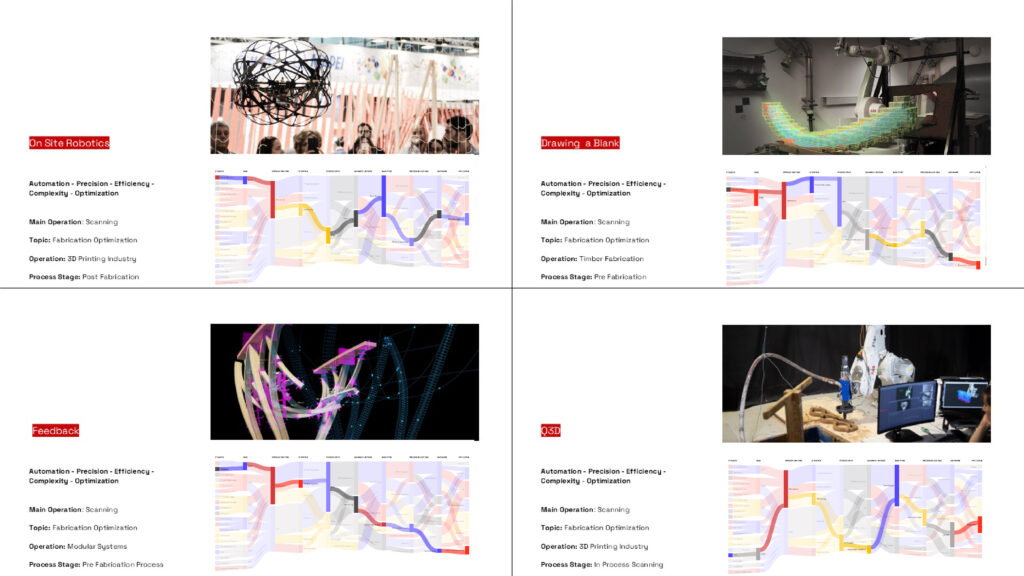

1. On-Site Robotics:

We used drones and 3D printing to generate real-time thermal analysis, improving material performance and reducing manual work in post-fabrication.

2. Drawing a Blank:

Scanning captured timber irregularities to optimize pre-fabrication workflows, reducing waste and enhancing precision in sustainable construction.

3. Feedback:

This project applied scanning in pre-fabrication of modular systems, streamlining data acquisition and enabling efficient assembly of complex geometries.

4. Q3D:

Real-time scanning monitored 3D printing extrusions, improving accuracy and reducing waste with dynamic feedback for optimized fabrication.

Overview of Topic: Data Optimization

Our data visualization projects focus on transforming scanned inputs into actionable insights. By leveraging technologies for mapping, monitoring, and preservation, we provide advanced solutions that enhance understanding of environments, safeguard heritage, and optimize spatial planning for various industries.

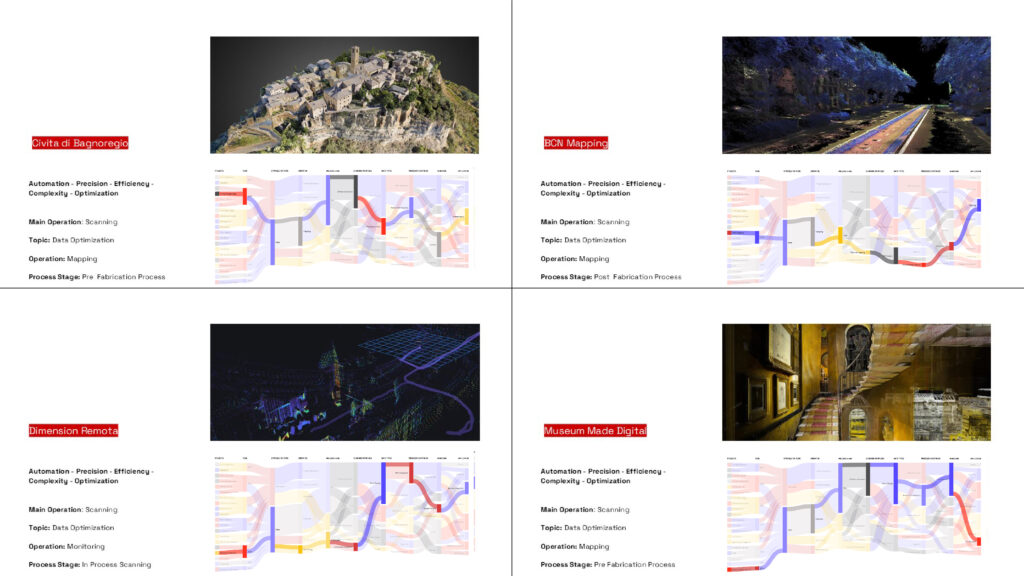

1. Museum Made Digital:

We used scanning to map cultural heritage sites, creating high-fidelity digital records for preservation and safeguarding historical structures.

2. BCN Mapping:

This project utilized scanning for post-fabrication mapping, providing comprehensive spatial insights to optimize urban planning and geospatial analysis.

3. Civita di Bagnoregio:

Scanning large-scale environments allowed us to visualize urban systems, enabling data-driven planning and advanced geospatial solutions.

4. Dimension Remota:

We applied remote scanning to capture real-time data in inaccessible areas, improving environmental monitoring and structural analysis without physical intervention.

Next Steps

In the upcoming semester, we plan to deepen our investigation into the integration of scanning technologies with 3D printing processes. Our focus will include exploring innovative scanning methods to enhance precision, monitor fabrication in real-time, and optimize material usage. This research aims to uncover how scanning can support adaptive manufacturing workflows, reduce errors, and improve efficiency in advanced construction techniques. By applying these insights, we seek to contribute to the evolution of smarter and more sustainable 3D printing systems.