AGENDA

The objective of this course was to design elements for the upcoming exhibition Macquina Climatica, in Parque de la Ciutadella, renovated to serve as an exhibition space; this historic precursor to the emerging paradigm of urban agriculture is currently under construction. For this course, our group was assigned to design a table 4.5m long with a map of Europe engraved in it showcasing various greenhouse projects all over the continent, which acts as the harvest table in order to keep the yield produced during the exhibition.

INSPIRATION

To start the assignment, we started looking for references and inspiration, one of the books that we referred to was “NEAR A THOUSAND TABLES” – FELIPE FERNANDEZ-ARMESTO. The book describes the different ways a table integrates itself in the lives of people. We were especially inspired by the use of a table to gather harvest, which we considered to be something close to what we wanted to design for this course.

Apart from that, we studied the tables available in Valldaura House, in order to understand the proportions and the convenience of using the table.

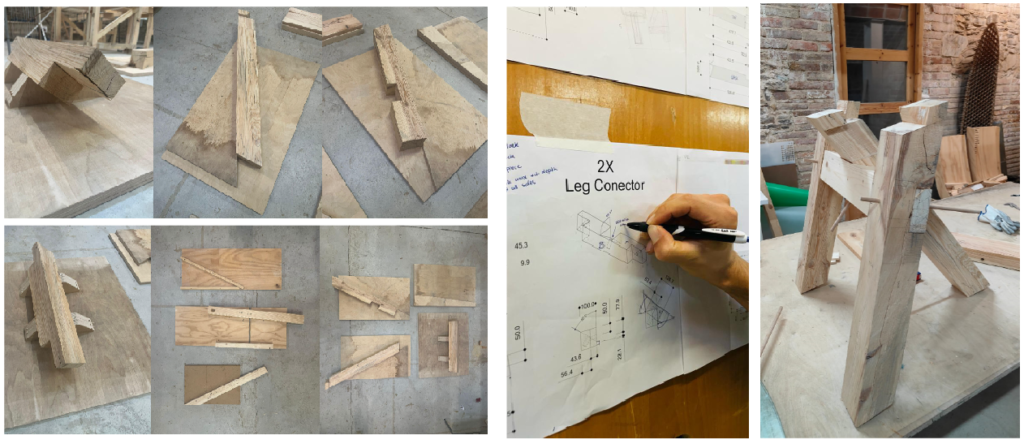

We also explored a few joinery details in order to eliminate using glue and screws. Various traditional woodworking methods, such as mortise and tenon joints, dovetail joints, and lap joints, could be employed without the use of glue or screws. These techniques rely on the precise shaping of wood to create strong and stable connections. Also the use of dowels provides the stability required for the structure.

EXPLORING THE DESIGN

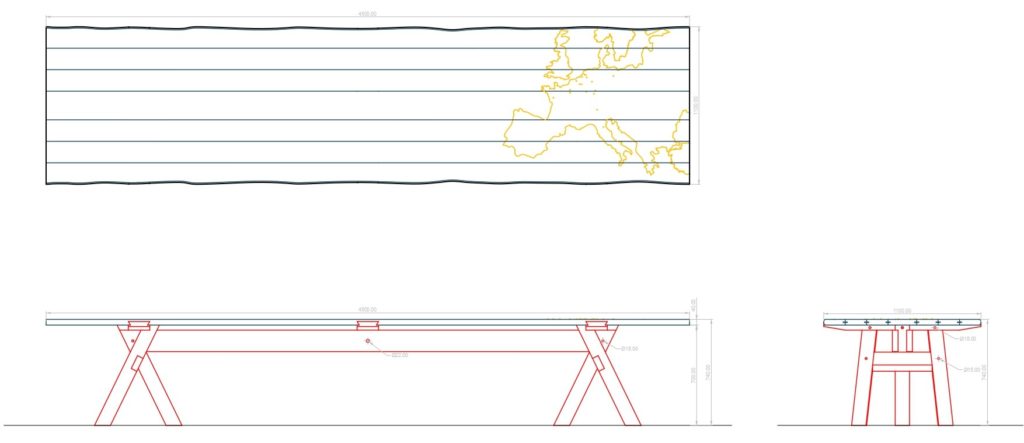

To begin with, we started sketching out various shapes that we could use to design the table top. One of the key factors we considered was the distance between people sitting opposite to each other. The idea was to provide a comfortable space between them to have a conversation, yet not too close that they have no personal space. After much deliberation, we settled to have a width of 1.1m for the table, with a rectangular shape.

We wanted to highlight the natural aspect of the wood and decided on having live edges (natural curvature of the tree laminate). We also decided to showcase the traceability markers on one side of the table as an homage to the quest that it underwent in order to become that particular part of the table.

TESTING AND PROTOTYPIG

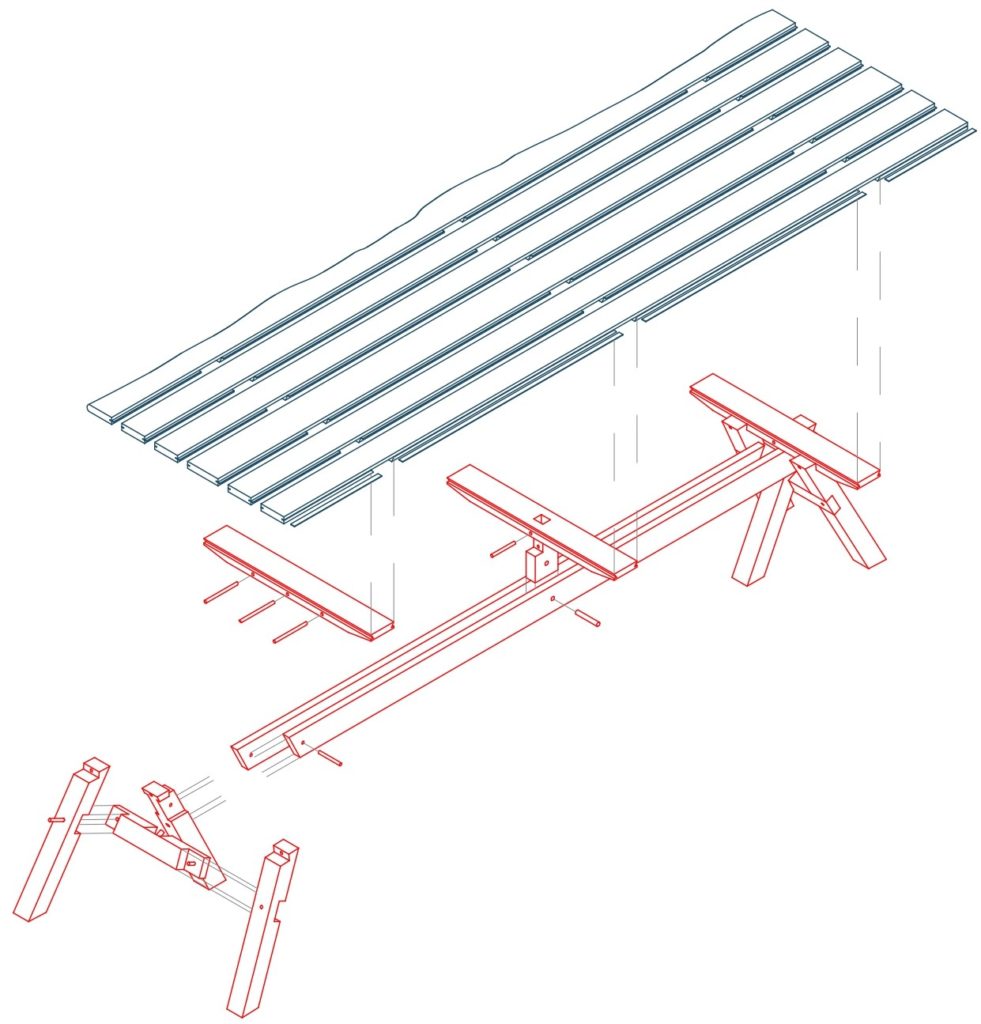

We started testing and prototyping different aspects of the design. We began with exploring out how to construct the structure of the table, by prototyping the legs. Our main goal was to eliminate the usage of glue and screws in order to keep the table purely made out of wood. We tested various joints to understand the strength and stability of the legs.

We also tested out the detailing of the Europe map on the table top, using the CNC Machine. We decided to engrave the map on one end of the table. With the CNC machine, we experimented with various depths and thickness of the drill bit to come up with the most aesthetically pleasing imprint.

WOOD PROCESSING

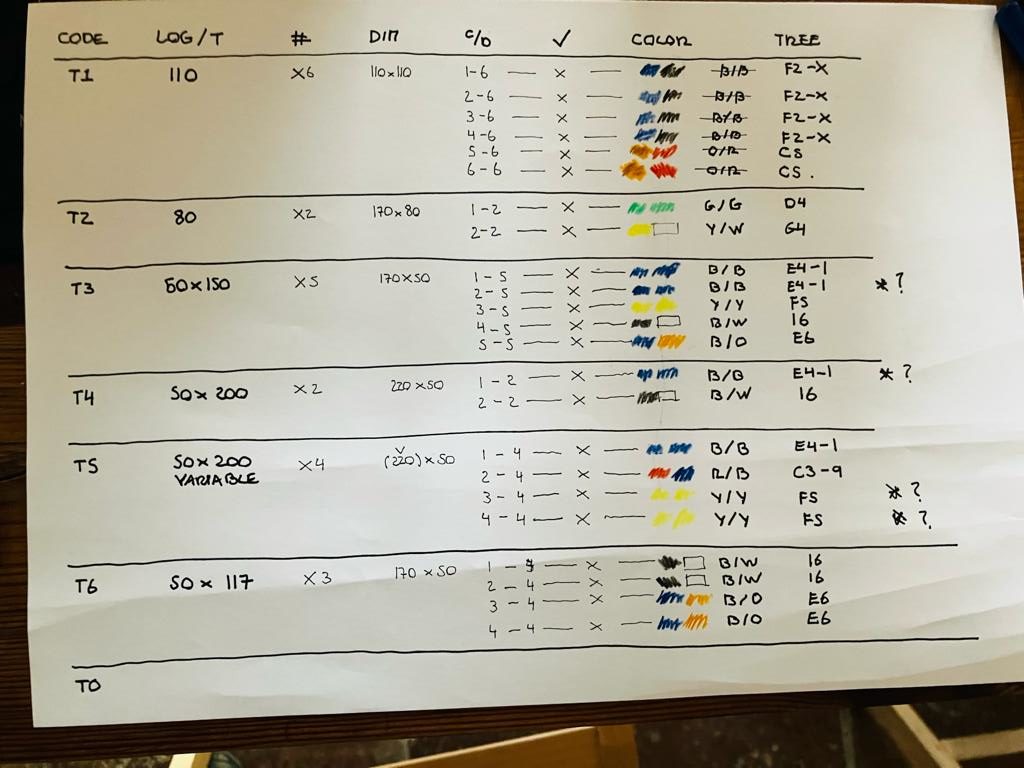

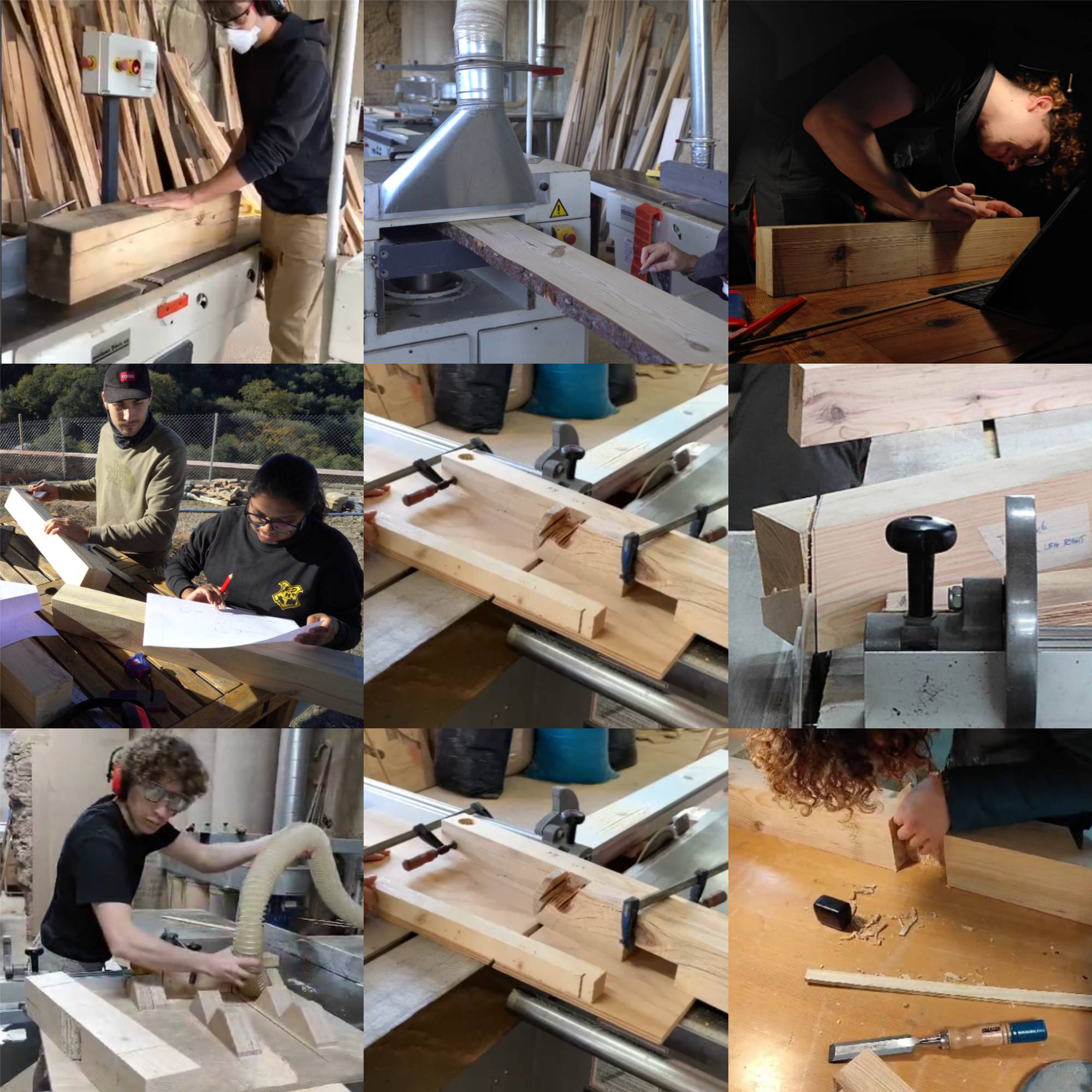

For this part of the project, we started with cutting the wood on the milling machine. We marked each cut piece with a different indicator in order to trace out its origin. Once all the pieces were cut, they were sent to dry out in a kiln.

THE FINAL CONSTRUCTION

The last phase of this project started with processing the dried wood. First we sorted out the pieces used in different parts of the table construction, and started planing and thicknessing the logs that would be used to make legs. Once that was done, we focused on constructing the structure first, by processing and shaping the stretcher and cleats. Then to refine and sculpt some of the parts we chiseled out the excess wood to create proper contours on the wood.

The process of designing and constructing a table made of wood is a rewarding journey that blends craftsmanship, functionality, and aesthetic appeal. From the initial design process to the hands-on construction, every step contributed to the creation of a unique and timeless piece of furniture. We learnt that crafting a wooden table involves not just an interesting design, but also thoughtful choices in materials, construction techniques, and execution skills.

In essence, the conclusion of this journey is more than a finished table—it’s a manifestation of passion, skill, and the timeless beauty of wood.