Introduction

Trencadis is a form of Mosaic art formed and developed by Architect Antonio Gaudi using discarded broken tiles. This was done by hand back then of course. Nowadays , with progress in the development of technology, robotics are nowadays used in accurately stacking bricks upon one another, 3D printing as well as placing pieces to form a pattern. This is where Trencadis comes into this project because in this weeks seminar, students used computation design to form a Trencadis pattern , which is physically built using a robotic arm.

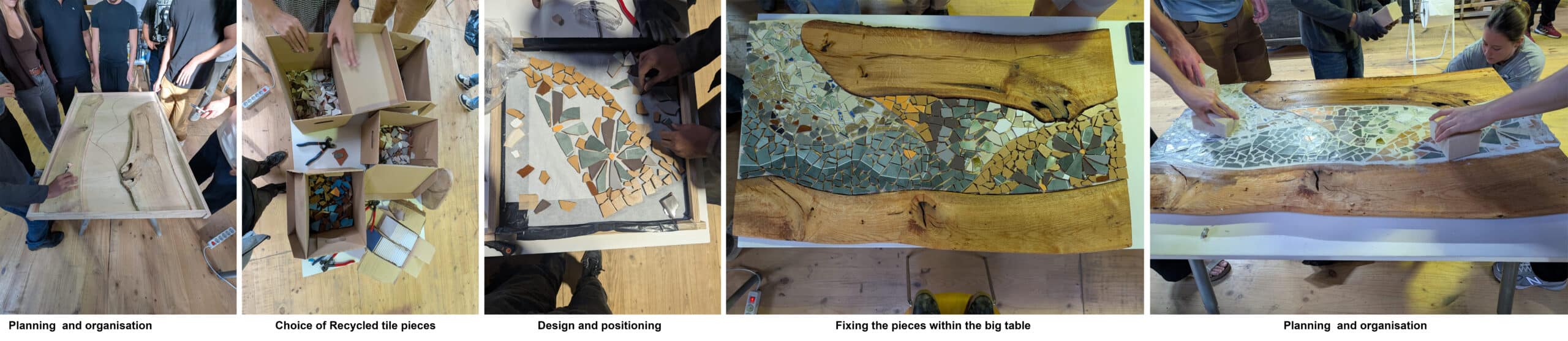

Hands-On Trencadis-Workshop with artist Evan Powell

In a guided workshop led by Barcelona-based ceramic artist Evan Powell (Brass Wheel Ceramics), he explained trencadís fundamentals: intuitive breakage for edge interlocking, color flow in assembly, and adaptive patterning echoing Gaudí’s organic mosaics.

We fractured ceramic tiles using hammers and pliers, sorted by hue , and assembled a river tabletop prototype—a surface with flowing tile “river” inlays to study the material process.

Powell’s bespoke ceramic expertise bridged craft intuition to robotic scalability for the checkerboard mosaic.

Ideation

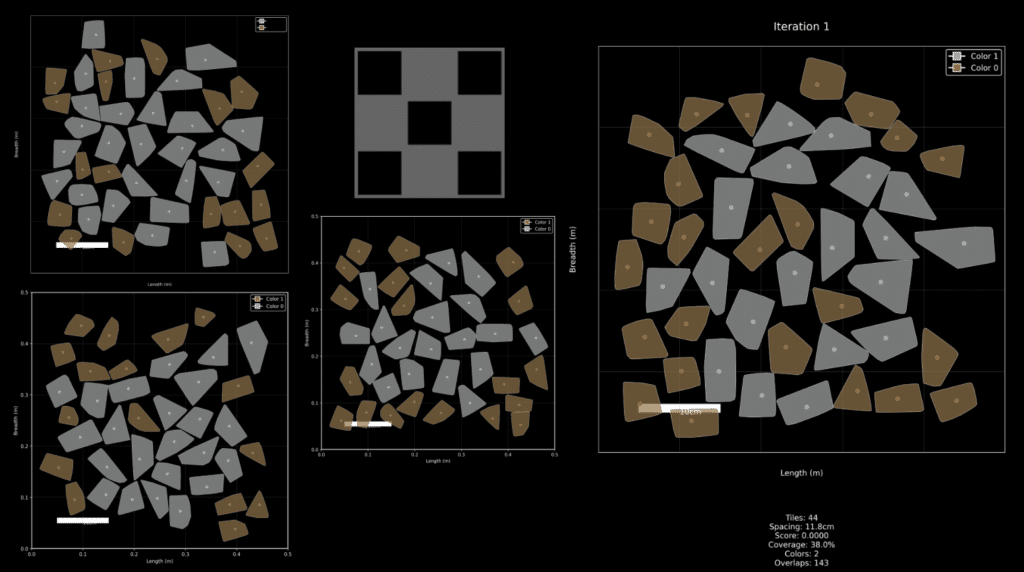

A checkerboard for its simplicity- assumed to be part of a conical surface —alternating brown and white squares (e.g., 4×4 grid)—to highlight the tension between geometric rigidity and the organic, irregular shapes of broken tiles. Parametrically, we used Rhino/Grasshopper to map scanned tile geometries onto the grid, accounting for variations in size/shape (5-10cm fragments).

Challenges included ensuring edge alignment within 5-10mm tolerances to reduce gaps; solutions involved algorithmic sorting by color and orientation. This strategy explores how manual processes can become parametric, enabling scalable designs for architectural applications like facades or floors.

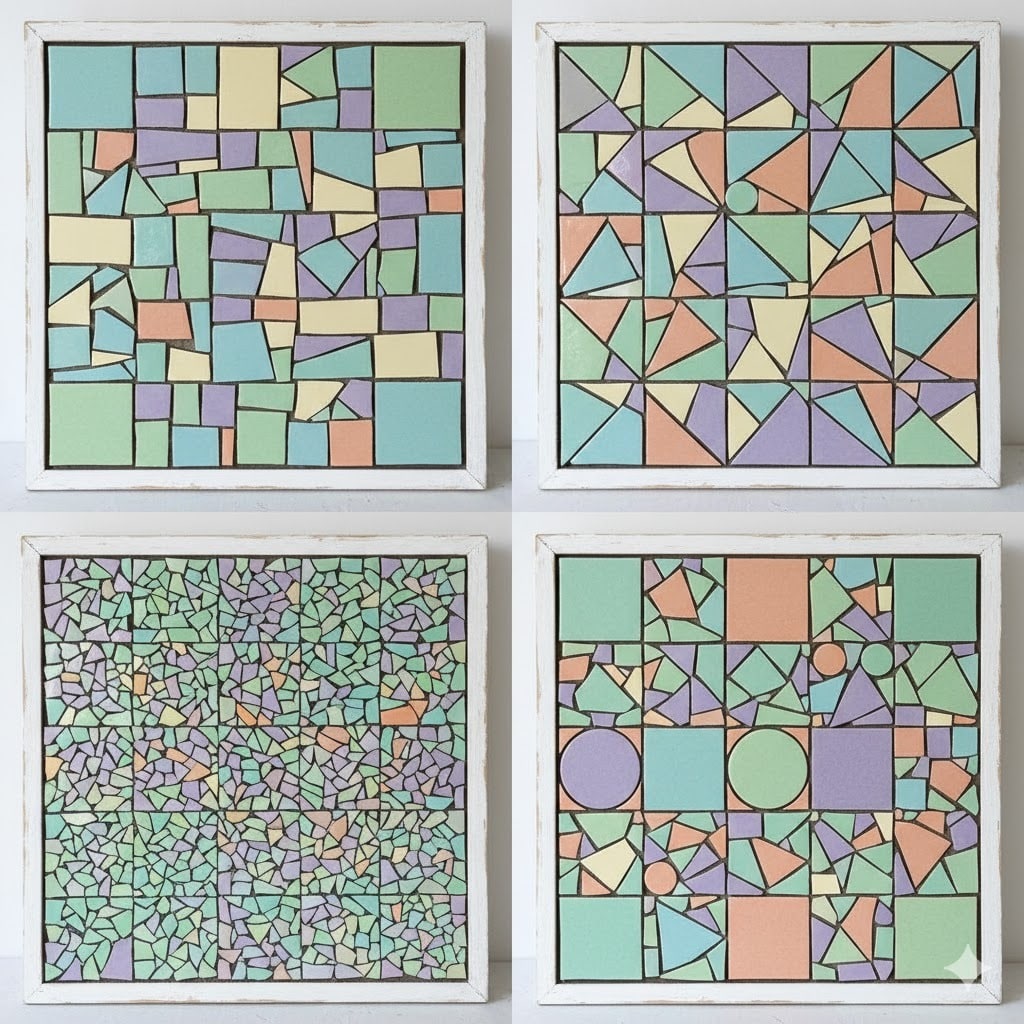

Our initial aspirations and design concept showing trencadis organized into the checkerboard for a flooring application

Algorithmic Iterations

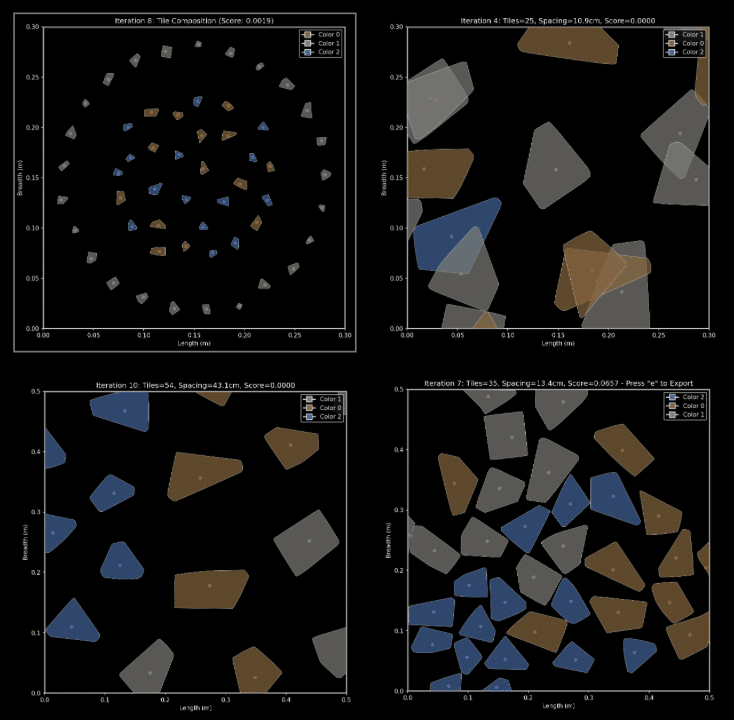

Iteration #1 Iteration#2 Iteration #3

Iteration #1

-Started experimenting with a simple linear grid

-Tested several variations of parameters to analyse: right from distance of the pieces up to rotation of pieces

-Pieces would manage to fit each other with taking consideration of negative spaces being formed

-Two sets of grout color would be used to form a checkered like pattern to compliment the selected colored ceramic pieces

Iteration #2

-Same grid structure was used but reduced to 4 panels

-Parameters used- reducing the space between the ceramic pieces, testing several rotation values and later using seed parameter to generate options

-Parameters used to further analyse which option has maximum use of pieces fitting with each other as well as reducing negative spaces, covering the whole tile space

Iteration #3

-Third iteration similar to the first but with change of grid lines matching perspective grid, causing the squares to change in area size

-The ceramic pieces, through changes in parameters from distance between pieces and orientation , managed to form a blend of jigsaw puzzle connection and stacking on each other to cover maximum space of each grid shape

-Two sets of colors were selected to act as background for the added pieces

Fabrication & Workflow

The fabrication process began with manual fragmentation during the bootcamp, where we broke ceramic tiles into brown, white, and gray pieces using hammers and pliers. We sorted these fragments by color and studied edge interlocking. This hands-on phase provided tactile insight into material behavior, forming the foundation for digital translation. The team aimed to prepare a diverse tile set to support the checkerboard color alternation, despite initial consistency challenges.

Building on craft skills, the team learnt to operate the robotic fabrication pipeline, utilizing 3D scanning to capture tile geometries and programming the UR10 robot for precise placement. This involved understanding data processing in Python to refine models, ensuring accuracy.

Additionally, we synthesized physical and digital workflows, integrating scanned tiles with parametric designs to create a cohesive mosaic.

Scanning and translation

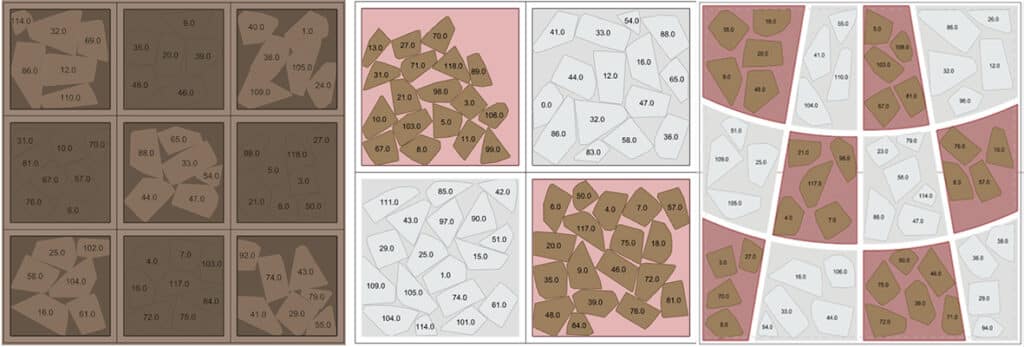

- We used Lidar scanning on Mechmind to capture the 3D geometries of broken tiles.

- Using Python, we processed point cloud data to remove noise and create accurate digital models.

- These were imported into Rhino, where Grasshopper scripts mapped the available geometries onto the checkerboard grid, adjusting for size and orientation.

- This step bridged physical fragments with computational precision, though some alignment issues persisted due to tile variability.

Emergent compositions

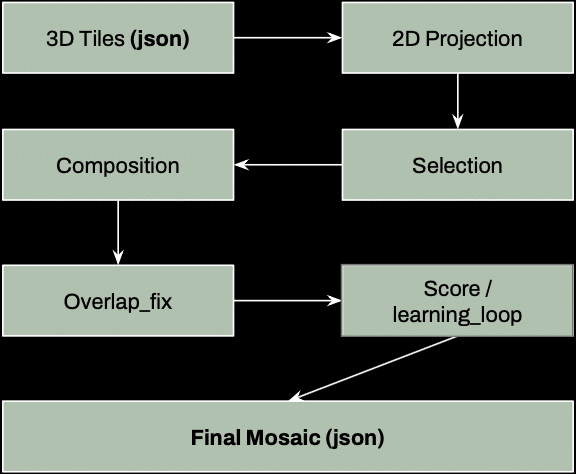

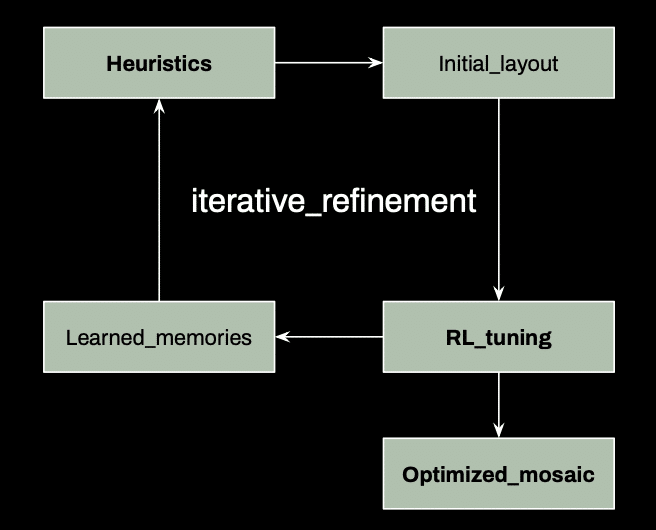

Moving beyond static algorithms, we wanted to explore blending heuristics (rule-based “instincts”) with RL (adaptive “learning”) to mimic the creative process.

Designs emerge intelligently, balancing aesthetics like an artist refining sketches. It’s valuable for scaling human creativity with AI: efficient, personalized, and innovative beyond manual methods—unlocking endless variations for real-world applications

Process: Projects 3D tiles to 2D, selects balanced subsets, arranges with harmony, resolves overlaps, and scores for beauty.

Key Feature: Adapts to user-defined goals (e.g., grayscale patterns).

Outcome: Dense, non-overlapping layouts with artistic flair.

Heuristic aesthetics

The core idea behind our aesthetic heuristics is to score tiles for visual appeal, focusing on coverage, scale, color harmony, curvature continuation, balance and symmetry. The approach rewards tight packing while penalizing overlaps and gaps, and it boosts goal alignment for personalized designs.

This magic touch adjusts dynamically for user patterns, ensuring each mosaic feels unique and cohesive. The impact is profound: it creates mosaics that feel natural yet optimized, turning raw tiles into harmonious art.

Heuristics and RL

The connection between heuristics and RL is seamless: heuristics provide the foundational rules for initial layouts, while RL fine-tunes them for perfection. In practice, initial rules like packing guide RL to focus on critical areas such as overlaps, creating a collaborative dynamic.

The benefit lies in combining human-like design intuition with AI-driven optimization. This synergy delivers consistent, evolving beauty in every run, showcasing how the system adapts and excels.

Future Improvements

- Looking ahead, our Trencadis AI could evolve by integrating more advanced RL like PPO (Proximal Policy Optimization) for smoother parameter tuning in continuous spaces, enhancing adaptability beyond Q-learning.

- We might extend to 3D surfaces or curved architectures, using vector projections for real-world builds. Adding user feedback loops would allow interactive refinements, blending AI with human creativity for personalized art.

- Efficiency gains could come from GPU-parallelized overlap resolution, handling larger datasets swiftly.

- Expanding to diverse materials or styles (e.g., stained glass) could broaden applications, fostering emergent designs in sustainability or digital twins—pushing AI from tool to collaborative artist.

Proposals and Ideas

These proposal envisions deploying the recycled checkerboard trencadís mosaic—as an immersive flooring element in any required setting .