Solid vs. Soft

How can an object low in inherent solidity still be structurally present and define architectural space?

This question lies at the heart of The Pneumatical Incrustation. Developed for the Complex Forming Seminar, this project explores the fundamental contrast between the solid and the soft. The goal was to investigate how “soft” forms could not only inhabit a space but define it, creating a dialogue between the rigidity of traditional architecture and the fluidity of pneumatic structures.

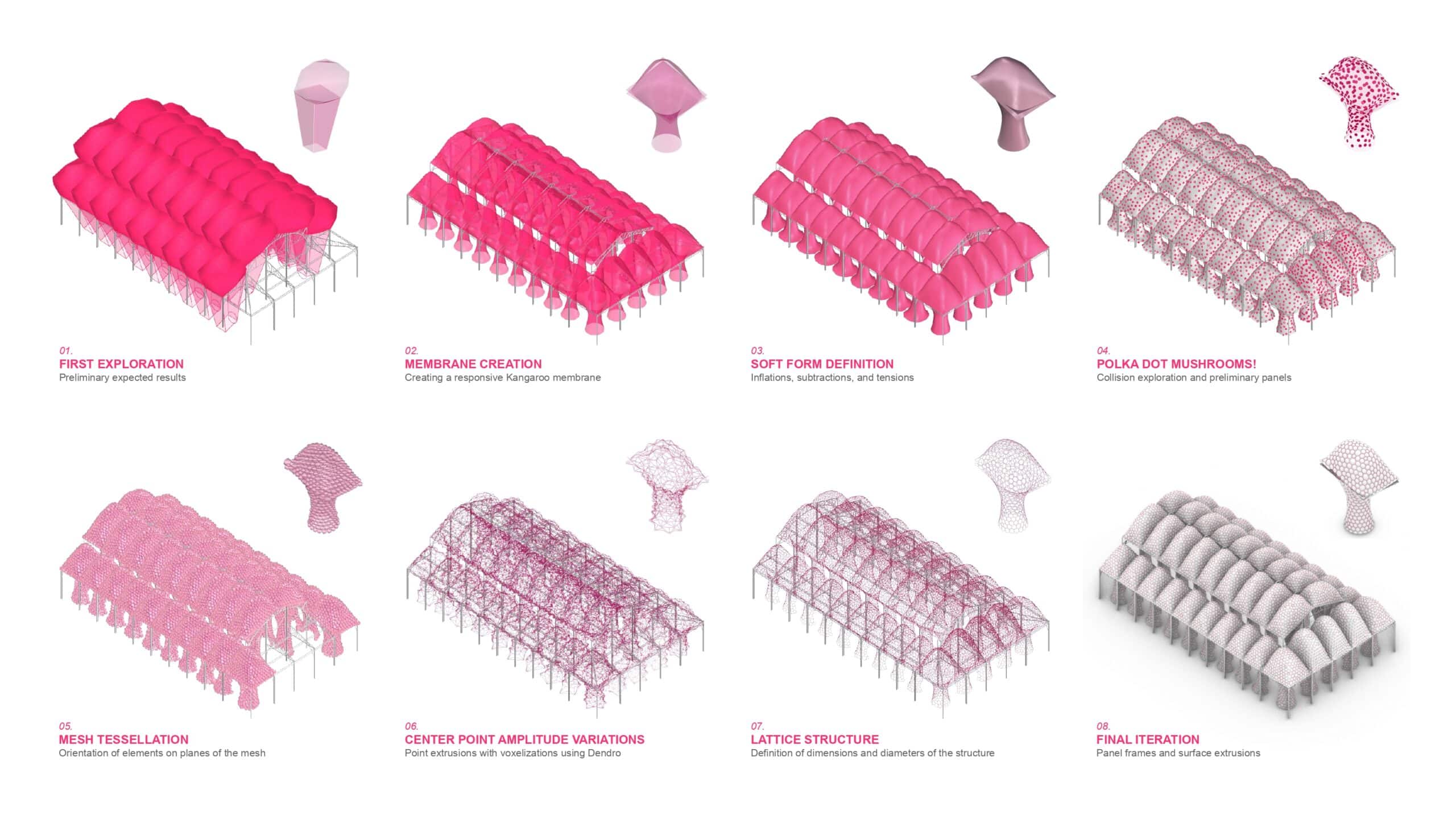

The Computational Challenge

Early explorations in the design process focused on utilizing tools like Kangaroo to generate complex free-form geometries through physical forces and responses. While these simulations created compelling forms, a significant hurdle emerged: standardization. Transforming complex, organic geometry into a constructible reality—specifically regarding panelization—proved to be a major challenge.

To solve this, I shifted toward a computational design methodology that balances complexity with quantifiability. I developed a pseudo-code that generates a membrane capable of hanging downward (creating columns) while simultaneously inflating upward (creating domes).

The Form-Finding Process

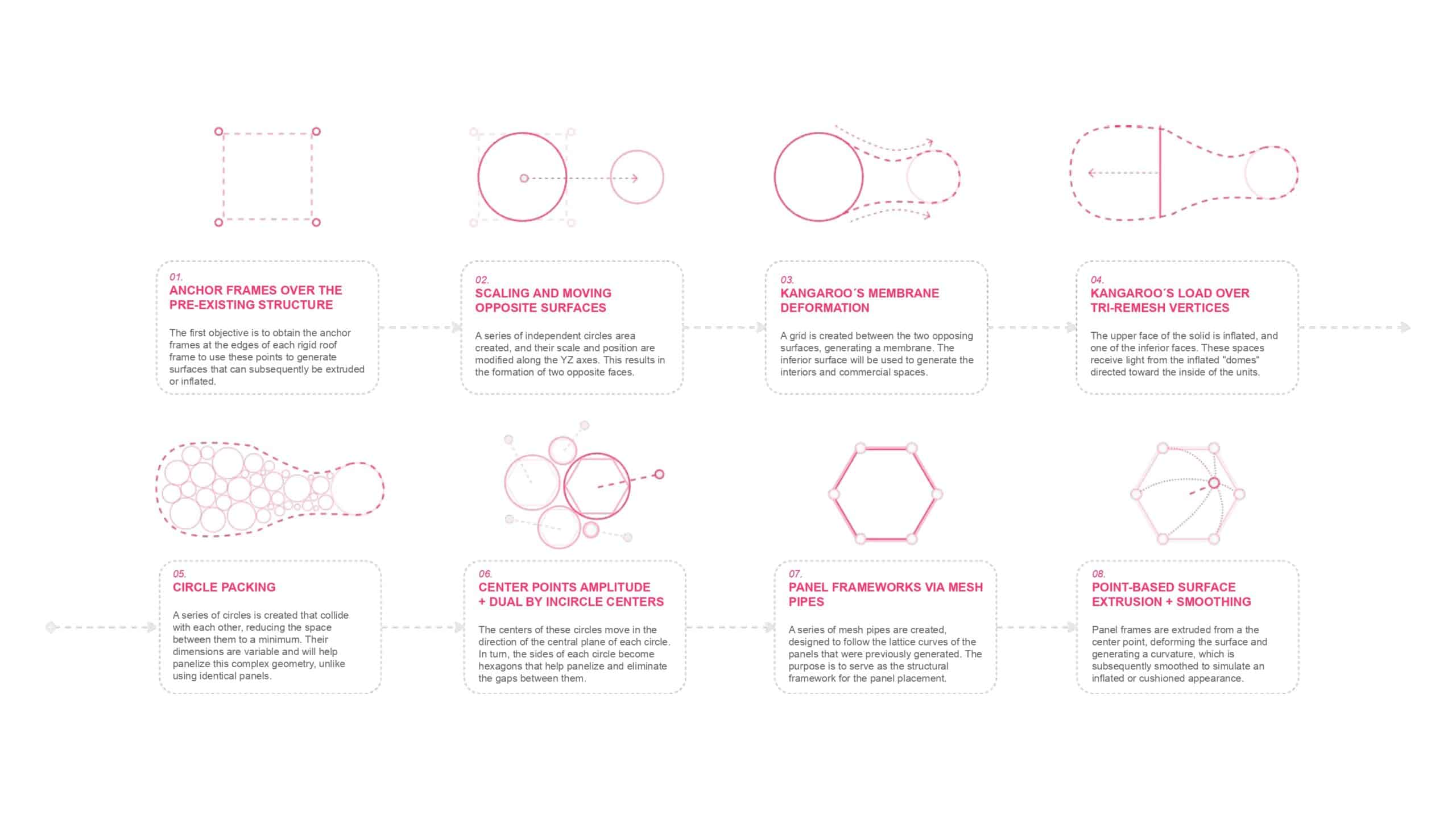

The geometry is not arbitrary; it follows a rigorous, step-by-step computational logic:

- Framework: A horizontal frame is created and subdivided along the structure’s existing grid.

- Inverse Extrusion: The mesh is extruded downwards to reach the ground, anchoring the form.

- Membrane Generation: The mesh is relaxed into a smooth membrane, forming column-like structures.

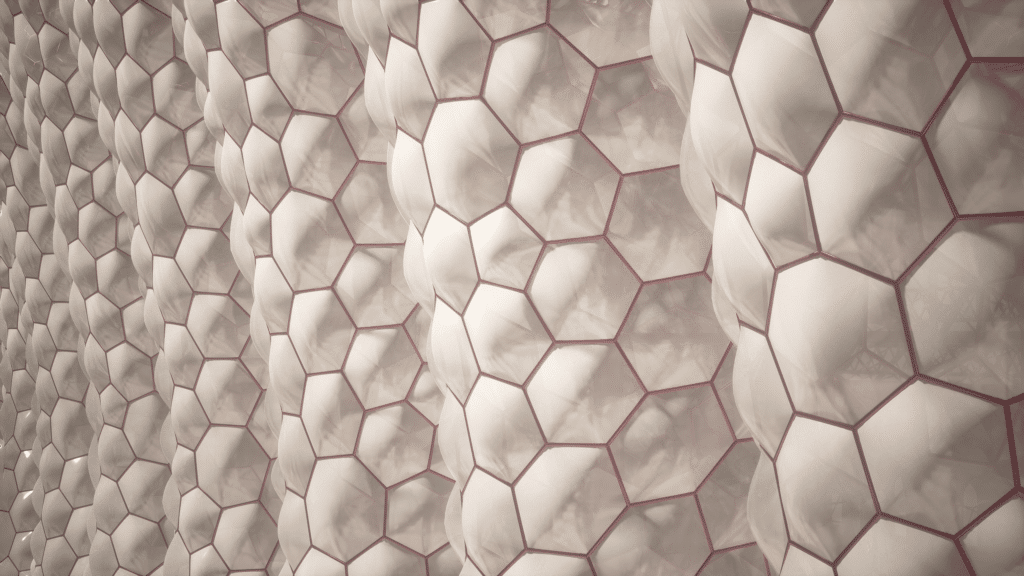

- Inflation: A negative load is applied to the upper mesh, generating the characteristic inflated, dome-like appearance.

- Trimming: The mesh is strategically trimmed to define openings for the shops below.

- Panelization: A Kangaroo definition generates circular collisions. These circles are then joined to create hexagonal panels using a ‘Dual by Incircle’ logic.

- Detailing: Each hexagon is processed by extruding its center point along its normal vector and smoothing the surface to create a pillowy, pneumatic aesthetic.

- Final Assembly: The system is populated across the grid, geometry is baked, and frame borders are added via mesh pipes.

Parametric Iterations

The beauty of this system lies in its adaptability. The final form was driven by four adjustable parameters:

- The structural descent of the columns.

- The inflation of the upper domes.

- The surface panelization density.

- The inflation magnitude of the individual panels.

By tweaking these inputs, the project can adapt to structural weights and constraints, resulting in a variety of potential forms.

Revitalizing the Context

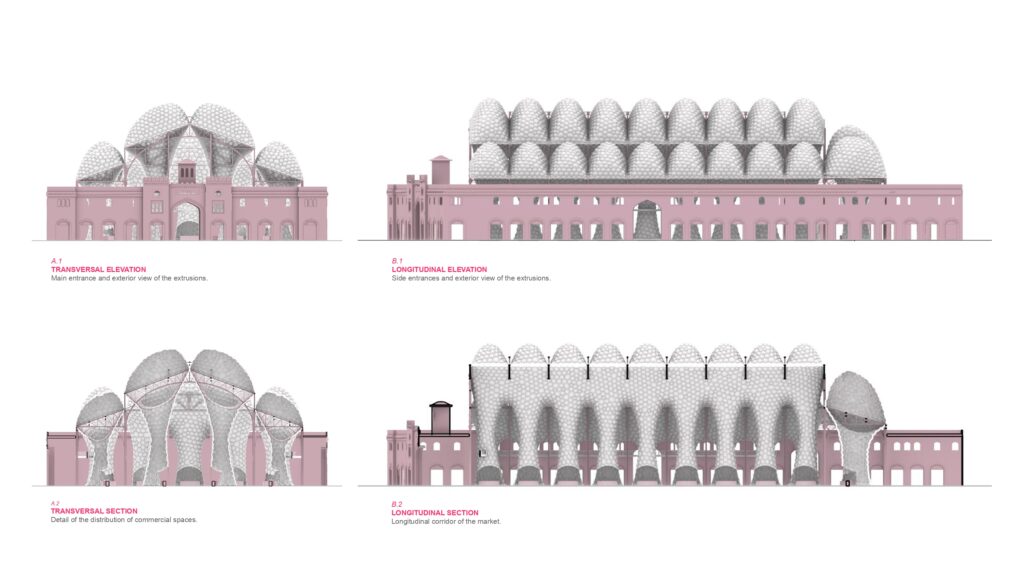

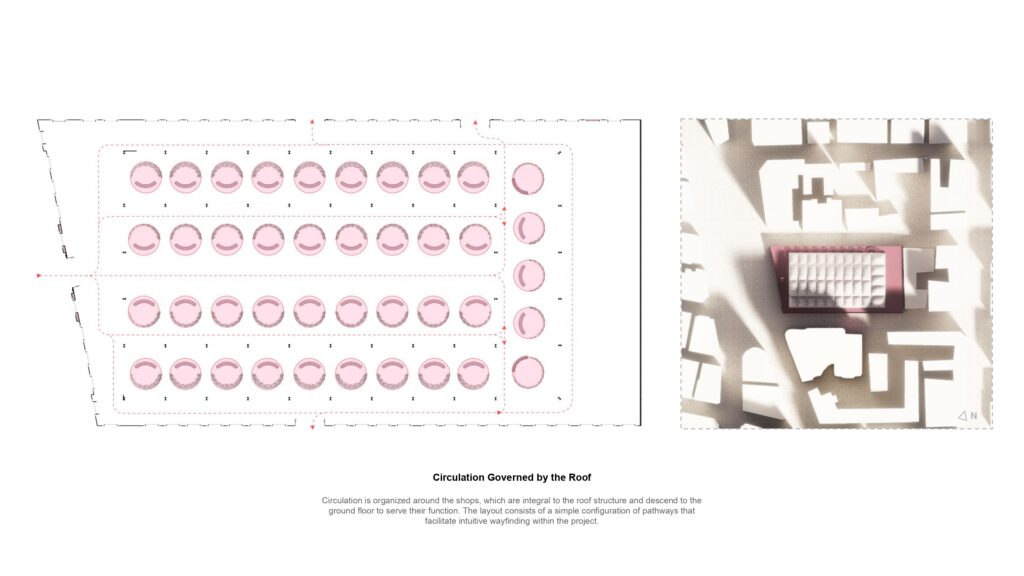

The site strategy applies this new system directly onto a decaying market. Rather than demolition, the project uses the pre-existing structural grid as a foundation for a modern transformation.

From the exterior, the volumes appear as extrusions emerging from within, hinting at the commercial activity below. Inside, the “pneumatical incrustation” creates a distinct spatial experience. The upper faces of the inflated mesh provide shade and filter diffused light deep into the space, while the lower faces descend to sculpt intimate interiors for shops and corridors.

The Resoulting Atmosphere

The Pneumatical Incrustation proves that we can revive neglected historical contexts without erasing them. By merging the rigid history of the site with a new, soft modular lightness, we create an architecture that is both respectful of the past and boldly forward-looking.