In today’s architectural landscape, digital fabrication has significantly expanded the way we design and construct building elements—offering unprecedented accuracy, efficiency, and formal freedom. Techniques such as laser cutting, CNC milling, 3D printing, and robotic manufacturing each bring distinct advantages in terms of material behavior, geometric complexity, and performance potential.

RE:CELL

Concept

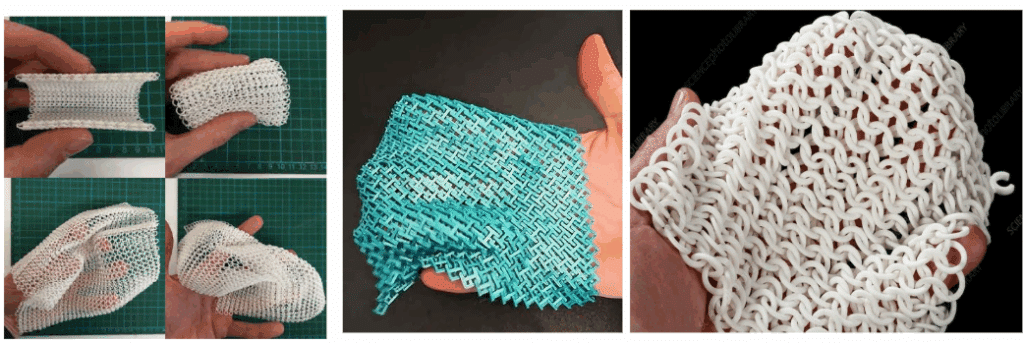

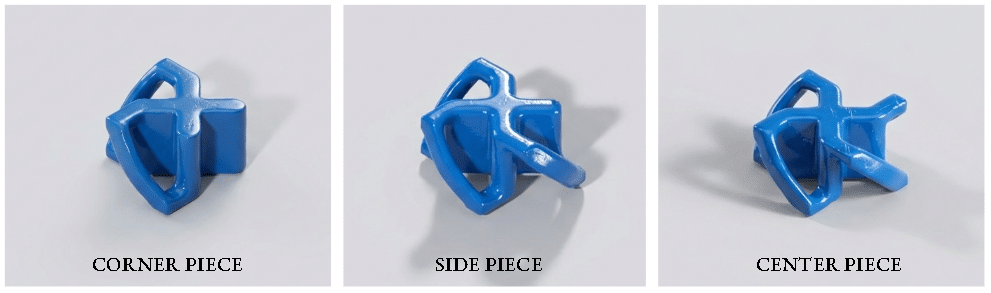

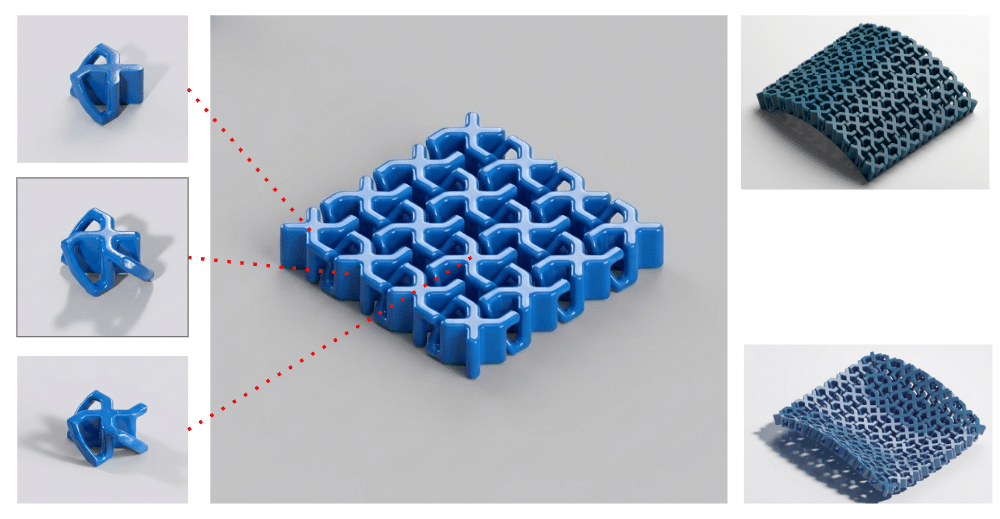

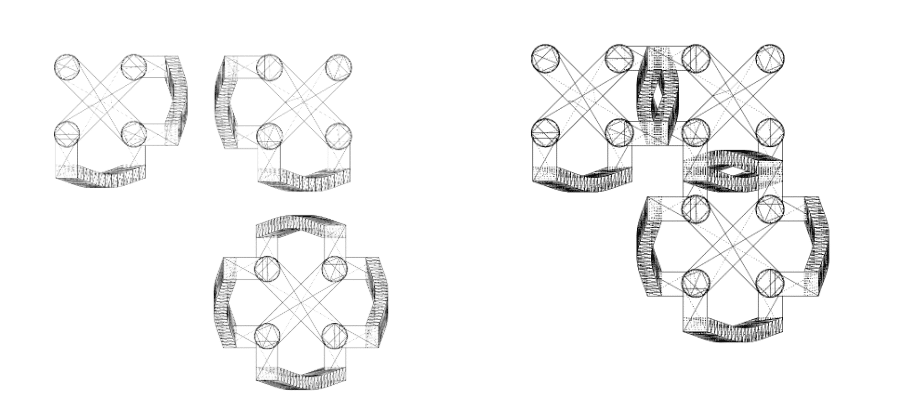

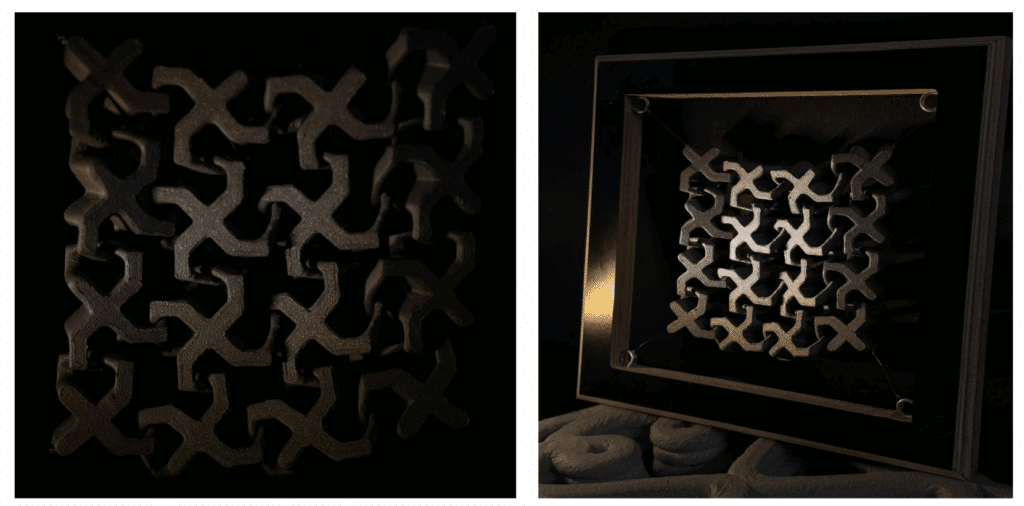

The Re:Cell is a 3D‑printed modular node designed to shade. Each module can interlock with others to form a breathable facade, an interior partition and a design installation at any given space. Due to its curved jointing points, the module can adjust to various shapes. When placed on a flat surface, it becomes flat. If its lateral sides are supported, it can transform into a vault, and when suspended, it floats according to the length of the strings.

Project Diagram

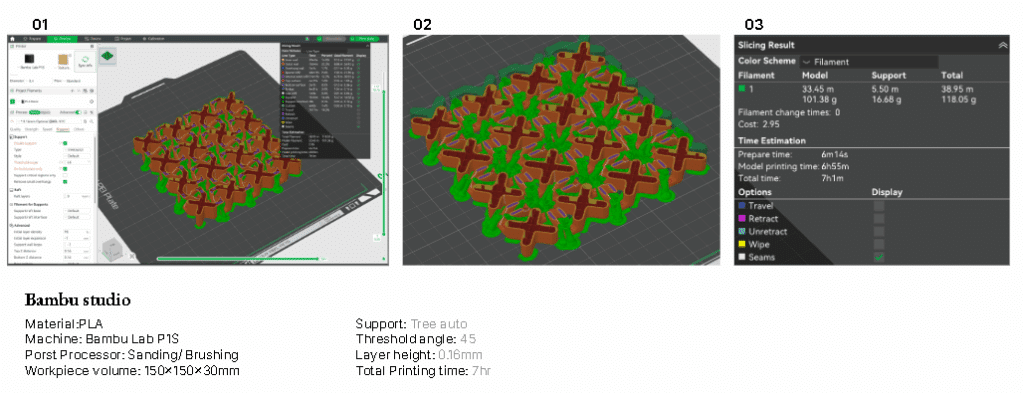

Fabrication Strategy

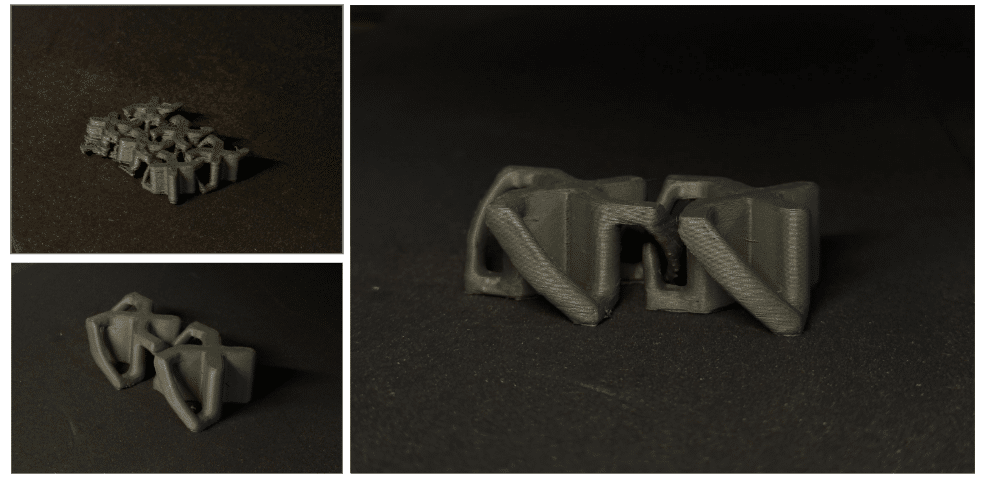

Prototype pictures

LASER CUTTING

Concept

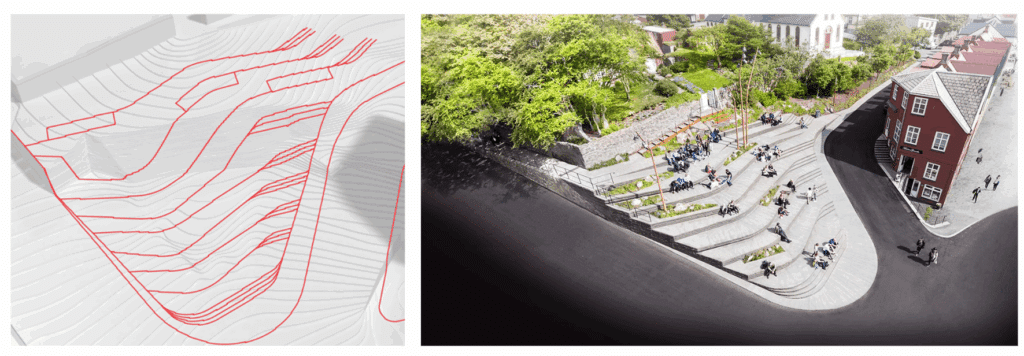

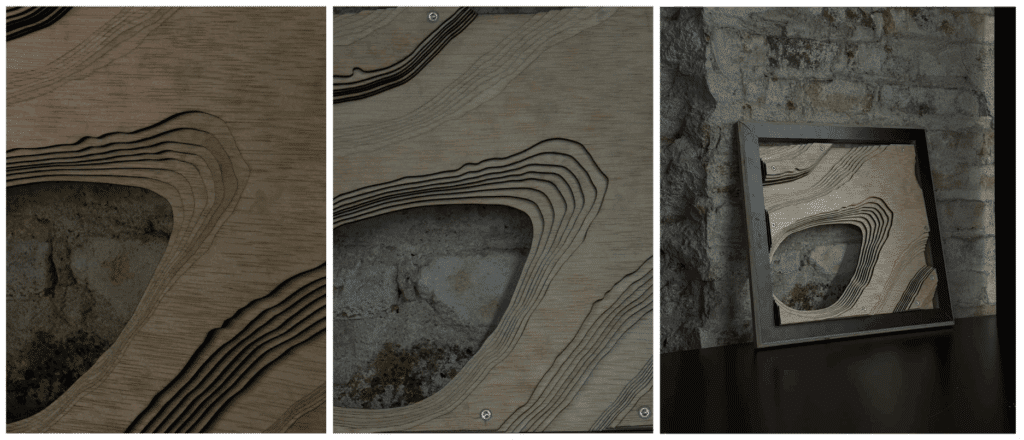

In a manner akin to the project Trappan í Vágsbotni executed by ZETA Architects, which converts an underutilized area into a public space, this project investigates the integration of natural forms to develop a variety of tiered urban spaces capable of accommodating diverse activities. The various layers, arranged atop one another, generate a range of widths and heights, facilitating both the separation and gathering of individuals to fulfill this purpose.

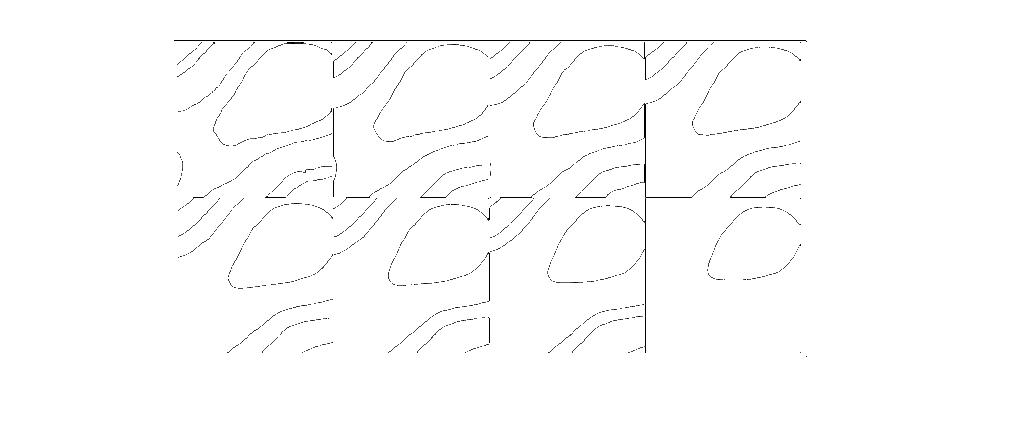

Project Diagram

Prototype Pictures

TRI-HEX

Concept

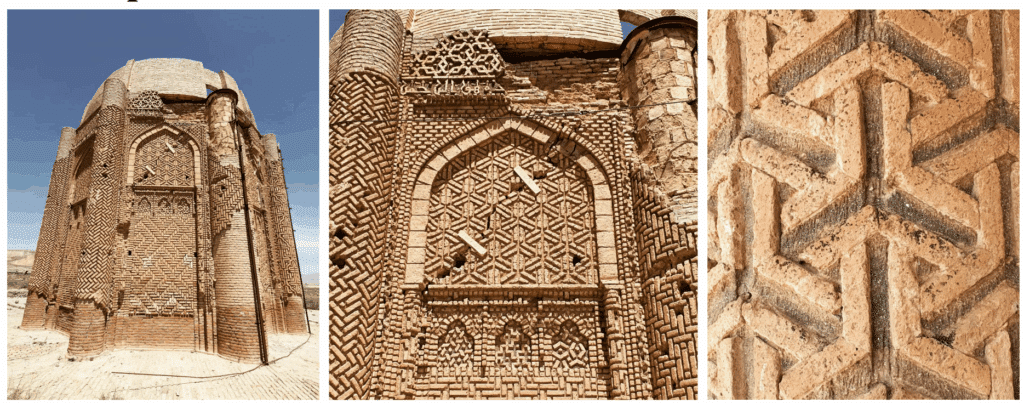

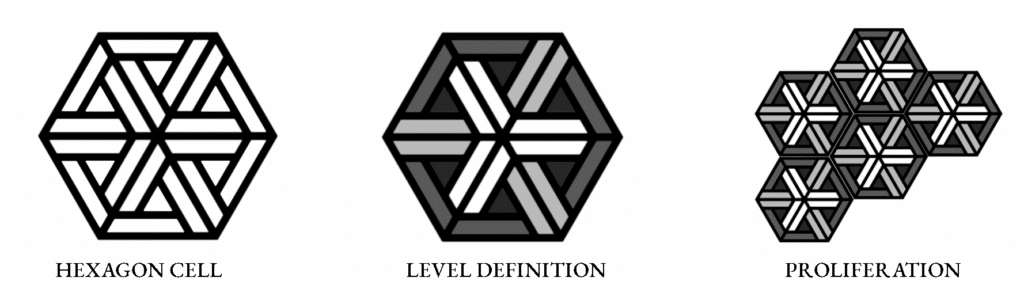

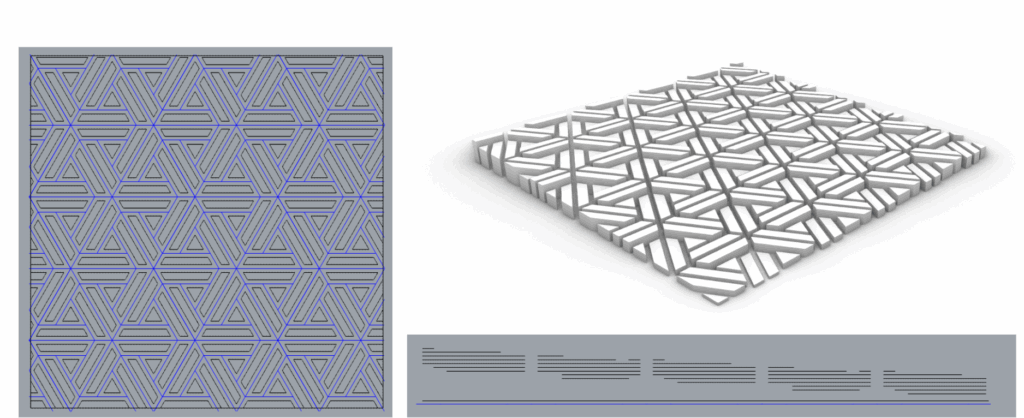

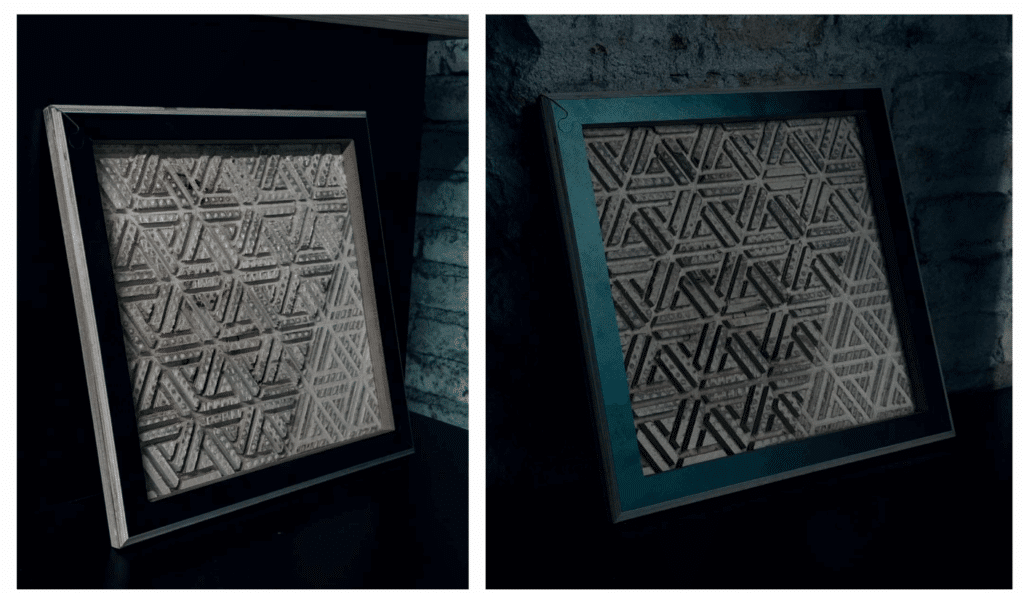

The Kharraqan Towers, constructed in 1067 and 1093 CE in the Qazvin province of Iran, are distinguished for their exceptional display of brick geometric ornamentation. The design they inspired features a hexagonal cell segmented into triangles that rotate around the center of the hexagon. The resulting surfaces from this segmentation are arranged at varying levels to enhance the dynamic interplay of shadows, which aids in the recognition of the pattern. The final stage involves replicating these elements to adorn a facade.

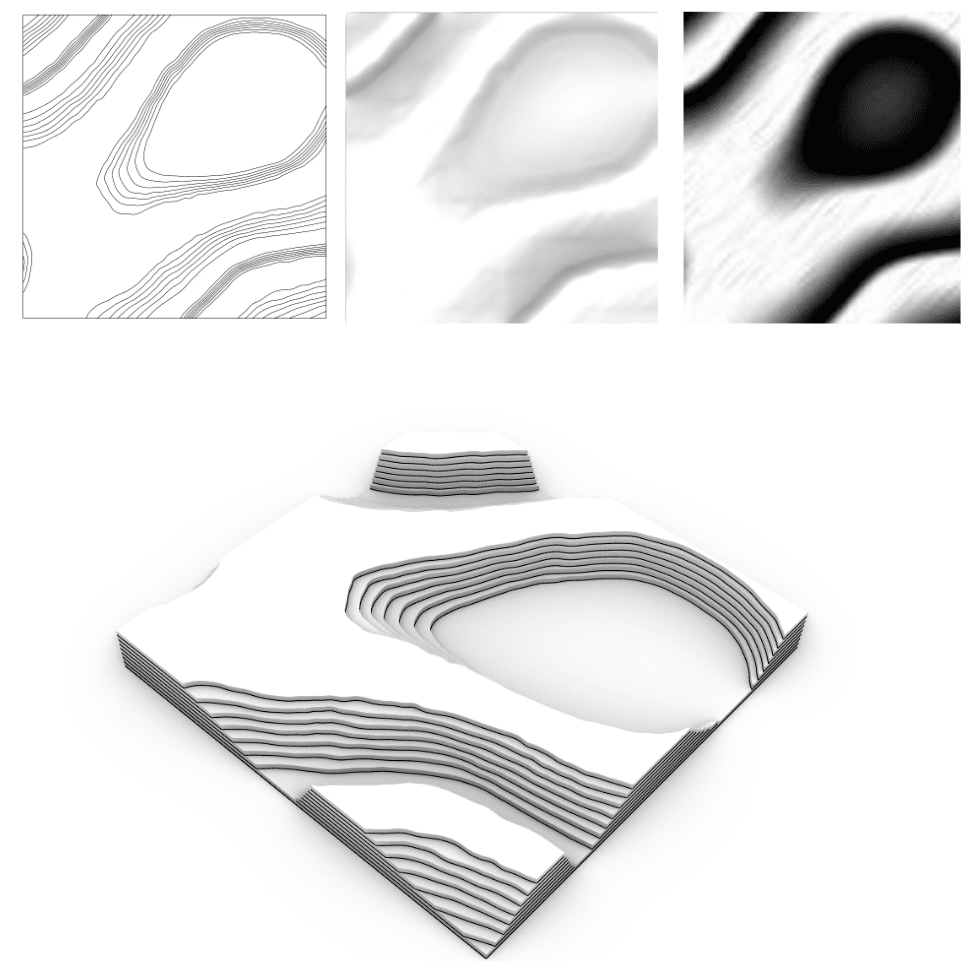

Project Diagram

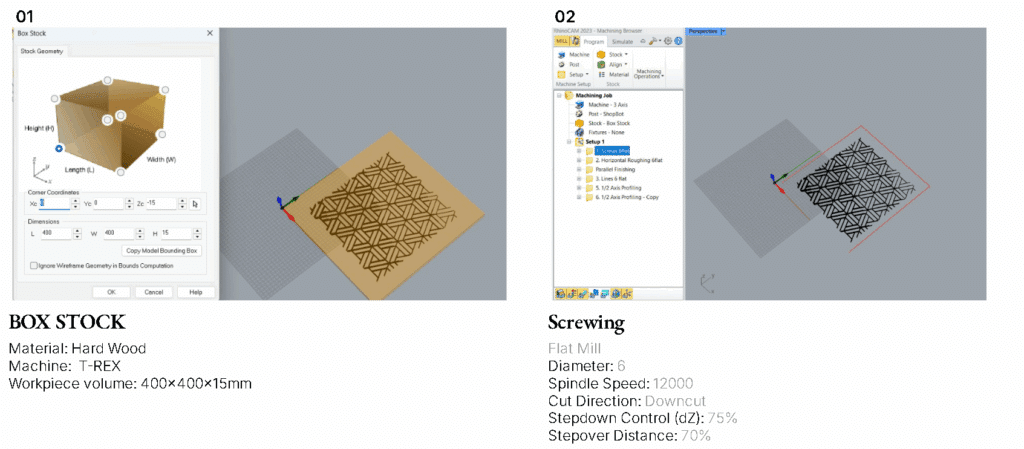

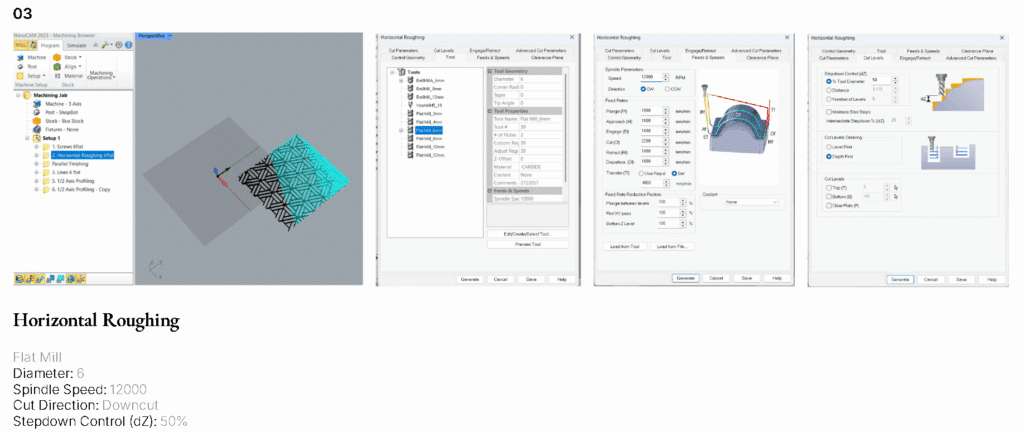

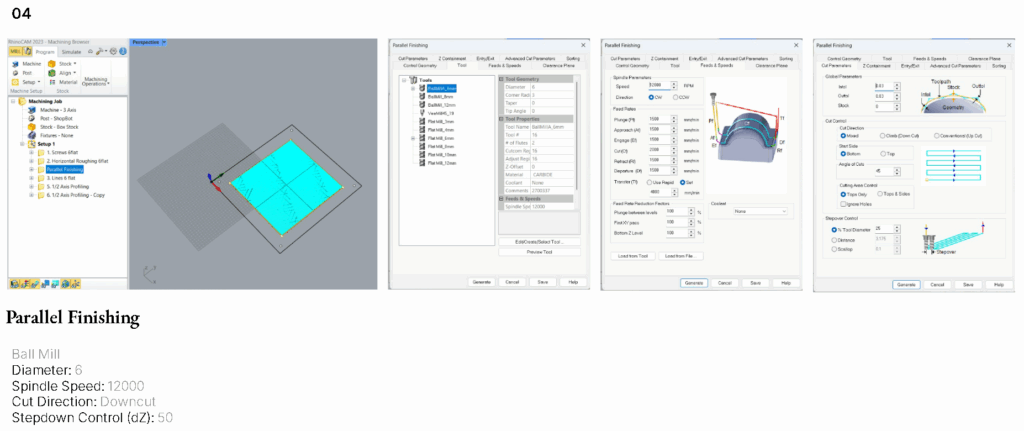

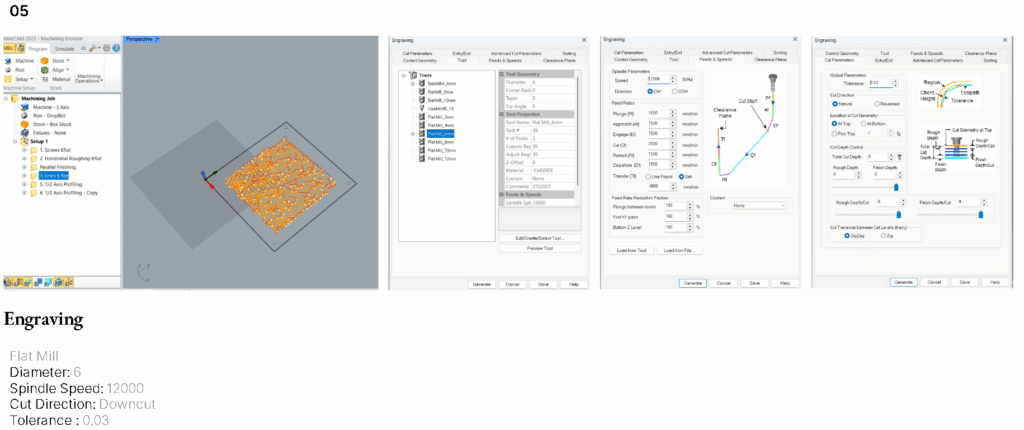

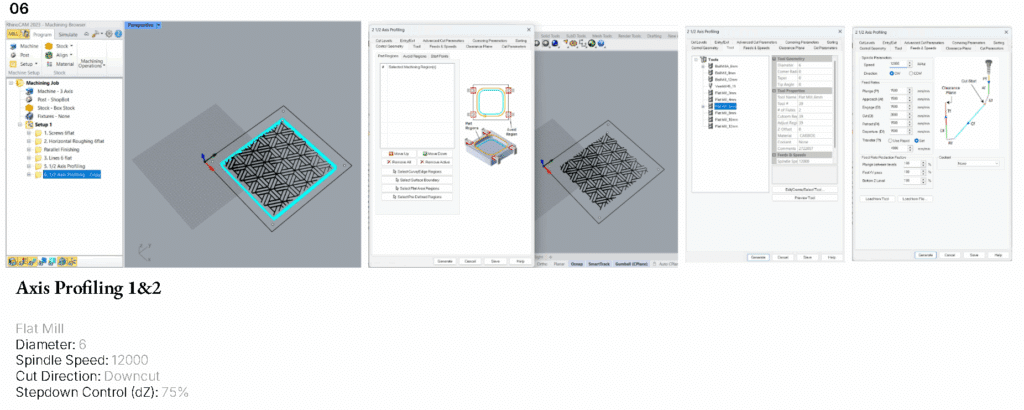

Fabrication Strategy

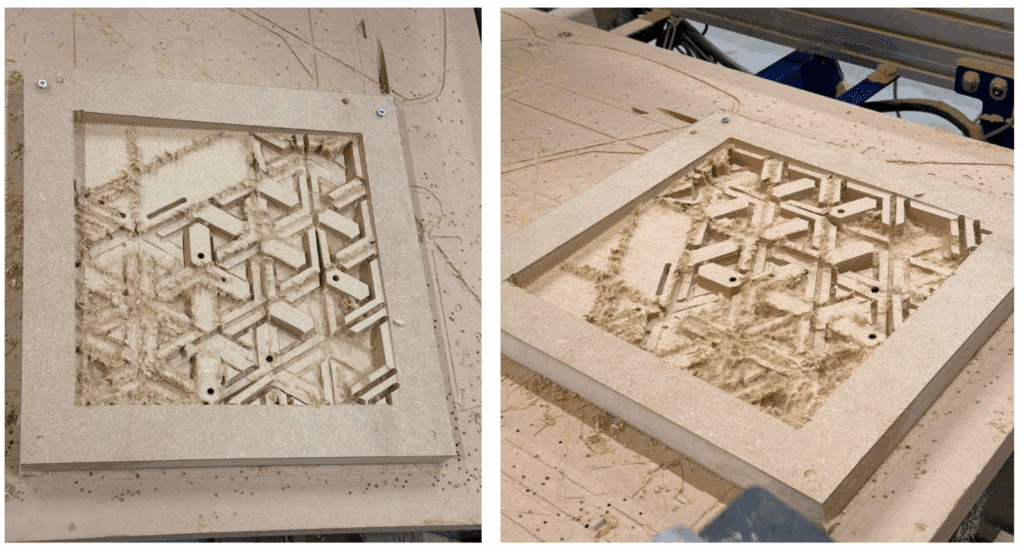

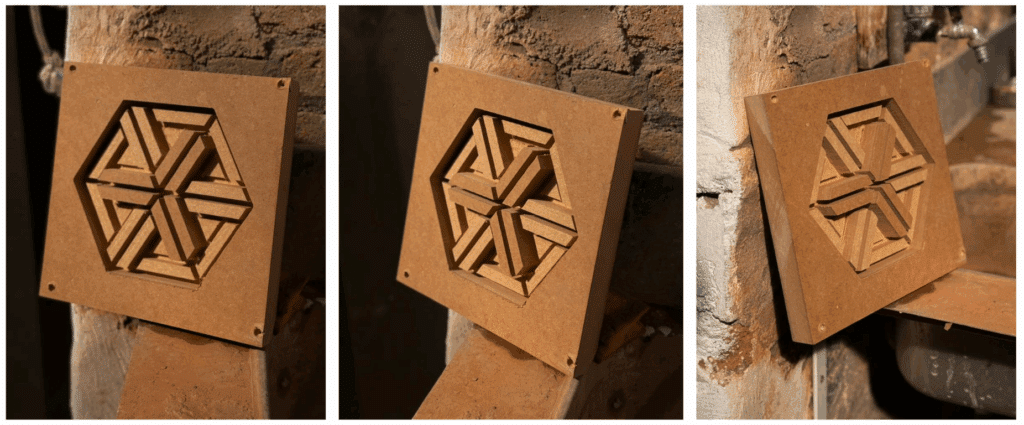

Fabrication Prototypes and Experiments

ROBOTICS

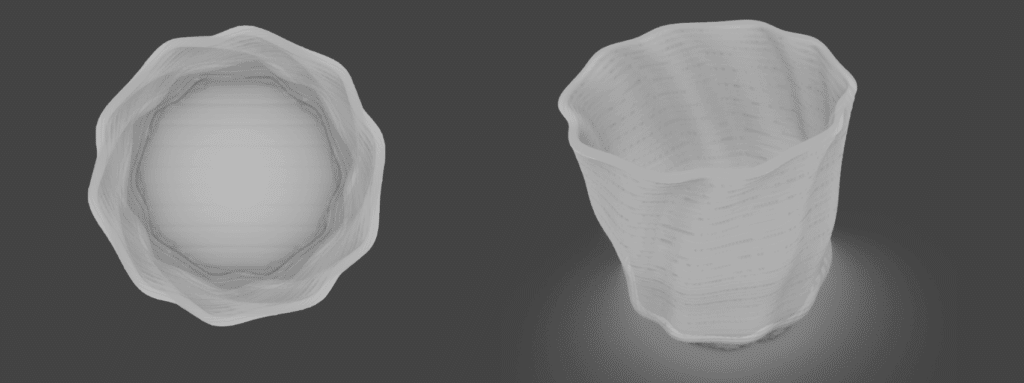

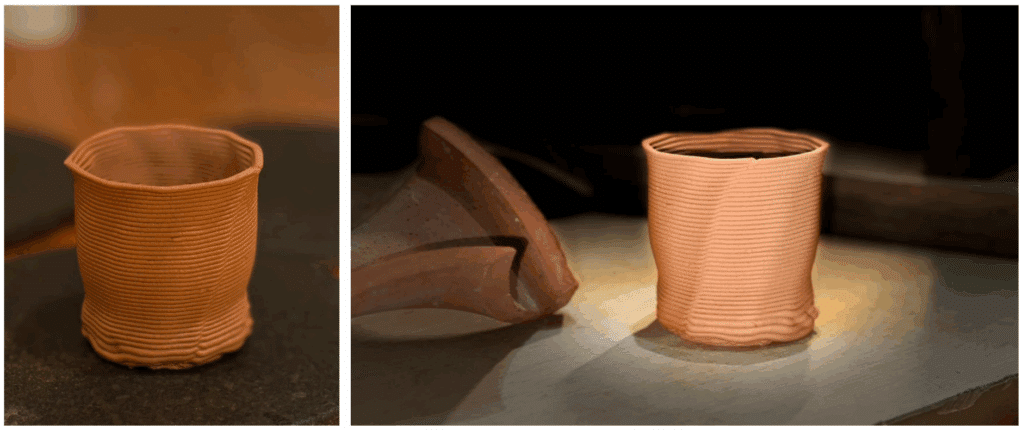

This clay vessel was generated in Grasshopper using parametric curves to define its layered geometry, then fabricated through robotic 3D printing, where a robotic arm precisely deposited continuous clay coils.

The result captures the digital script’s form while preserving the natural imperfections of clay extrusion.