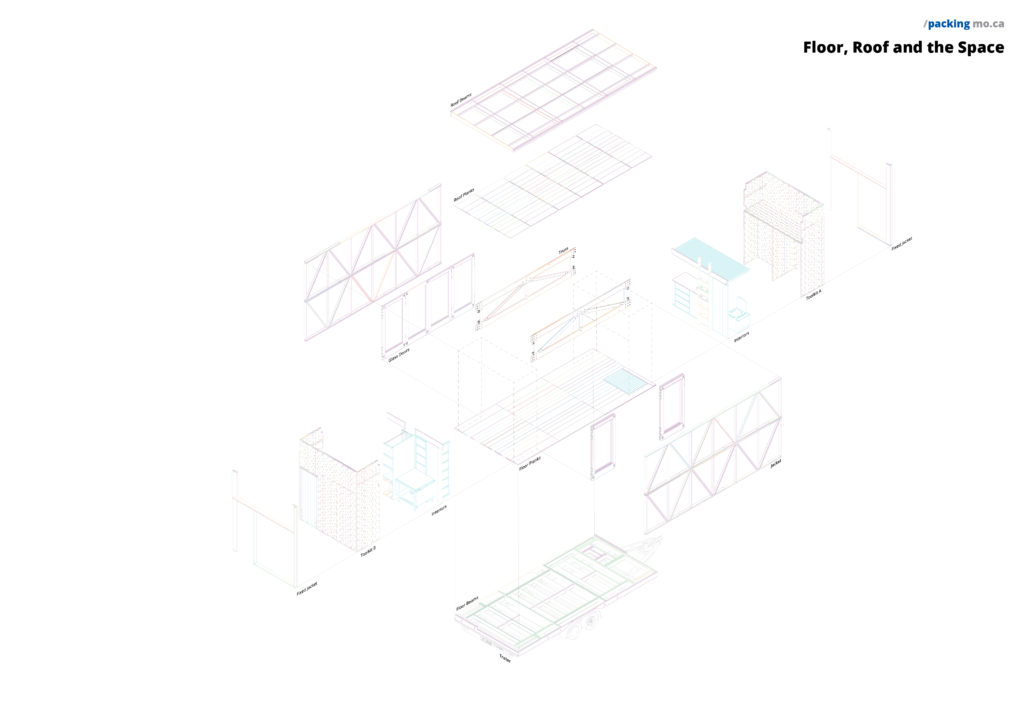

This years Material Production started after the final design for the prototype was chosen and ran parallel to the further development of the design.

The main goals were:

– to monitor the amount, humidity and density of the locally sourced aleppo pine wood

– to simulate production flows in the workshop (tools and time needed, tracebility)

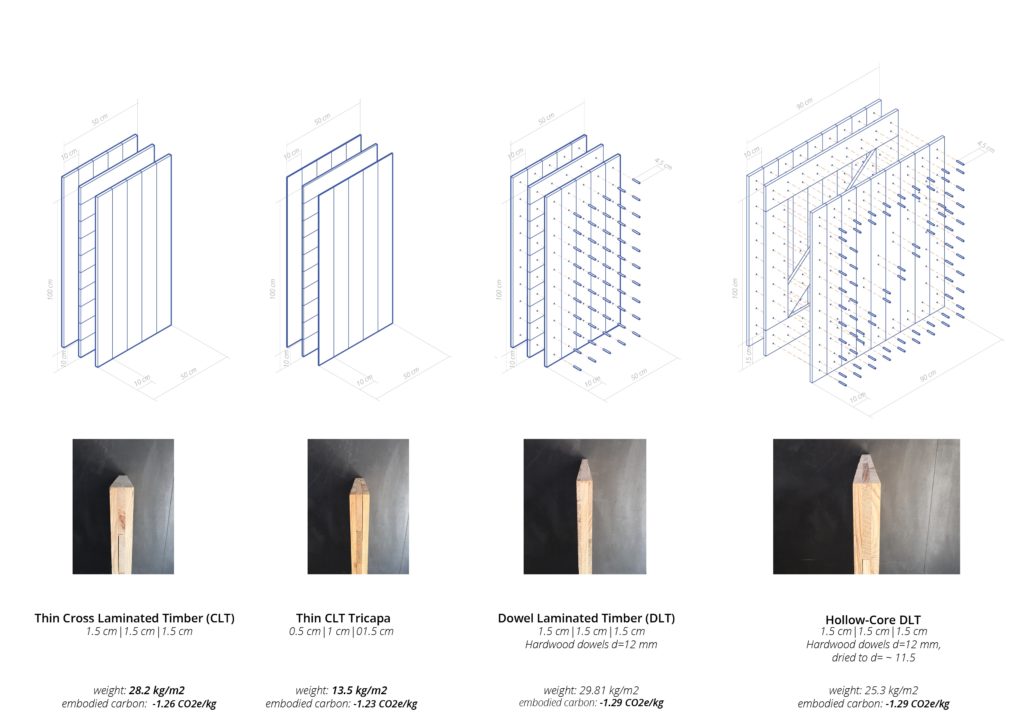

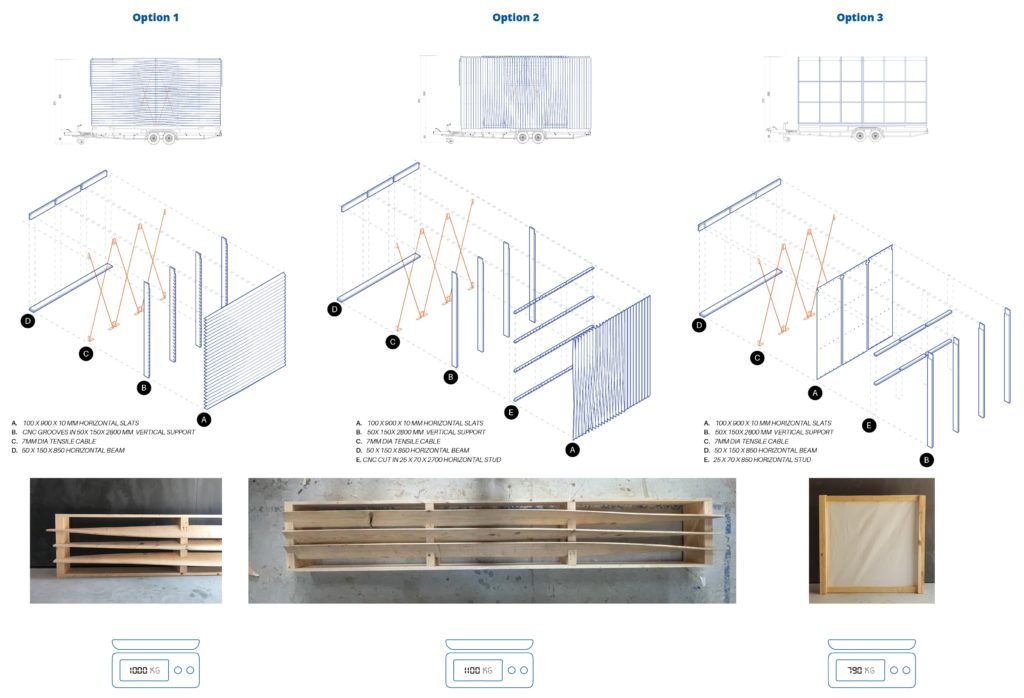

– to prototype leightweight structural components

– to prototype important connections and mechanisms

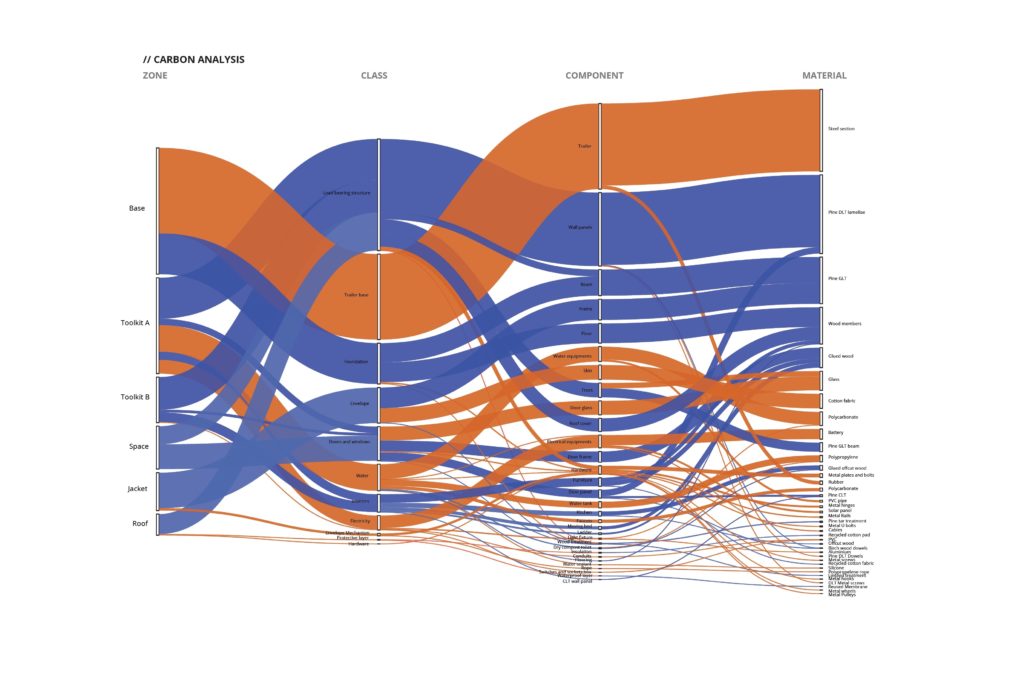

– to calculate and compare the embodied carbon of different components/solutions

Since the timber we harvested in December 2022 and milled since then was still drying (prototyping started end of May), we scavenged the wood yard for usable pine wood left behind from the previous years. All prototypes were made with these leftovers. Simoultaneously we sampled our milled timber for humidity and weight.

Soon the carpentry became very busy. As a small material production core team plus a rotating group of the design team we made ourselves familiar with the machines and workflows. Always supported by our FabLab manager and companion Bruno! Based on a combination of formal cad-based production drawings, the previous MAEBB year´s knowledge and a lot of enthusiasm we produced our first CLT-panels, followed by GLT-truss connections, facade modules and furniture prototypes.

As one main constraint of the mobile catalyst was weight, we tried to minimize the thickness of each component. This meant a lot more planing and a lot more sawdust in the end. Therefore for all additional timber we milled, we chose a plank thickness of 25 mm instead of 35 mm.

Aside from the Cross-Laminated-Timber panels we prototyped an adhesive free technique called Dowel-Laminated Timber which was further developed in the course of the project with the help of the freely available files and documents of the Open Terrace project (by students from a previous MAEBB course). A hollow version was also prototyped but due to minimal savings in weight not followed further. In the end though it was used for the external doors of the final prototype.

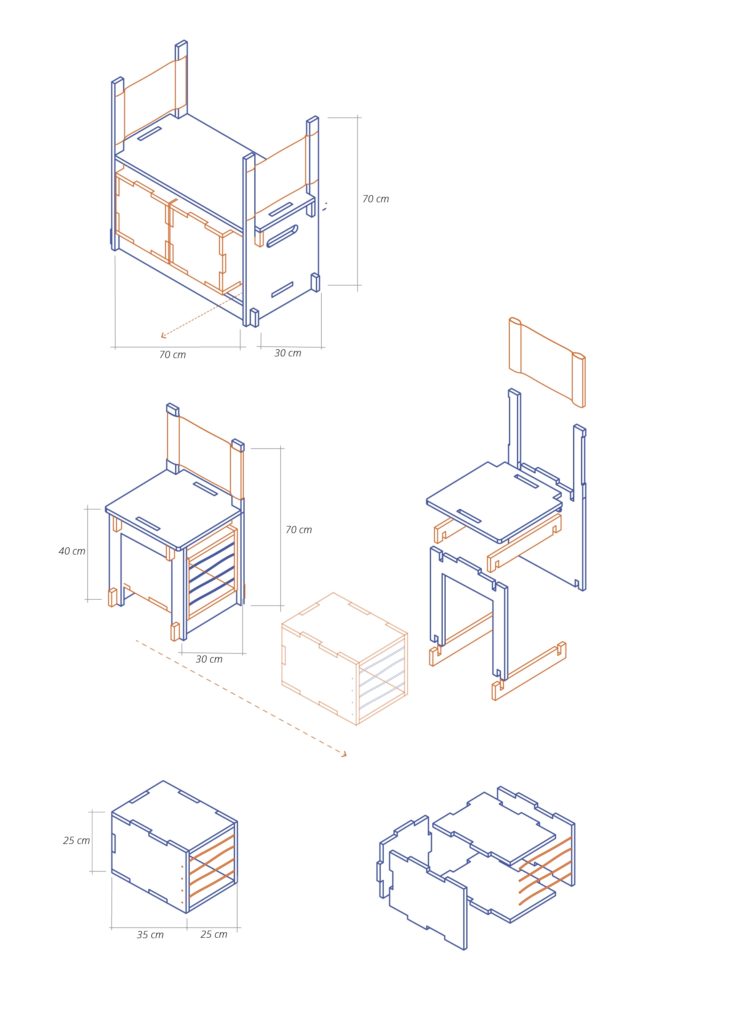

For the facade a variety of modules were prototyped, ranging from simple timber slats, thin and long steam-bent lamellae to a combination of timber and a water-resistent organic cotton fabric. As fabric is a very leightweight material it was soon also tested in other elements like this early chair prototype CNCed on leftover plyboard.

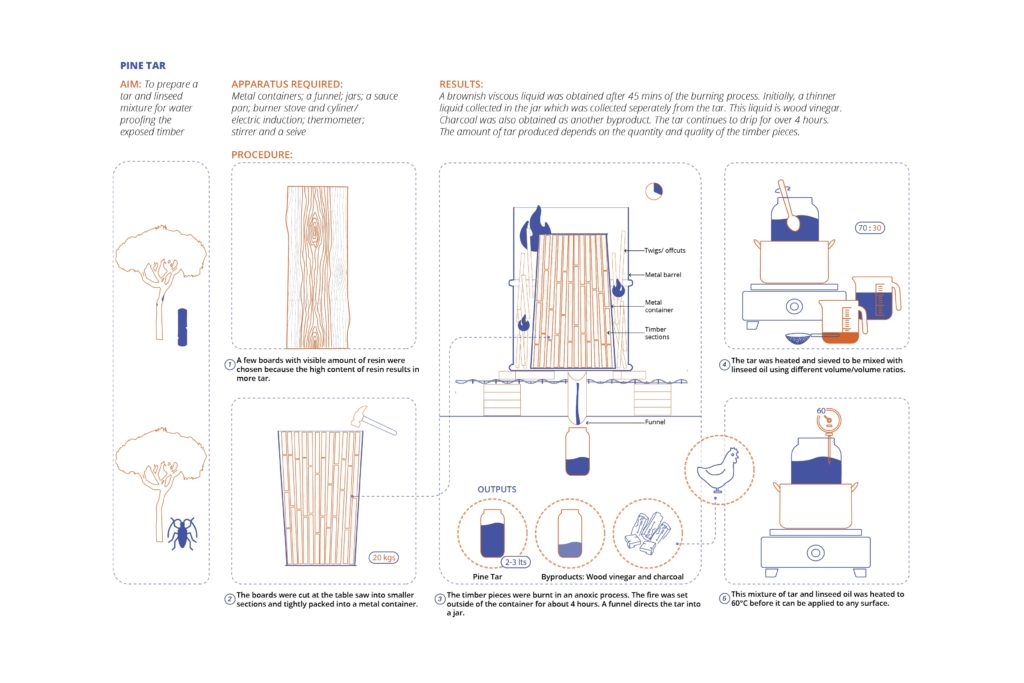

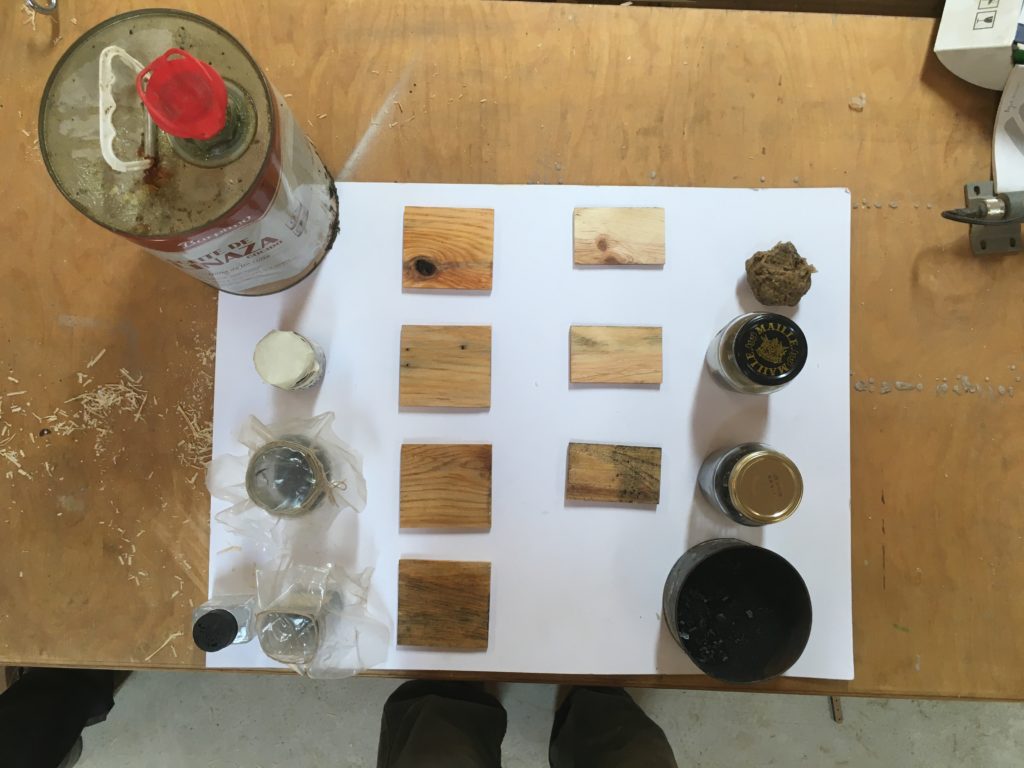

Tarring is a very old technique to protect timber buildings against moisture. First introduced to us through the faculty, we soon started building a set-up to harvest our own tar from the pine wood and creating different mixtures and coatings. Aiming to reduce the amount of industrial products used in our final prototype and to identify the components and products with the highest embodied carbon impact, a small team jumped into the life cycle assessment and tracebility of the whole structure.