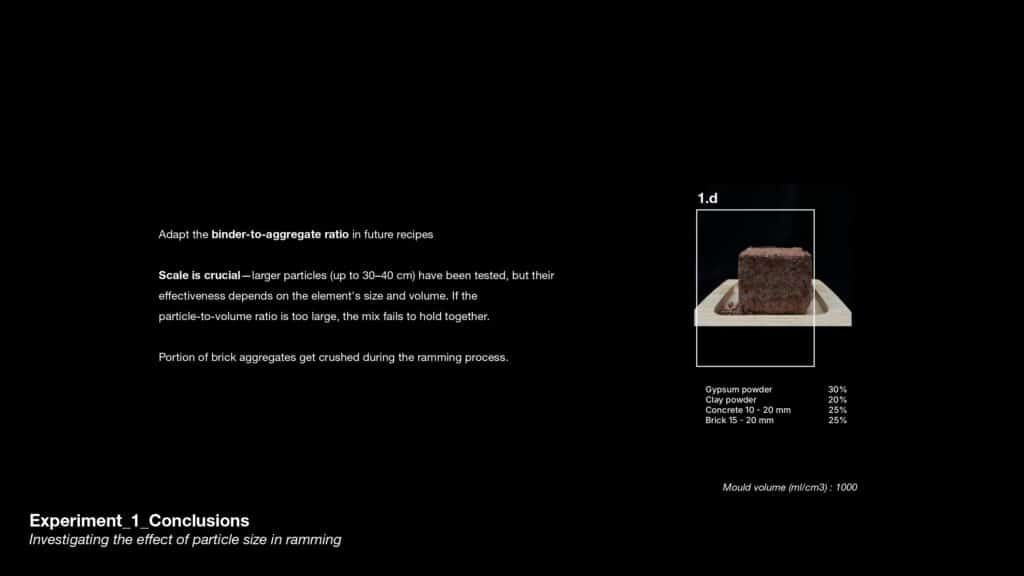

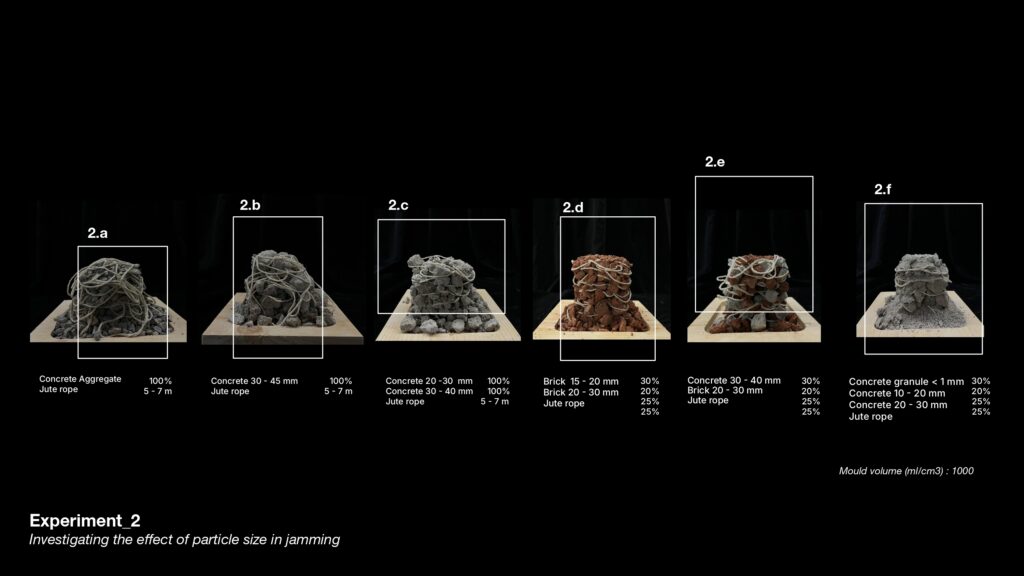

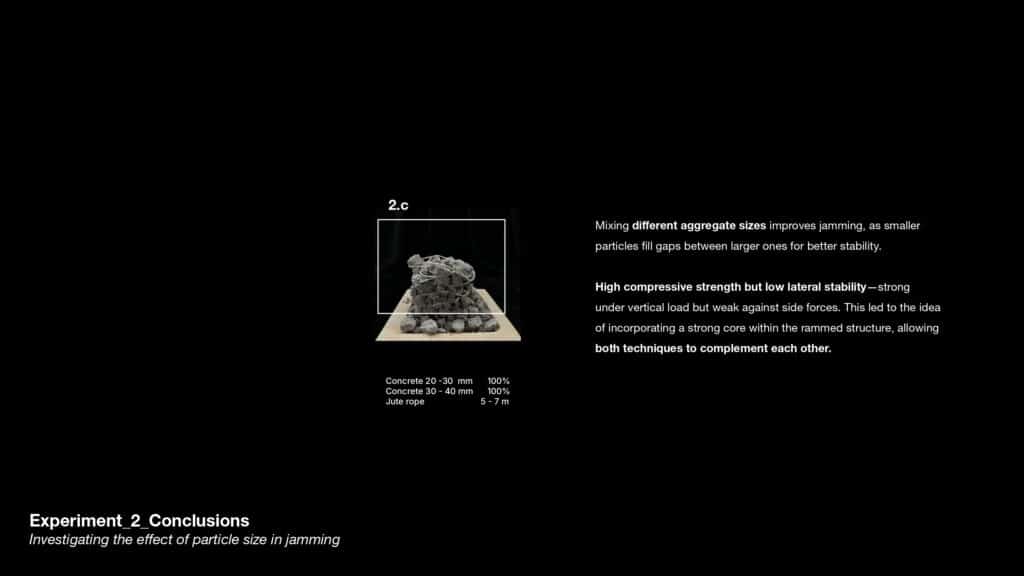

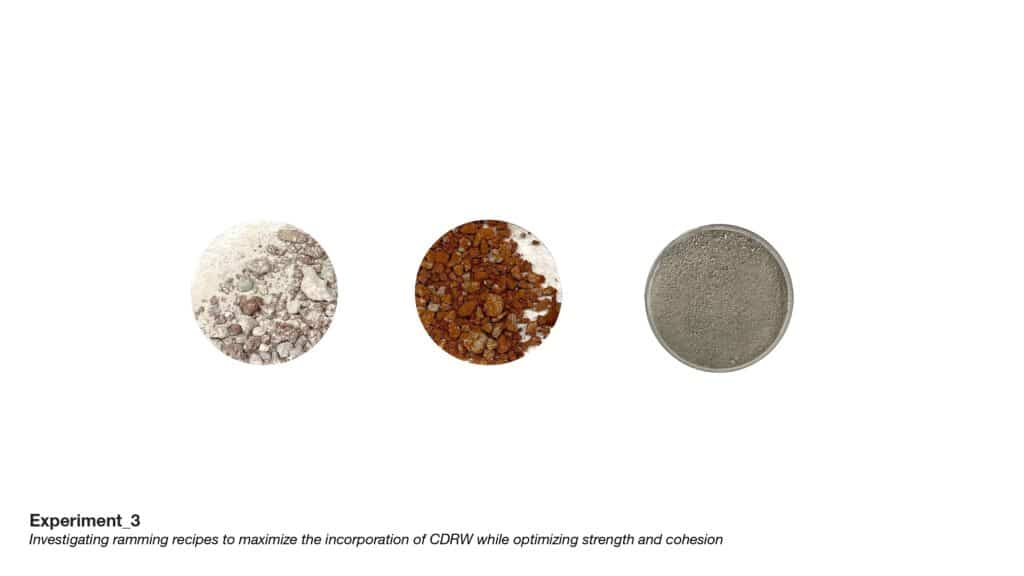

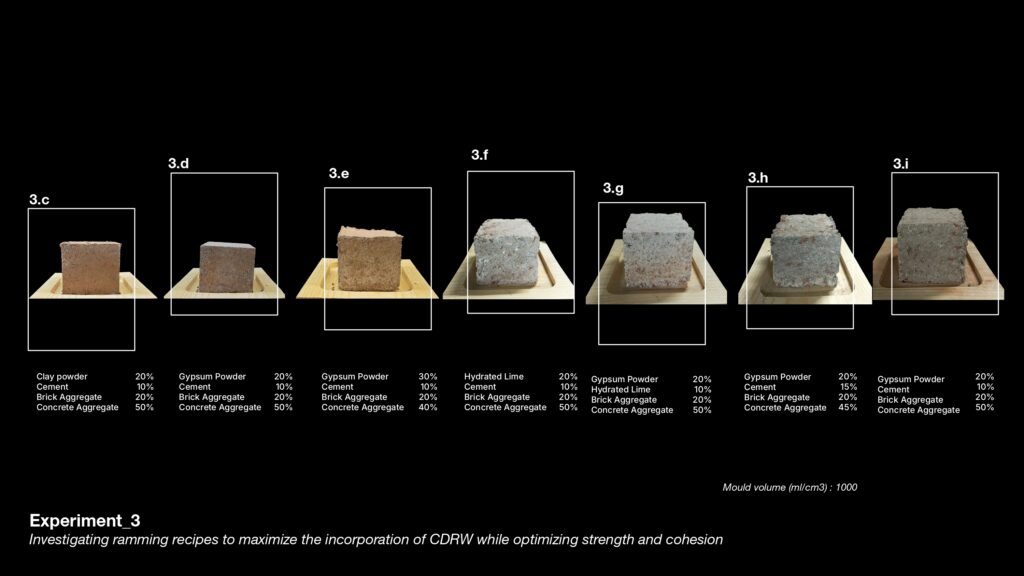

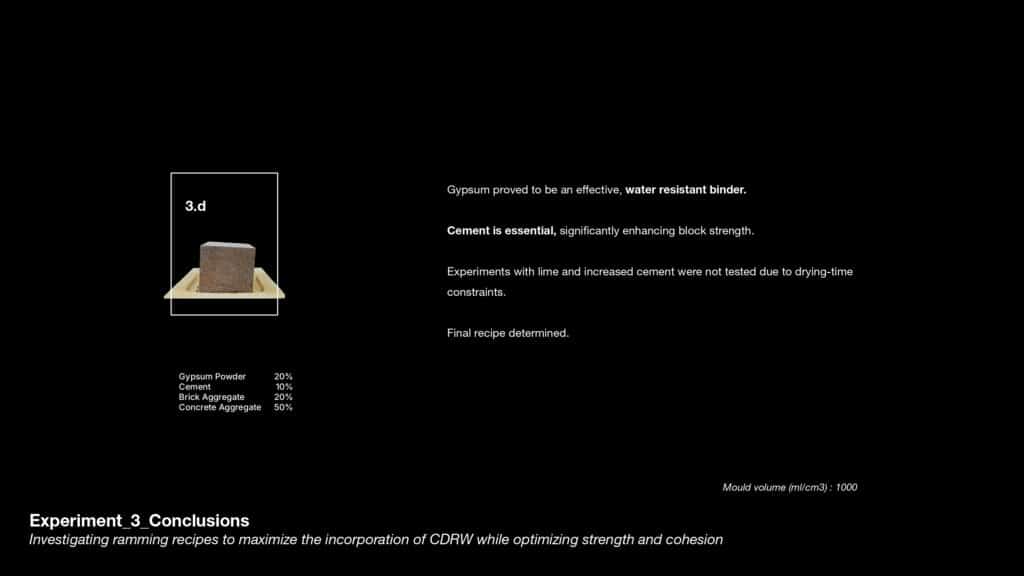

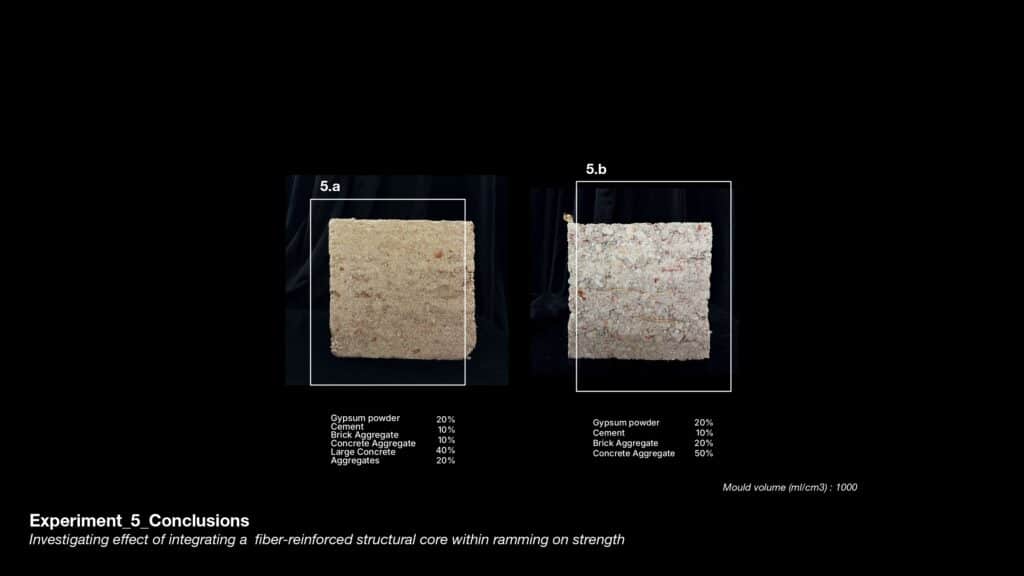

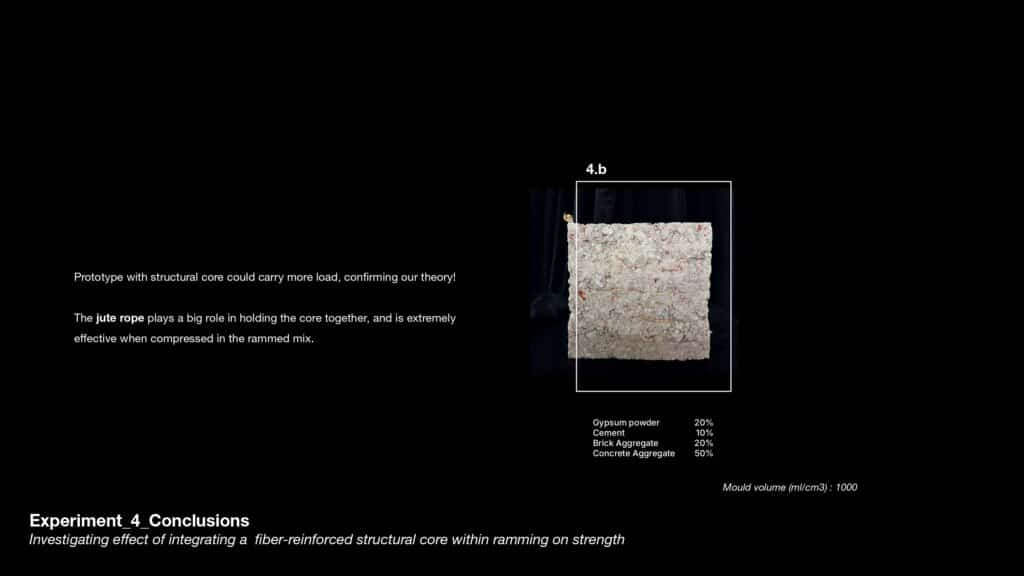

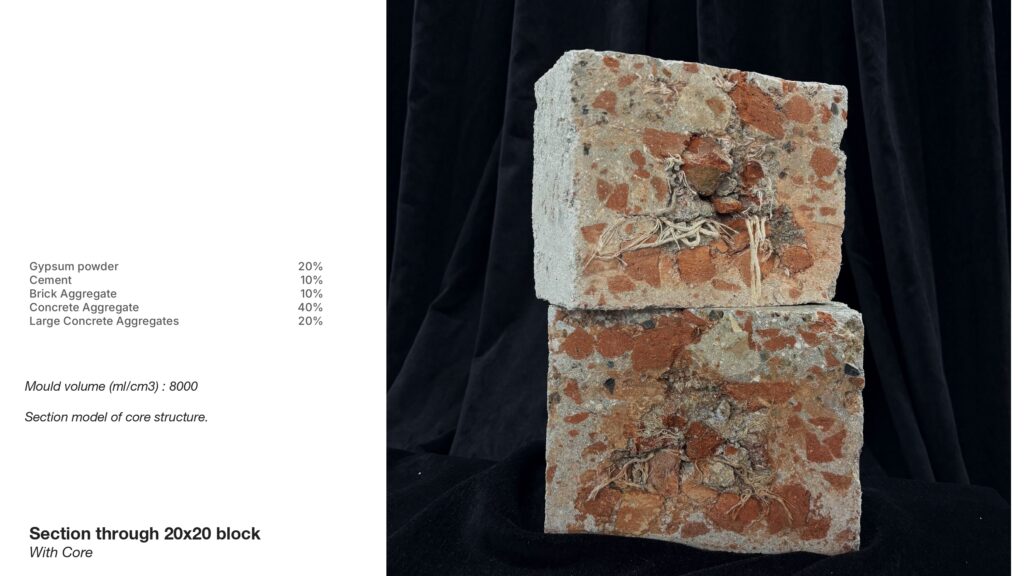

SecondMatter challenges architecture’s extractive processes and wasteful material cycles by upcycling Construction Demolition Renovation Waste (CDRW) into structural and non-structural applications. It blends ramming, which compacts granular materials into high-strength forms, with jamming-inspired interlocking of irregular aggregates. Large concrete waste pieces form a reinforced core, wrapped in a rammed mix of fine brick and concrete aggregates bound with gypsum and cement, enabling monolithic walls, prefabricated panels, tiles, and reinforced columns.

To address material inconsistencies and manual ramming challenges, SecondMatter integrates a digital interface for optimized core placement and explores robotic automation for enhanced precision and scalability.

RESEARCH QUESTION

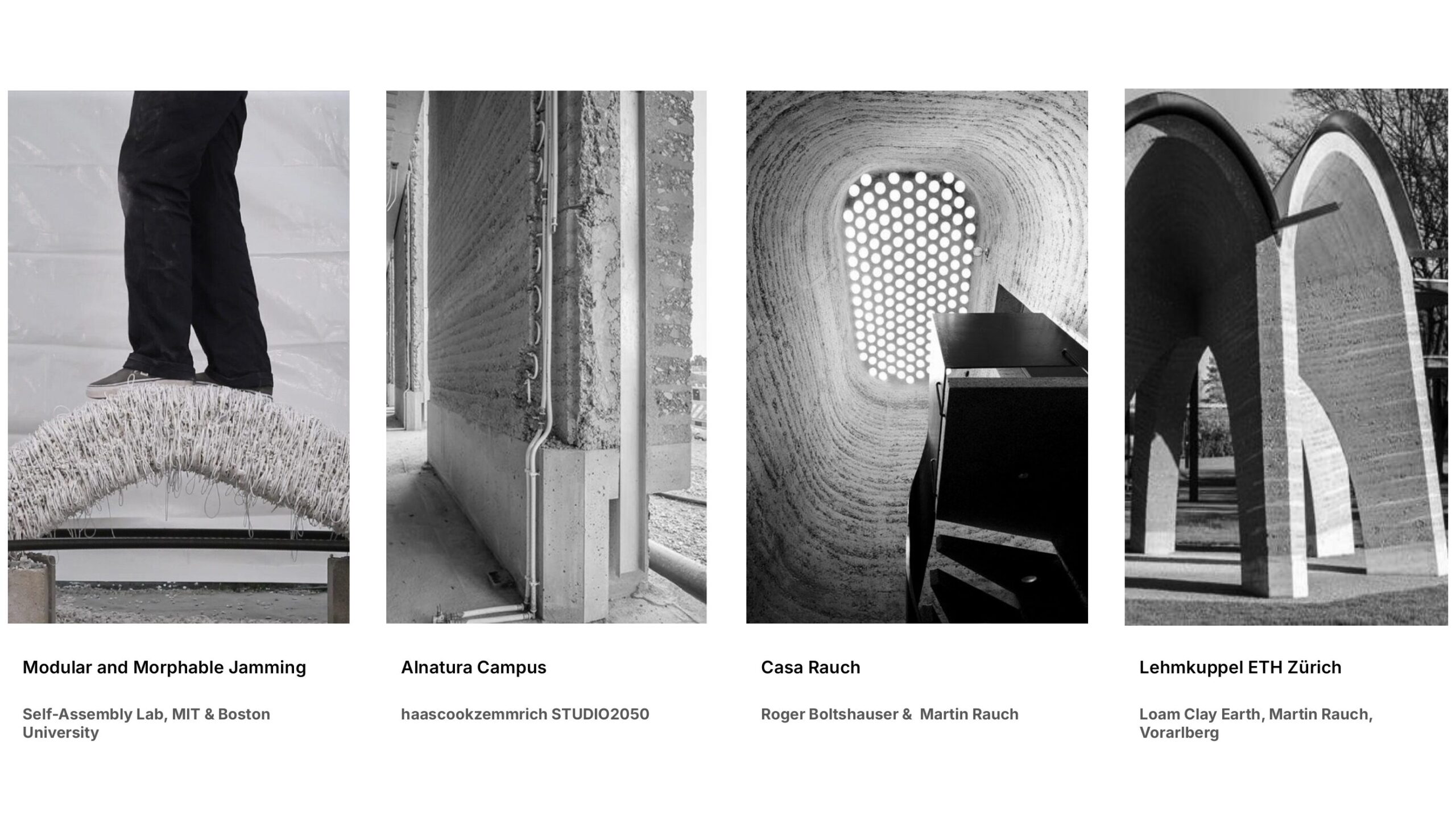

STATE OF THE ART – Case Studies

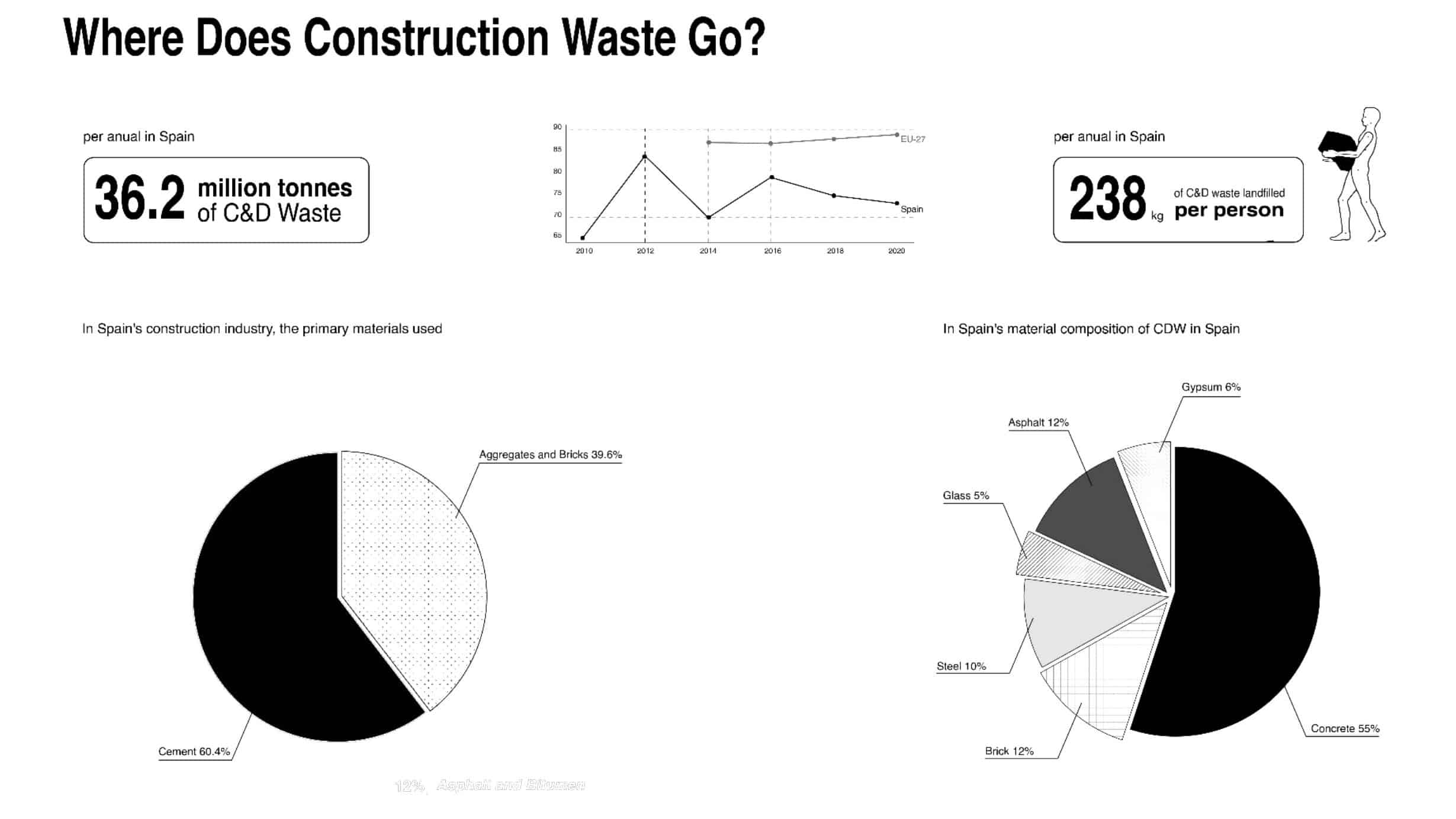

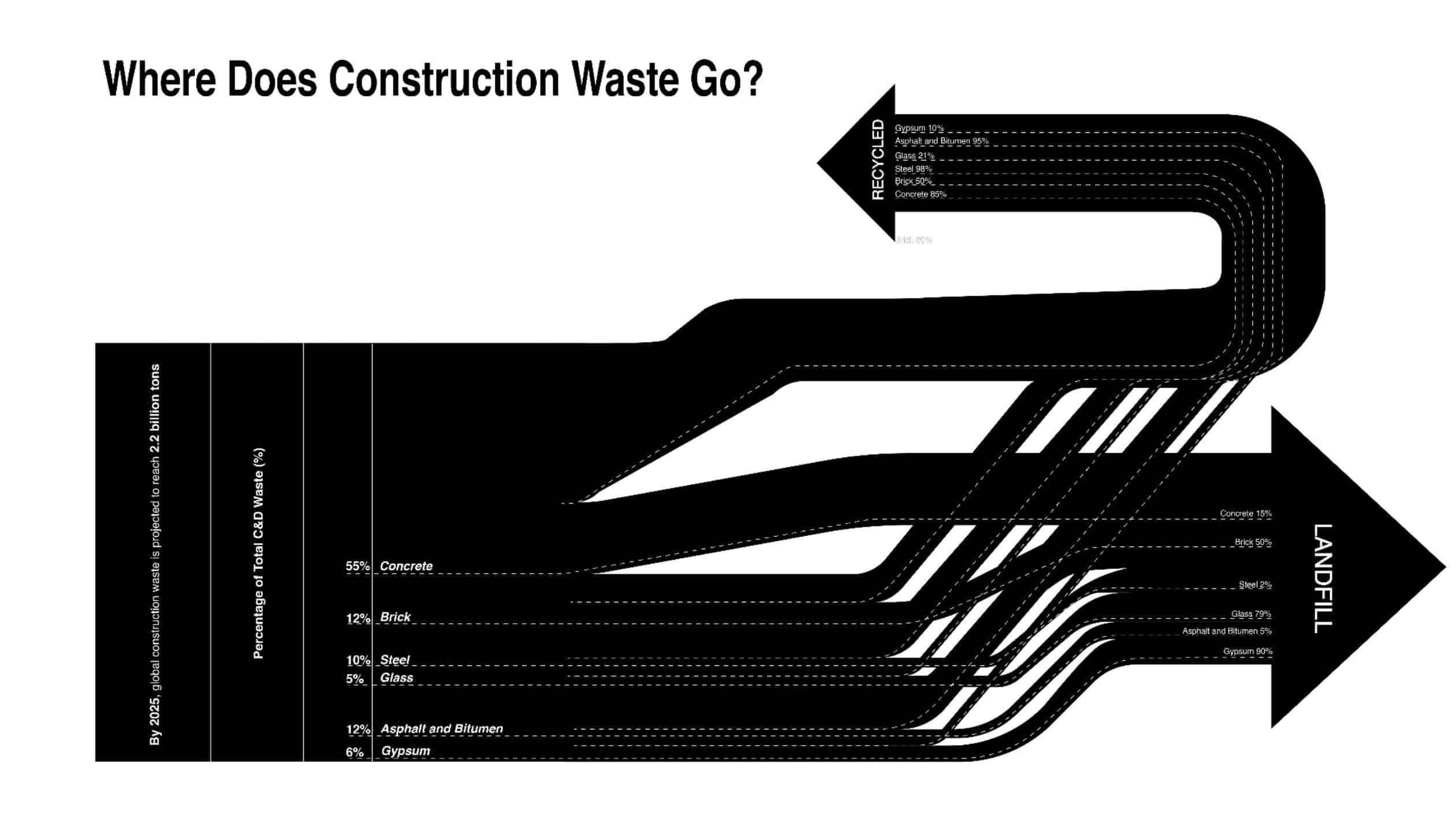

Digital Data – Research

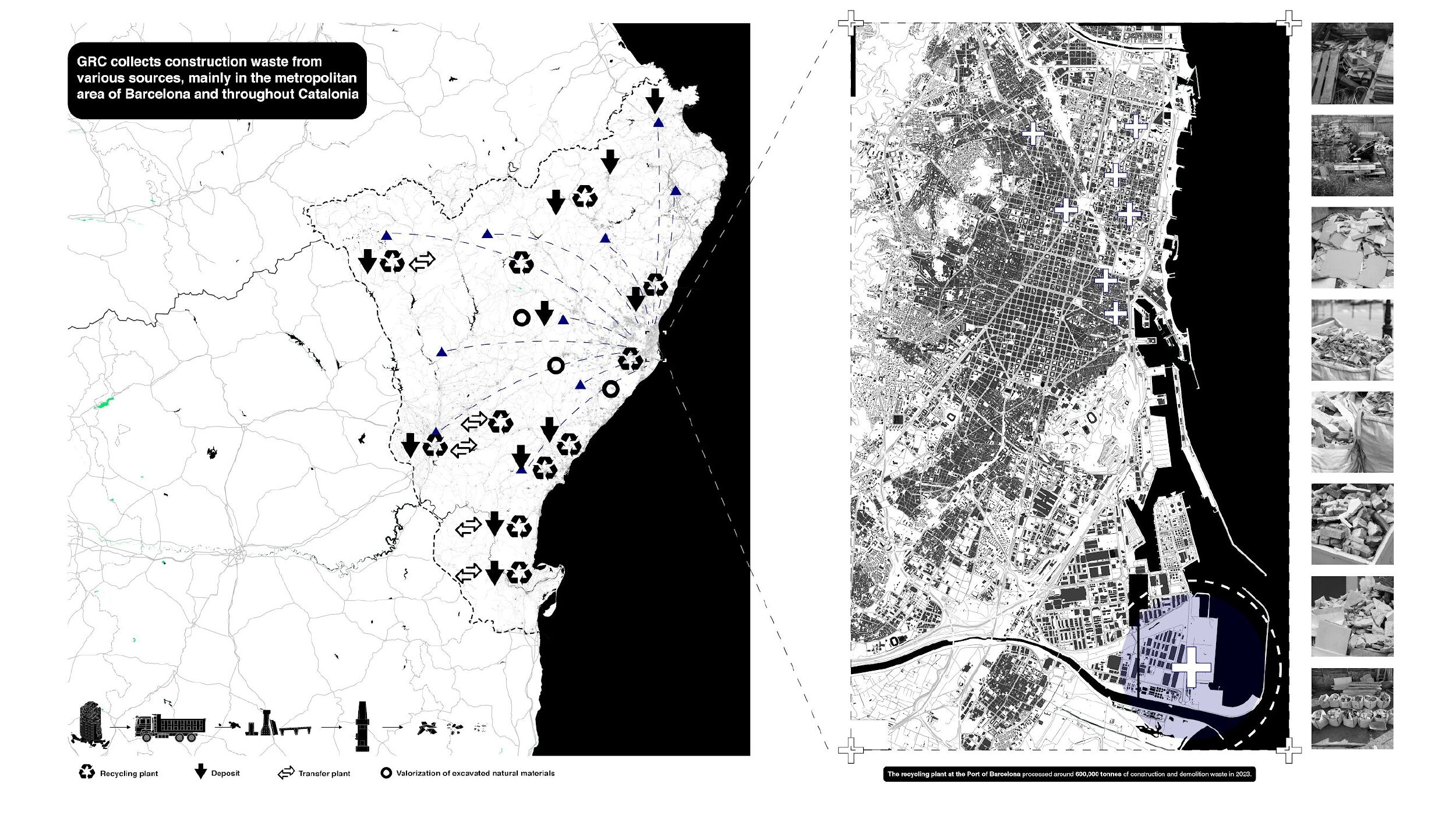

MATERIAL SOURCING

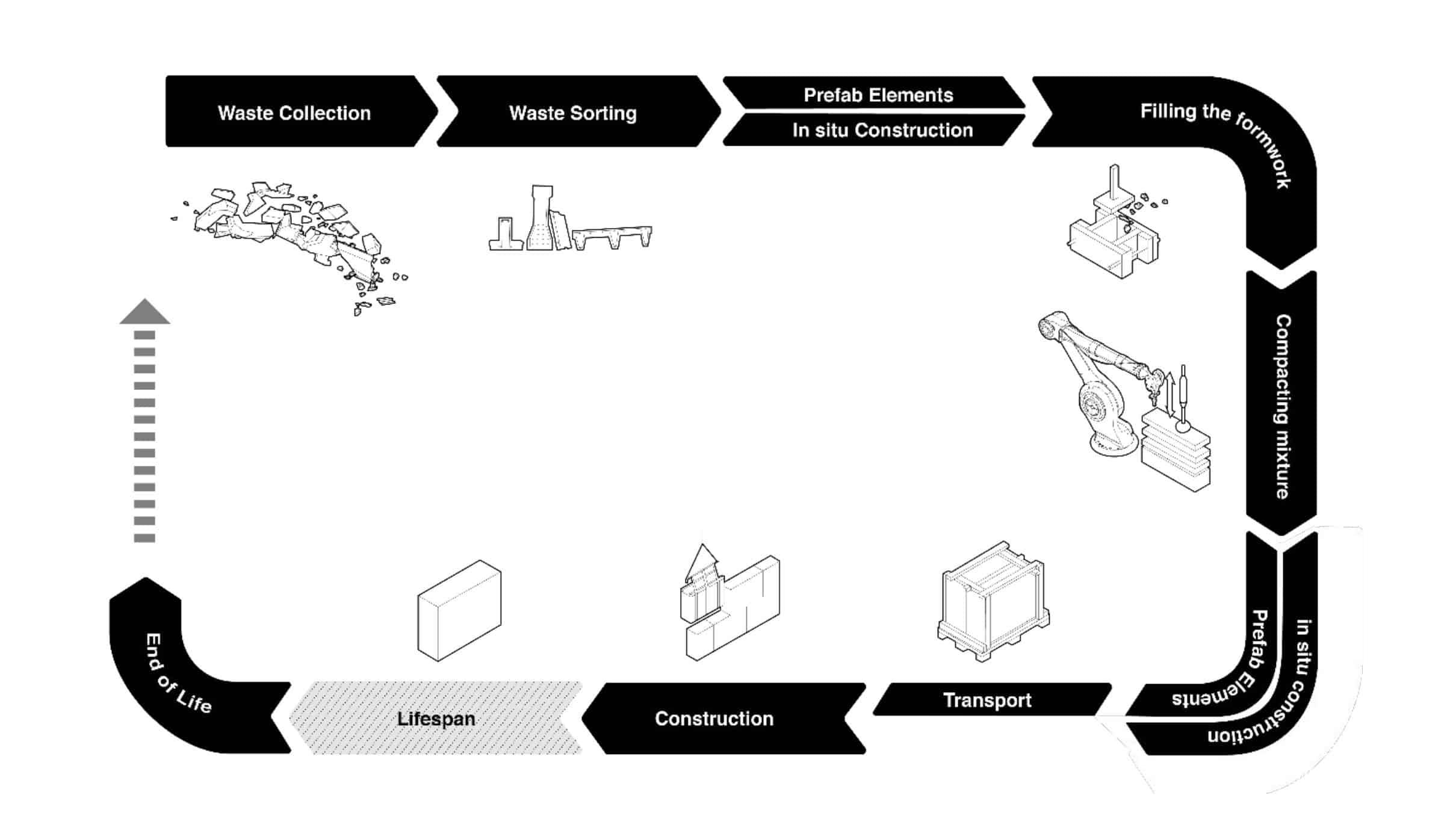

WORKFLOW DIAGRAM

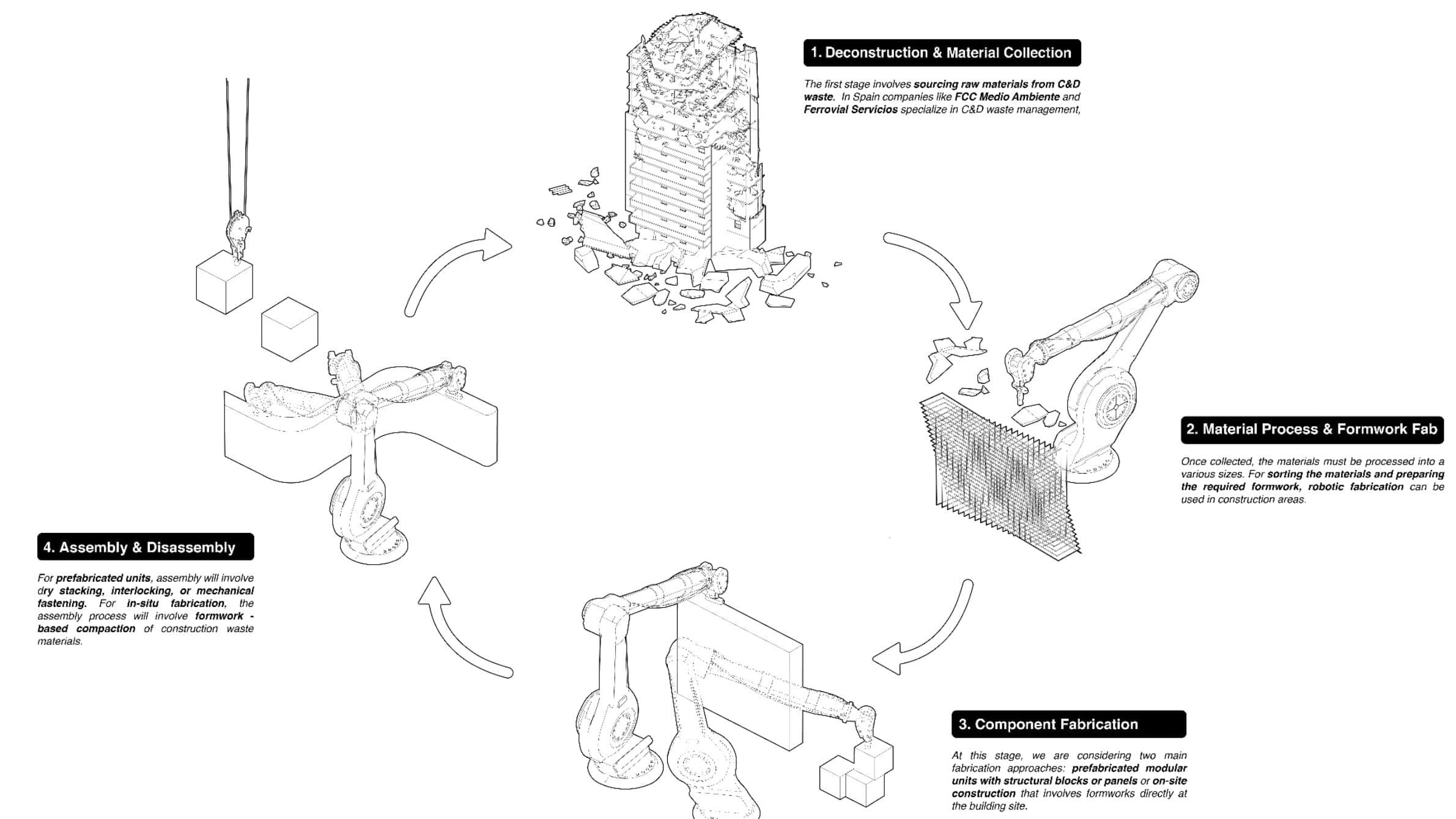

MANUFACTURING PROCESS – Conceptual Diagram

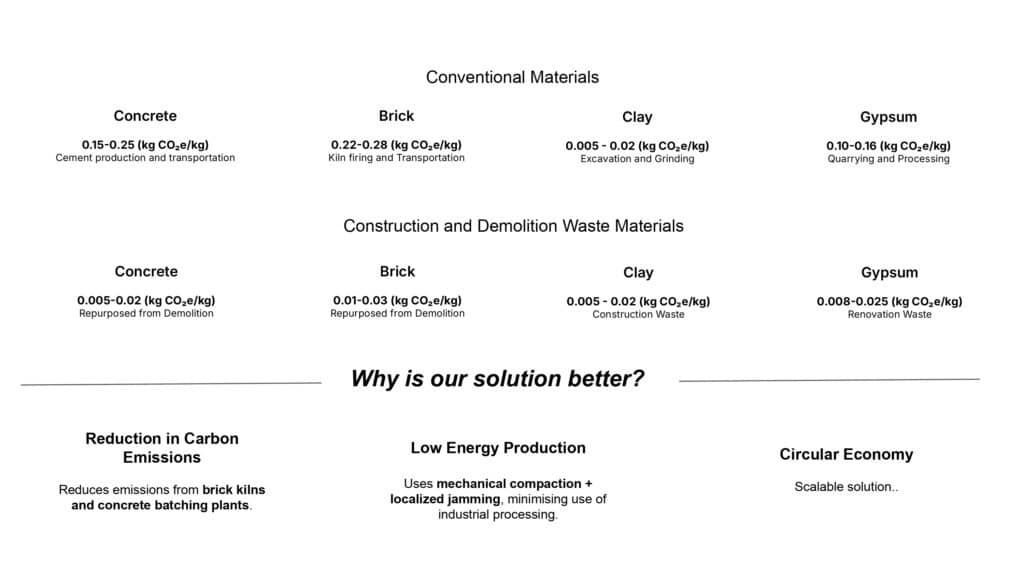

EMBODIED CARBON – Analysis

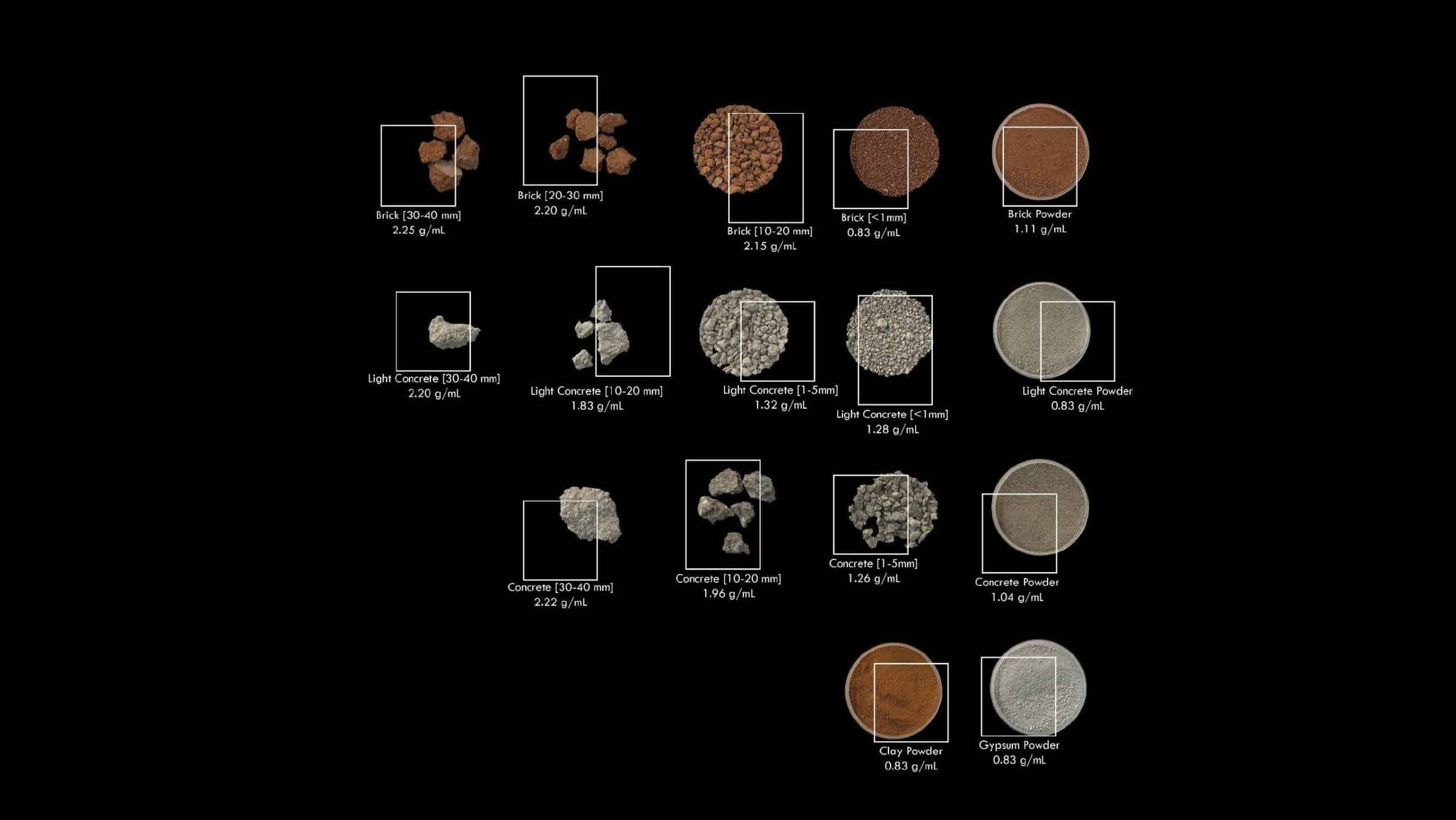

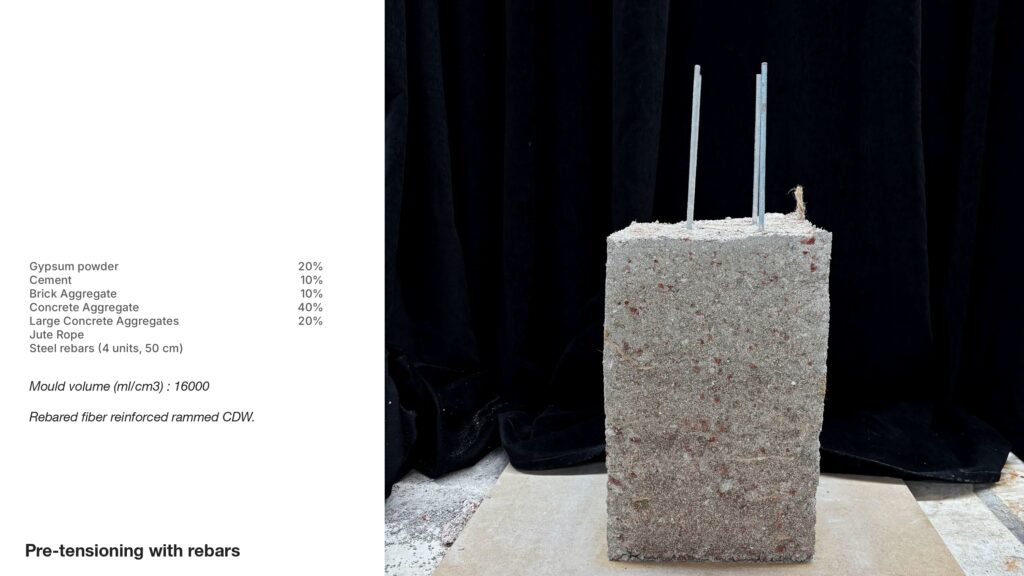

MATERIALS

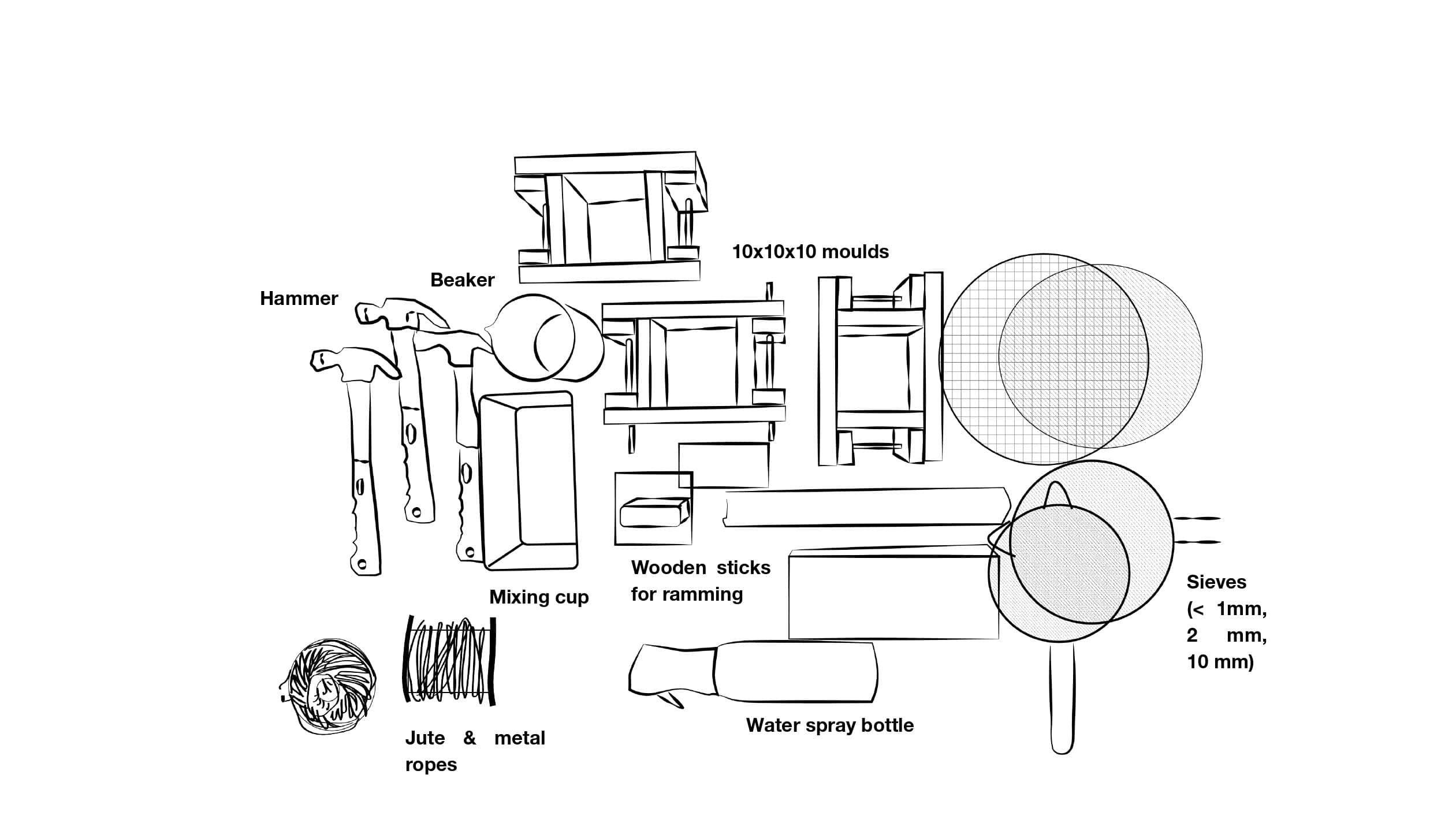

TOOLS – For Manual Ramming

MATERIAL PREPARATION

SORTING – Varied Sizes

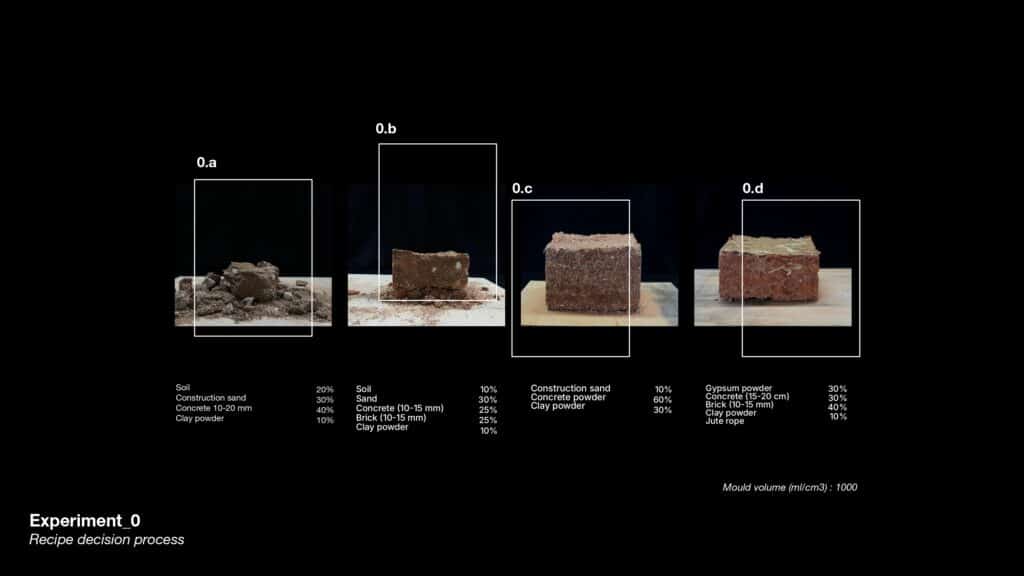

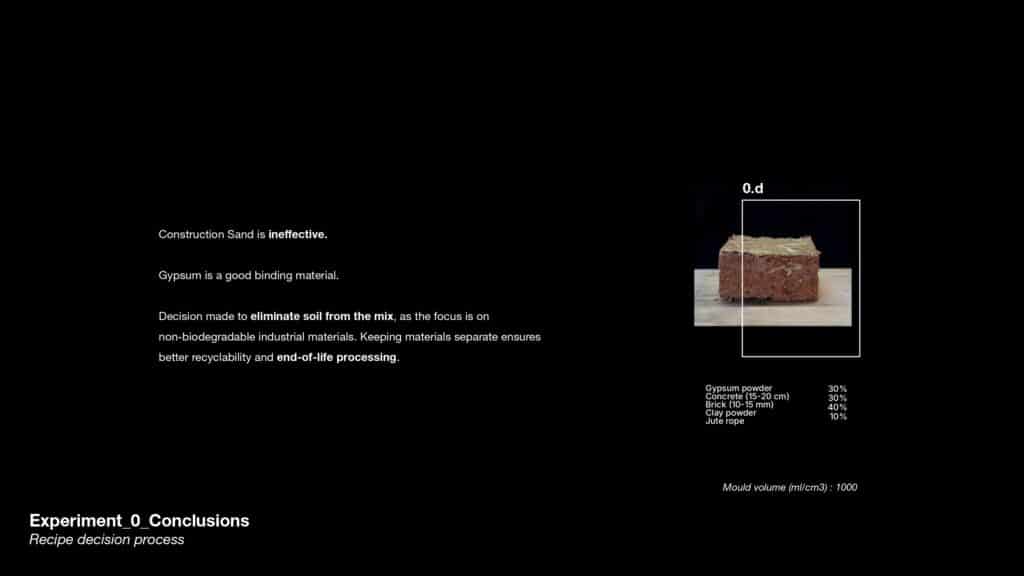

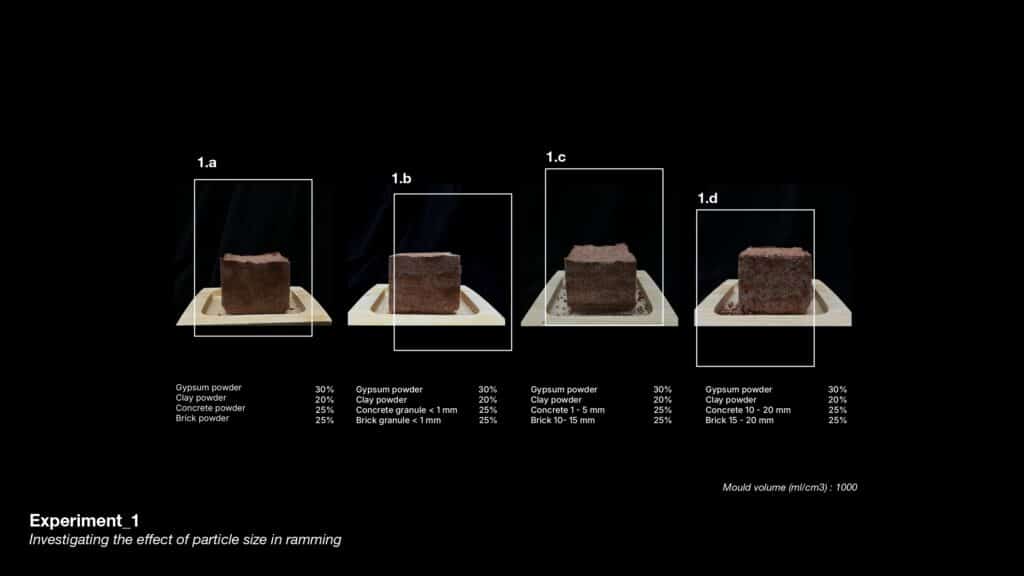

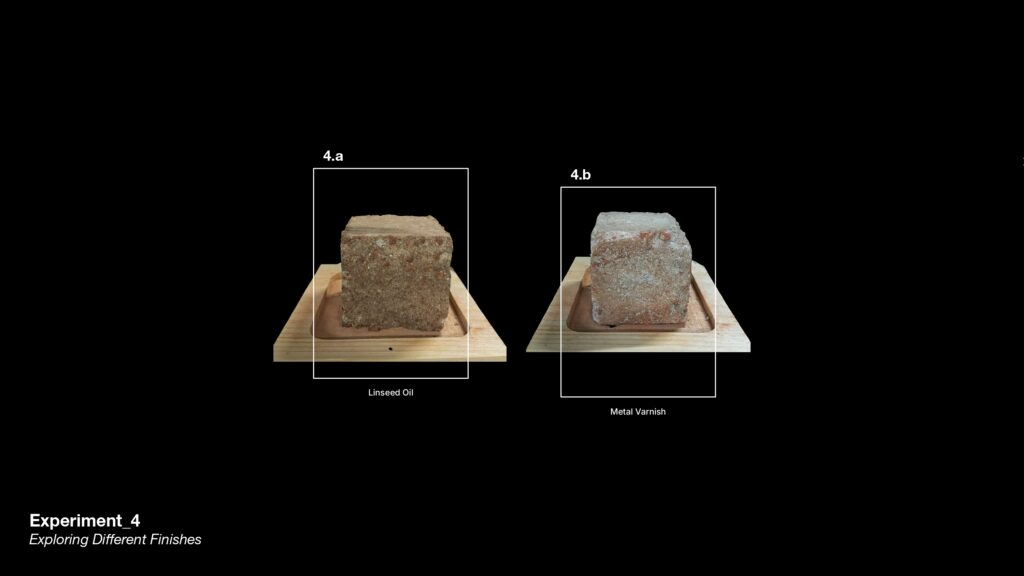

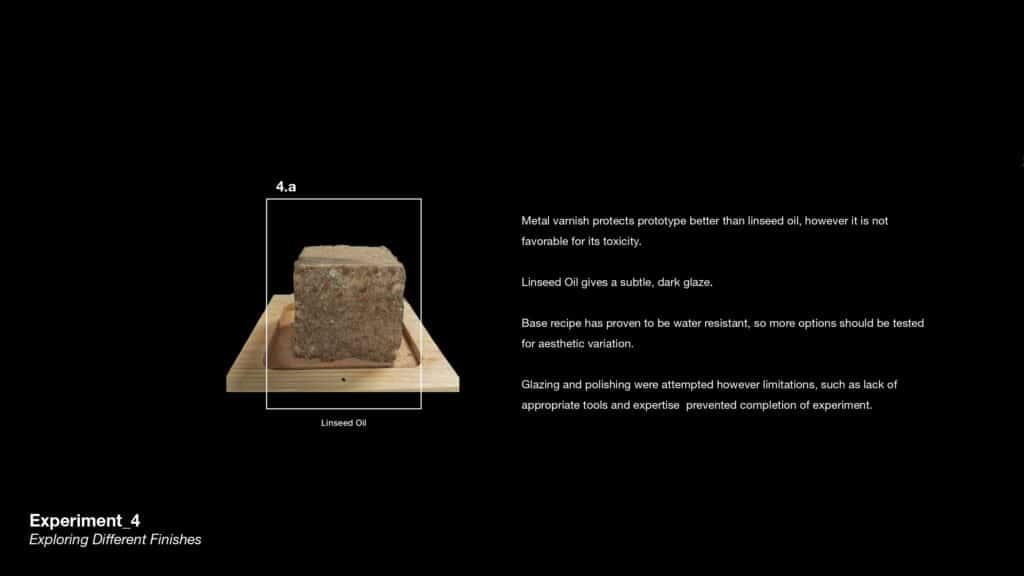

PROTOTYPES

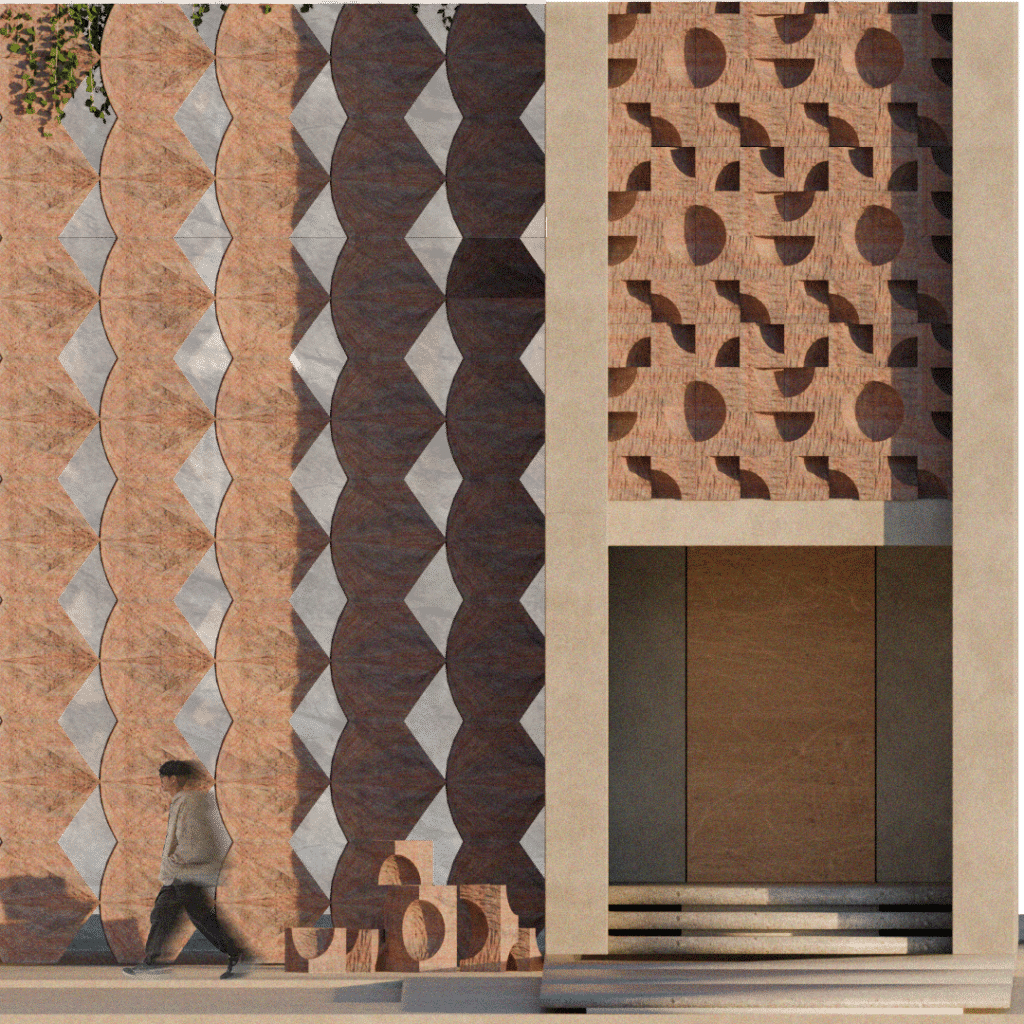

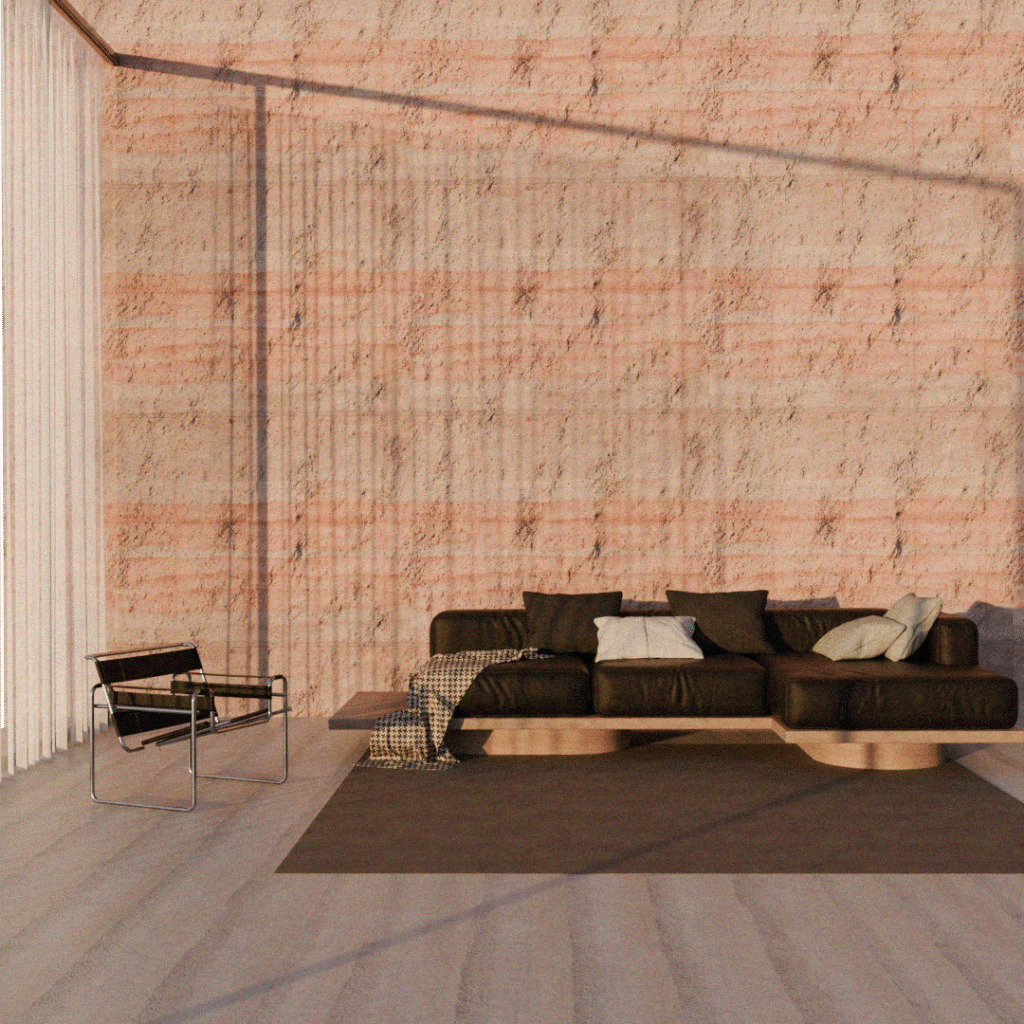

DESIGN PROPOSAL

DESIGN – Modular Elements

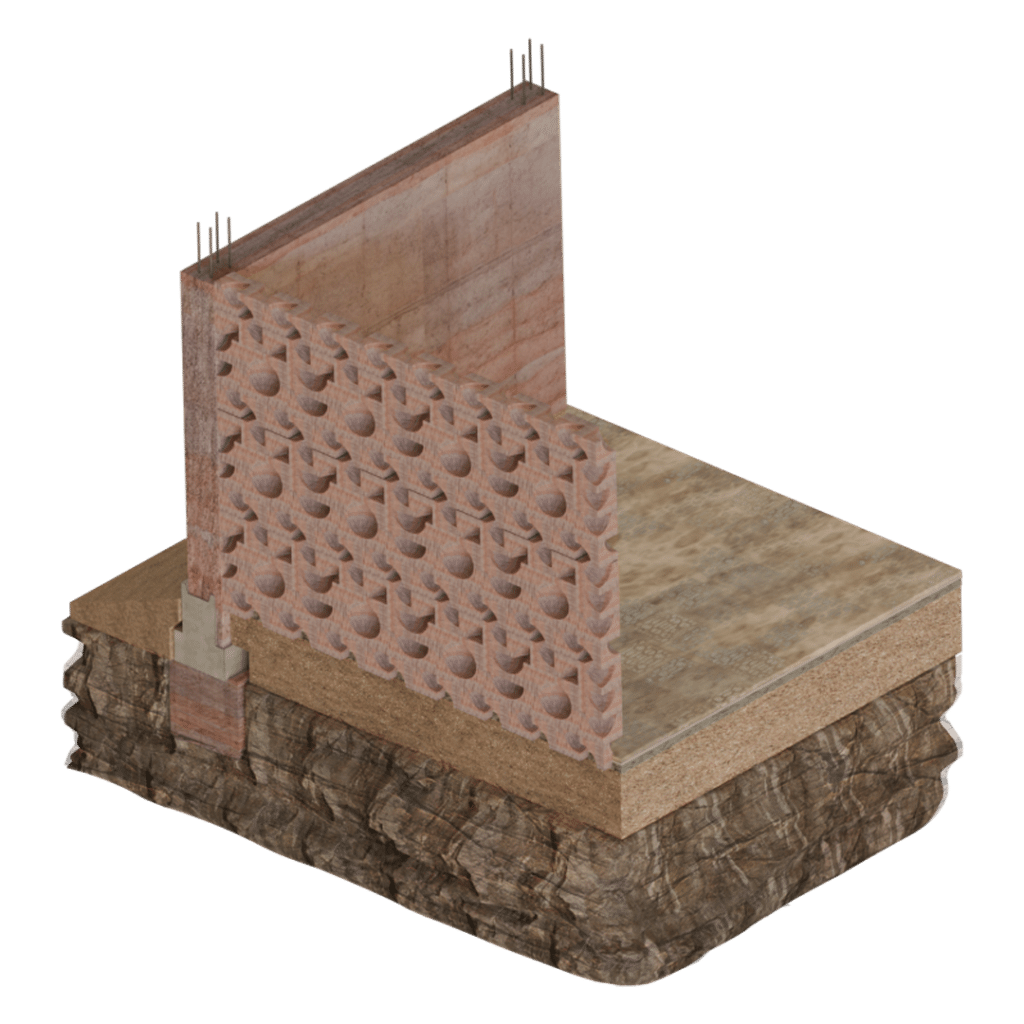

DESIGN – Structural Elements: Load Bearing Walls or Columns

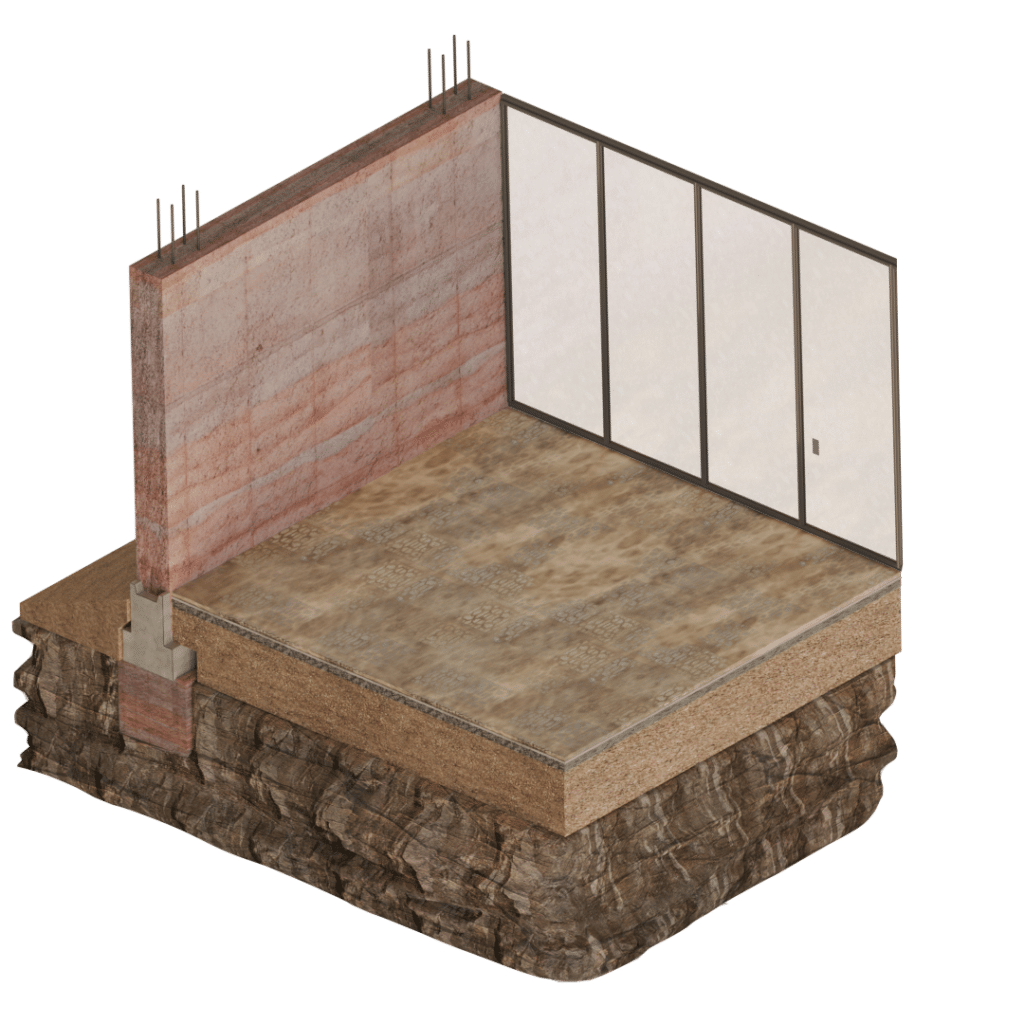

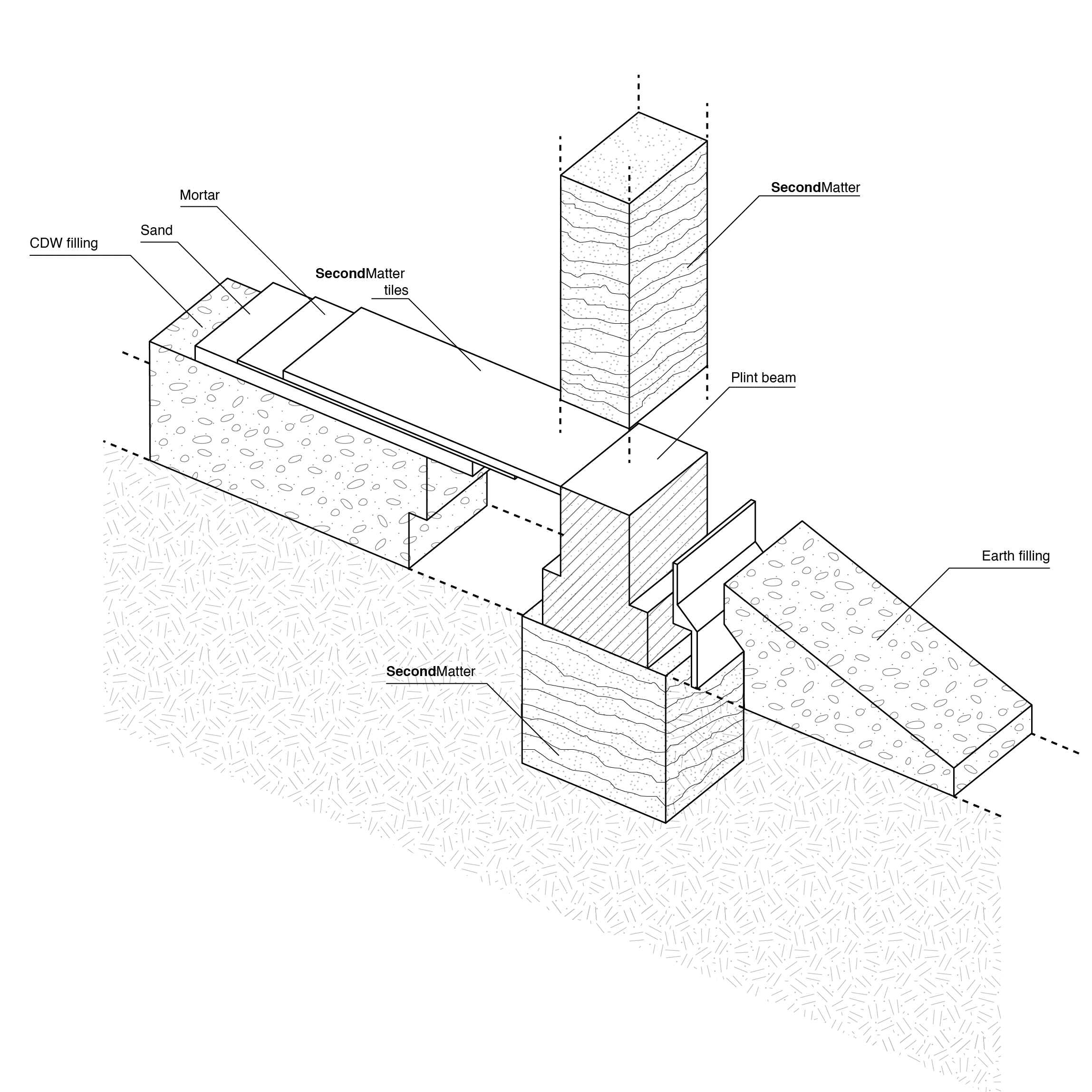

Connection Detail for Foundation to Wall

DESIGN – Slab Connection

DIGITAL INTERFACE

REFERENCES –