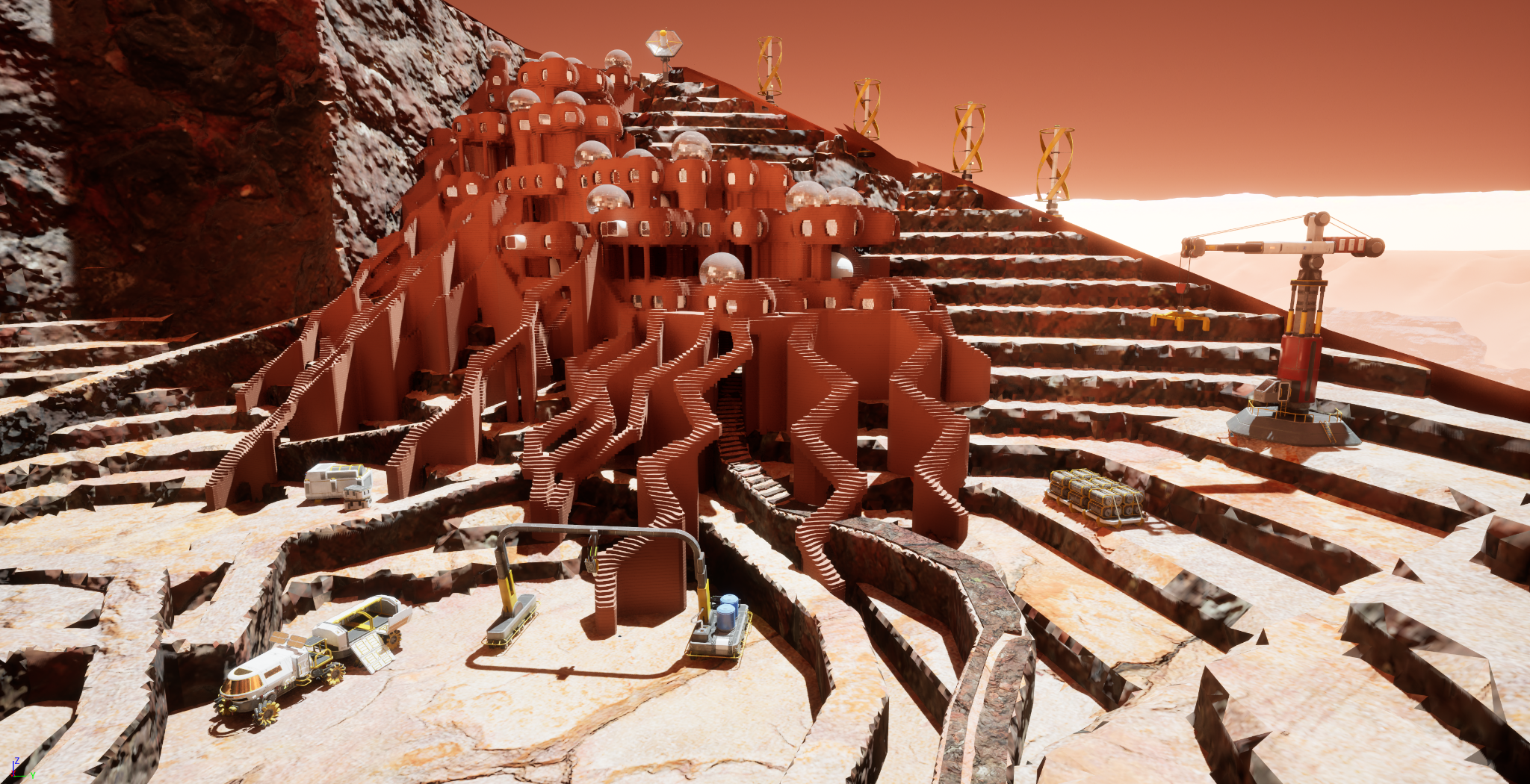

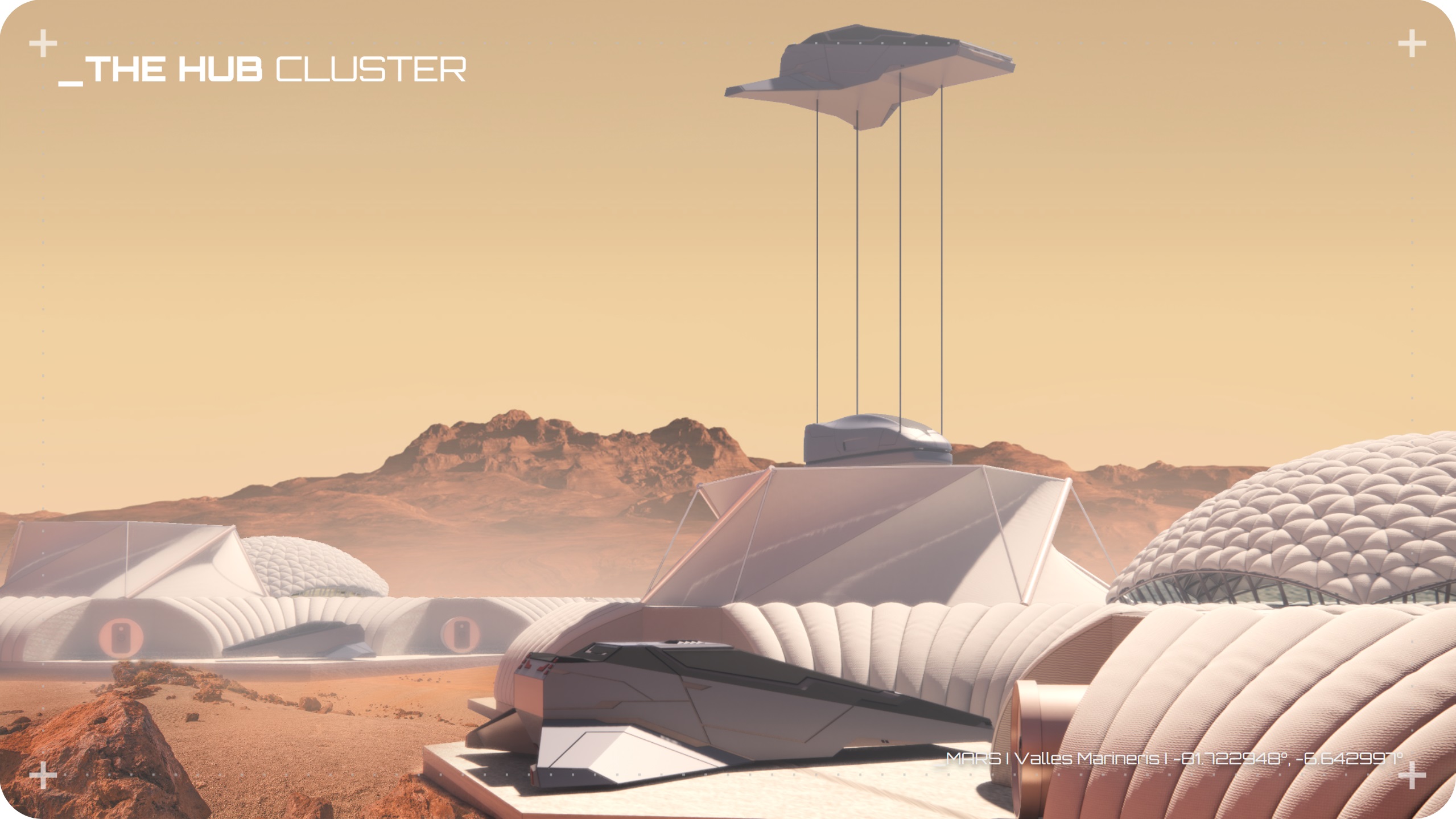

Alfafa Colony: Integrative Modelling

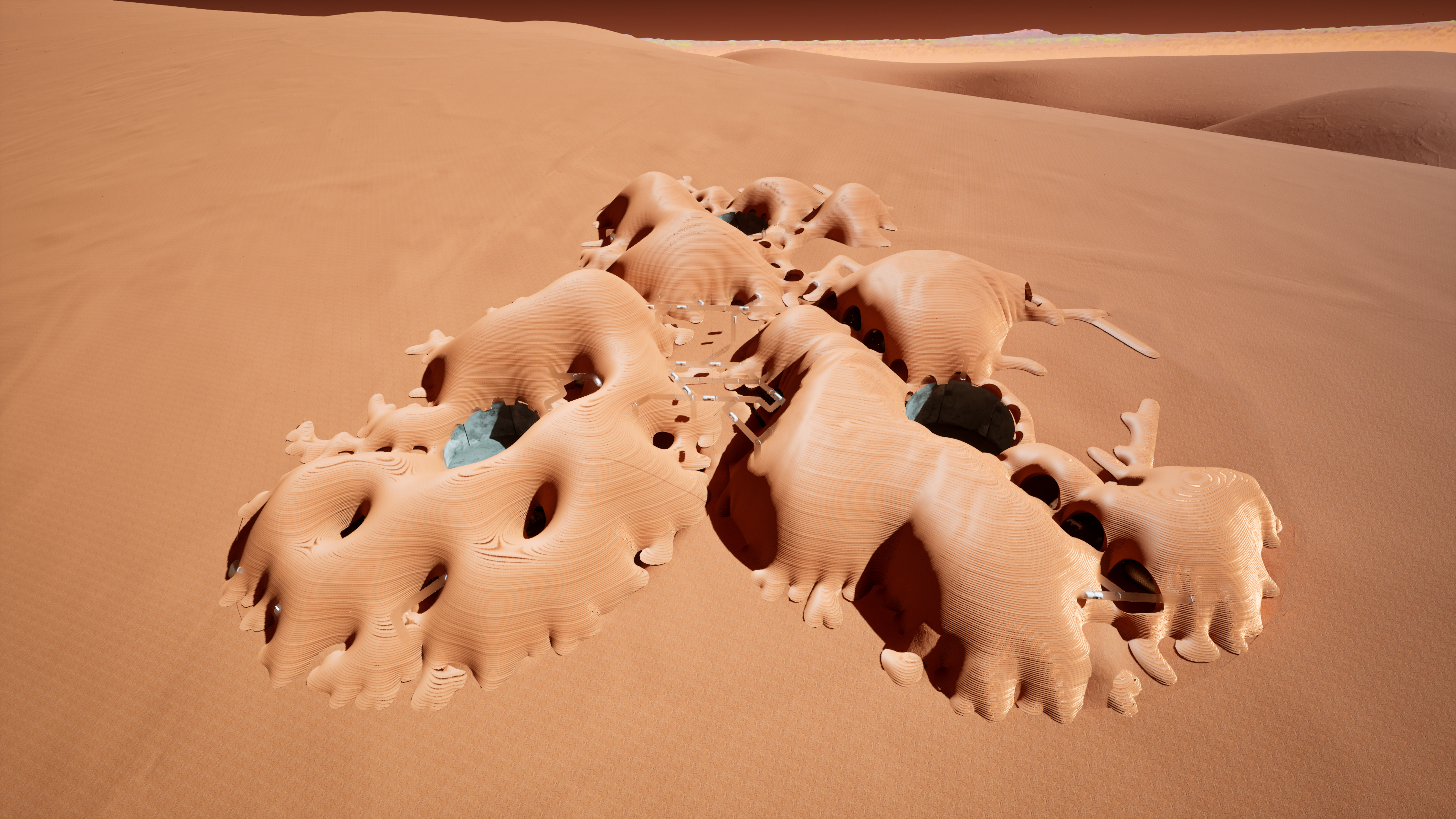

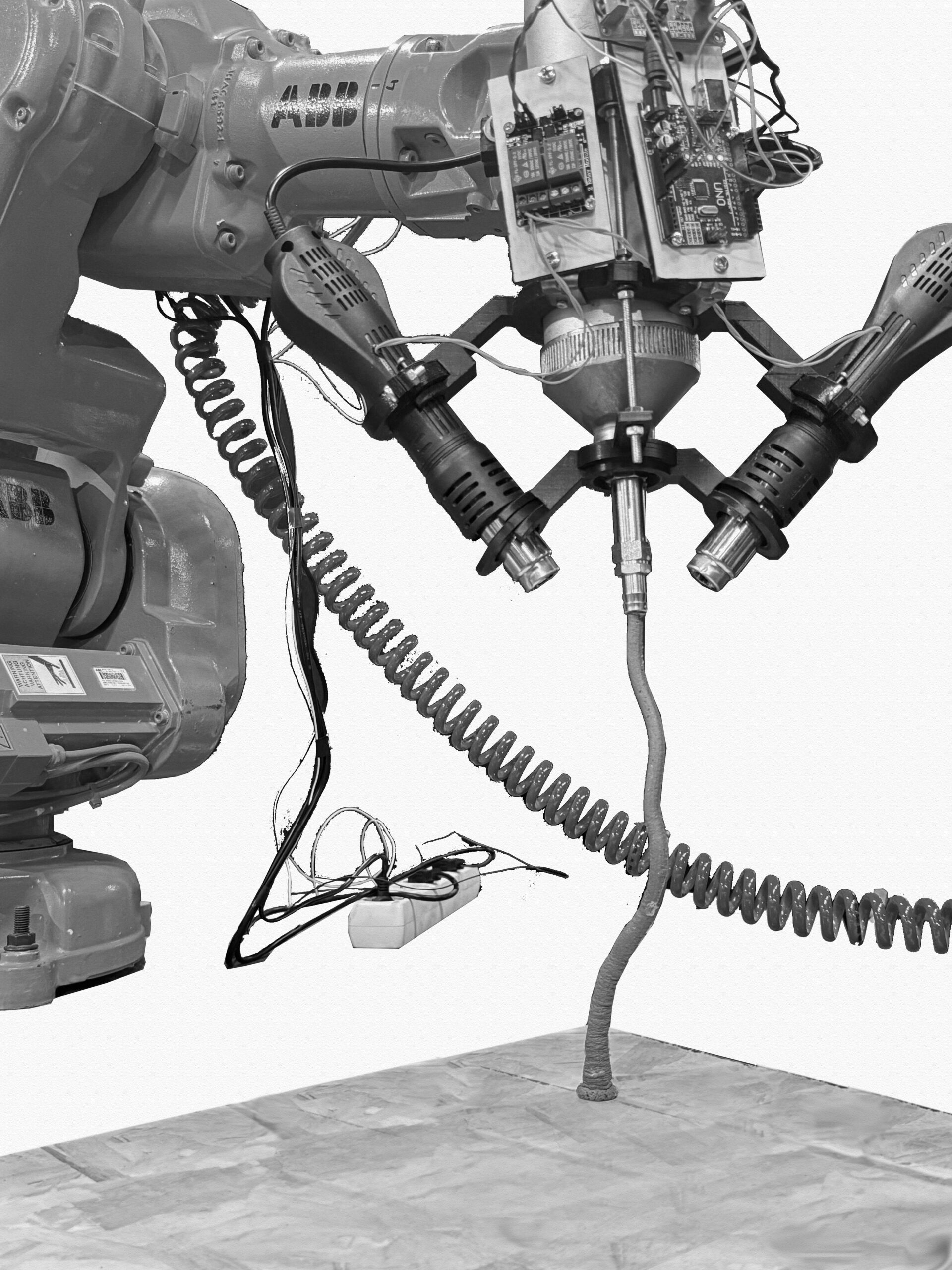

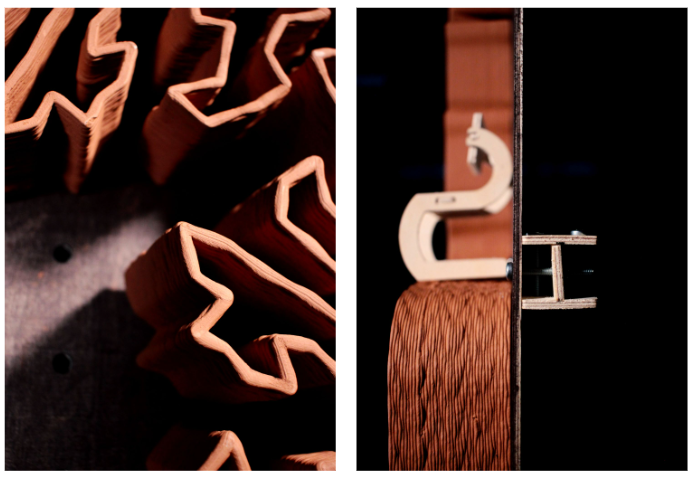

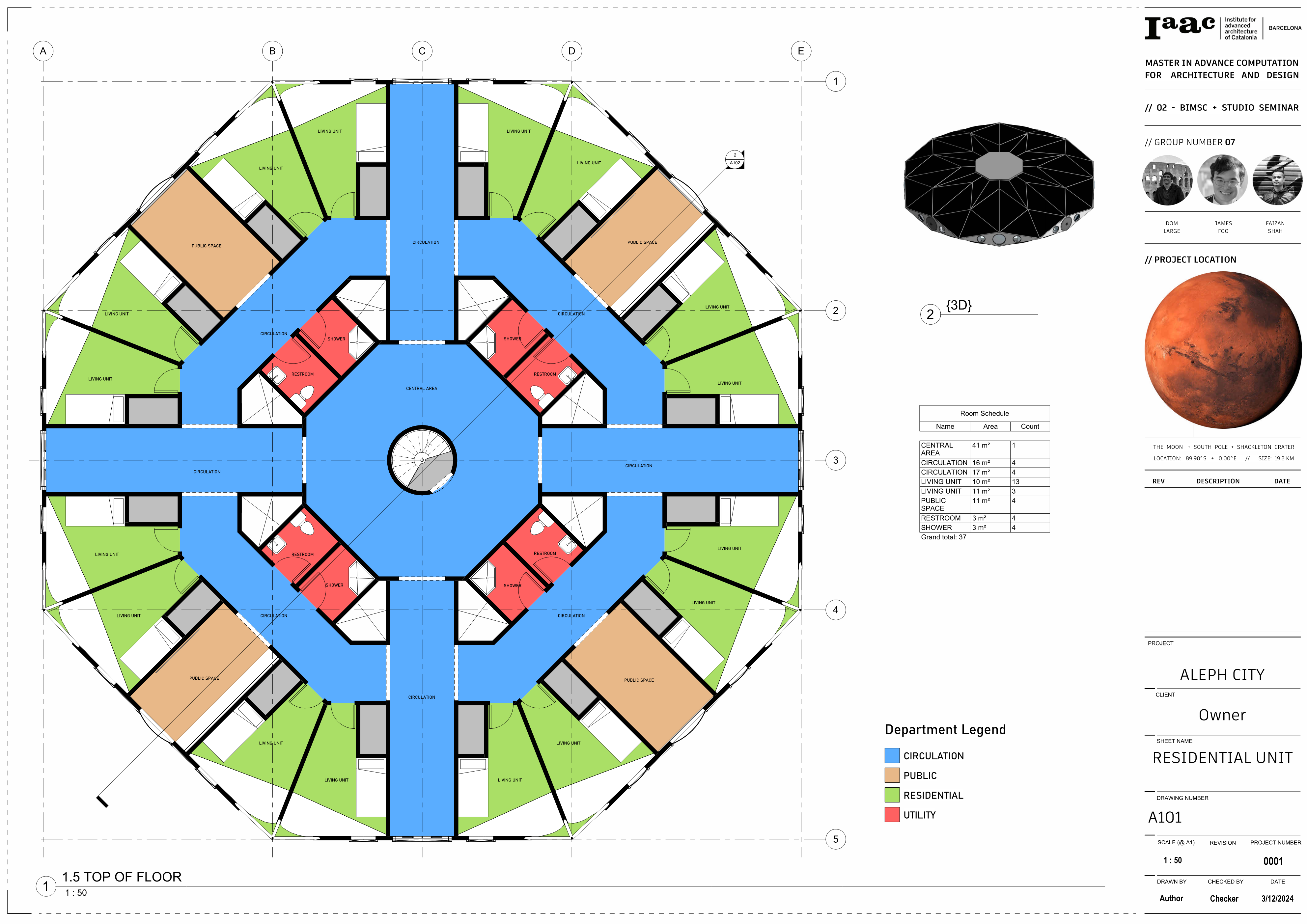

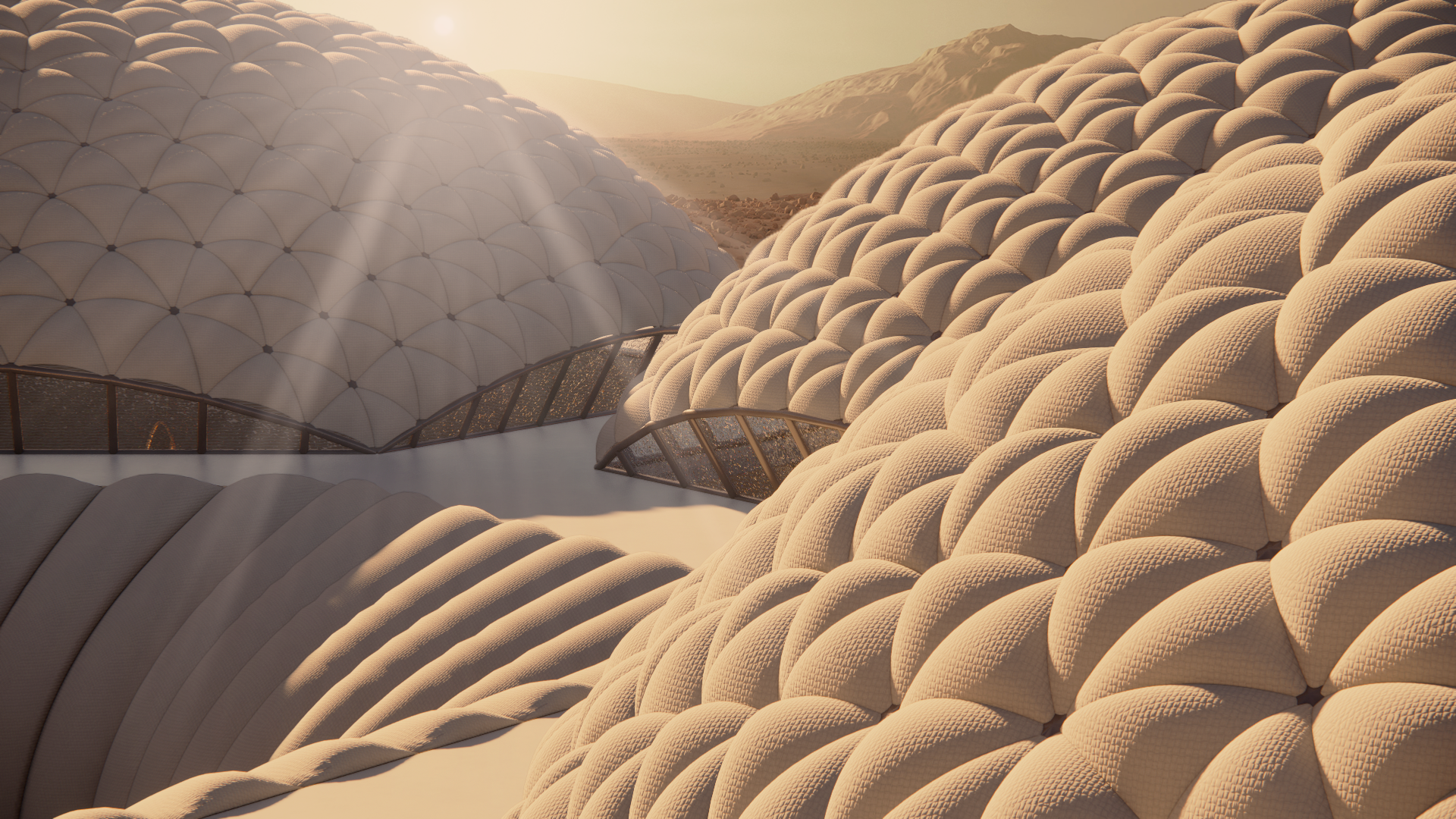

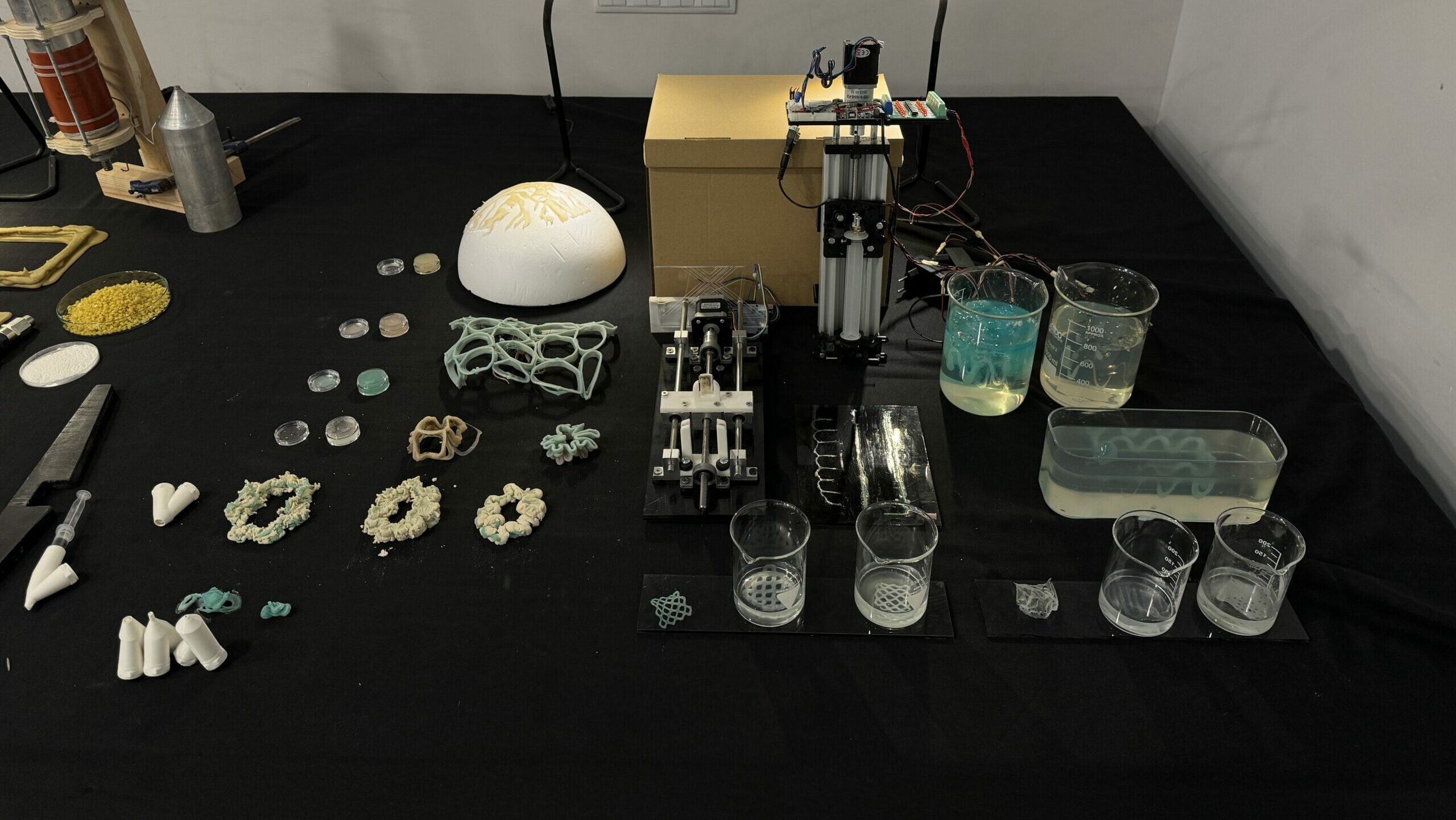

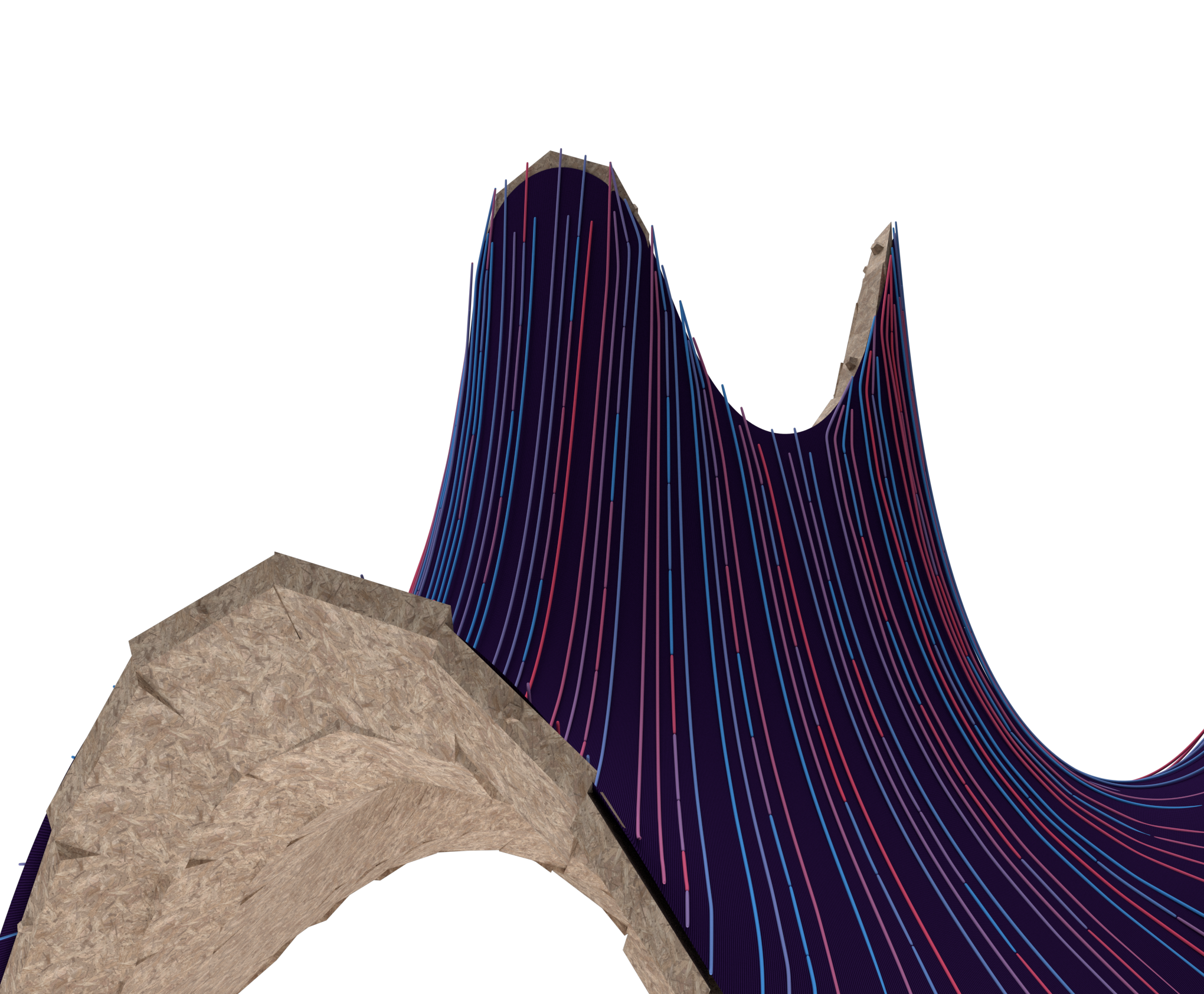

Project Concept Establishing a Martian food colony around a Mohole, designed based on growth morphology of alfalfa for efficient organization and development using L-systems. These terminologies are further explained below. Moholes Moholes on Mars are massive cylindrical excavations in the regolith, reaching up to 1 km in diameter and 7 km in depth. With temperatures … Read more