The umbraculo bench is designed to be placed in the Umbraculo, Parc de la Ciutadella, Barcelona. It is designed as an organic shaped bench focusing on materiality, ergonomics as well to be a state of art element. It is designed and constructed using CLT panels made using pine wood lamellas.

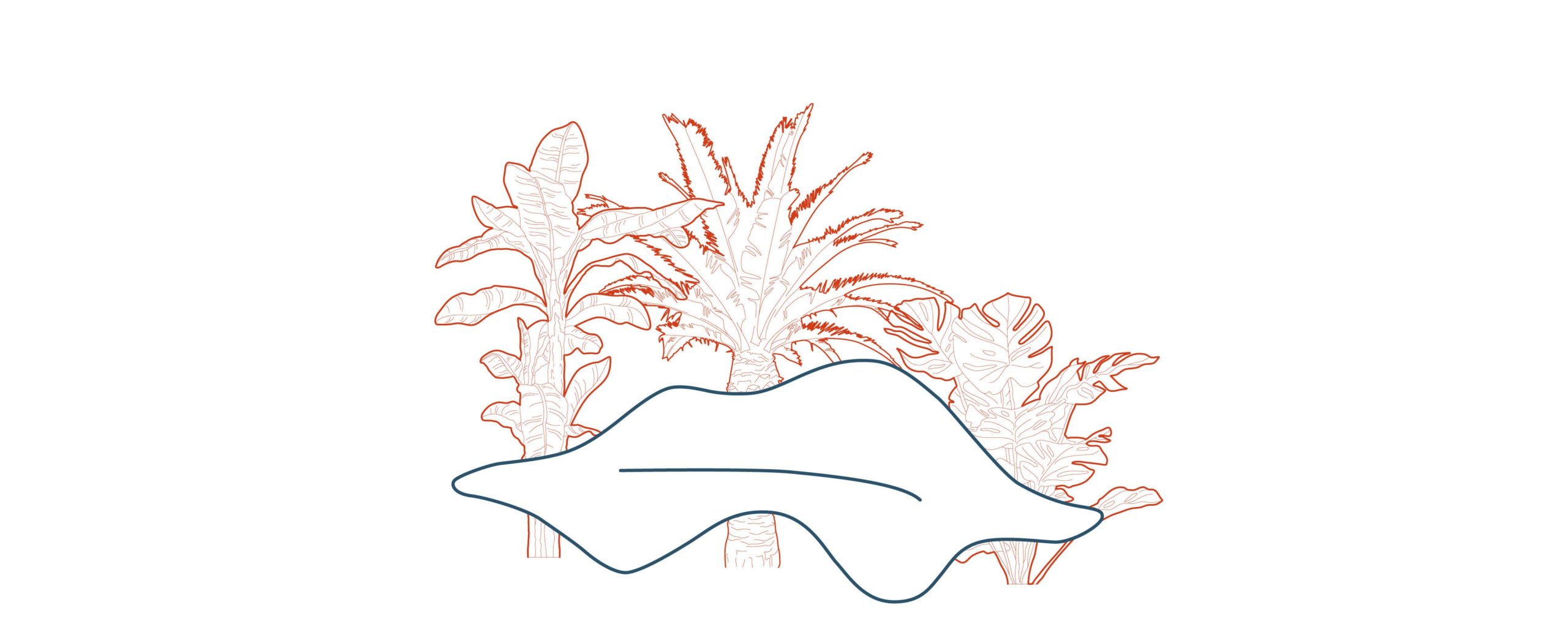

The Umbraculo

The Umbraculo translates to shade house. Located in the Ciutadella Park, it is an iron building with a trefoil profile where different tropical and subtropical plants grow. The umbráculo, one of the buildings built on the occasion of the Universal Exhibition of 1888, recreates the conditions of the shady and humid forests where the planted species grow.

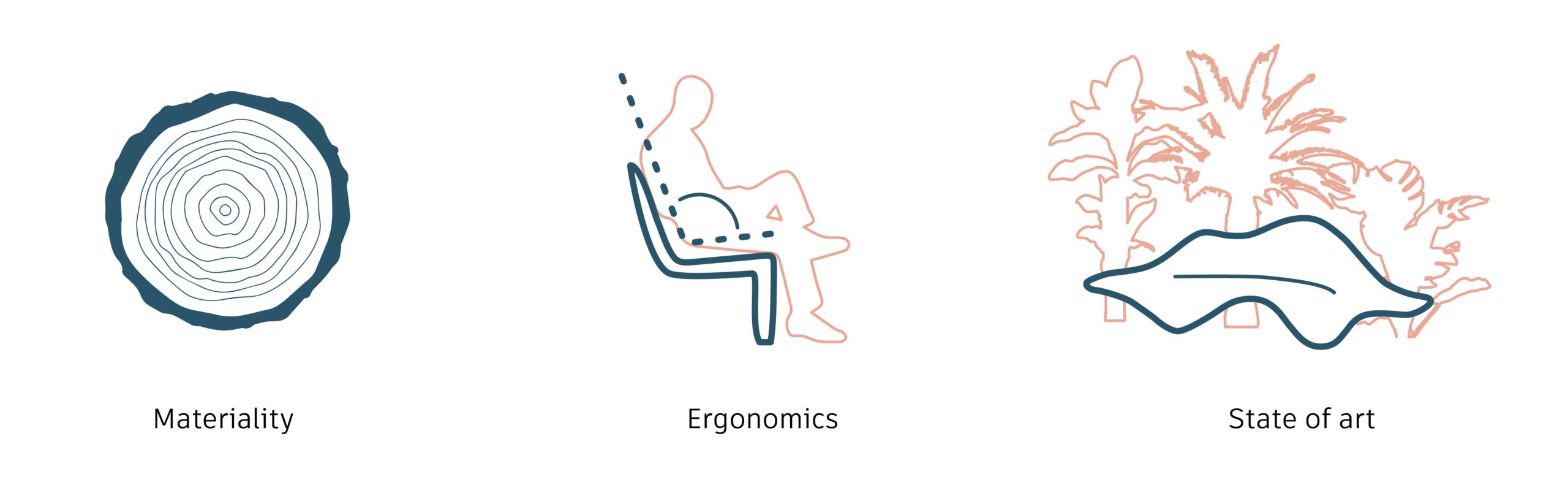

Design Philosophy

The design focuses on three main aspects for its philosophy. The first aspect it focuses on is the materiality, the design aims at showing the extremities wood can exploited to. Next the design aims at being highly ergonomic and welcoming, attracting people and instilling a feeling of wanting to sit on the bench. Finally, the design is oriented at being a state of the art production.

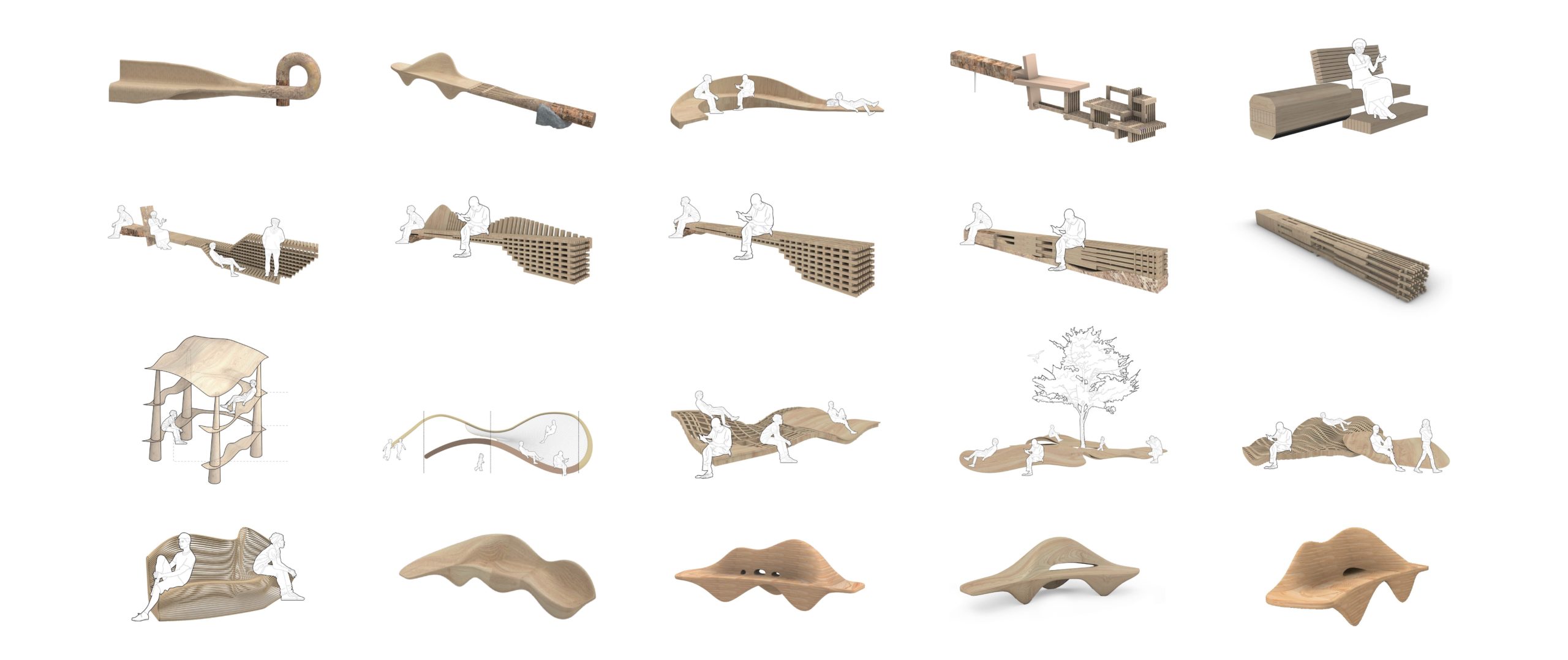

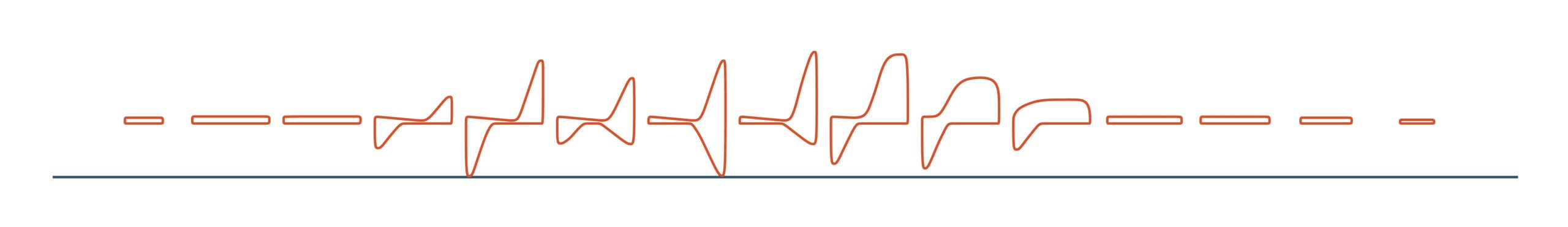

Design Iterations

The design process went through many iterations until the final design was decided upon. The various iterations were focused on the same design philosophies as the final design i.e., ‘materiality, ergonomics and state of art’.

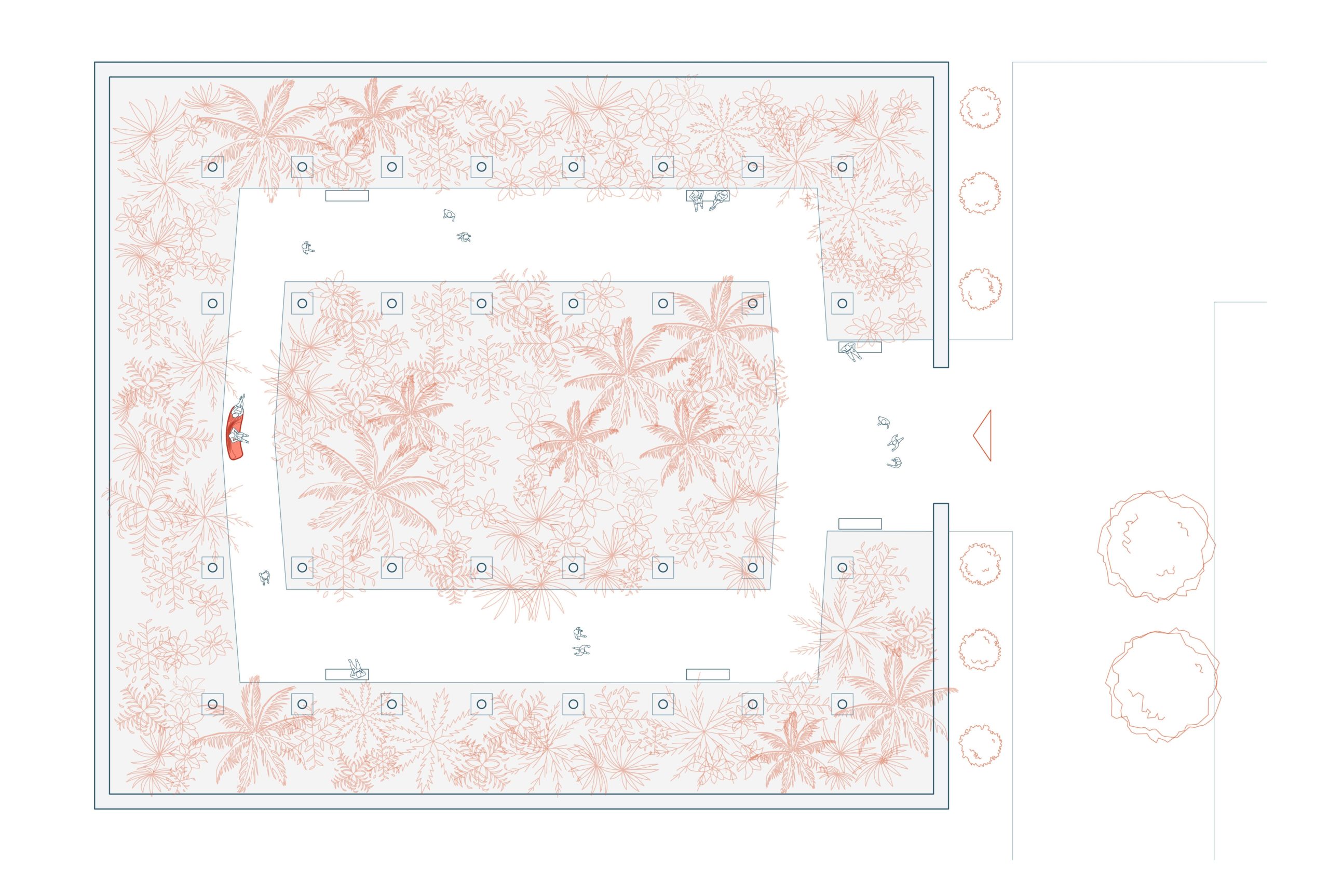

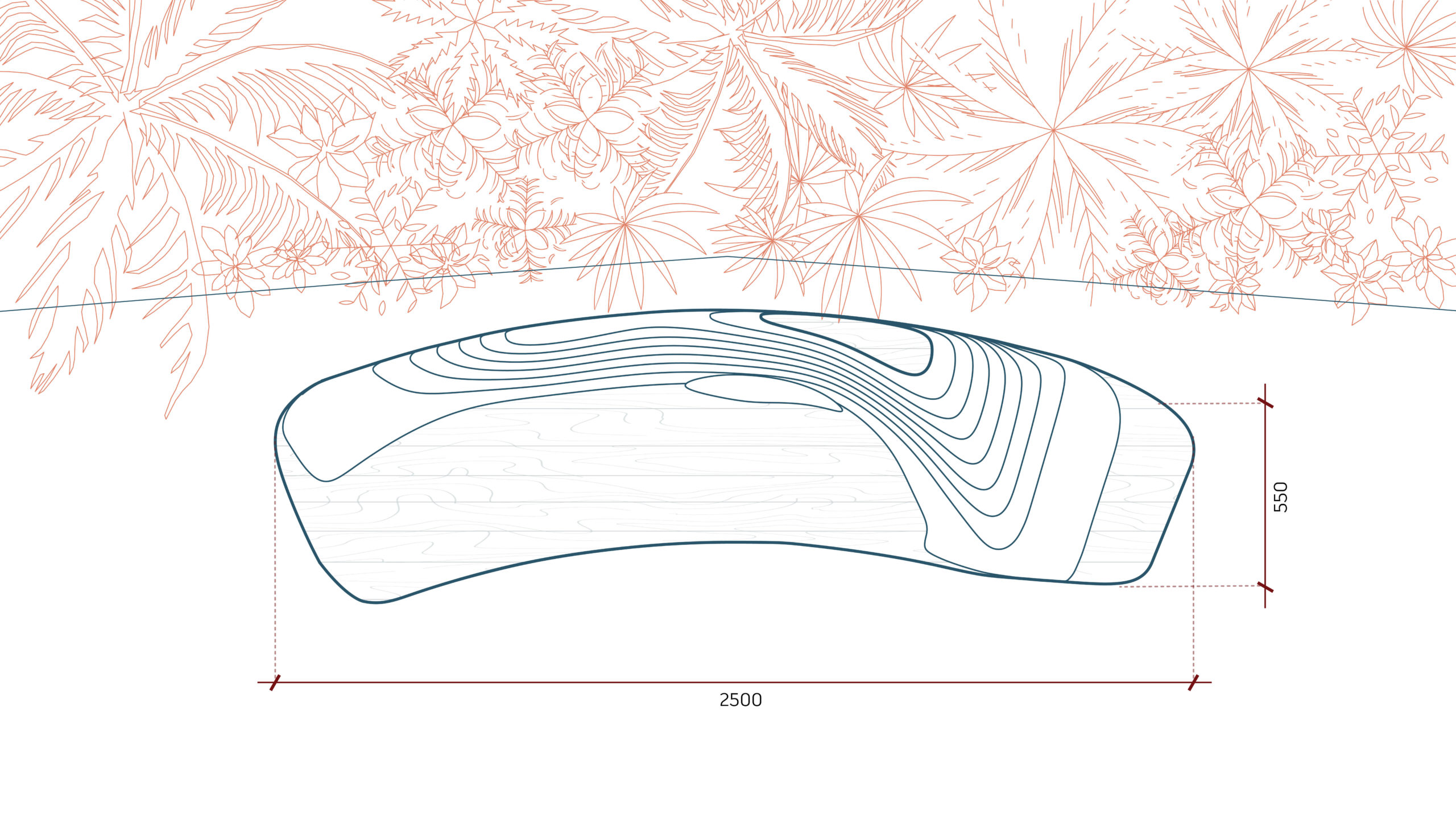

Design Proposal

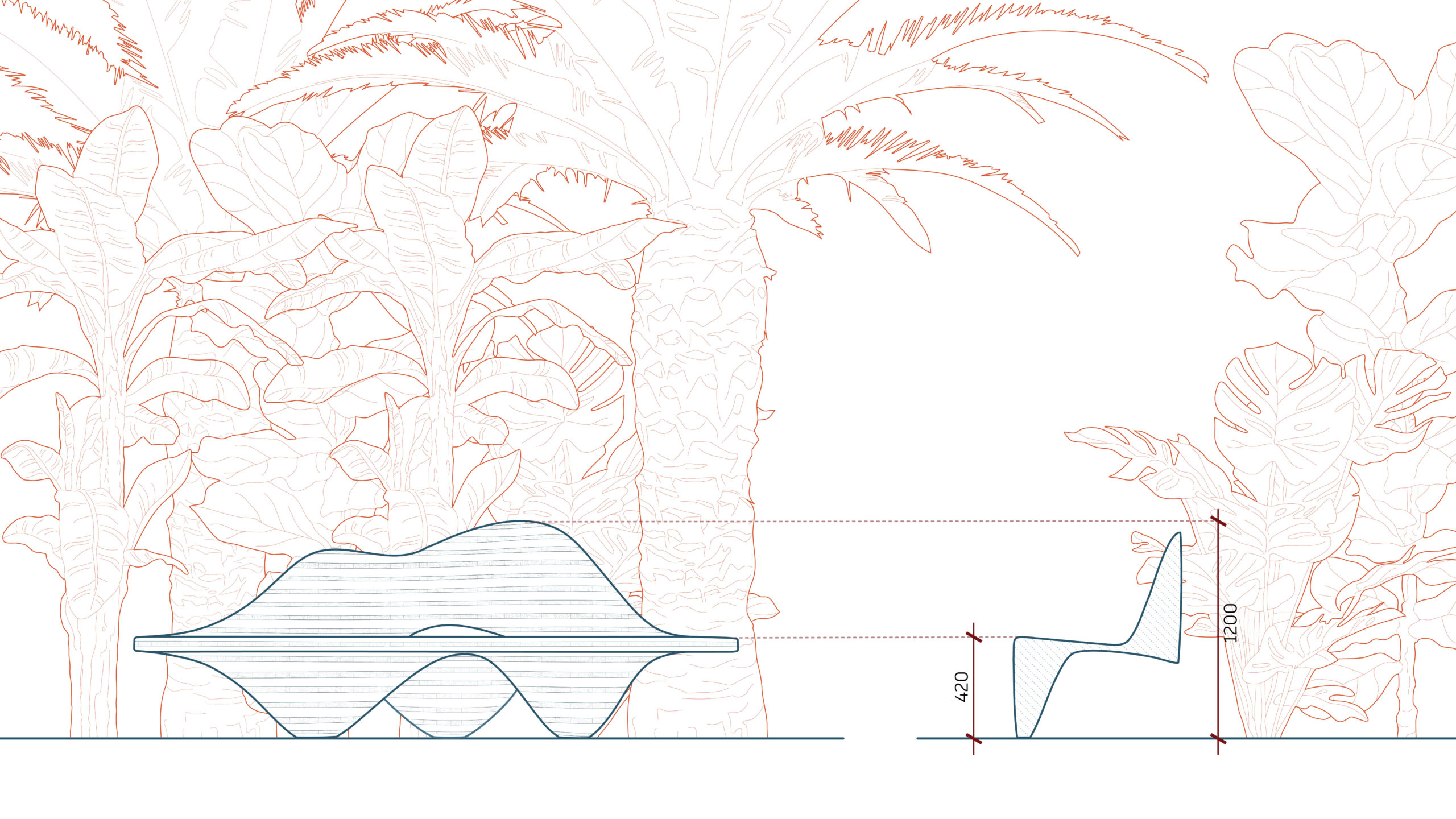

The bench was designed to be 2.5m in length and 0.55m in width making it comfortable for 5 people to easily utilise it. With a seat height of 0.42m and a total height of 1.2m the bench was made ergonomical and comfortable. It was decided to place the bench at the very back of the site and avoid the entrance so as allow the bench to appear as a part of the tropical vegetation. The aim was to make it appear as though the bench was meant to be amidst the vegetation. Along with this it becomes an interesting pause point for visitors as they walk through the umbraculo.

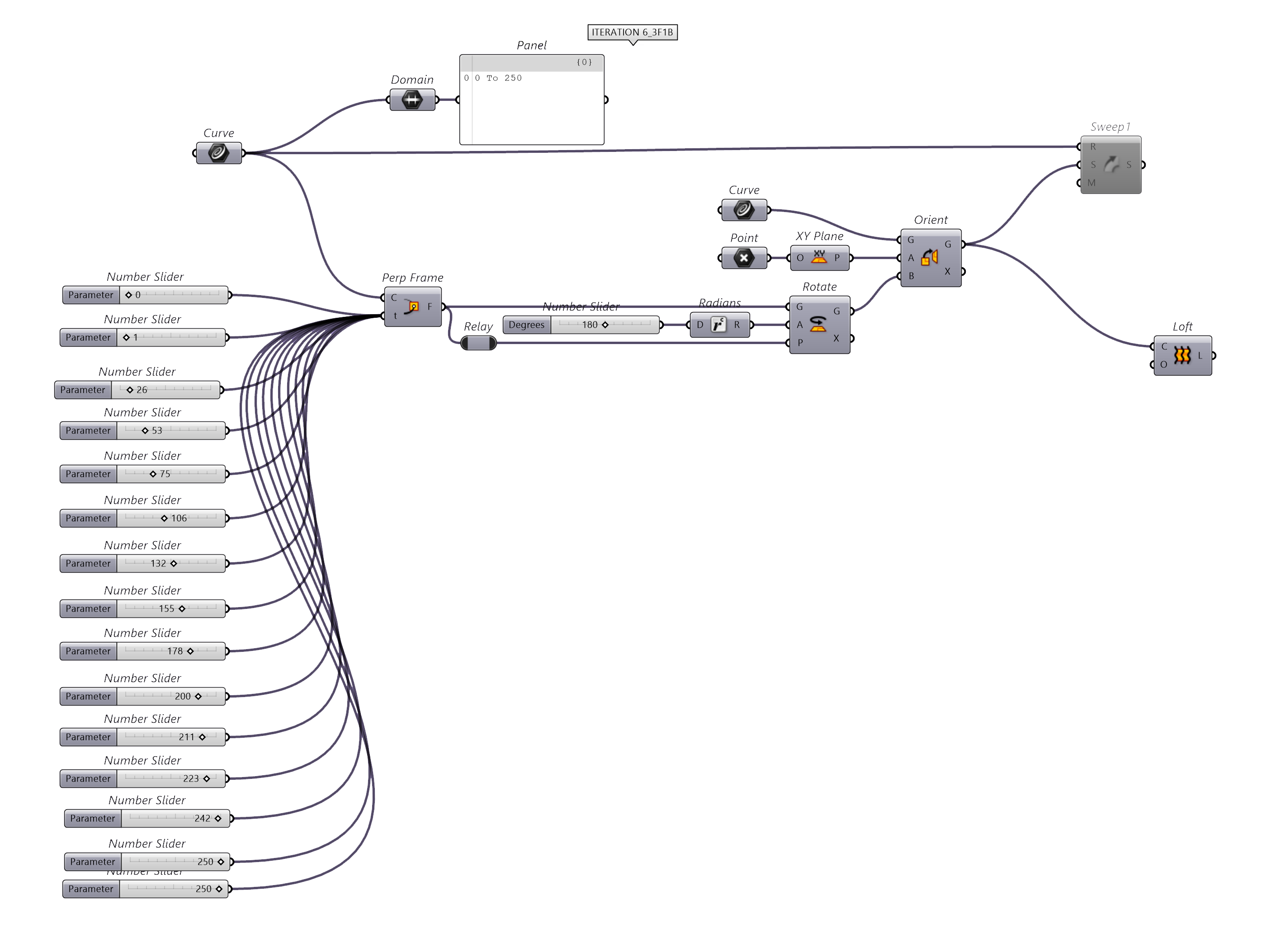

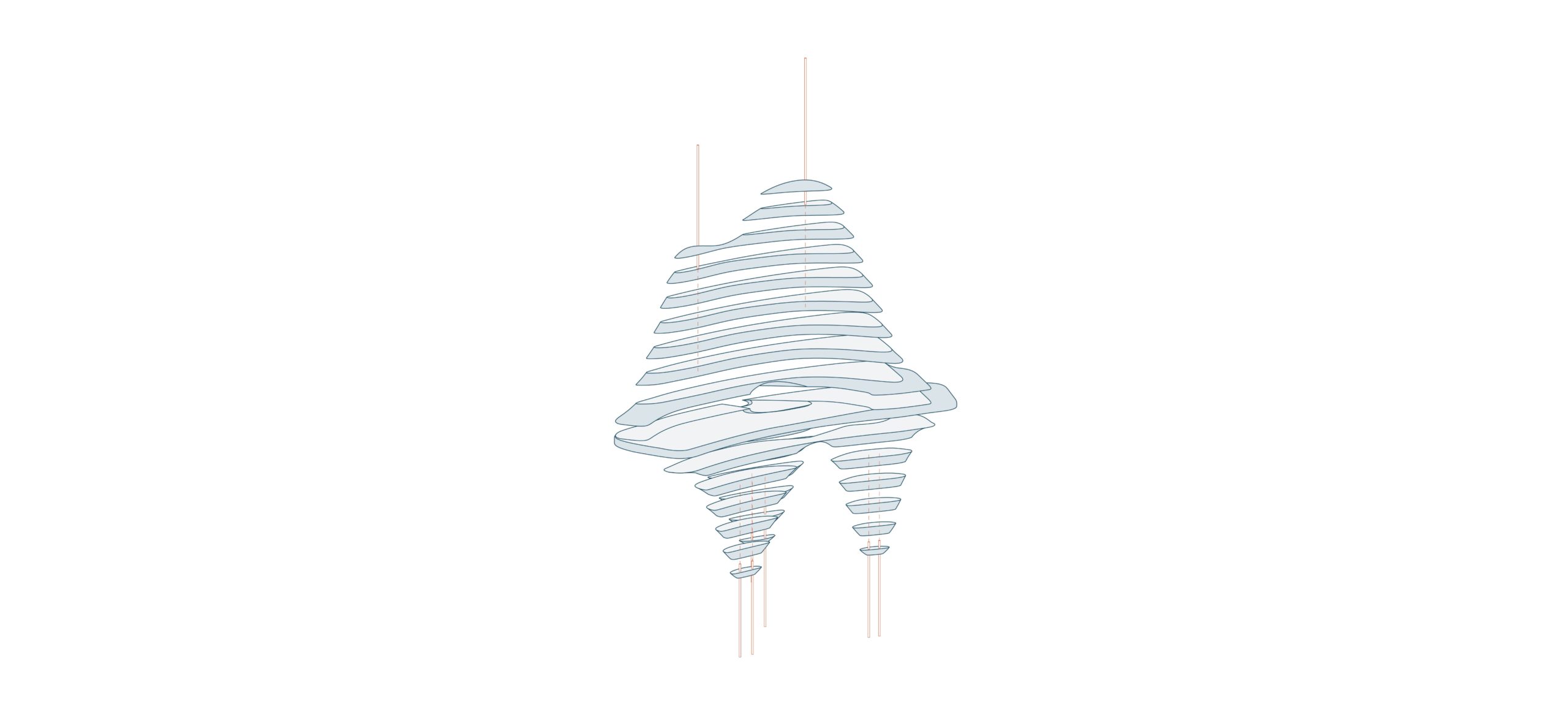

Grasshopper

The transition of the different parts of the bench was designed based on the ideal ergonomic seating. These different sections were lofted along the desired path using the grasshopper plugin of the rhino software to generate the final form of the bench. By creating these different sections we were able to achieve a seamless curvature and transition in the bench making it comfortable for all user groups.

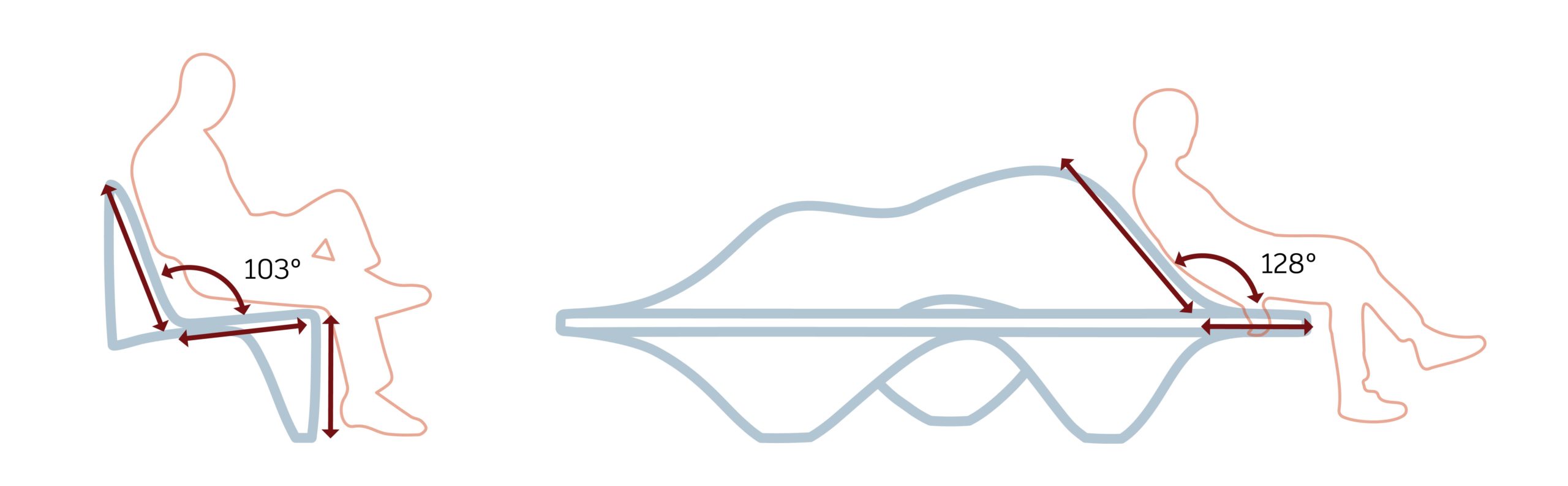

Ergonomics

Before we started designing the bench we first focused on the ideal ergonomics of a bench, those which would be suitable for a diverse user group. Once the deep dive was completed, we concluded that the the angle between the seat and the backrest of the bench should be a 103 degrees and the angle for a more laid back position should be a 128 degrees.

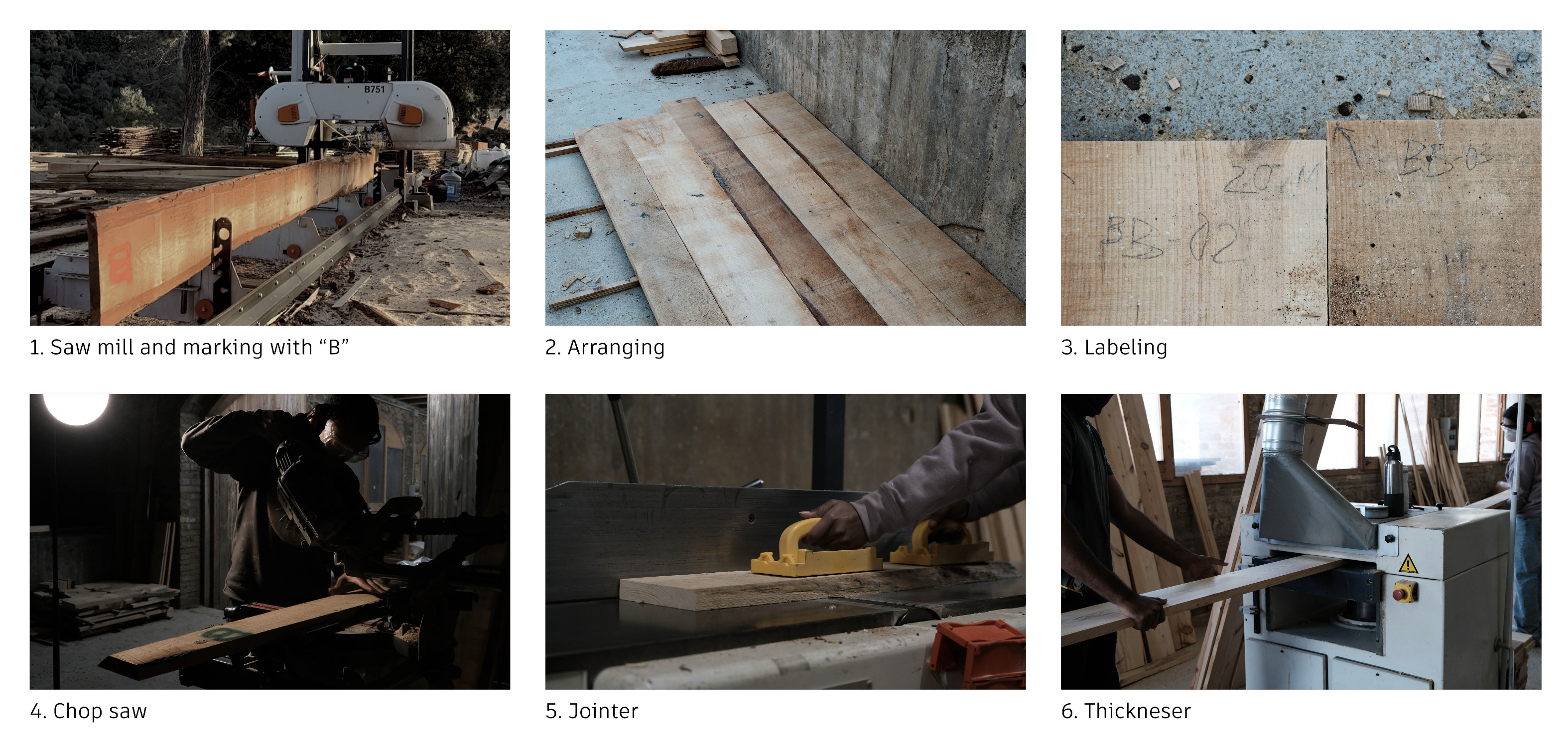

Production

1. Timber Preparation Phase

The timber preparation phase was a sequence of processing the pine planks to make sizes required for CLT panels. The dried timber of 4.5m in length was cut to size on the saw mill to the largest available width based on the tree. The lamelas were then arranged in a sequence to attain the dimension of the CLT panel of 2m x 1.2m. They were then labelled as per the placement as well as their panel number and cut to the necessary length utilising the chop saw. Once all the pieces were cut to size they were planed and levelled using the jointer and thicknesser.

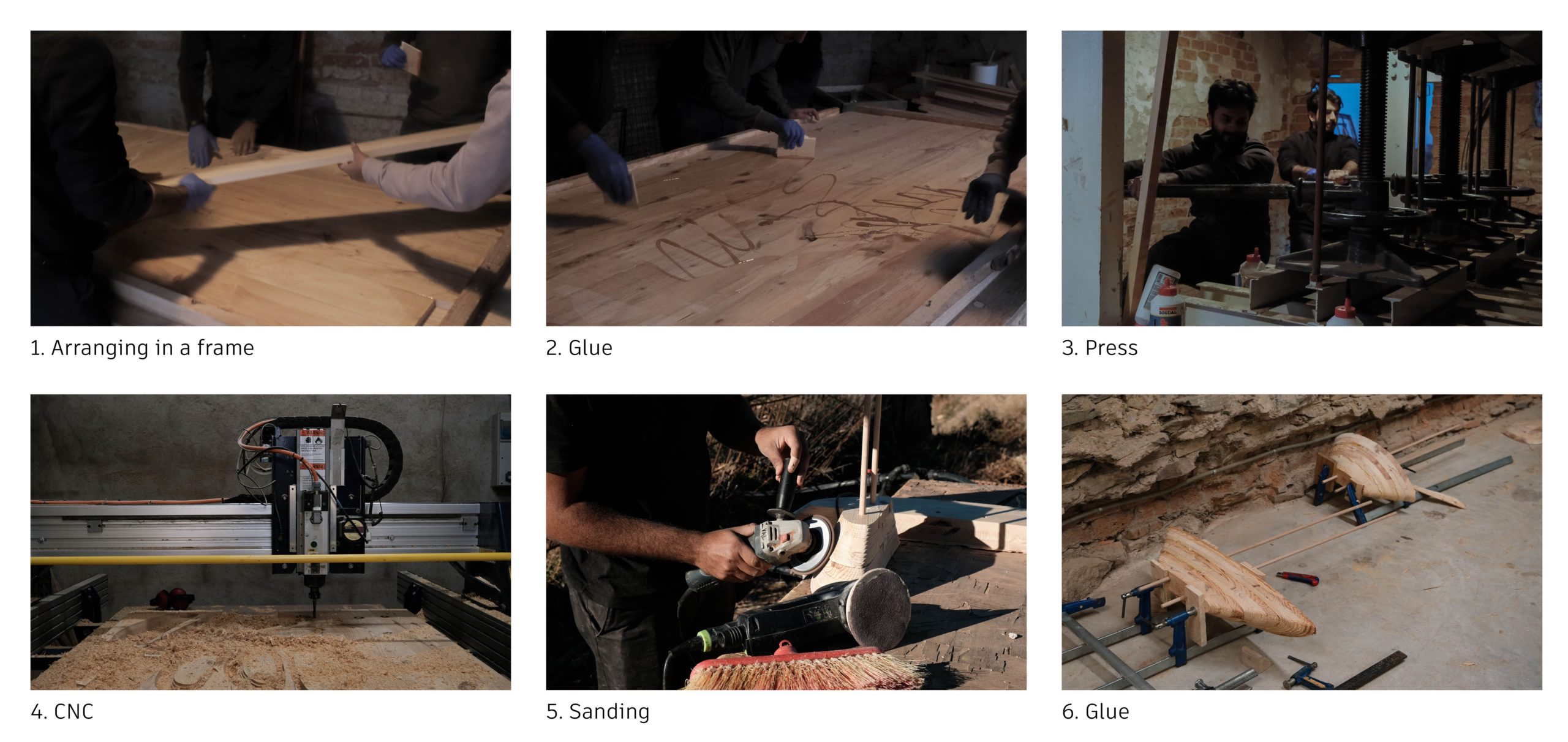

2. CLT Preparation, Bench Assembly & Sanding

The panels of wood, were arranged in their CLT format using a fence that aids as a guide for alignment but also as compression on all the sides of the CLT panel. Once arranged and verified the first layer was placed and a polyurethane adhesive was utilised to glue the next layers. The panel was then placed under a mechanical press which provided the necessary compression and were left to dry for four hours. Once the panel dried, it was placed on the CNC. The CNC was pre-programmed to cut the necessary parts of the bench. The pieces were then connected to each other using the same polyurethane adhesive and dowels for alignment. Each piece was then sanded to clean and sculpt the bench to desired shape.

Final Product

The final bench is an organic shaped bench designed to showcase the materiality, ergonomics as well as to be a state of art design.