Employing a passive design strategy for construction can be a viable way to address this issue since buildings use the majority of the energy consumed in a city for heating and cooling space. The goal of the study is to create a passive heating and cooling system in a controlled environment by experimenting with the hydraulic property of water movement caused by capillary action in different building materials.

Research Framework

Buildings use the largest portion of the energy consumed in a city for heating and cooling space, so employing a passive design strategy for construction can be a good way to deal with this situation.

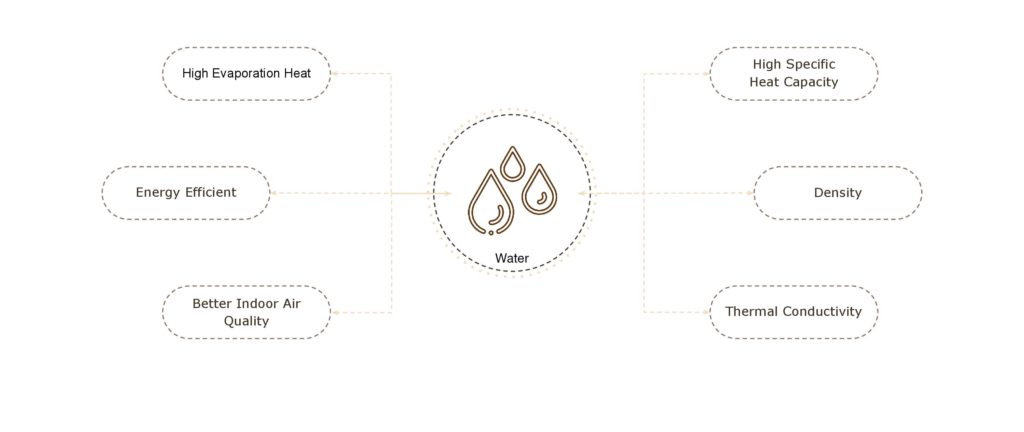

Choosing Water as a Source of Passive Cooling System

Why Water?

State of Art for water

Making use of clay – particularly terracotta – to cool things down naturally is a low-tech method that’s been used for centuries. When water seeps through porous terracotta and evaporates at the outer surface, the evaporative heat loss cools down the inner space with the water.

When drenched in water – which gives the installation a beautiful waterfall effect – the humid clay traps some of the heat from the air and the process of evaporation gradually lowers the air temperature.

Research Statement

Globally, active heating and cooling systems in buildings hold a large sway in the area of energy usage. The research is focused on developing a passive heating and cooling system in a controlled environment, by experimenting on the hydraulic property for flow of water by capillary action in various building materials to optimize the capillary rise.

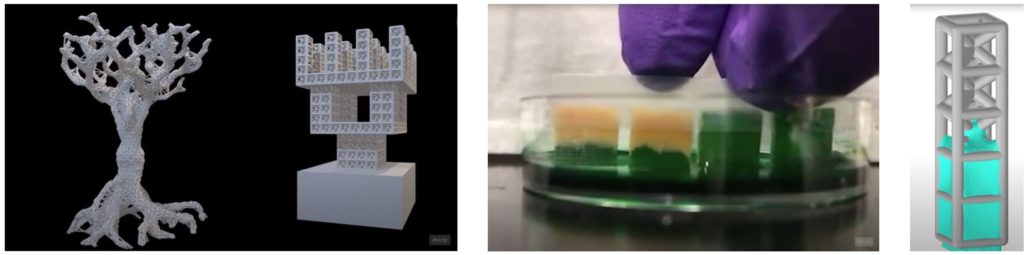

State Of Art Capillary Action

The paper clay air-humidifier is an earthenware object designed for the home environment. To work, it simply uses capillarity and evaporation.

Material : Composite earthenware paper clay

Liu says that his humidifier was inspired by the way trees work in nature: “The bottom water storage part is like the ground and soil. The extension curves [which are inside the water container] are like the roots of a tree absorbing water. The main part carries water upwards and radiates, like tree trunks and branches.”

Material : Clay & Ceramic

The researchers produced a small cube design with cross beams that “holds” water when exposed to the fluid. By arranging a structure of such cubes, it’s then possible to design arbitrary geometries where the entire surface includes exposed fluids.

This effect is used in nature: trees, for example, obtain water from the soil through capillary action: the surface tension of the water tends to draw the fluid through the tube up into the tree.

State of The Art Conclusion

- Incorporation of this system in different scale has yet to be explored.

- If applied on the bigger scale, what is the structural stability of the material.

- If the system is placed in exterior wall or environment what will be the Weathering effects

Aims & Objectives

Aim

To maximize the capillary rise of water in the system, try to discover the construction material with the best capillary action properties in combination with the most optimal geometric lattice structure.

Objectives

Property Study of the material to support the capillary action

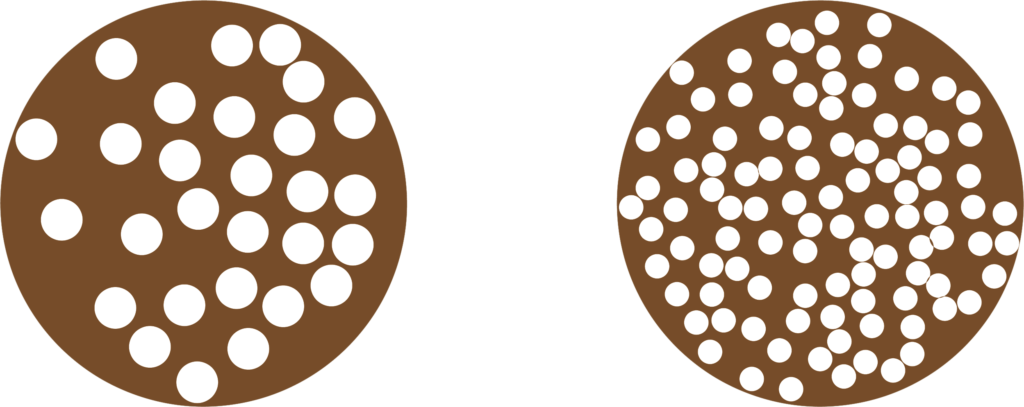

Porosity Of the Material

More the porosity more the water absorption in the material here are few list of material with maximum porosity:

- Gas Concrete

- Gypsum Plaster (Lime Putty)

- Fly ash

- Clay Bricks

- Sponge

Water Absorption

- Sponge

- Paper

- Gypsum Plaster

- Clay Bricks

- Cotton

- Concrete

Bulk Density of material

More the bulk density less the porosity, hence less water absorption

- Paper

- Clay Bricks

- Lime Plaster

- Gypsum Plaster

- Gas Concrete

Hence working with plaster is the best material comparing the properties necessary for capillary action.

Plaster

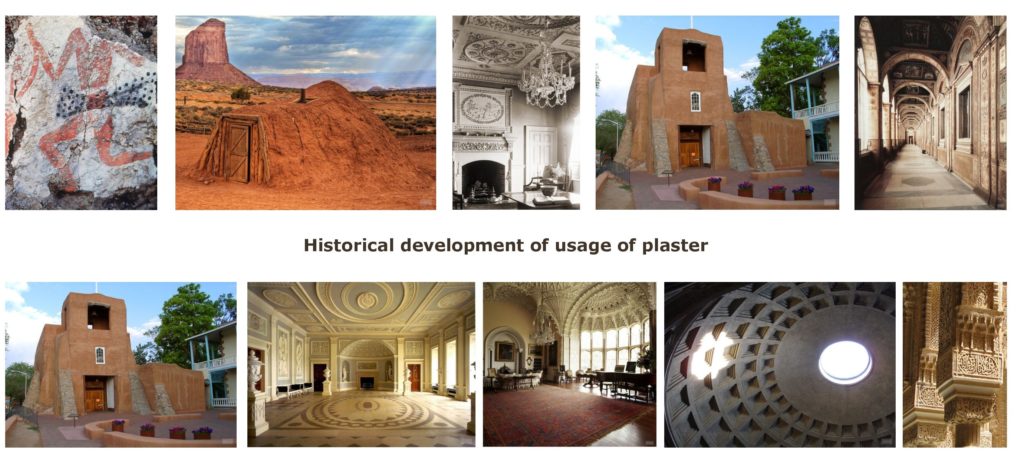

Timeline of plaster

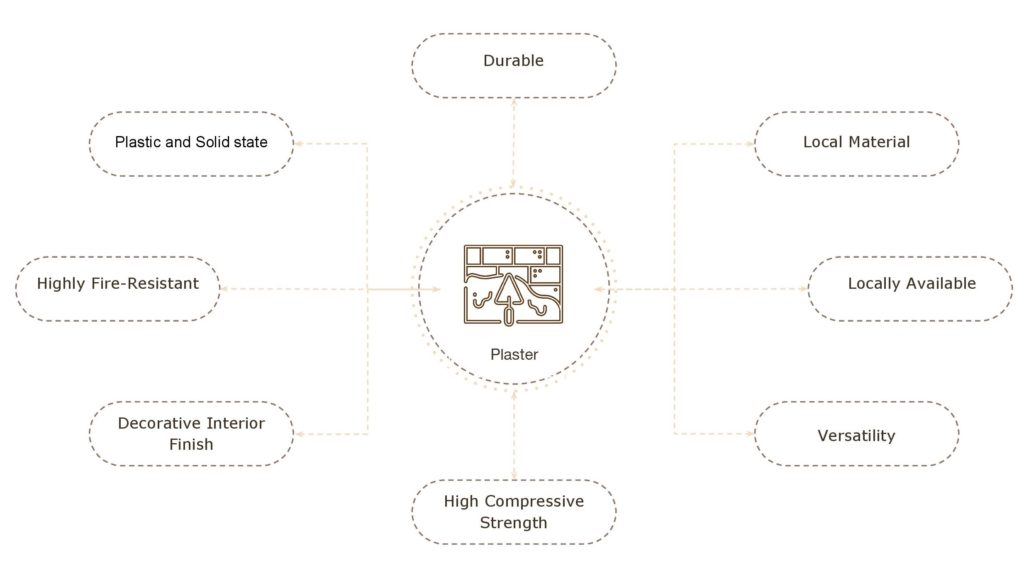

Properties & Advantages of plaster

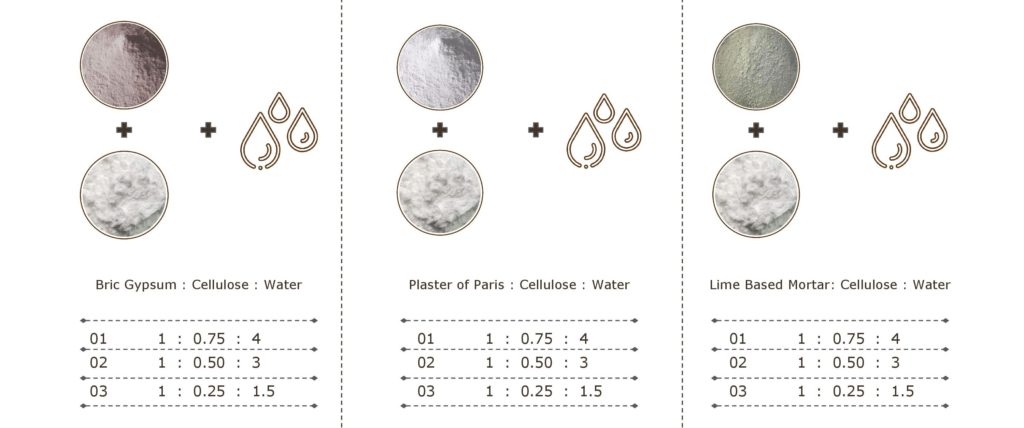

Material Experimentation Of Plaster

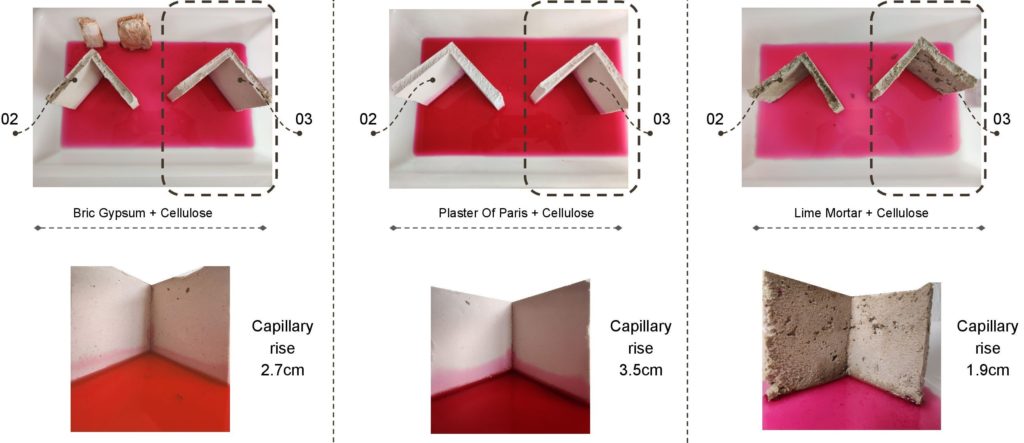

Conclusion: After keeping for 6 hrs in the water it was evident that POP had the highest amount of capillary movement and water absorption in all 3.

Project Statement

The project’s goal is to investigate alternative water transportation methods in structures to irrigate surfaces that can operate as passive cooling through capillary action. It specifically suggests using a multi-material manifold consisting of plaster and concrete that can controllably transport moisture by capillary action over extended distances with the best structural durability.

Fabrication

Plaster Fabrication

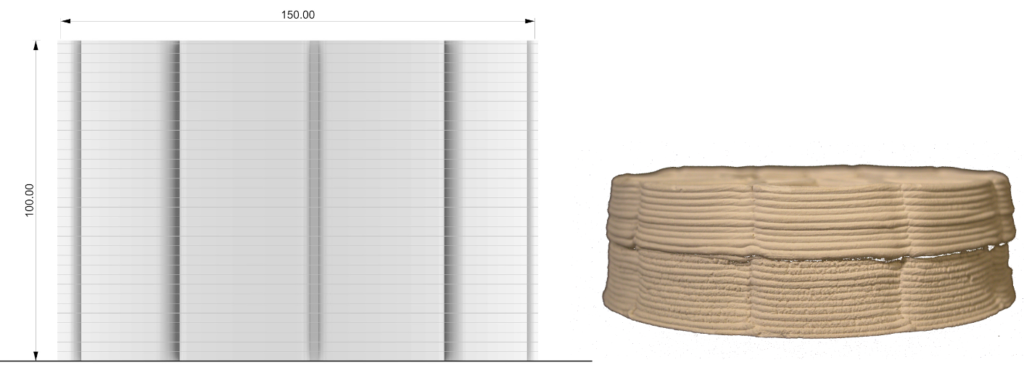

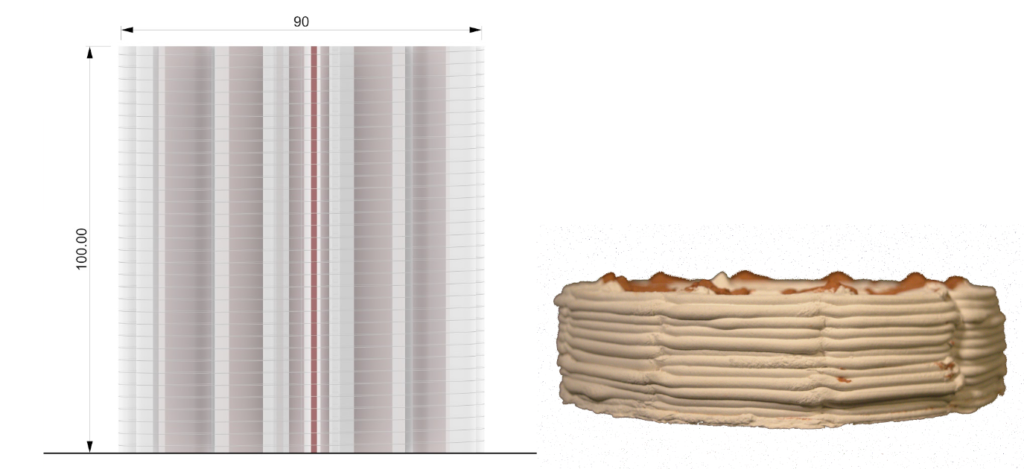

PARAMETER – First test

Material Plaster + Cellulose

Robotic arm ABB 120

Nozzle size 6mm

Speed 15% to 20%

Pressure 2.5

Layer distance 1.75 mm

PARAMETER- Infill Test

Material Plaster + Cellulose

Robotic arm ABB 120

Nozzle size 6mm

Speed 15% to 20%

Pressure 2.5

Layer distance 1.75 mm

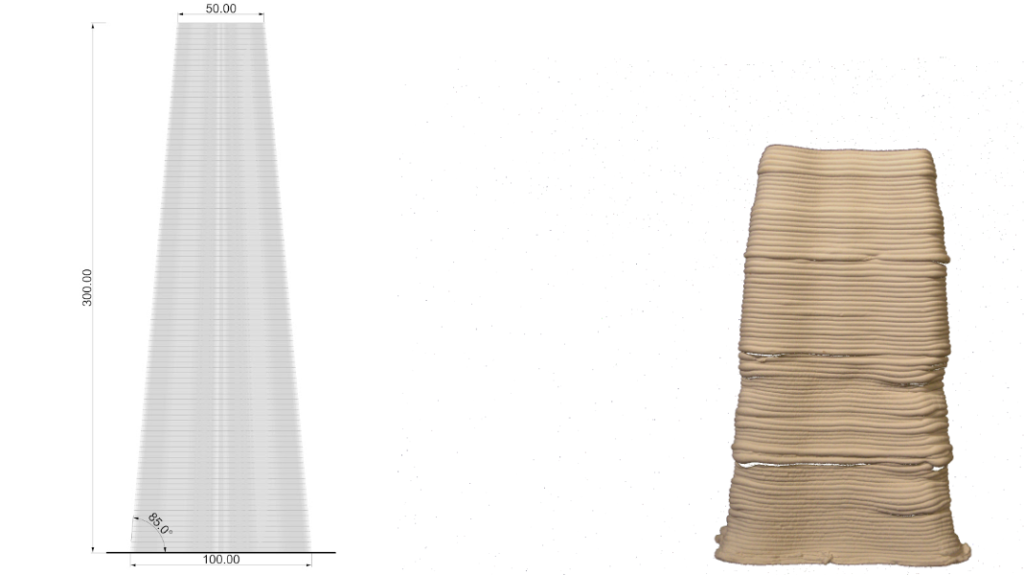

PARAMETER – Height Test

Material Plaster + Cellulose

Robotic arm ABB 120

Nozzle size 6mm

Speed 15% to 20%

Pressure 2.5

Layer distance 1.75 mm

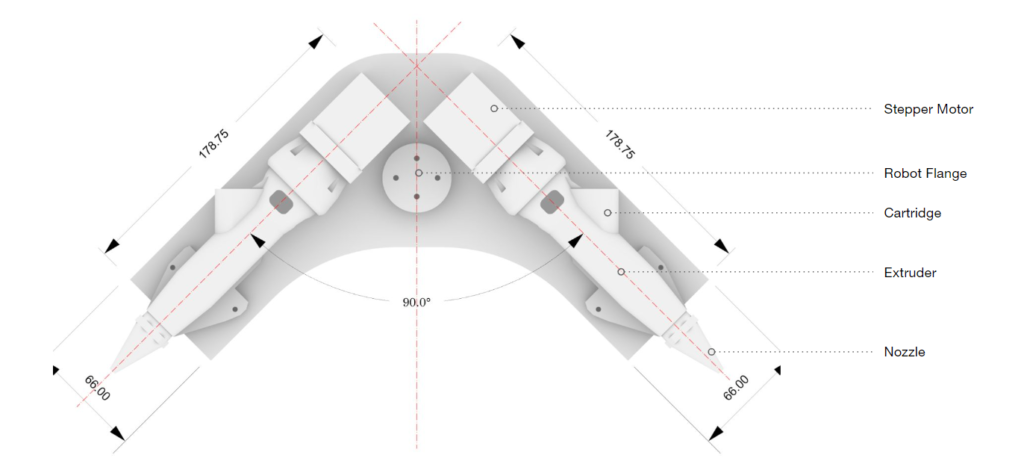

Dual Extruder Setup

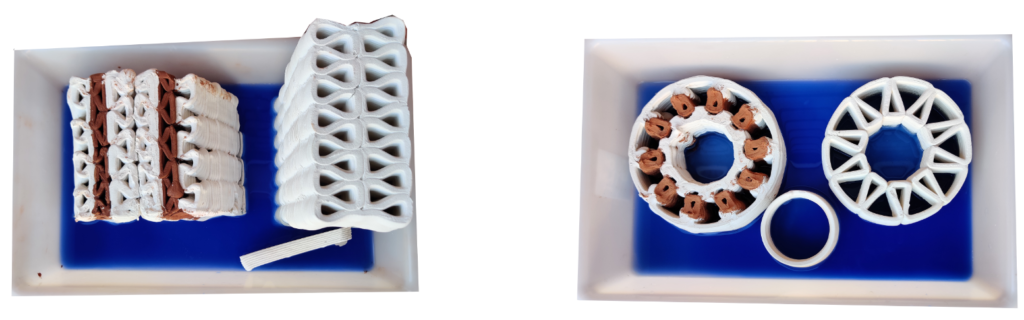

PARAMETER – Dual Extruder Infill Set-up

Material Plaster + Cellulose

Robotic arm ABB 120

Nozzle size 6mm

Speed 15% to 20%

Pressure 2.5

Layer distance 1.75 mm

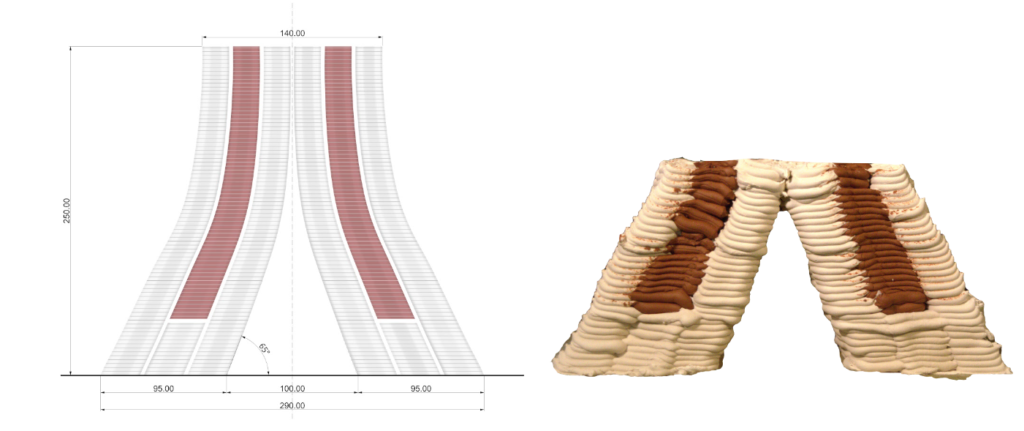

PARAMETER – Geometry Based on Above Observations

Material Plaster + Cellulose

Robotic arm ABB 120

Nozzle size 6mm

Speed 15% to 20%

Pressure 2.5

Layer distance 1.75 mm

Capillary Test

Testing prototypes in 2 cm deep water to test the capillary action and water movement in the geometry

Future Steps

- To develop a geometry that optimizes the speed of movement of water upward.

- Need to control the moisture in the system.