Our project for the Large-Scale 3D Printing with Biomaterials workshop focuses on the transition from conventional, high-emission construction to a circular, bio-based architectural model. Utilizing a 6-axis robotic arm, we have developed an acoustic envelope system composed of a cork-based bio-composite sourced from recycled stoppers. The research prioritizes a “File-to-Factory” workflow where computational geometry is directly informed by the physical constraints of the material paste. Instead of relying on standard geometries, we implemented a high-relief micro-textured surface designed specifically to maximize acoustic performance—addressing parameters like reverberation and sound clarity—while providing essential structural “self-bracing” to support the self-load of the wet cork during the additive process. This approach transforms carbon-negative waste into a performative architectural skin, shifting the focus from operational energy to the significant reduction of embodied carbon in the built environment.

Manifesto

We target the global challenge of embodied carbon in construction—39% of energy-related emissions, per the World Green Building Council —by prototyping cork-based acoustic envelopes via robotic 3D printing, while addressing the local Catalan cork waste crisis (1,036 tons/year landfilled) and its undervalued potential beyond stoppers. Our aim: prove cork’s viability for stable, high-performance partition walls that decouple temperatures across large spaces through thermal inertia and insulation (thermal conductivity λ ~0.037–0.040 W/m·K; R-value ~R-3.6–4.0/inch), integrating sound diffusion, insulation, and disassembly via parametric design.

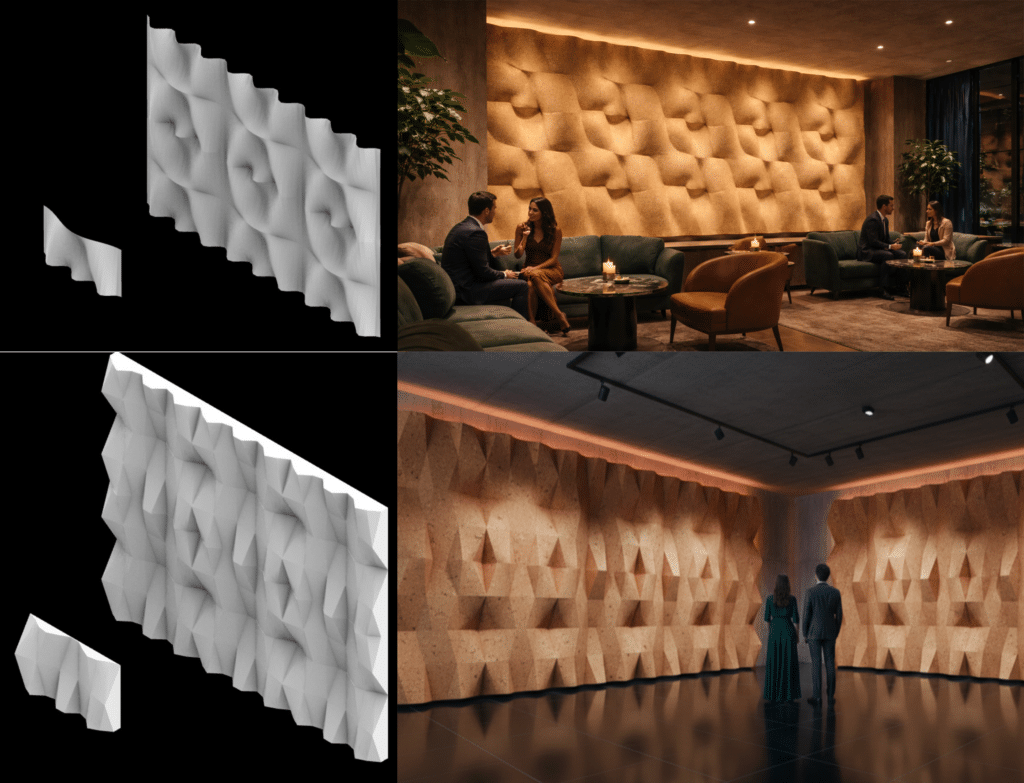

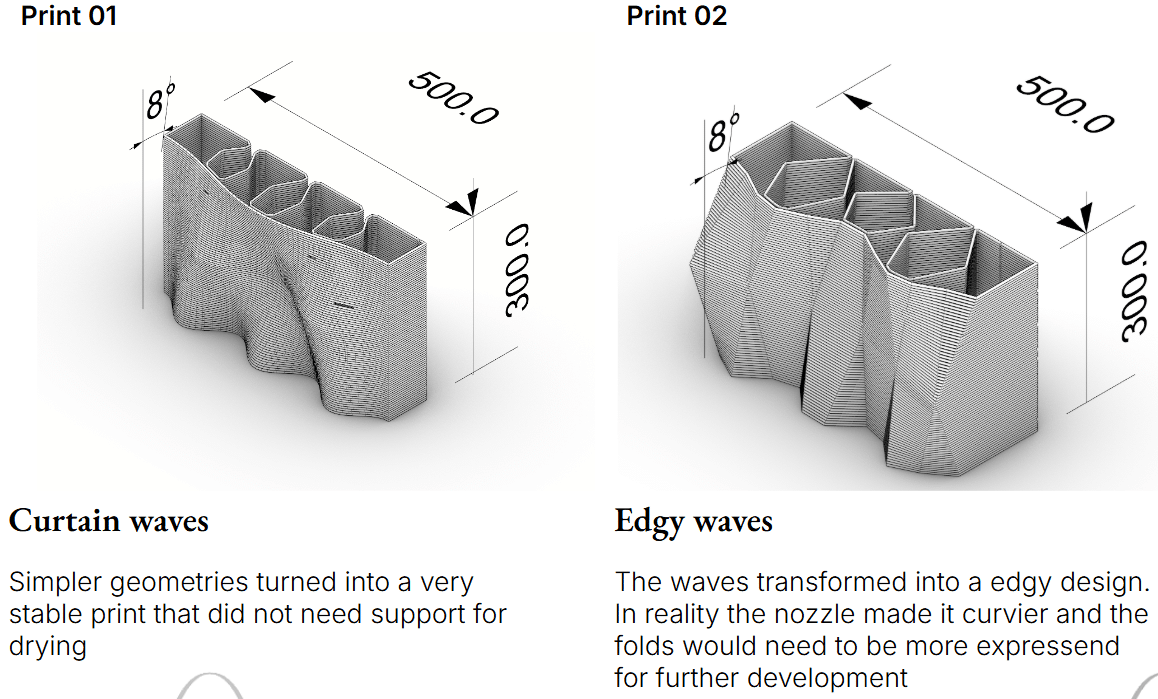

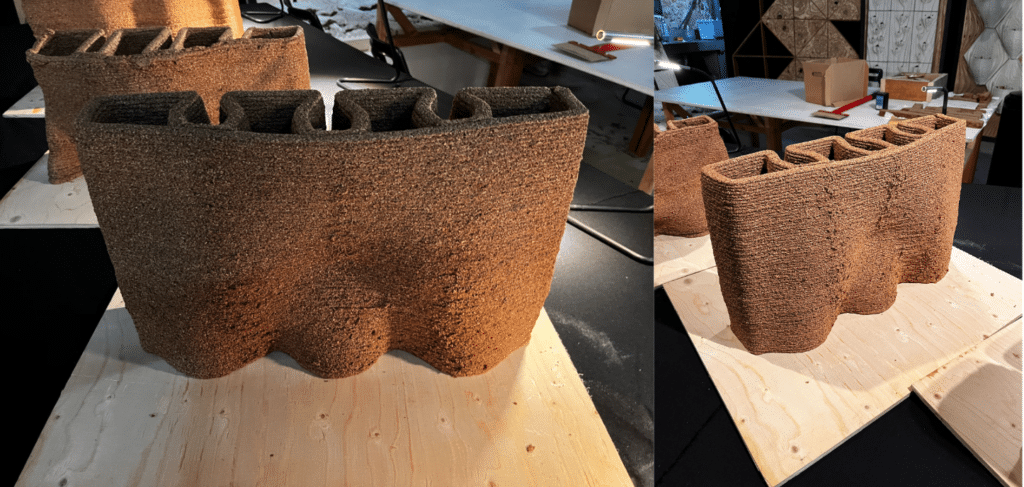

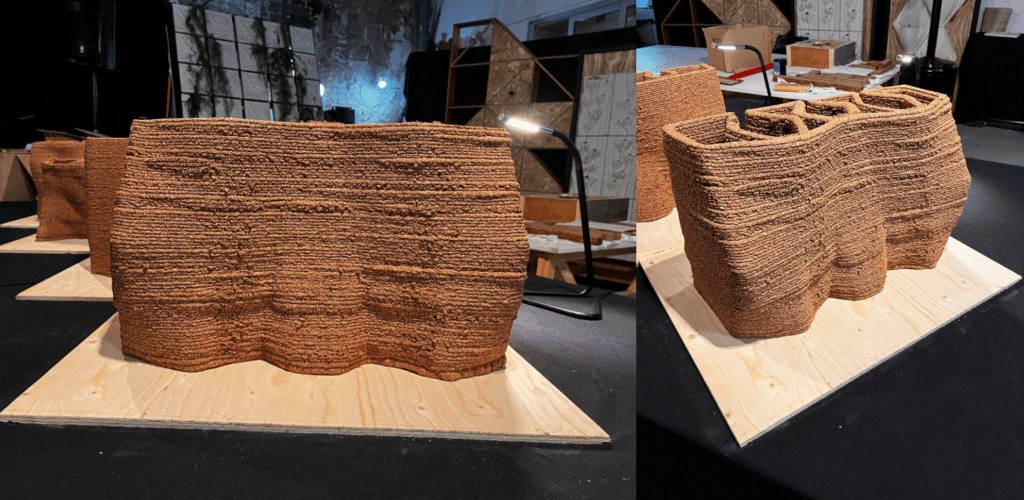

We prioritize stability over ornament: large-nozzle extrusion favors bold, thick paths—tilted curtain-like merges and sharpened Voronoi edges—that resist tipping in drying and ensure consistent acoustic scattering, as validated in our prints. Parametric scripting tunes curve exaggeration, cantilever angles, and path intersections for fabrication constraints, evolving simple geometries into scalable facade systems informed by robot kinematics and performance metrics like efficiency (material vs. waste) and lightness (void vs. volume).

Guided by the Catalan Cork Institute (ICSuro), we harness cork’s proven traits: sound absorption coefficient (α) of 0.3–0.7 (NRC up to 0.7, absorbing 70% of waves); thermal conductivity ~0.037–0.045 W/m·K (R-value ~R-3.6/inch); extreme hydrophobicity (suberin limits uptake to lenticels); and fire class E (flame-retardant, low smoke). This local collaboration unlocks cork’s circular chain—from northern Catalan forests to robotic extrusion—for regenerative panels that insulate acoustically/thermally while enabling disassembly and soil return.

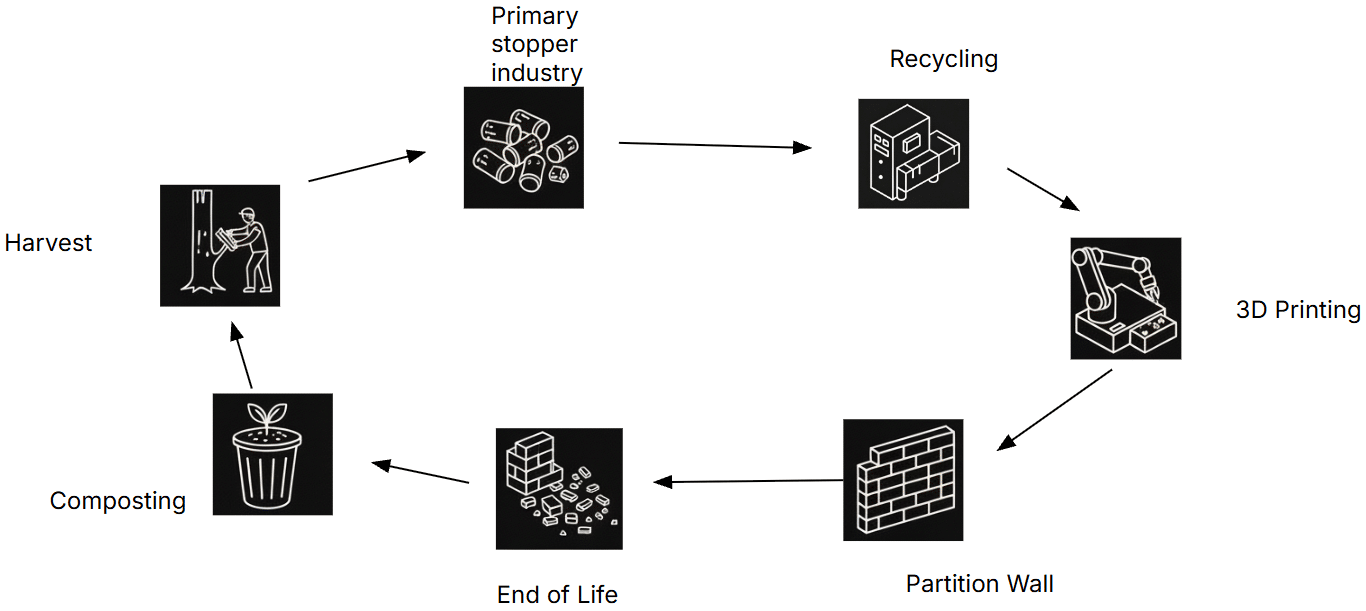

Sourcing

Cork is harvested from the bark of the cork oak tree (Quercus suber) during the summer season. The tree is not harmed during harvesting. The bark regenerates, allowing it to be harvested 15–20 times over a 200–300 year lifespan. It is then transported to the Primary Stopper industries , where mostly manufactured as solid seals for wine bottles. When discarded they are recycled, where an opportunity is presented to use them as the main mixture for 3D printing blocks that can be used to erect partition walls. As its life span ends, meaning its use is over , it can be used as composite for the soil.

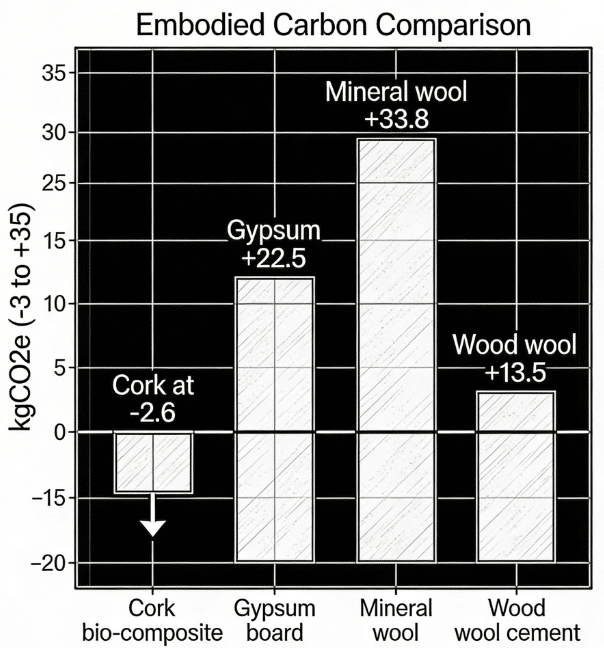

Embodied carbon comparison

Cork is considered as an eco-friendly material, meaning it emits least carbon emissions. Unlike the other materials that are industry manufactured and when discarded as useless, cork can be recycled and reused .

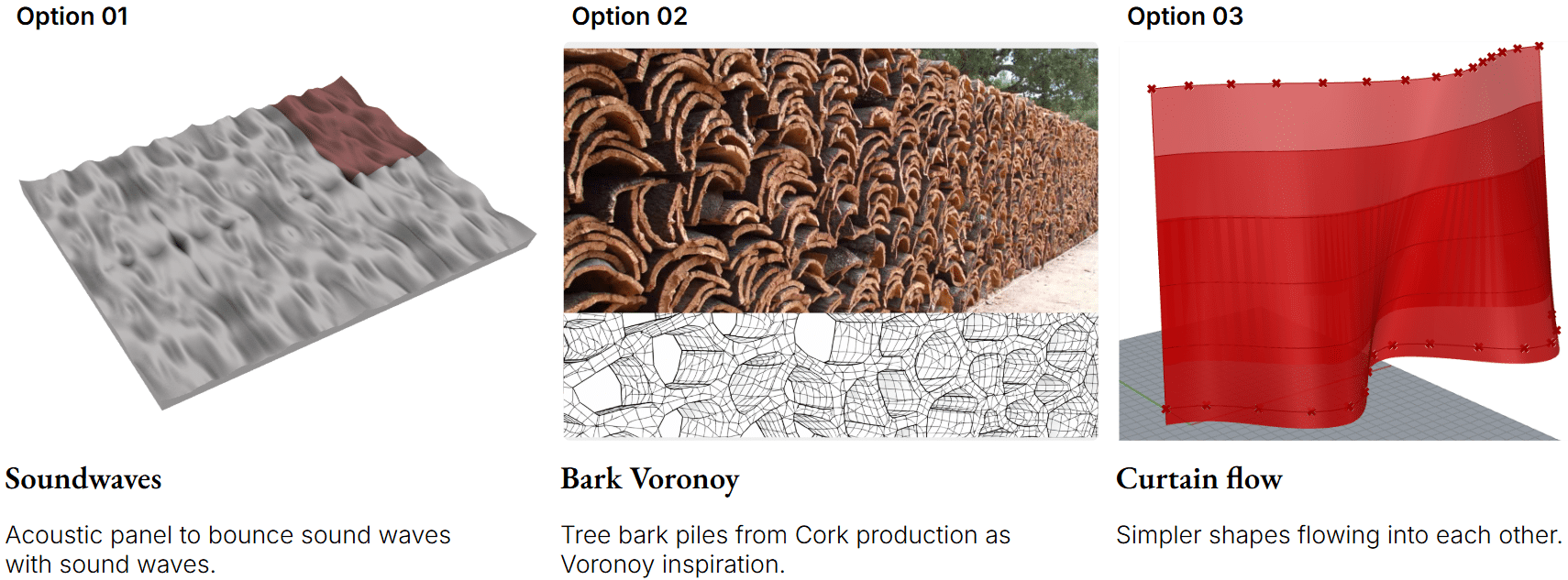

Design options

As a group of 4, we critically worked on design options that follow the criteria;

- Acoustic performance design

- Easiness in 3D printing using ABB Robotic arm

After some time there were options generated

The first option was inspired from the water waves generated when a smooth water surface gets disturbed. The second aimed towards a complex design using voronoi as geometry which could enhance the room’s acoustics. The third option was more towards a simple design, using three sine curves ; three troughs for base, two troughs for center and Single trough for the top end, lofted together to form a surface.

Observation of the 3D print model

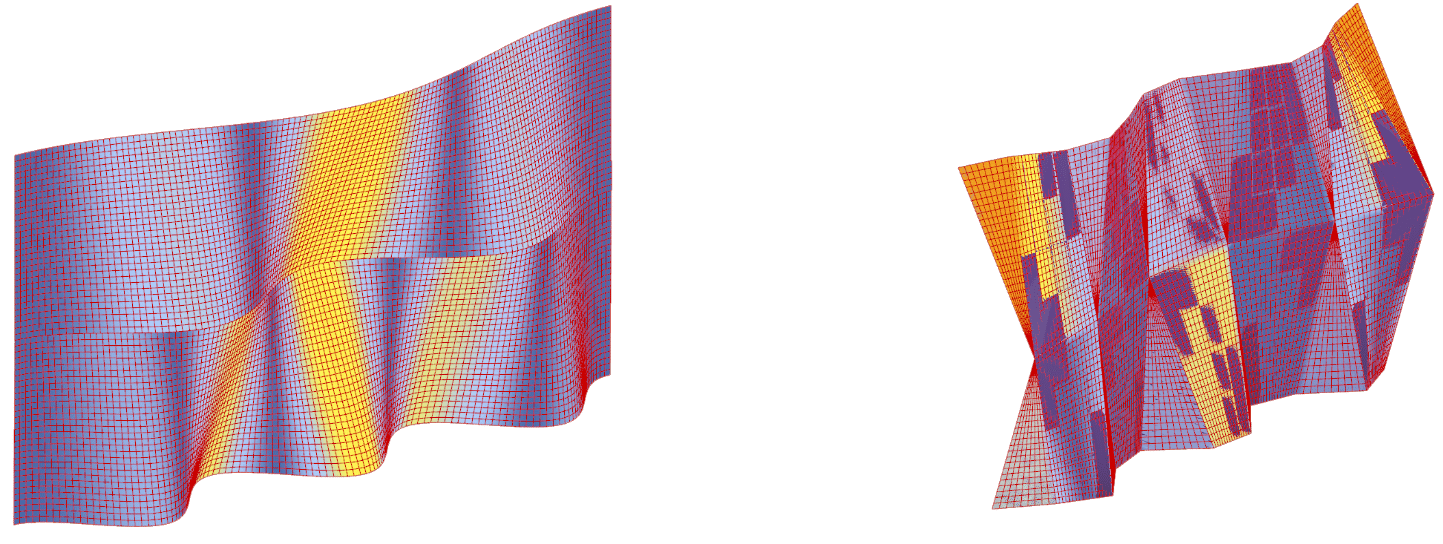

After modeling the two prototypes using grasshopper, an angular analysis was done on the two finalized prototypes.

The max. angle tested was 45 degrees. From module 1 results are more stable as the surface rendered blue are less than 45 degrees and near 0 degrees angle, whereas the yellow renders show near 45 degrees and red show its leaning on to or more than 45 degrees. Module 2 shows there are areas that will lean on to or more than 45 degrees, which will be unstable. However, there are vertical lines that act as reinforcements that can hold the flat angled surfaces together.

Acoustics simulation

Using Paradigm plugin, acoustics simulations were done to show the performance of the prototype modules.

To prepare the 3D printing a grasshopper simulation script was prepared to ensure the 3D printing goes smoothly

Practical applications