Introduction to Digital Fabrication

Team : Sejin Park & Hasan Hirji

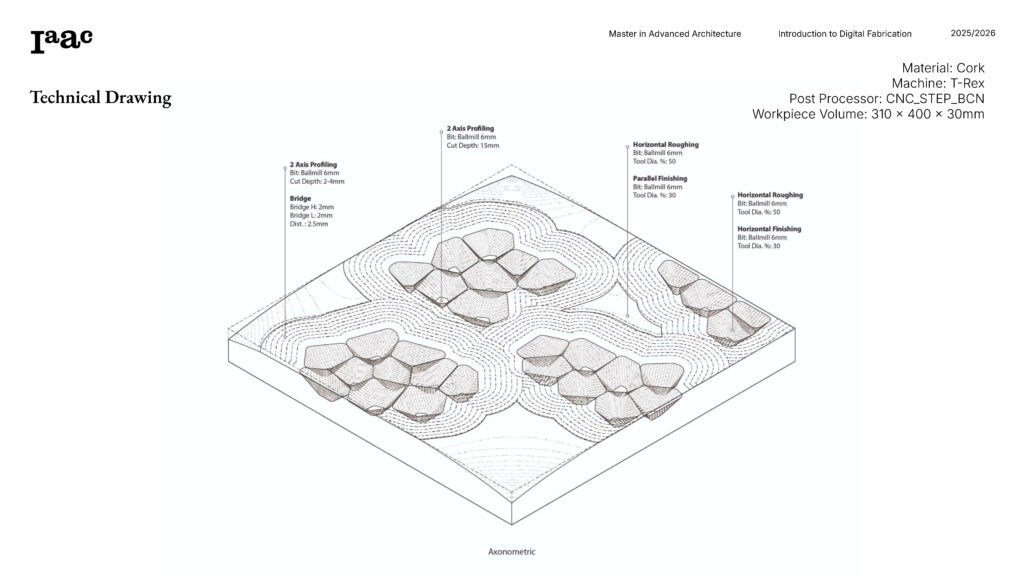

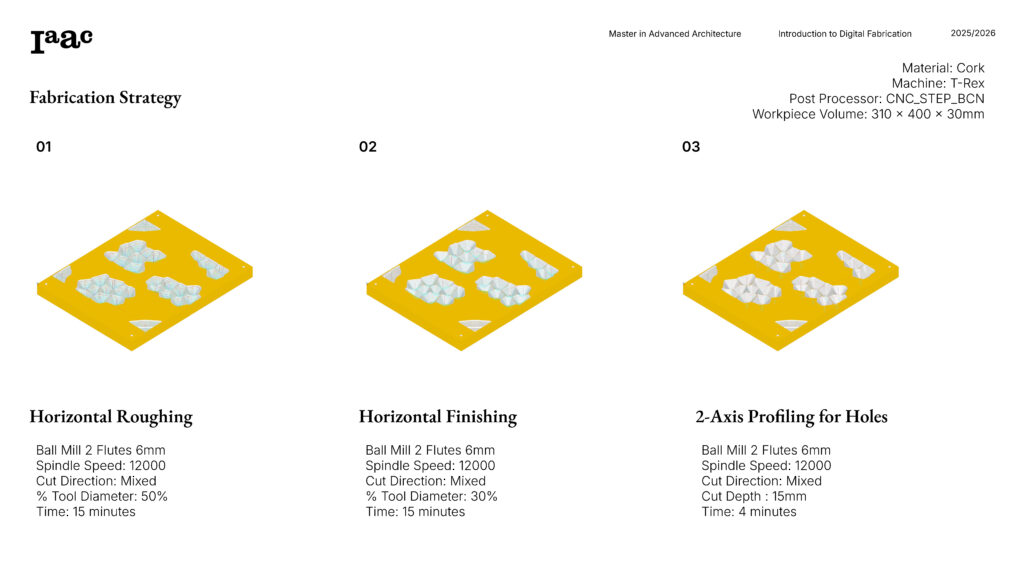

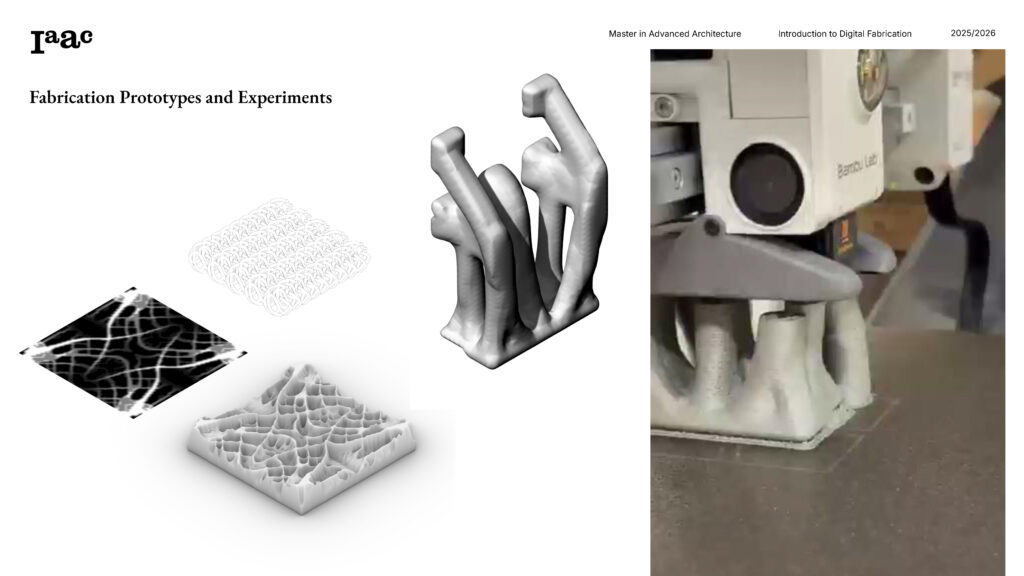

CNC Milling

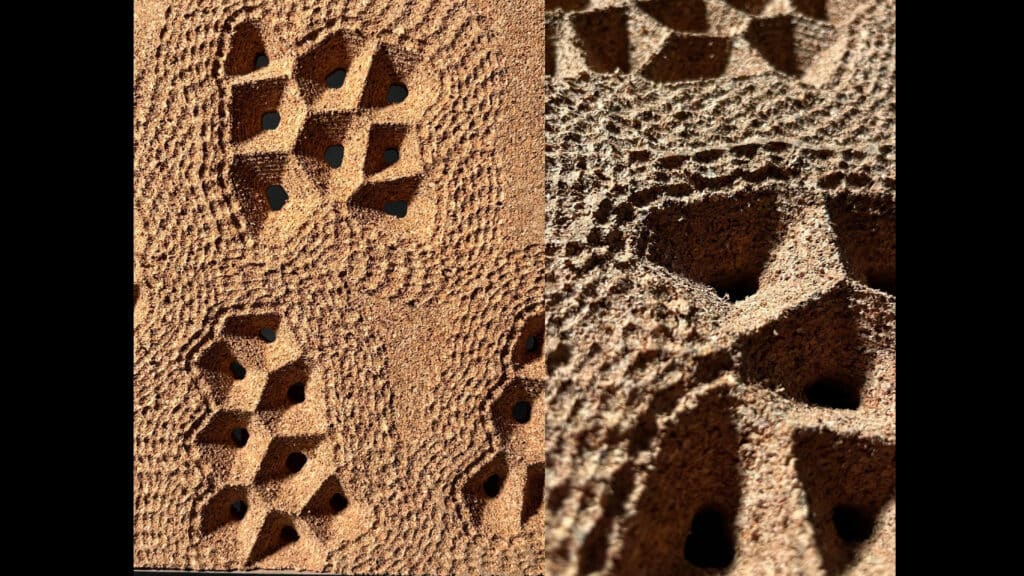

During the CNC Milling process, RhinoCAM software automatically creates bridges; a necessary milling process outside of commands that one might use to manipulate material. We began with the idea of testing the frequency and depth of 2-axis bridging path movement presets to create efficient and unique textures. Iterative physical testing and digital simulations helped us to develop a series of tooling methods with the CNC that focused on achieving organic geometries through sloping, variable finishing grains based on tool diameter percentage in step over, and our bridging texture. The malleability of cork proved most suitable for this fine grain experimentation to avoid chipping, resulting in a smooth finish resembling hand rendering on adobe.

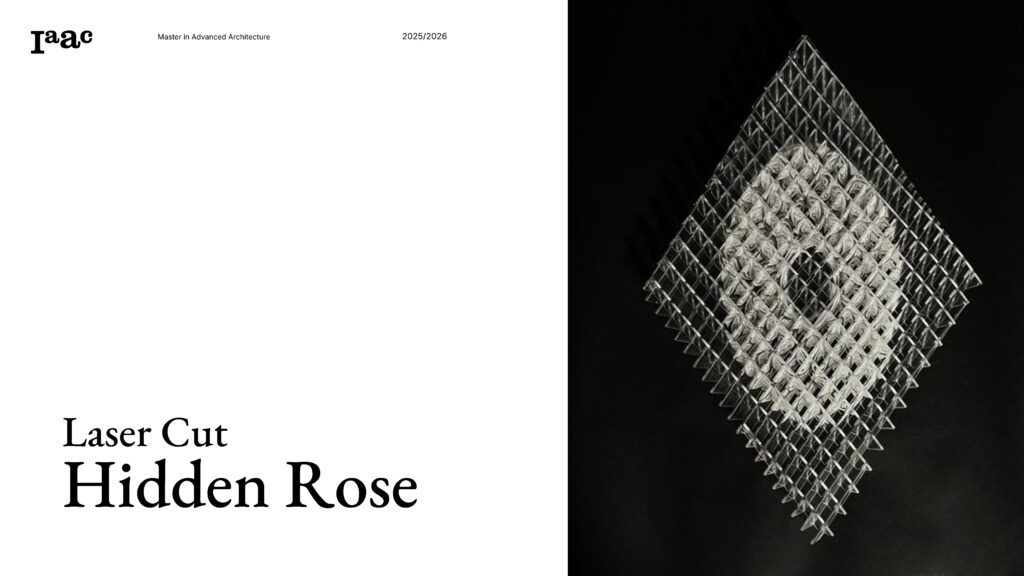

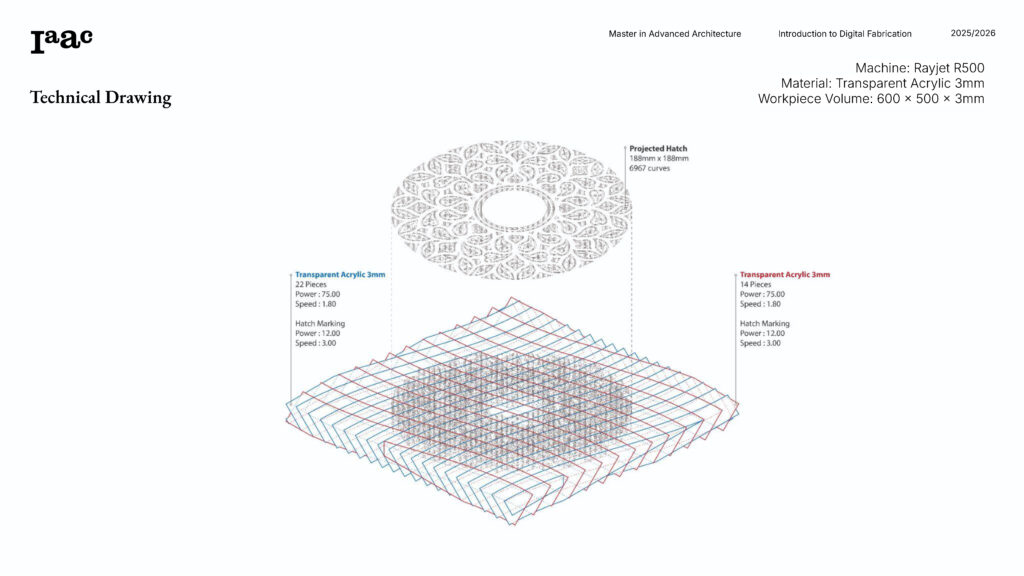

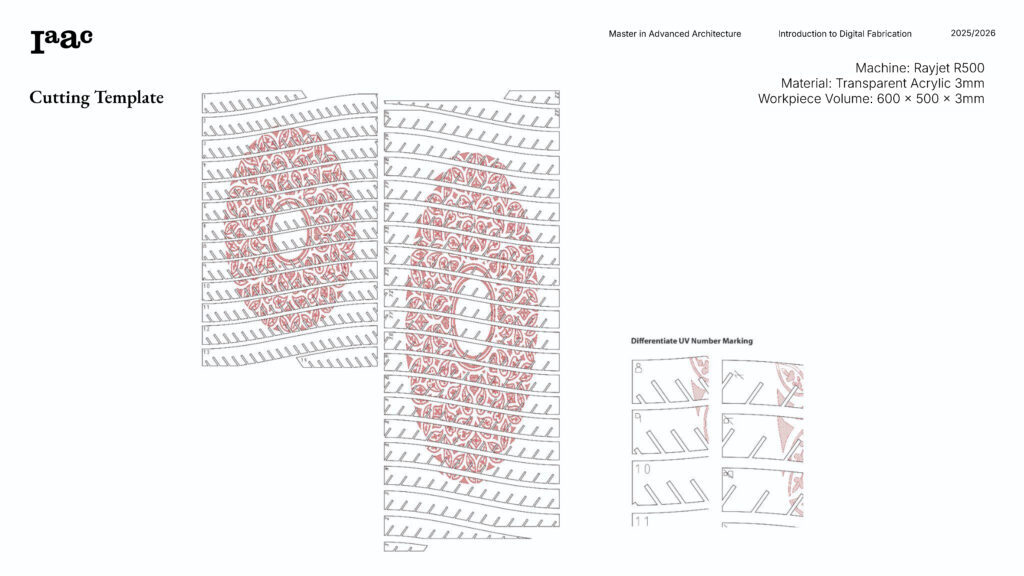

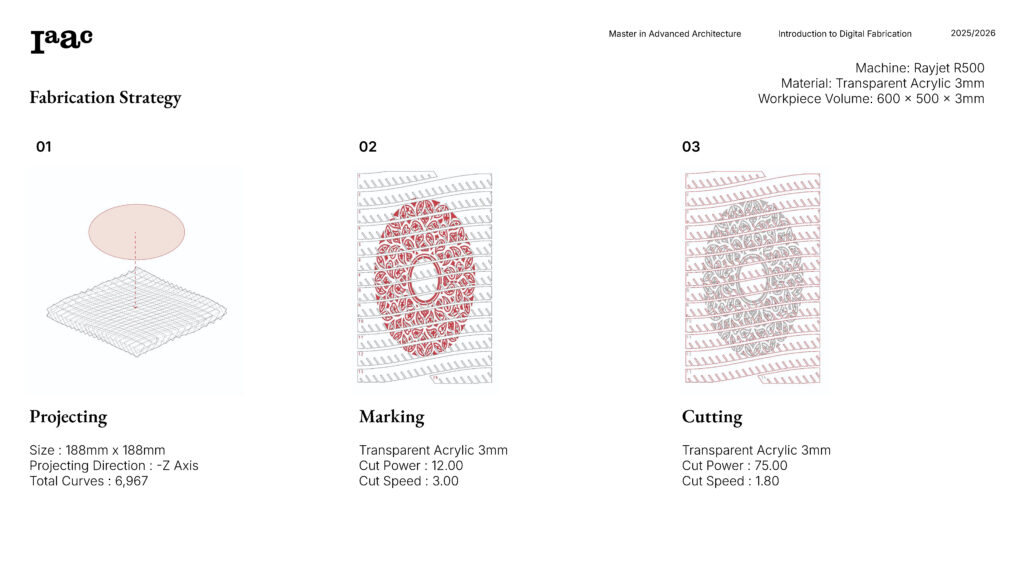

Laser Cutting

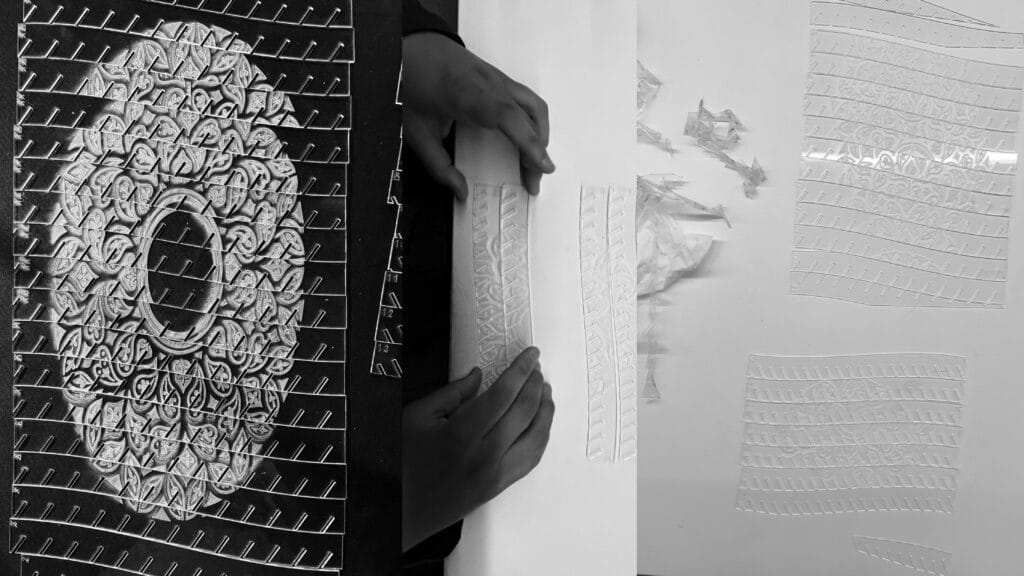

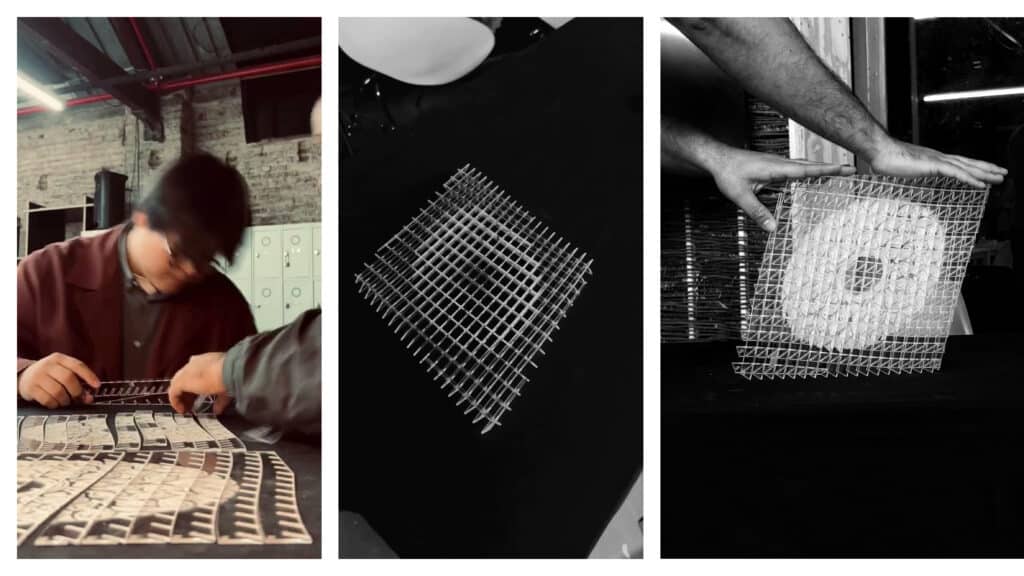

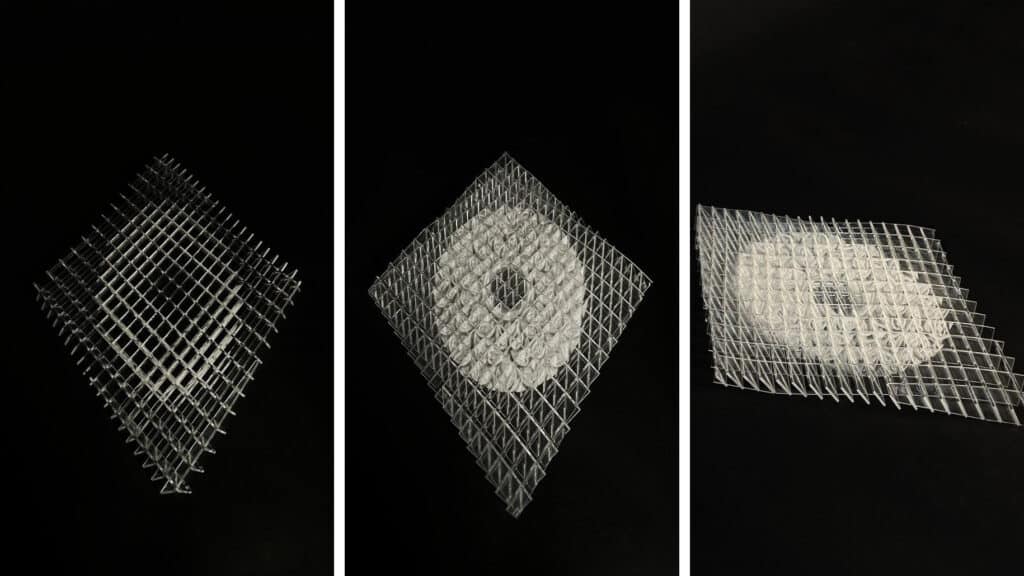

Waffling, the laser cut technique our team was assigned, is often seen as an exclusively structural process, turning 2D planes into 3D assemblies. In this process, the surface of the waffle assembly is often abandoned, or used as a frame for a superimposed facade. We were interested in how one might use rotated plane relationships found in waffle assemblies as an exterior projection surface for pattern geometries. Through digital iteration, we tested transparent assemblies that played with the eye, working with subtle cut curvatures and projection angles for engraved surfaces. Simulations allowed us to imagine how the viewer might see a 2D engraved pattern within the 3D assembly when looking from certain angles, with the pattern disappearing from another angle.

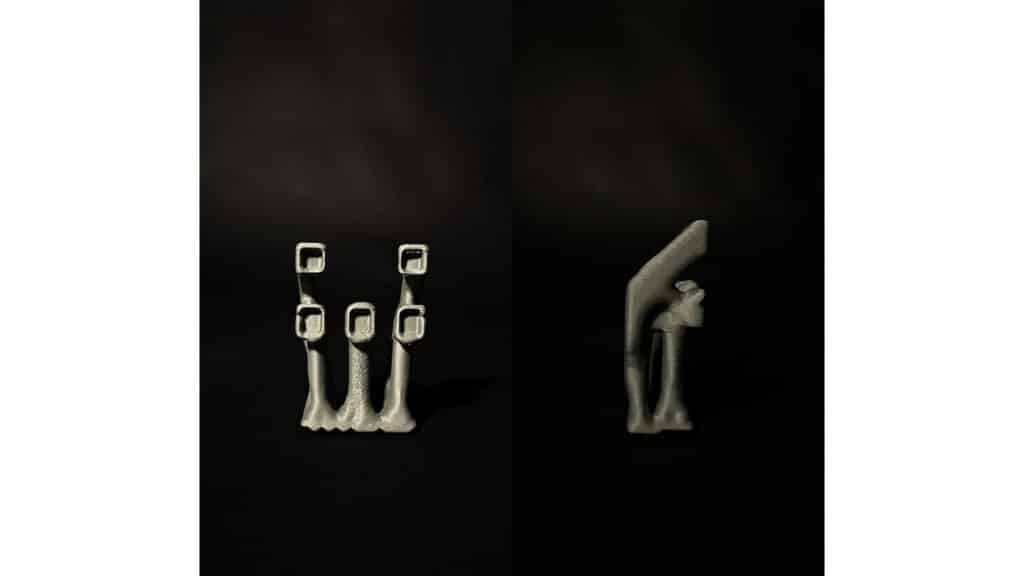

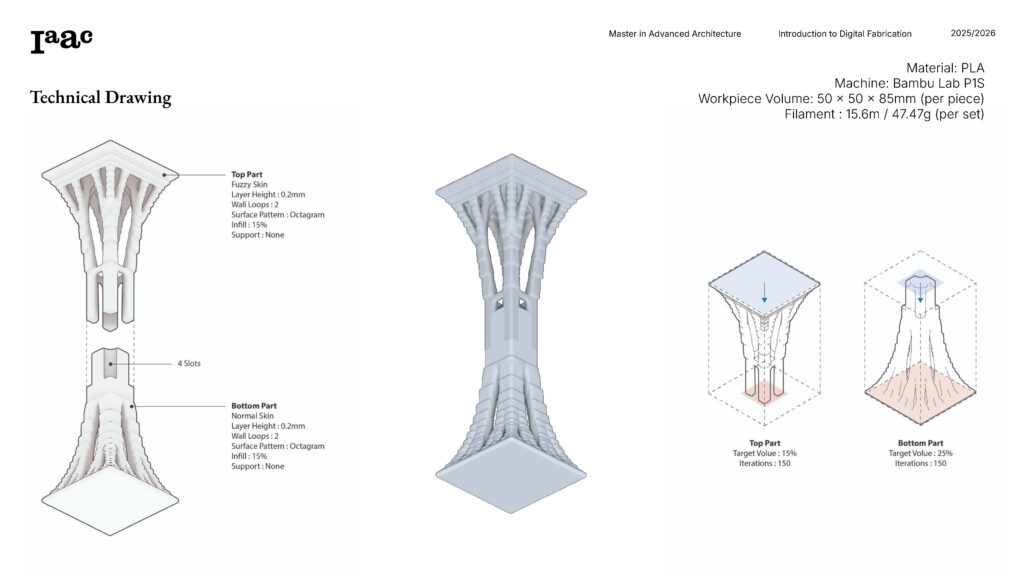

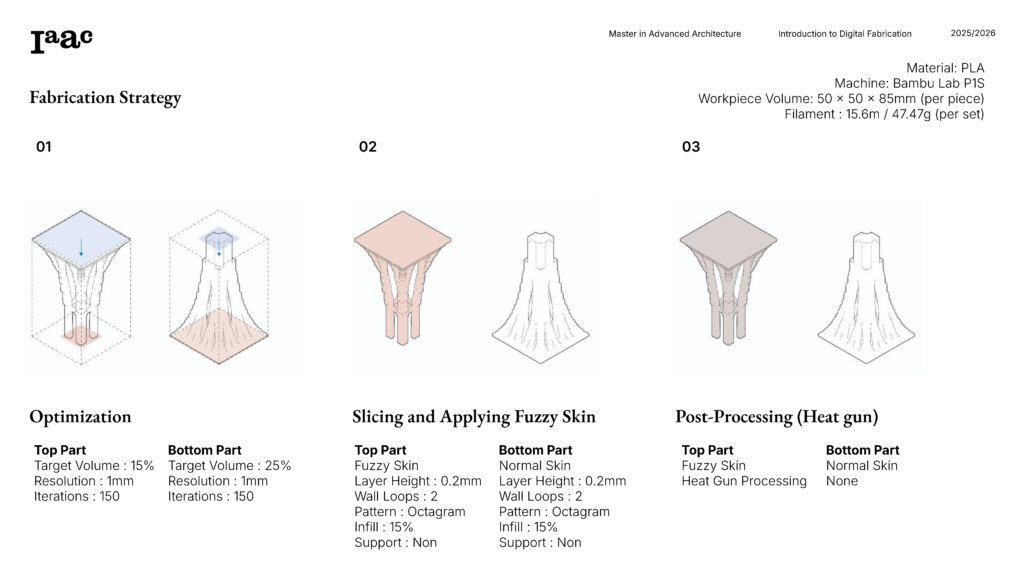

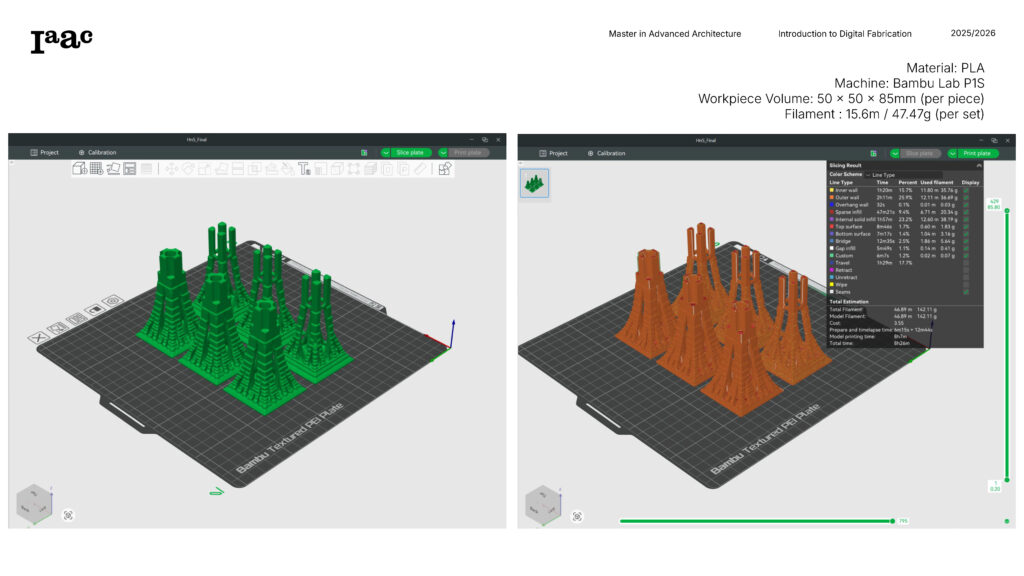

3D Printing

Material waste, geometry orientation, and strength are three factors that define 3D printed fabrication. Through extensive iteration, we sought to topologically optimise our geometry; to refine our material layouts within the Bambu printer bed parameters. Using the Millipede plugin for Grasshopper, we tested many optimised models, focusing on weight distribution. This method generated materially efficient geometries that required little or no supports when orienting the prints on the printer bed as a counter-force. Through this iteration, one can 3D print a colonnade assembly whose capitals and bases act as their own supports during the printing process. Reducing unnecessary material increased the geometric interest of our pieces, resulting in a novel, organic column order.

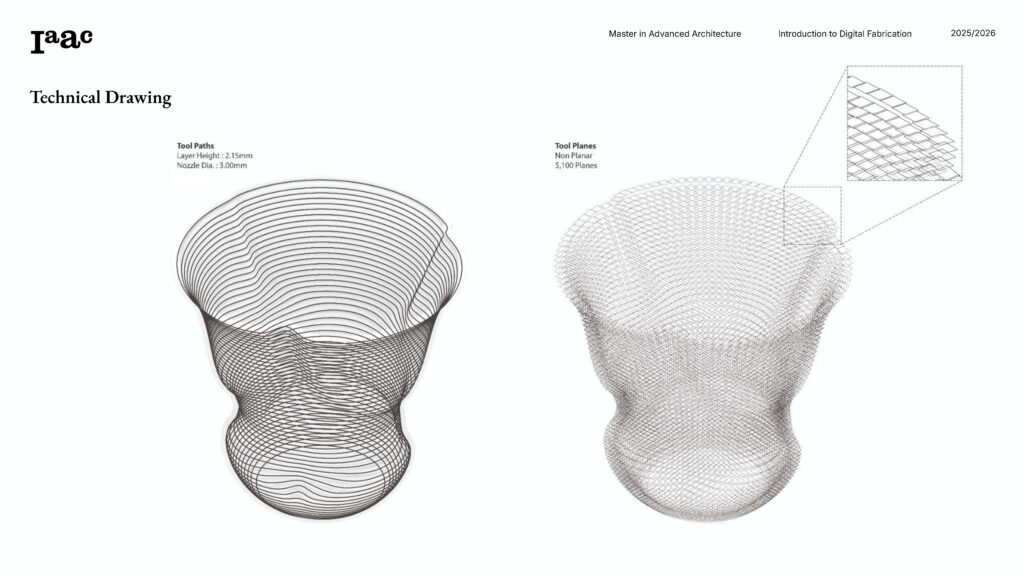

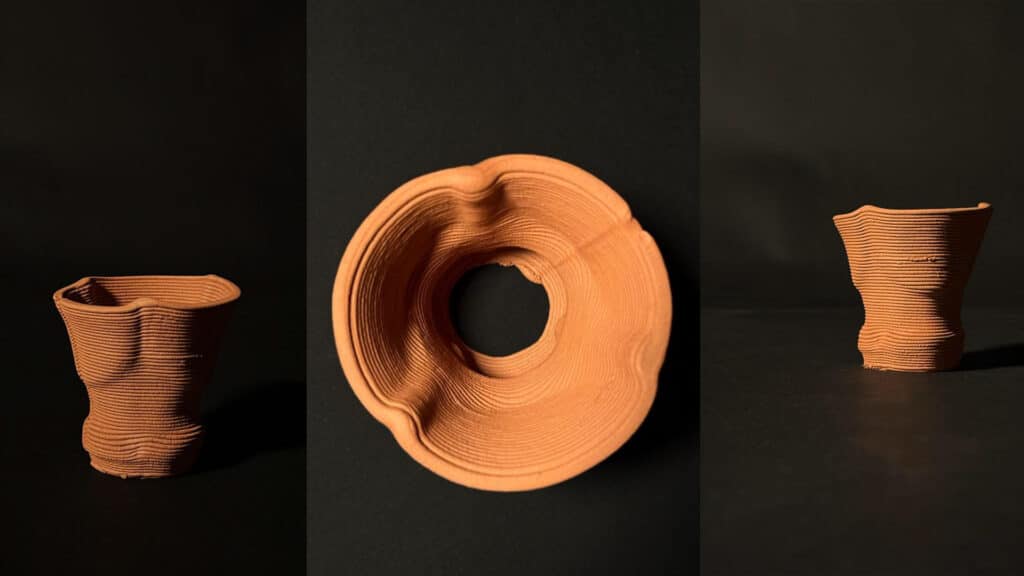

Robotic 3D Printing

Our team was interested in non-planar clay 3D printing and how we could utilise robotic movement to achieve lip curvatures similar to traditional, hand sculpted cups. We developed several digital prototypes based on these design goals, and tested their performance using Grasshopper digital robotic fabrication simulations. These digital prototypes began with direct copies of traditional cup silhouettes and became more experimental as we manipulated surfaces and played with textures. Through this project, we learned how to test our designed geometries with the robot simulation, to better understand the contouring capabilities, physical limitations of the robotic arm, and how to account for non-planar seams.