From Design to Construction: A Conversation With Oriol Carrasco

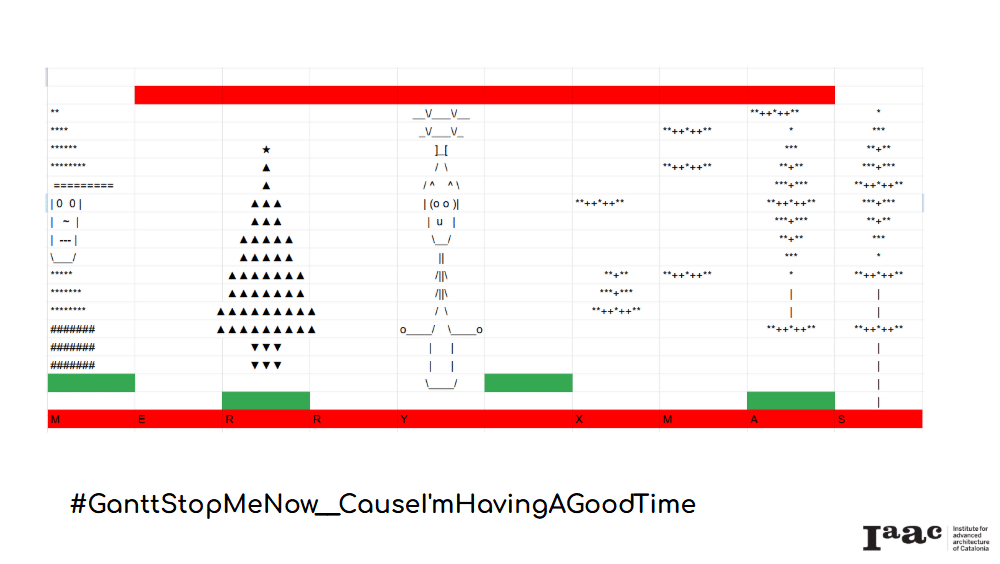

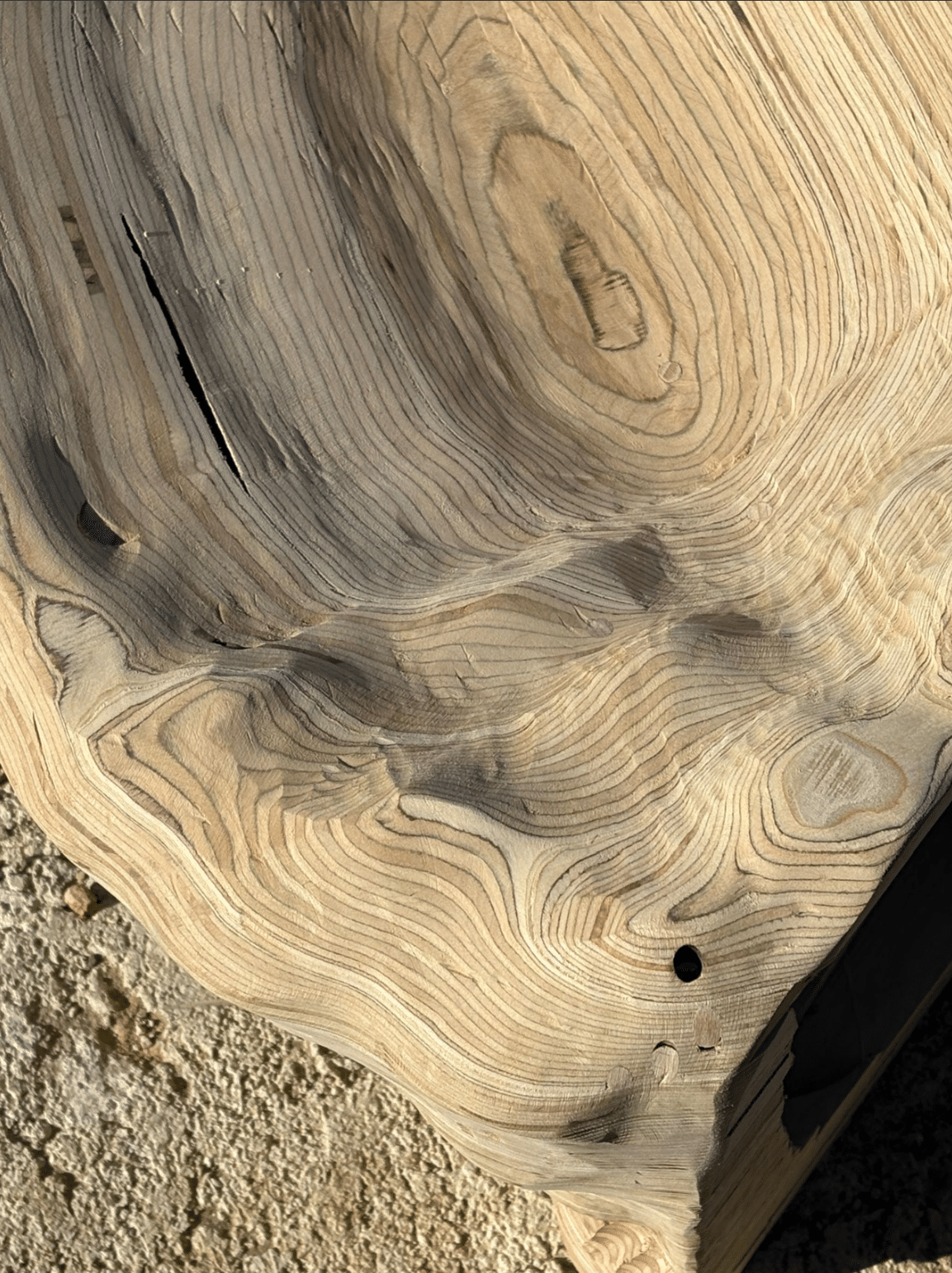

Oriol Carrasco – Anomaly.Build Oriol Carrasco is a PhD architect from Barcelona. He is a senior fabrication expert at IAAC with extensive expertise in composite manufacturing. Oriol currently teaches in MAA and 3DpA programs. He has been co-leading the Design with Nature research line since 2013, teaching now in the metabolic introductory studio. He has … Read more