The Master Programme in Robotics and Advanced Construction is an innovative educational format that offers interdisciplinary skills and understanding through a series of class seminars that are put into practice through hands-on workshops. IAAC gives students the opportunity to create individual studio agendas and develop Pilot Thesis Projects based on the knowledge acquired during the seminars and workshops split into 3 Modules. In this way, IAAC puts together an experimental learning environment for the training of professionals with both theoretical and practical responses to the increasing complexity of the construction sector.

Print – Scan – Cut

Preliminary steps towards a hybrid workflow for smooth 3D printed surfaces. Aim To develop a hybrid workflow to obtain smooth surfaces on 3D printed clay for improved alignment and surface finish. State of the Art Additive manufacturing enables the precise and cost-effective creation of complex designs while minimizing waste. One of the shortcomings common to … Read more

re(al)form

The construction industry has shown an increasing interest in adapting to more environmentally friendly materials, with wood gaining popularity as a natural and sustainable option for buildings. However, the wood industry contributes a significant percentage of energy consumption during the entire wood lifecycle, encompassing tree cutting, transportation to sawmills, and delivery to construction sites. Additionally, … Read more

Machine Learning for the Prediction of Clay Deformation

Optimizing 3D Printing with AI prediction Introduction In this seminar we applied the concepts of machine learning to estimate the deformation during drying of simplified 3D printed clay objects. To do this, we trained an artificial neural network (ANN) to predict the movement of discrete points within the printed object. This project is very relevant … Read more

Thermal Sensing for Advanced Cork Manufacturing

This research study delves into the realm of advanced robotics and semi-automated manufacturing processes that take into account the material properties of cork. Specifically, it explores the design and fabrication of a surface system that is optimized for both aesthetic appeal and functional performance. Building on the knowledge gained in a previous term on robotic … Read more

Insightful Sensing

AIM \\ To create custom designed, 3D printed interior surface cladding, constructed of individual components with high quality surface finish and tolerance. CONTEXT \\ Last term we designed a dual end effector that would have an extruder and a wire cutter within the same tool, allowing us to post process the 3D printed pieces to … Read more

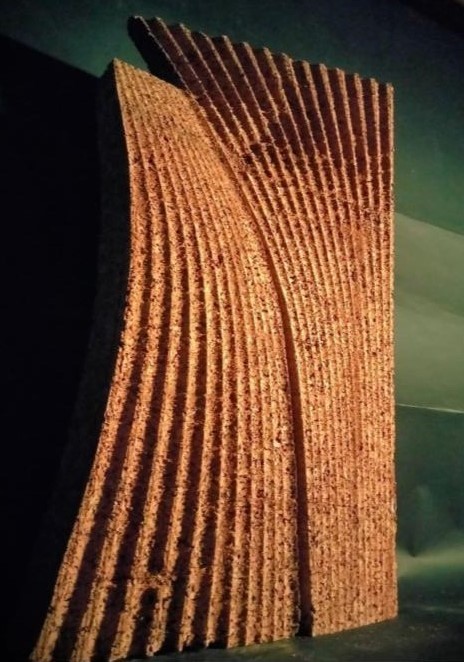

Robotic Manufacturing of Cork Surfaces

The objective of this studio was to implement an automated robotic process for the efficient fabrication of modular cork blocks, essential components of a doubly curved acoustic surface. The key objectives encompassed the following: By addressing these objectives, the studio aimed to advance the field of robotic fabrication while emphasizing the acoustic potential of cork … Read more

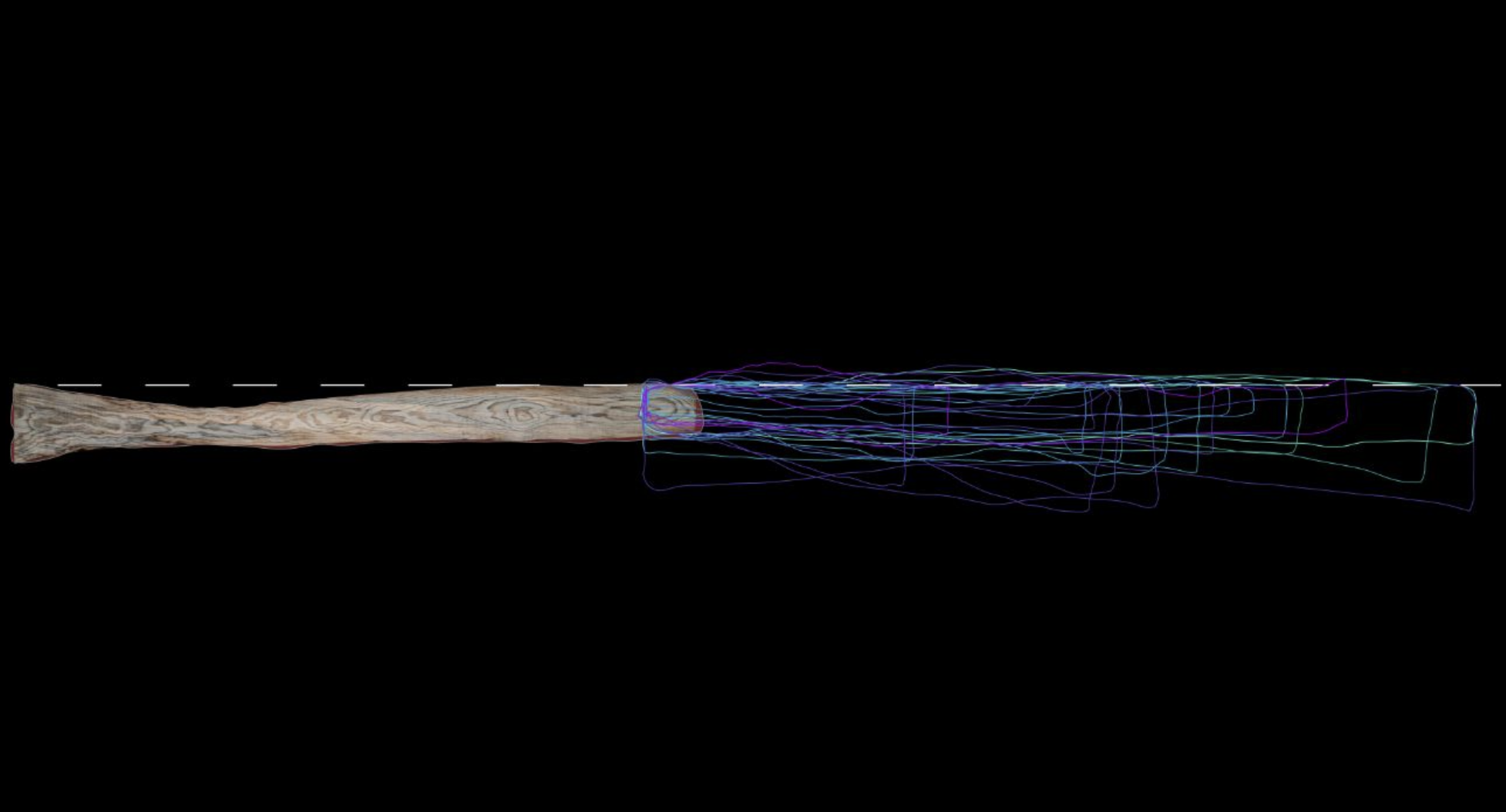

Ruled Stereotomic Manufacturing

Ruled surfaces are a way to address both simplicity in terms of design rules and at the same time complexity in terms of the outcome. In this workshop we aimed at defining design rules which are performance driven, to obtain modular geometries. Through parametrization and manipulation of computational workflows we generated paths and mapped them … Read more

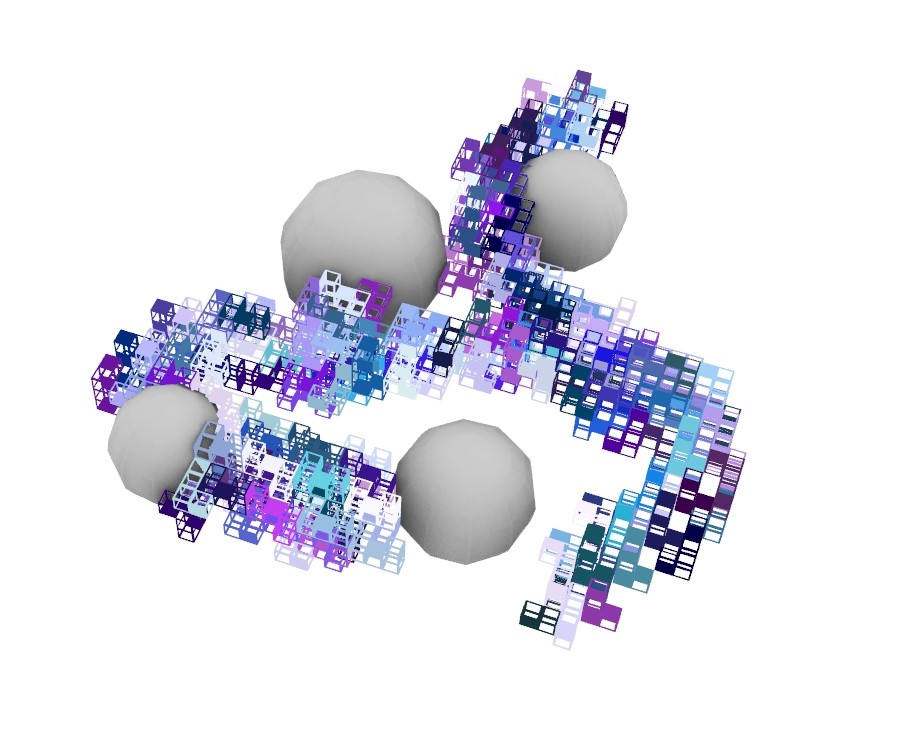

Permutation Growth

Abstract The introductory course of Software I focuses on the computational logic for assamblage and growth processes guided by algorythms. For starting, voxels were created as basic units and then joined to create a basic element geometry. By using Grasshopper and Anemone plug-in, different growth assamblages were established depending on the element’s position and starting … Read more