This research focuses on one of the main limitations of 3D printing with earth: low stability in the wet state. Today, the maximum daily printing height is around 20 cm, which limits construction efficiency. This project explores how to improve wet-state stability to enable taller, faster, and more consistent earthen walls.

STATE OF THE ART

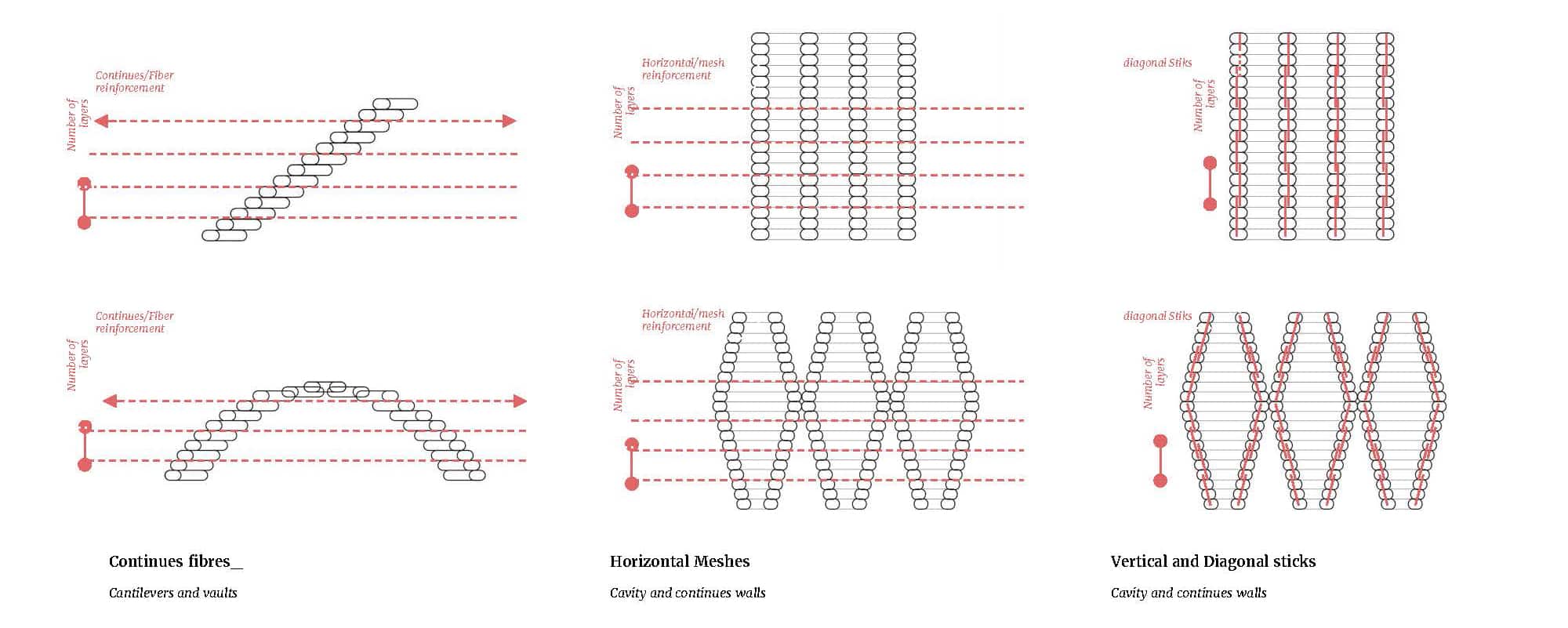

Architectural Reinforcement Logics

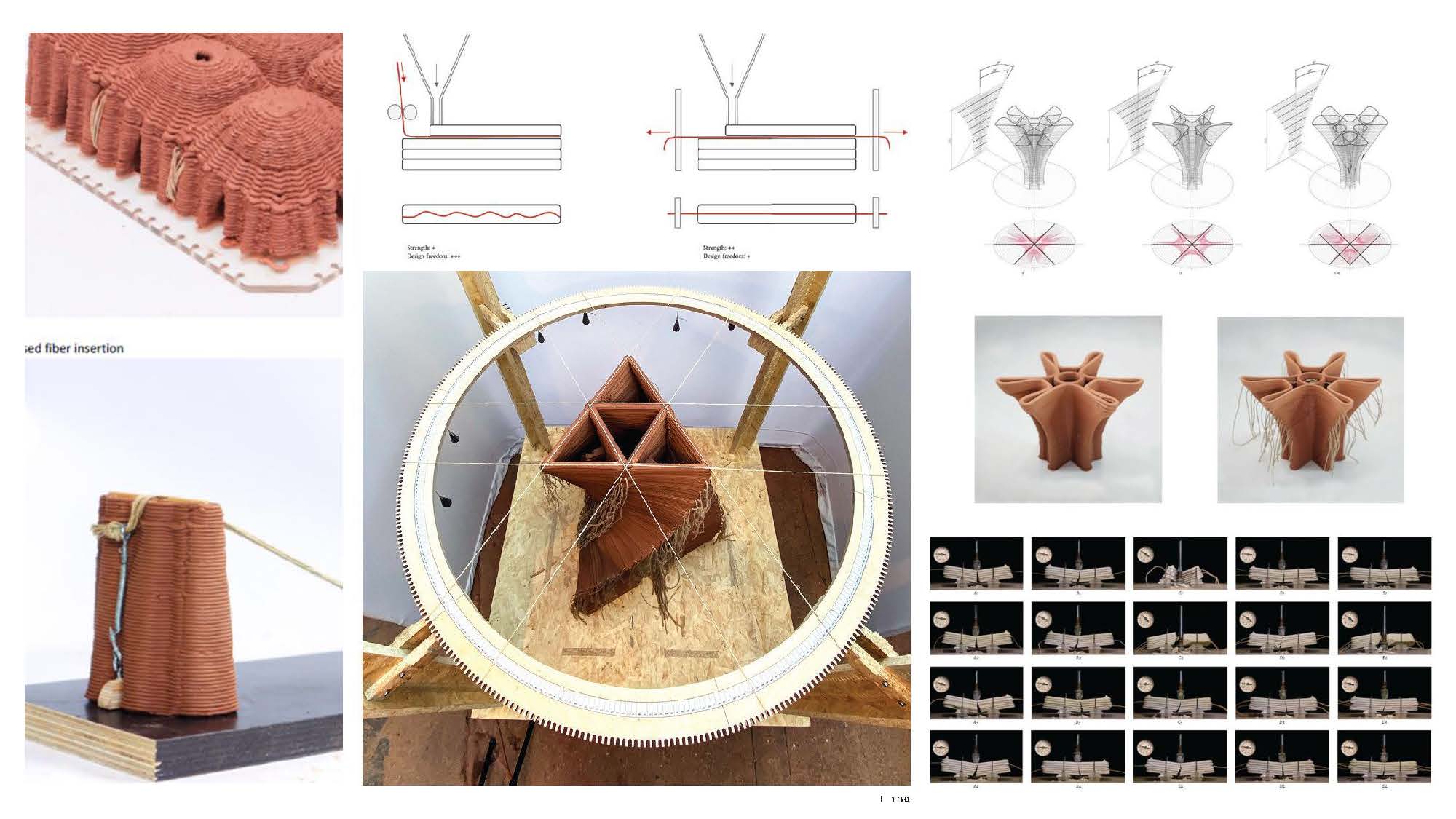

We reviewed reinforcement strategies in architecture, from vernacular techniques using natural fibers to contemporary systems such as vertical steel bars and post-tensioned cables. These precedents show how reinforcement elements can significantly improve structural performance, even in early material stages.

Architectural Reinforcement in 3D Printing

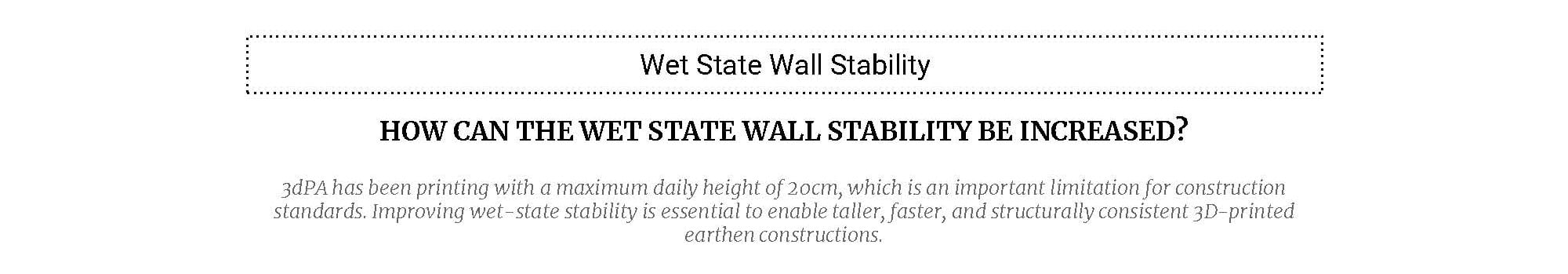

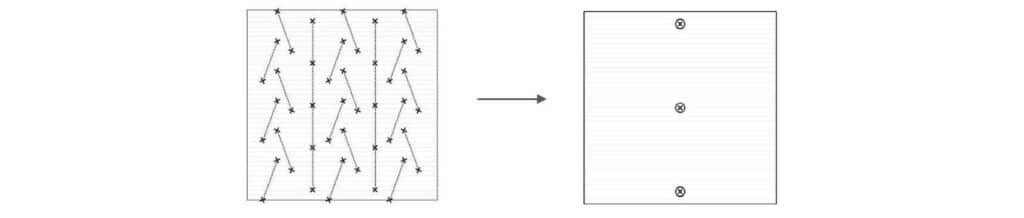

Four main reinforcement strategies are used in 3D printing today: optimized geometry patterns, vertical reinforcements, horizontal reinforcements, and combined systems. Each method affects wall stability in different ways and influences the achievable printing height.

IAAC Research on Reinforcement Strategies

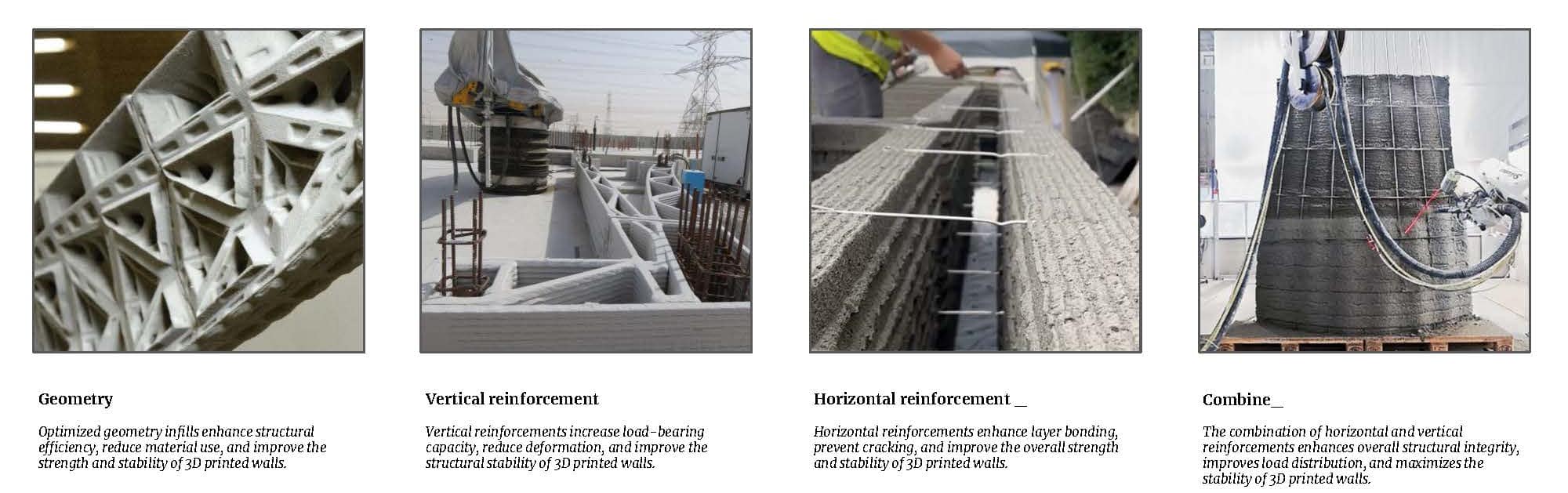

Previous IAAC research has focused mainly on horizontal reinforcement systems, which improve interlayer bonding and reduce buckling. However, vertical reinforcement in 3D-printed earthen walls remains largely unexplored.

Continuous Fibers (Vaults & Cantilevers)

Continuous fiber reinforcement has been used to stabilize clay vaults and cantilevers in the wet state. This strategy reduces cracking, increases durability, and opens possibilities for more complex geometries.

Horizontal Mesh Reinforcement

Horizontal mesh reinforcement improves wet-stage strength, reduces axial deformation, and stabilizes both cavity walls and continuous walls. Still, this method does not directly address vertical load limitations.

W E T STATE

After reviewing the existing research, we defined our main focus: understanding the behavior of earth in the wet state and exploring how vertical reinforcements can improve its buildability.

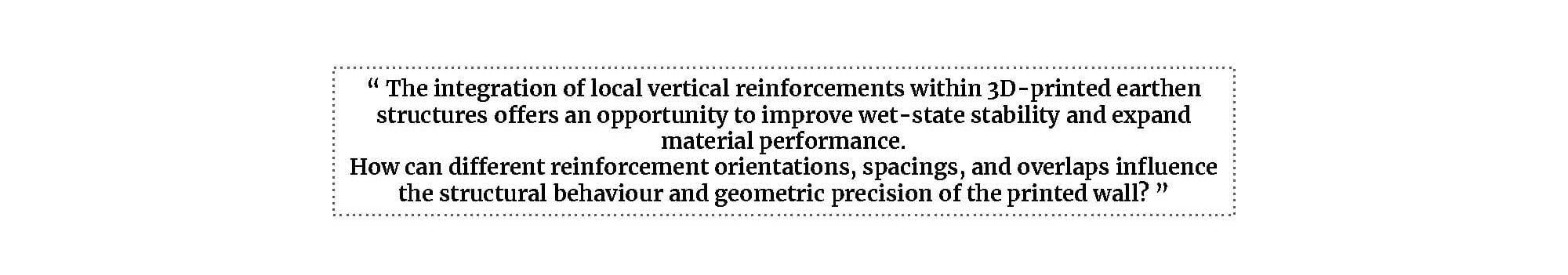

Our research question asks how local vertical reinforcements can improve wet-state stability, and how variations in orientation, spacing, and overlap affect the structural behavior and geometric precision of the printed wall.

Methodology Overview

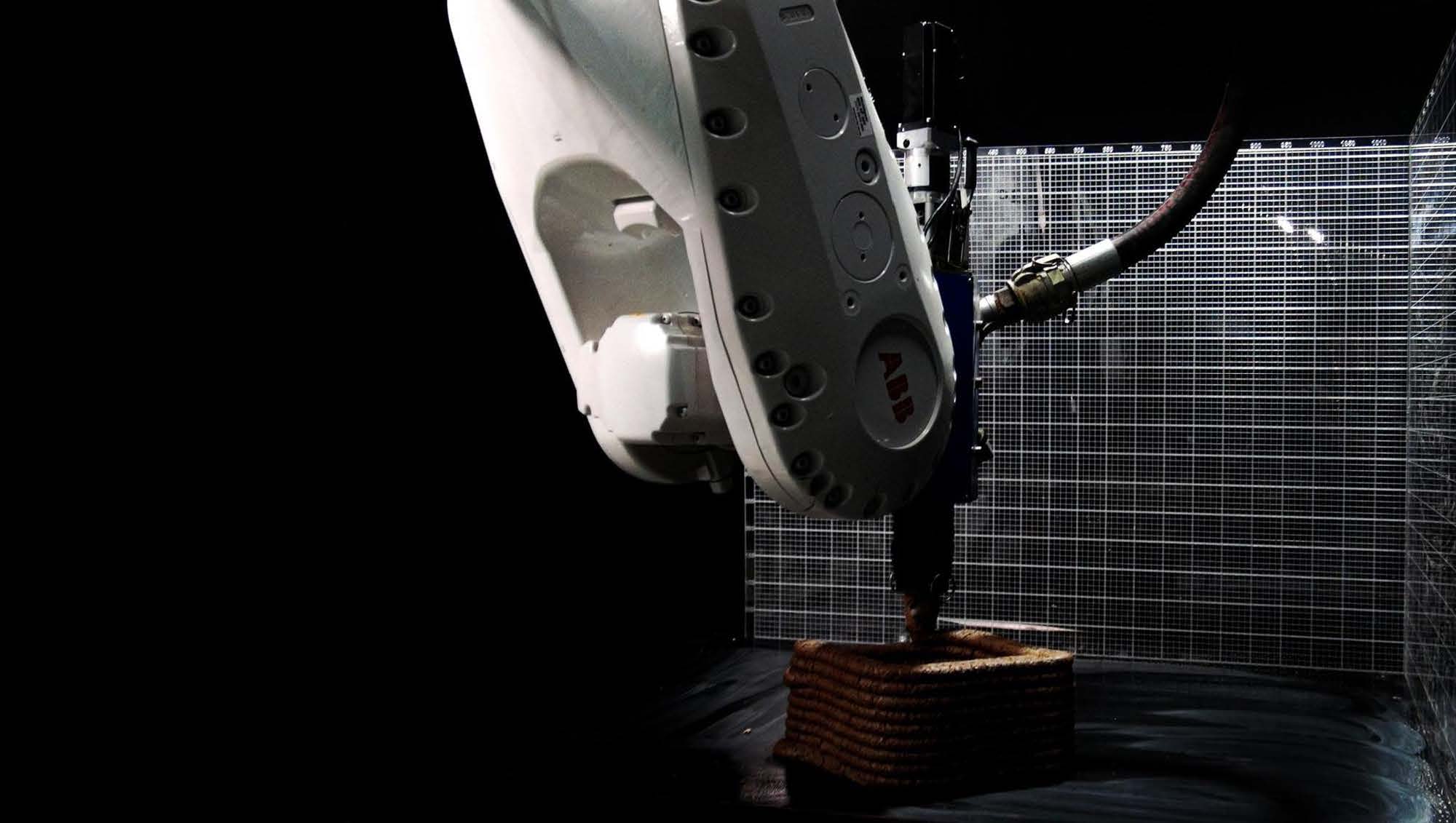

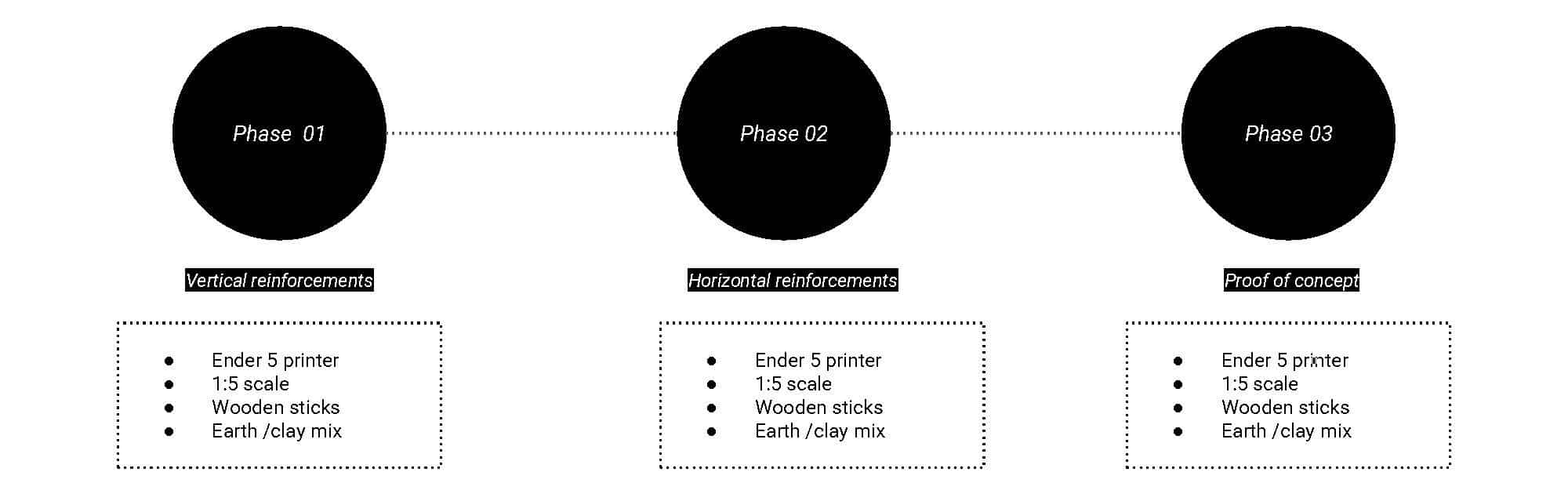

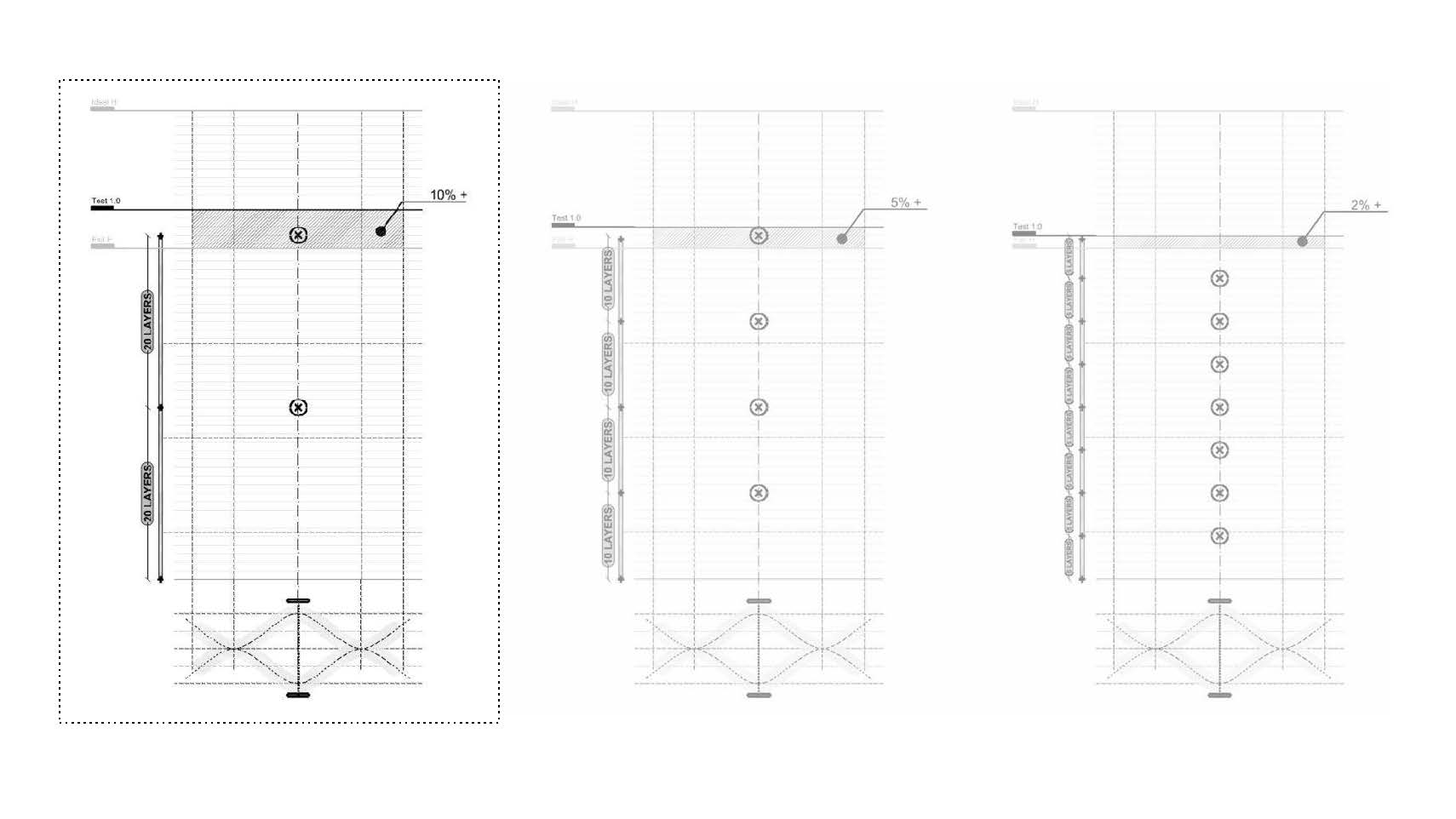

The methodology includes three phases: 1:5 scale tests with an Ender 5 printer, integration of vertical and horizontal reinforcements, and a final 1:1 scale test using an ABB robot. Each phase helped define parameters and evaluate buildability.

Methodology Details

Initial tests defined key parameters such as stick quantity per layer, angle, overlap, and printing period. Collapse tests and insertion tests helped analyze how each variable affected wet-state stability.

Two geometry configurations were tested—single line and double line—to measure displacement and compare structural performance under different reinforcement strategies.

Baseline tests standardized the stick insertion process and provided a reference for evaluating how vertical reinforcements influence printability

Vertical Reinforcement Typologies

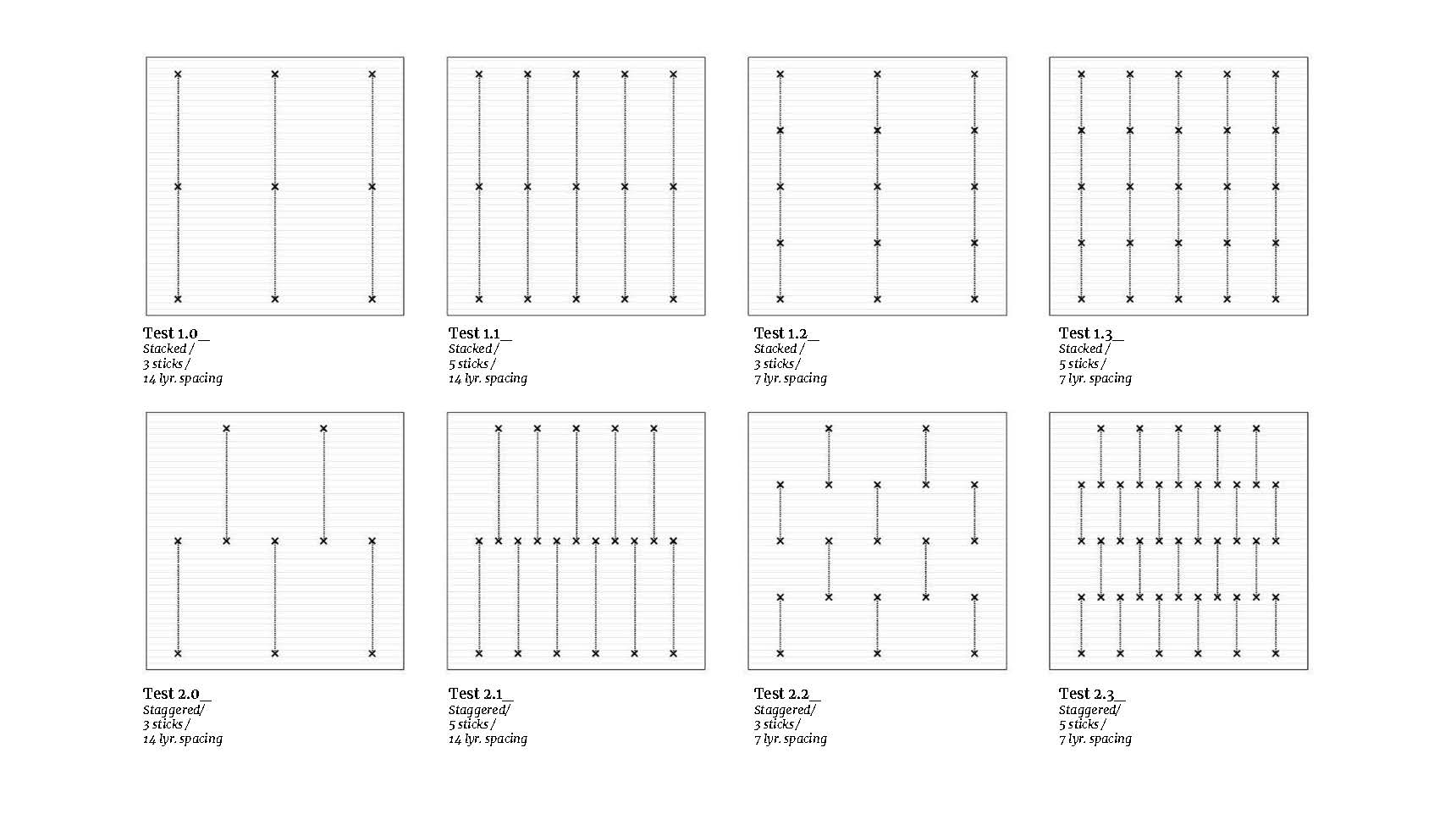

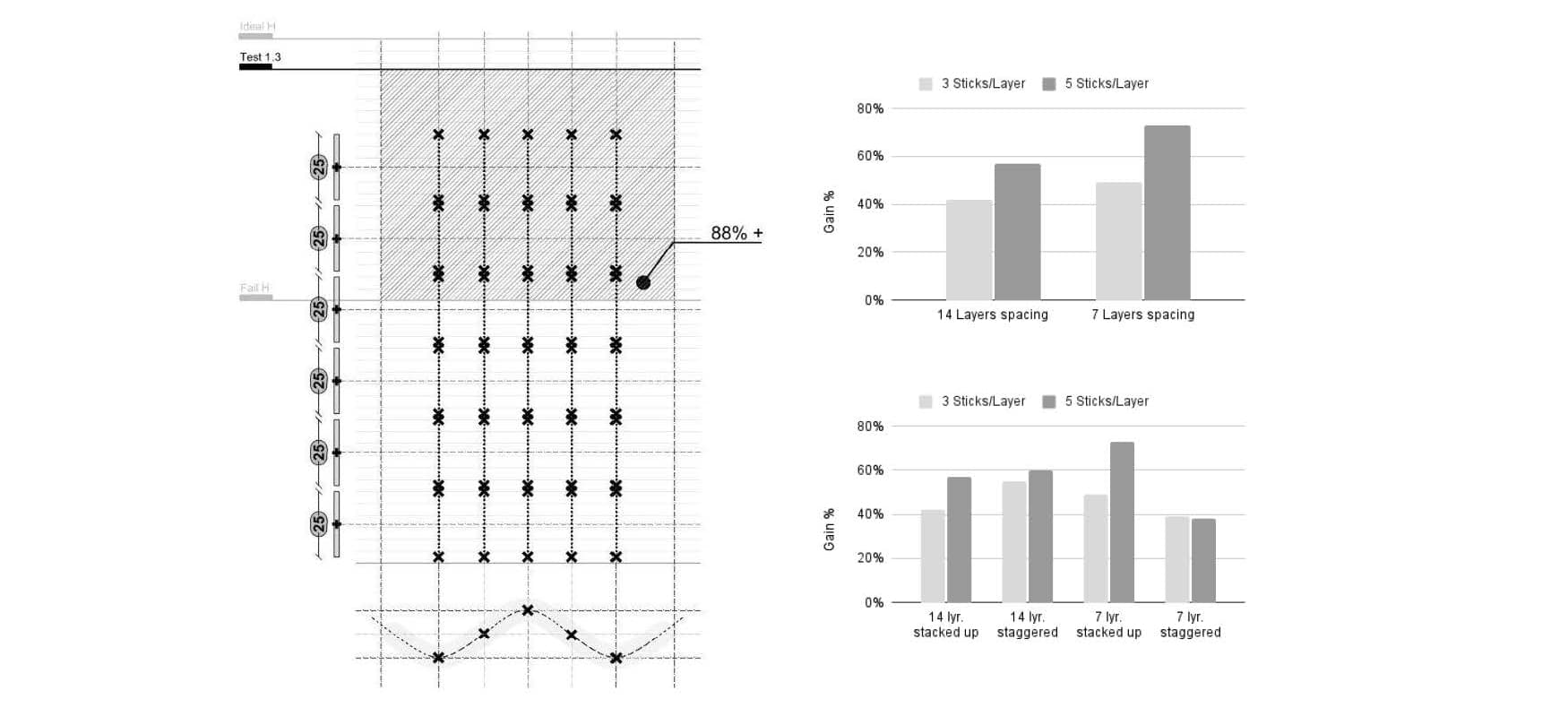

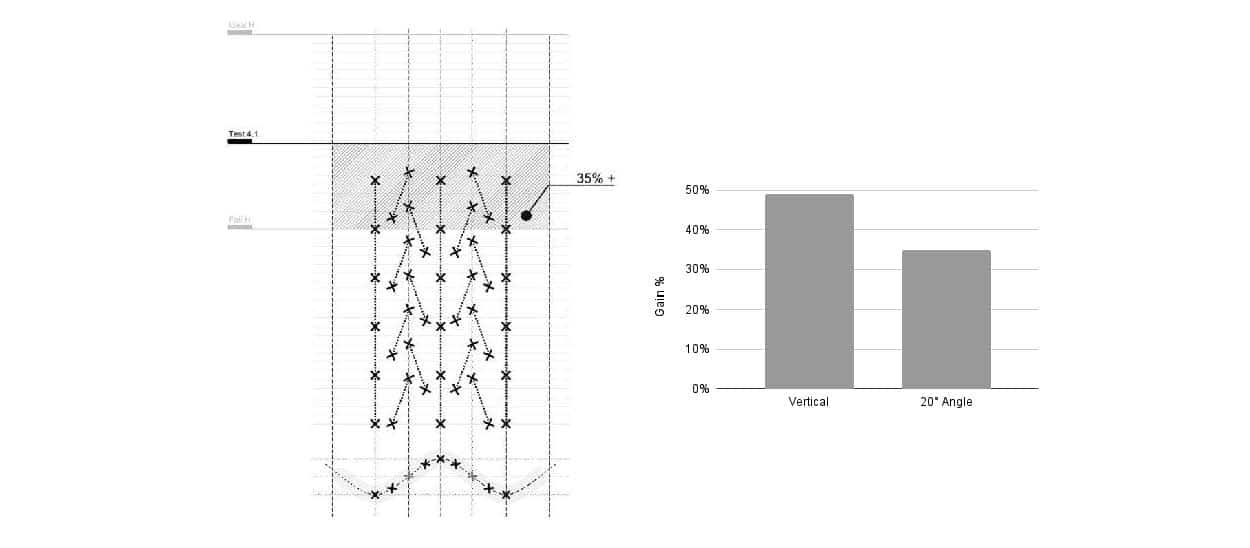

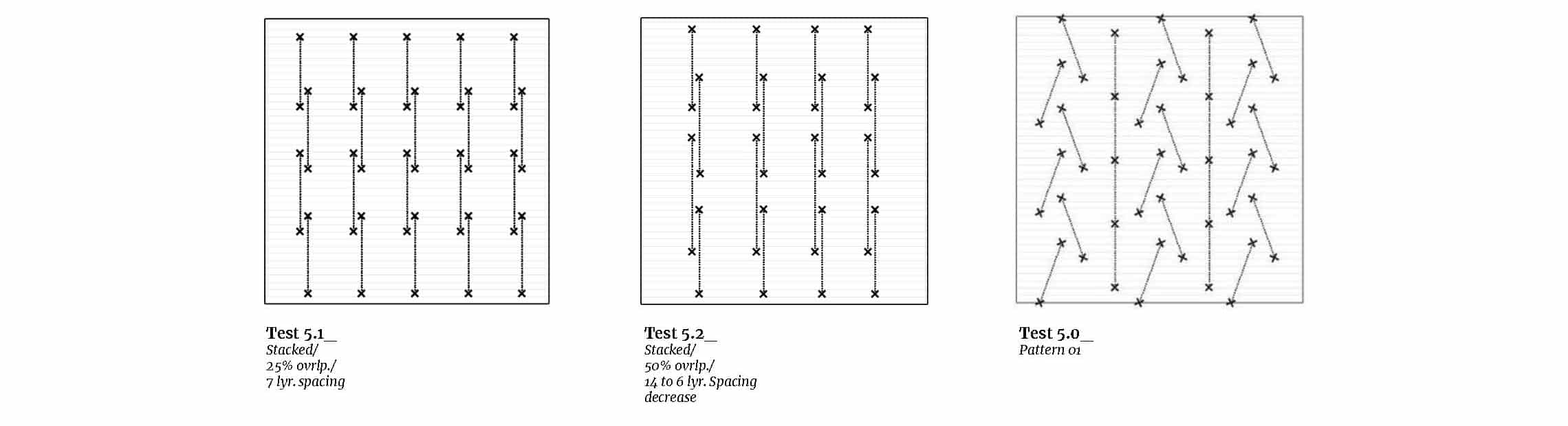

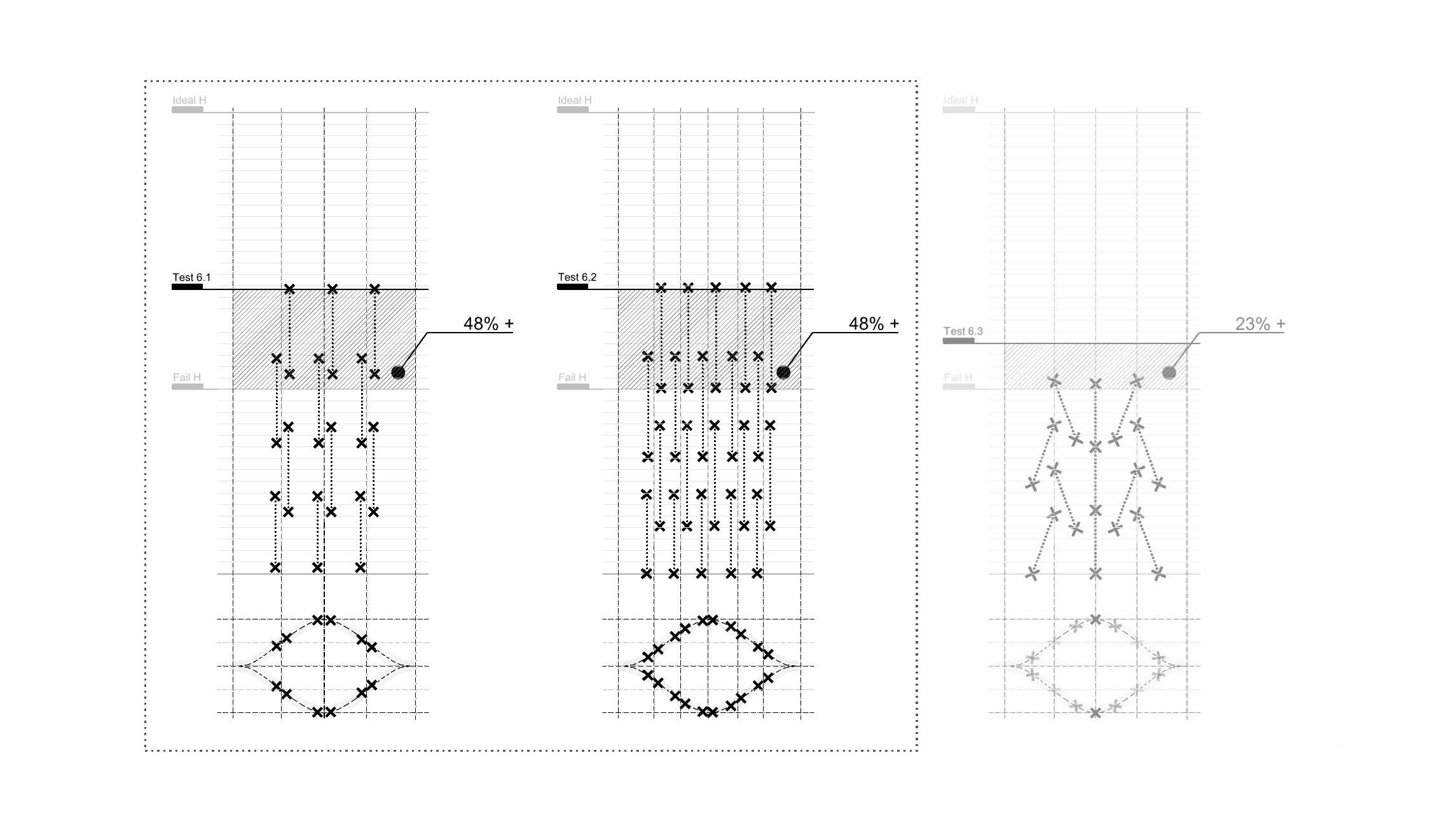

Catalogue 01: Aligned vs Staggered

How do variations in spacing and arrangement pattern, of reinforcements affect the buildability?

Catalogue 01 explores how different reinforcement arrangements affect the overall buildability of the printed wall. Two main patterns were tested:

- Aligned sticks, which follow a straight vertical trajectory through the layers.

- Staggered sticks, which shift position between layers to distribute forces more evenly.

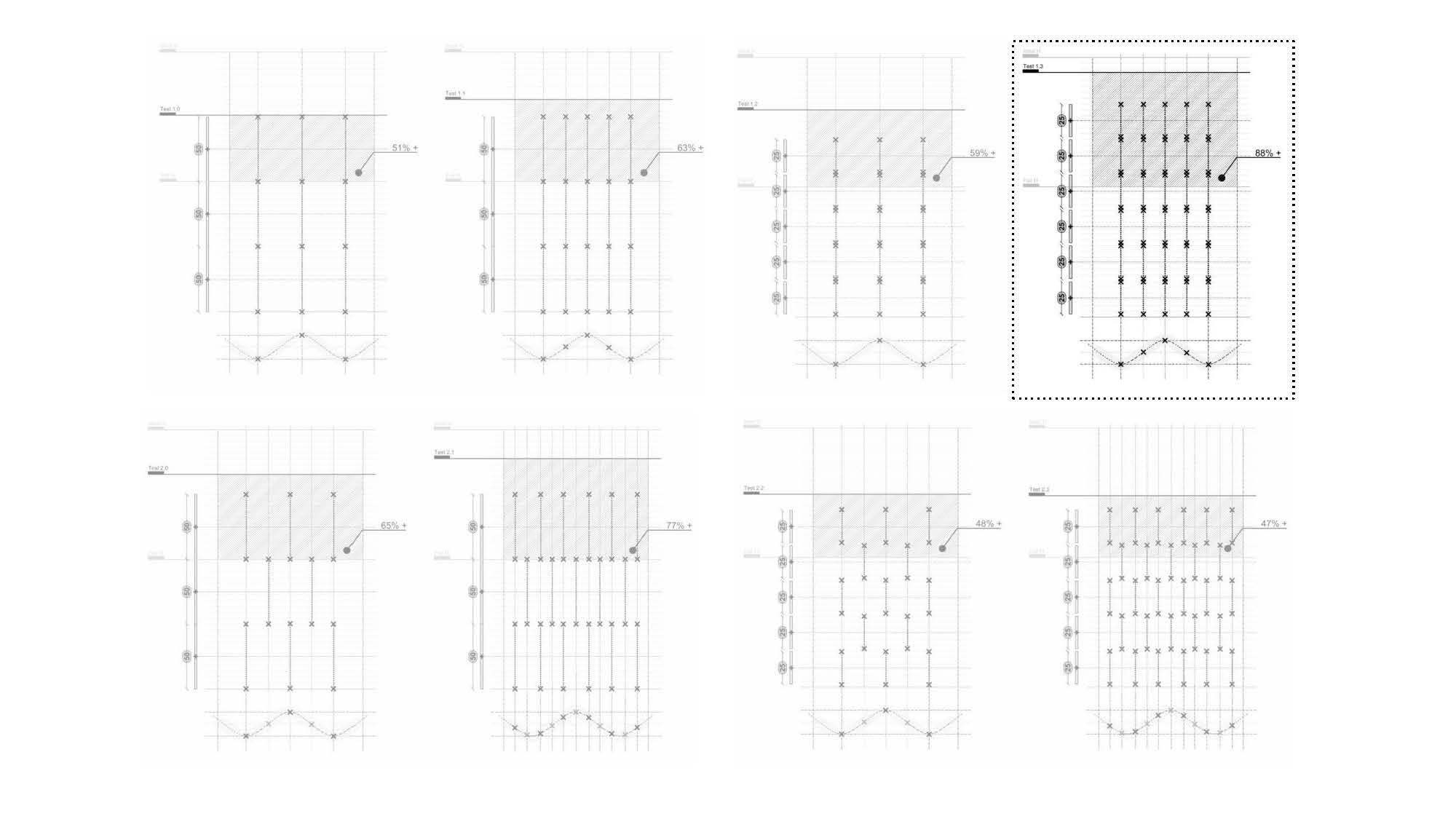

Each configuration was tested with varying numbers of sticks per layer and different vertical spacings. These experiments aimed to understand whether increasing reinforcement density or modifying the pattern has a measurable effect on wet-state performance.

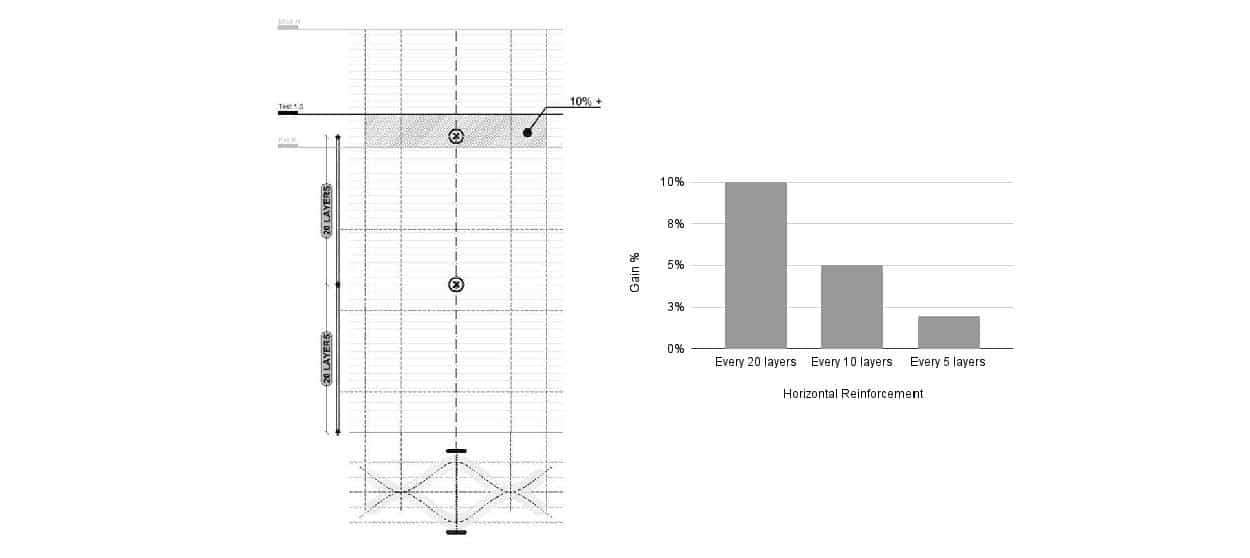

The results show a clear trend: walls with more reinforcement elements and smaller spacing between layers performed significantly better. Higher density reduces unsupported material volume and increases local confinement, which helps the wall resist collapse during early layers.

Staggered patterns presented benefits when spacing was large, as the lateral distribution of sticks helped reduce localized weaknesses. However, when the spacing became smaller, staggered configurations introduced handling challenges—such as misalignment and insertion errors—which ultimately reduced consistency. These findings highlight the delicate balance between structural logic and practical constructibility.

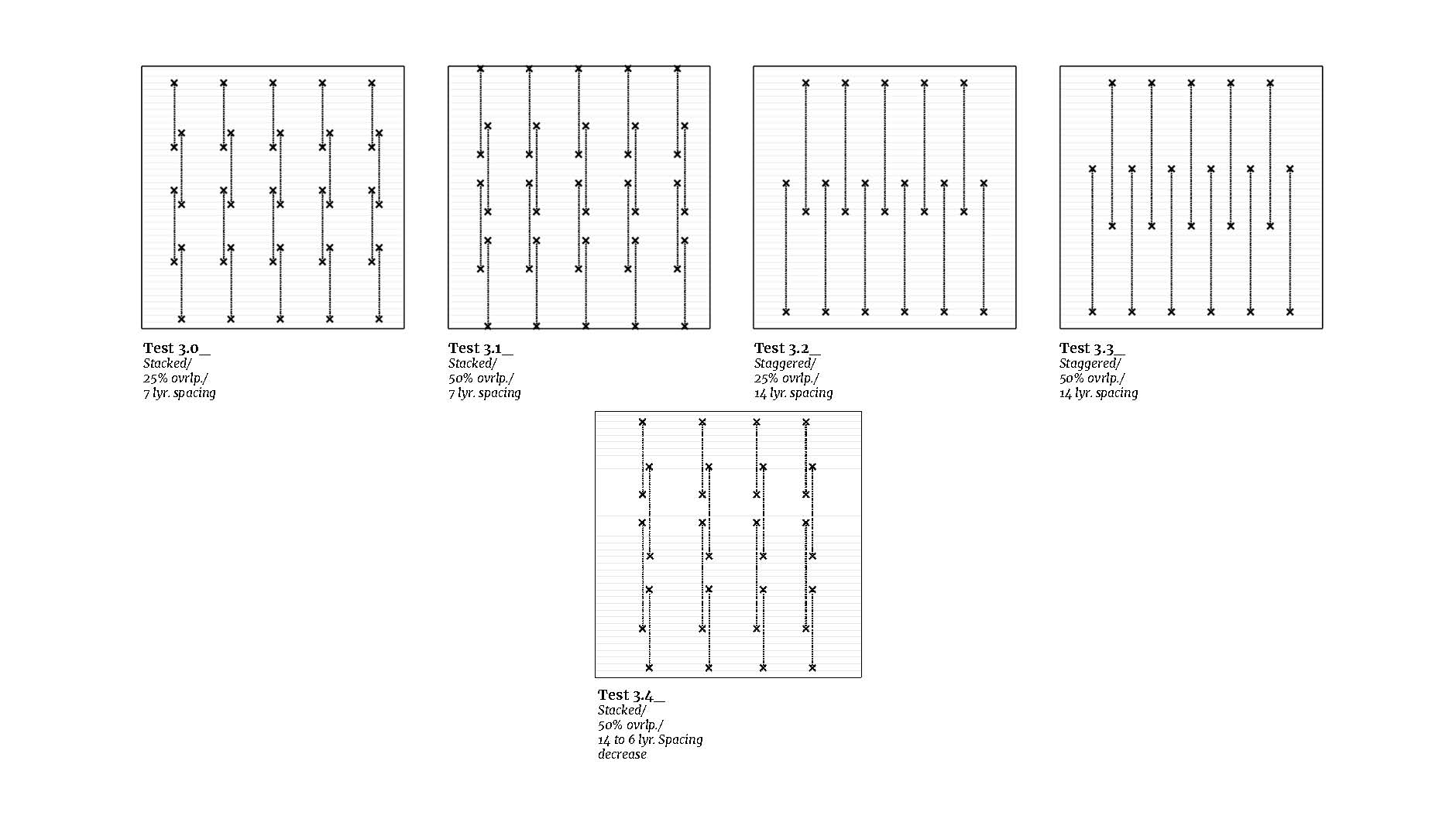

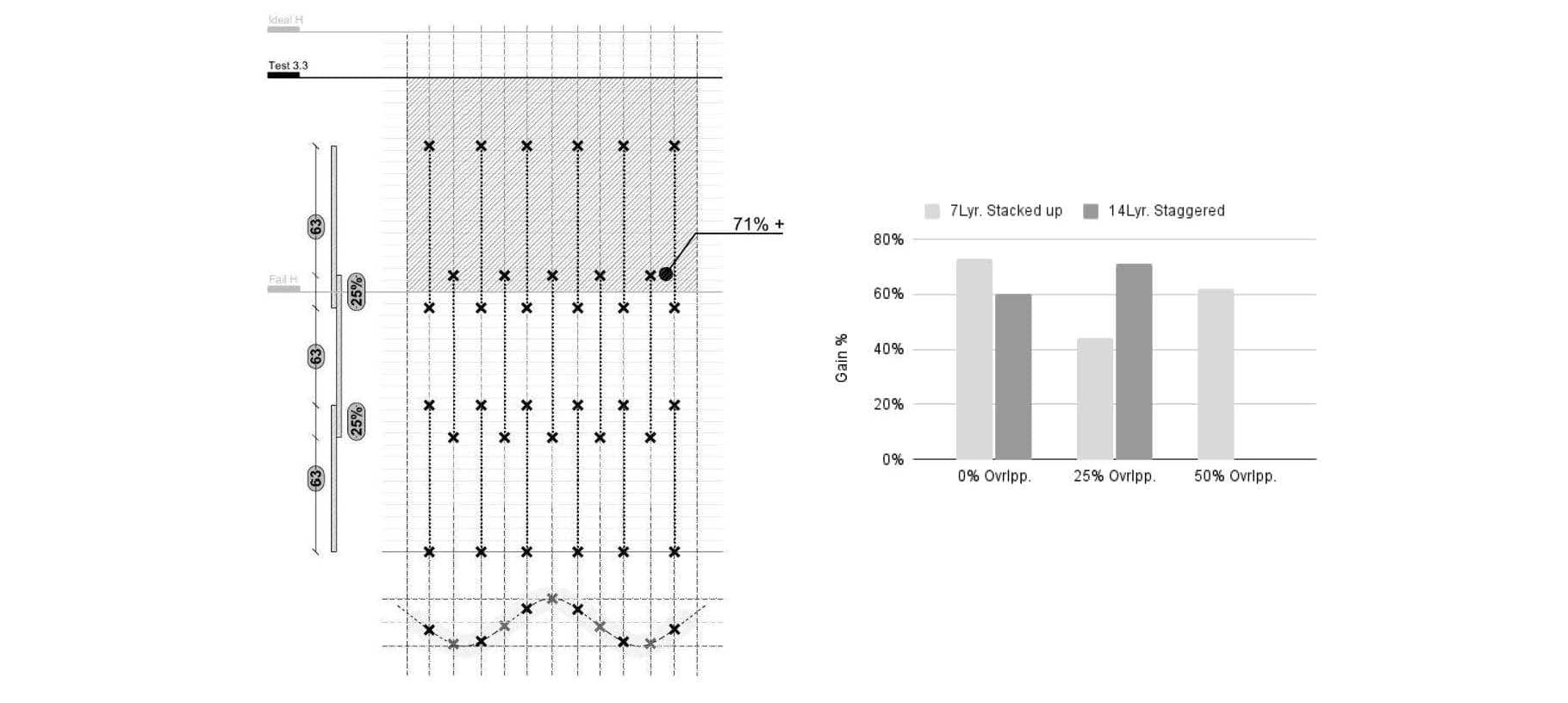

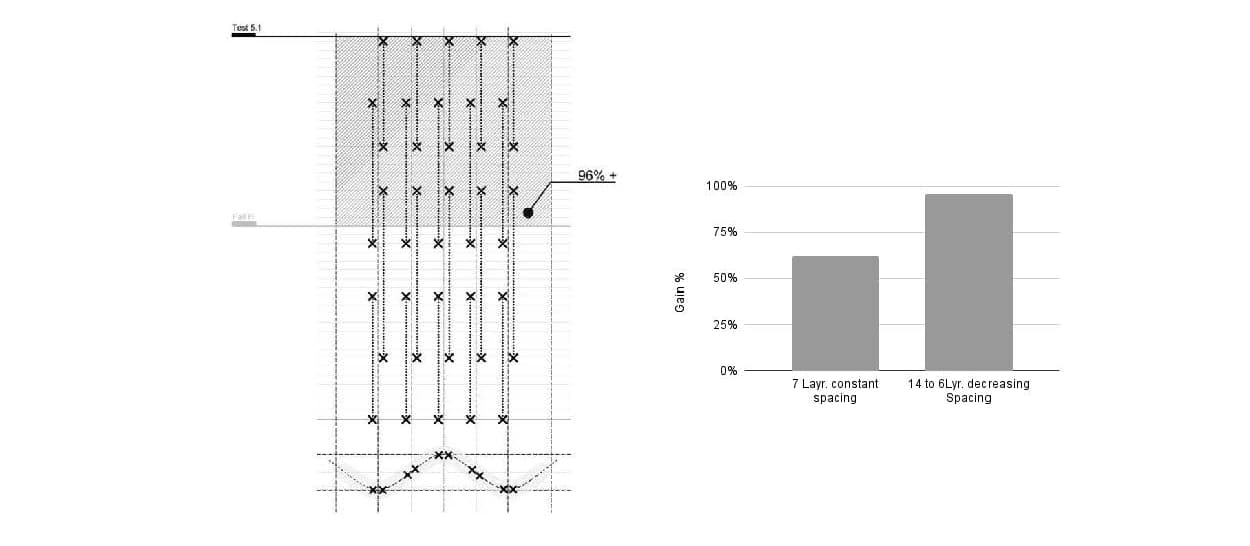

Catalogue 02: Overlap Strategies

Catalogue 02 examines the effect of vertical overlap between reinforcement elements. Overlap refers to how much the sticks extend through multiple layers rather than ending at a single layer boundary.

The goal was to evaluate whether greater overlap creates stronger interlayer continuity and helps carry loads more effectively in the wet state. Five configurations were tested, varying both overlap percentages and spacing strategies.

Increasing overlap consistently improved buildability. When sticks extended across multiple layers, they acted like microscopic “columns” that transferred loads more evenly and reduced local instability.

Higher overlap also reduced layer displacement and minimized rotational movements of the wall. This added continuity helped delay collapse and allowed the wall to reach greater heights without suffering structural failure.

These results suggest that continuity in reinforcement plays a critical role in stabilizing wet material, especially in taller prints.

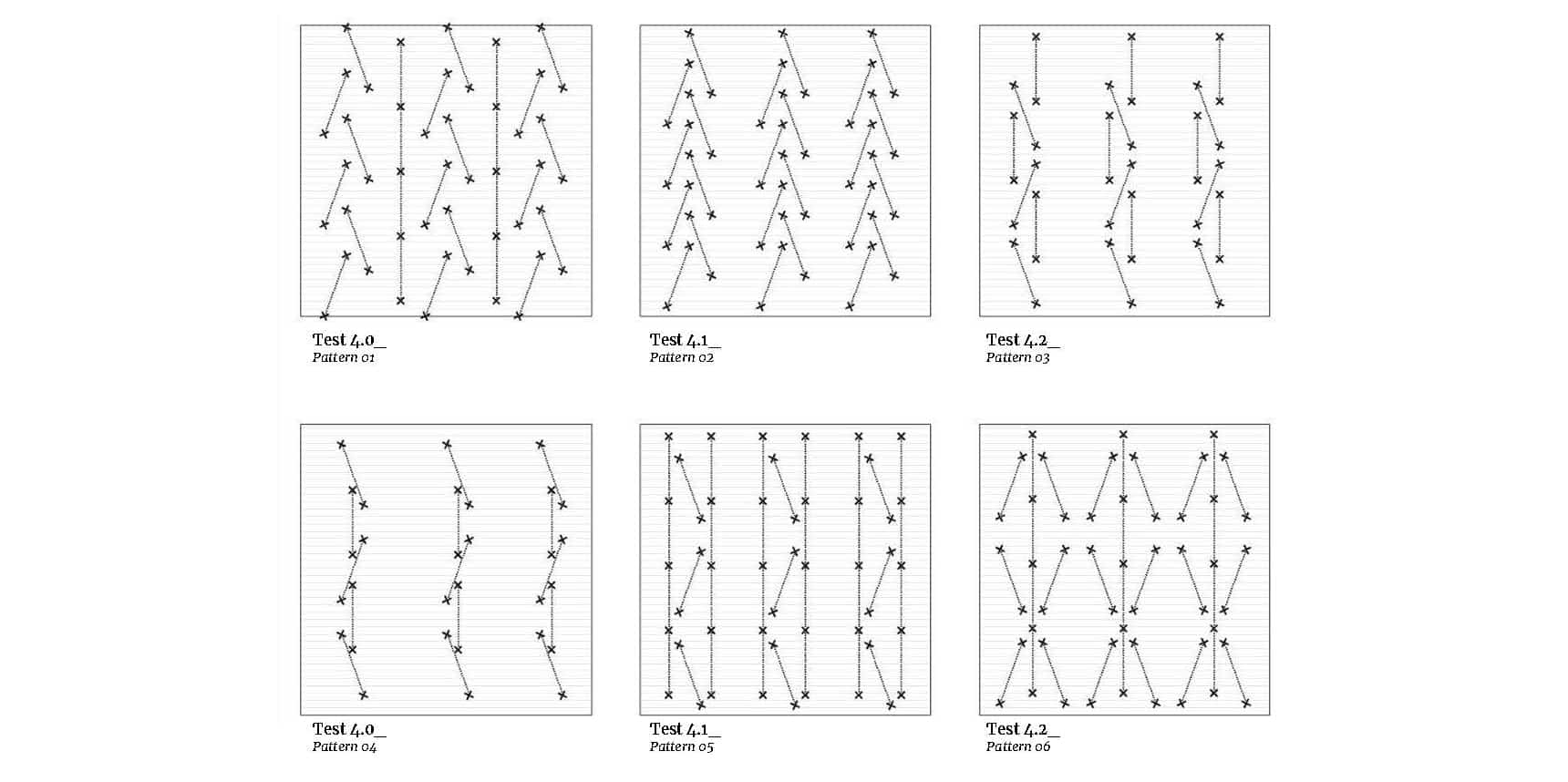

Catalogue 03: Diagonal Reinforcement Tests

In this catalogue, we explored whether diagonal reinforcement could contribute to wet-state stability. Six different patterns were tested, all incorporating inclined sticks inserted between layers.

The hypothesis was that diagonal sticks might help resist lateral deformation, similar to bracing systems used in traditional construction. However, diagonal insertion also introduces horizontal forces that could potentially disrupt the wet material.

The tests showed that diagonal reinforcement significantly decreased buildability. The angled sticks generated horizontal and torsional forces that twisted the printed geometry and displaced the layers.

In many cases, the print failed shortly after insertion due to shear effects created by the diagonal elements.

Although diagonals are effective in dry or semi-rigid materials, they are incompatible with the plastic behavior of wet earth. This confirms that reinforcement strategies must align with the material’s mechanical properties in its weakest state.

Horizontal Reinforcement Strategies

This phase evaluated the addition of horizontal reinforcement elements within a double-line geometry. These elements were intended to link the two walls and improve lateral resistance during the printing process.

However, integrating horizontal elements during wet-state printing proved difficult. The tested geometry did not provide enough structural support or confinement to accommodate these reinforcements effectively.

Horizontal reinforcement did not result in improved buildability under the tested conditions. Instead, the extra elements increased the risk of deformation by interrupting the natural settling of the wet material.

These results suggest that while horizontal reinforcement is useful in other contexts—such as cavity walls or dry-stage stabilization—it requires a specific geometry and workflow that differ from the one tested here. Future research could explore geometries better suited for this strategy.

Printing Sequences (No Reinforcement vs Vertical vs Horizontal)

By comparing three printing sequences, we were able to observe the impact of each reinforcement strategy on the behavior of the wall during printing:

- No reinforcement resulted in early collapse and rapid loss of geometric accuracy.

- Vertical reinforcement significantly improved the achievable height and reduced deformation.

- Horizontal reinforcement added complexity but did not improve performance in this configuration.

This comparison clearly shows which strategies work best under wet-state conditions.

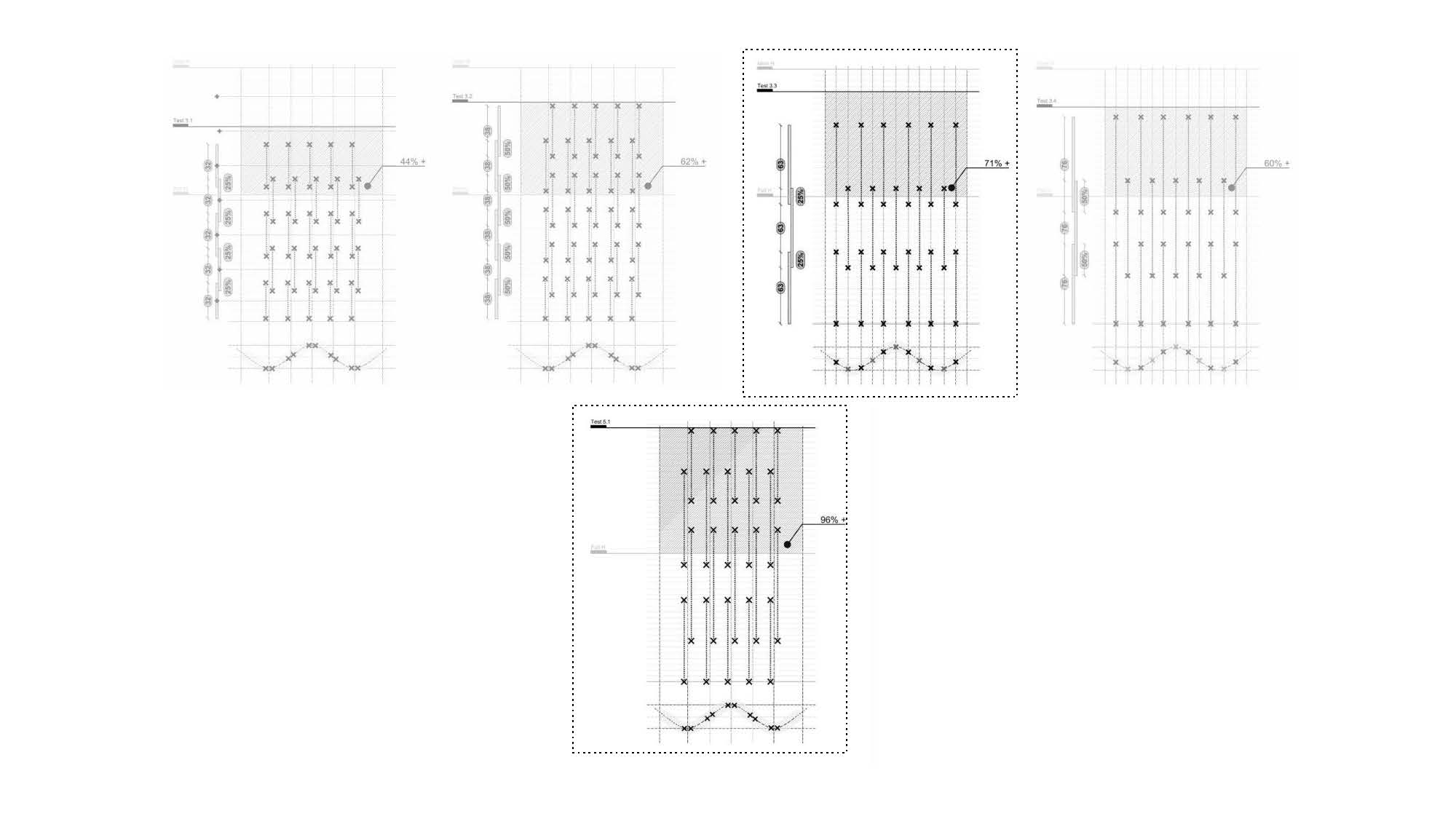

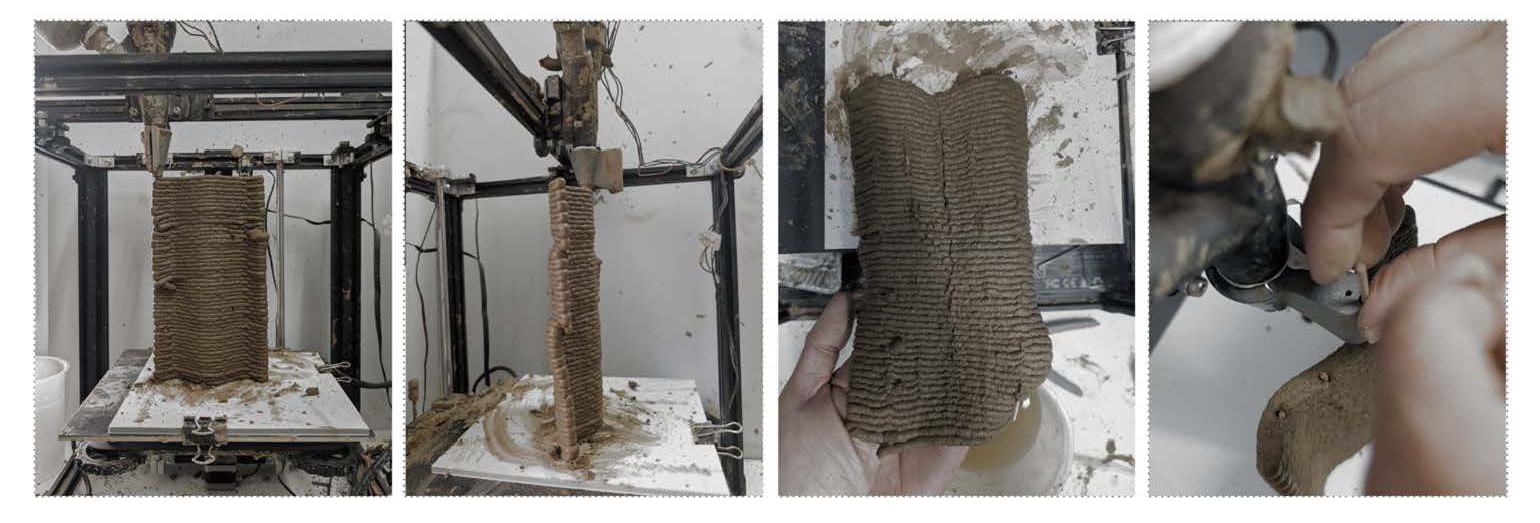

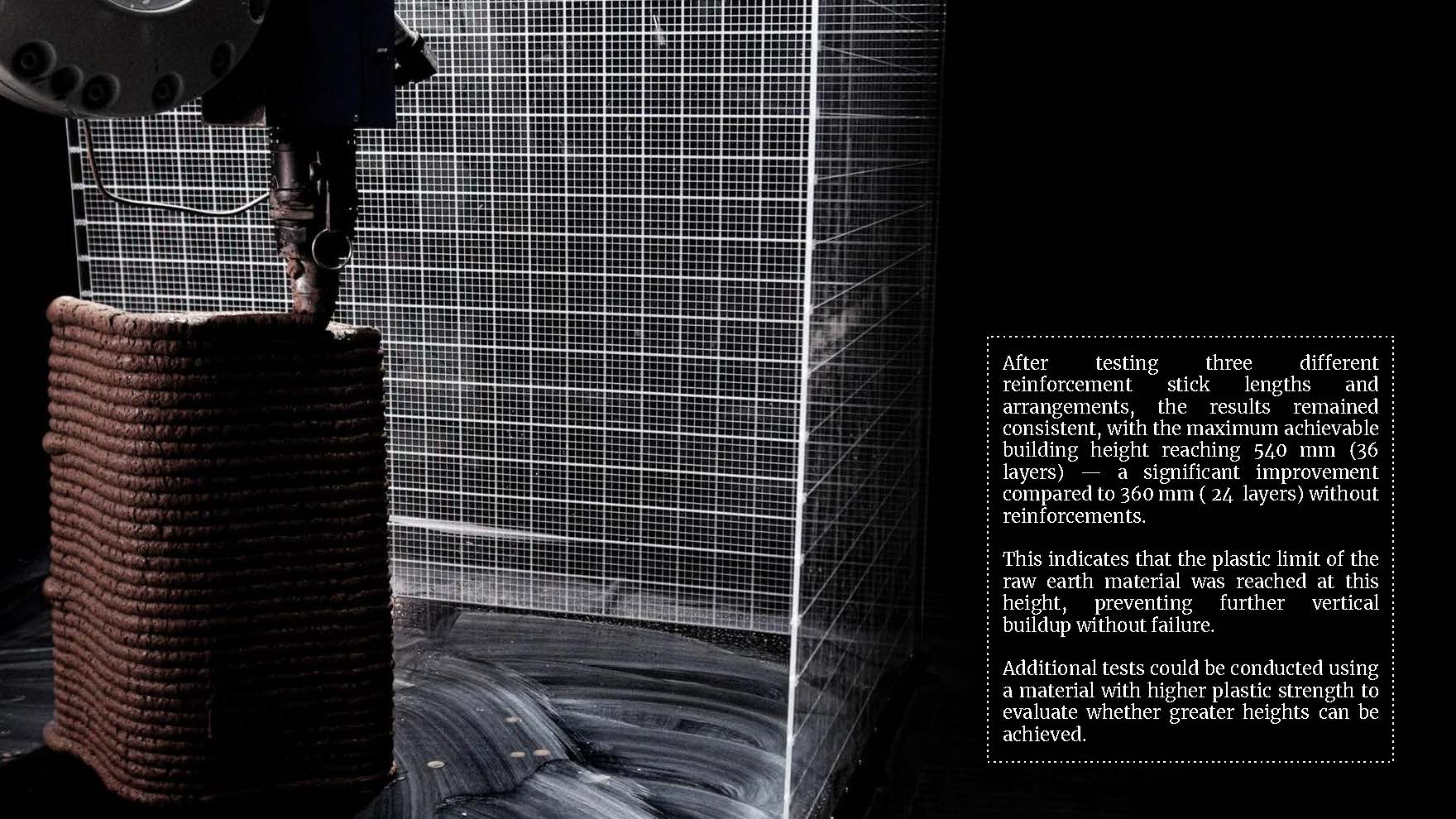

Scale-Up: 1:1 Vertical Reinforcement Tests

After defining the most effective 1:5 configurations, we scaled them up using an ABB robot with a WASP extruder. The goal was to validate whether the reinforcement strategies would work similarly at architectural scale.

Although the prints performed well, they did not reach the full expected height. This was due to the earth mixture reaching its plastic limit, meaning the material could no longer support additional weight while still wet.

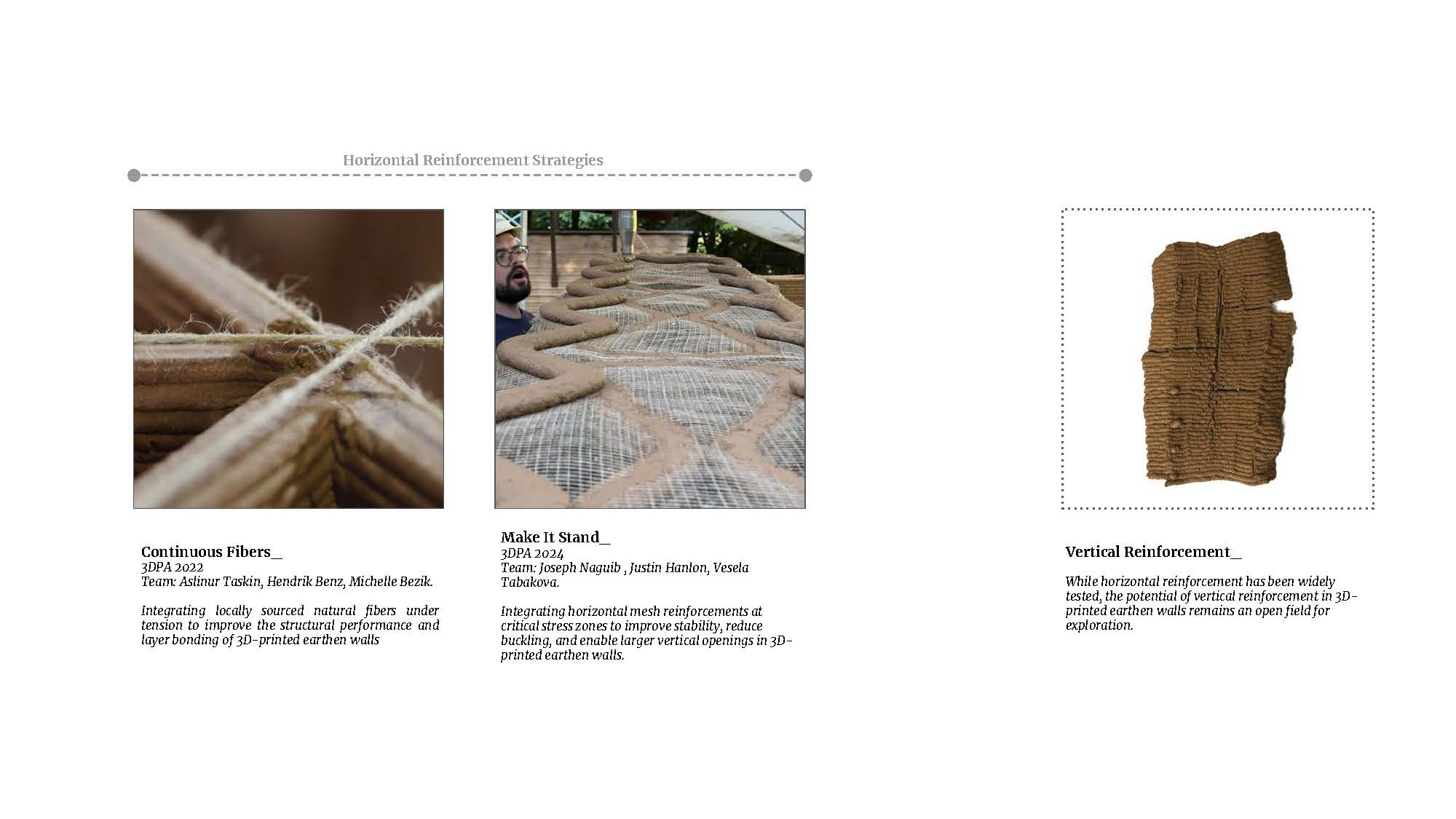

Scale-Up Results: 540 mm Maximum Height

The maximum height achieved in the 1:1 tests was 540 mm, compared to 360 mm without reinforcements. This represents a significant improvement and validates the potential of vertical reinforcement strategies.

However, once the material reached its plastic threshold, further printing led to deformation and collapse. This indicates that while reinforcement can extend limits, the material properties ultimately define performance boundaries.

Future studies could explore alternative mixes with higher plastic strength to overcome this limitation.

Final Comparative Overview (Fibers, Meshes, Sticks)

The overall comparison of reinforcement strategies shows that each method performs best in specific contexts:

- Continuous fibers excel in complex geometries such as vaults and cantilevers.

- Horizontal meshes work well in cavity walls and structures requiring lateral stability.

- Vertical sticks are most effective for increasing buildability and height during the wet printing phase.

This cross-analysis helps position vertical reinforcement as a valuable but previously underexplored strategy in 3D earth printing.

Final Conclusions

The research demonstrates that vertical reinforcements significantly improve wet-state stability and allow for higher printable walls before collapse.

However, the earth material itself remains the main limiting factor once its plastic threshold is reached.

The study suggests that future work combining vertical reinforcements with improved material mixes could unlock even greater heights and performance, moving 3D-printed earth closer to architectural standards.