Why – Problem context

In the current forestry industry, only 40% of each harvested tree is actually used for construction or valuable products. The remaining 60% often ends up as waste — discarded, chipped, or burned as firewood.

This imbalance sparked a fundamental question:

Can we change this ratio?

Driven by that inquiry, we began exploring new ways to give value to what is traditionally overlooked — the irregular, twisted, or branching parts of the tree that never make it into the standard supply chain. Our goal:

To shift from 40% usable material to 60% — or more.

In Catalonia, the most common tree species are pine, beech, and oak. Among them, oak stands out

Oak trees grow in highly irregular, organic forms, with crooked branches and complex geometries that don’t fit into the standard logic of industrial processing. For that reason, oak produces the highest amount of waste in the forestry system.

That same complexity is paired with remarkable material qualities:

Oak is harder, more flexible, and more resistant than its local counterparts.

That contradiction — being both the most discarded and the most capable — made oak the perfect candidate for our research.

We chose to work with it not in spite of its irregularity, but because of it.

The Research Question

This investigation into forestry waste and material potential led us to a fundamental question:

State of the Art

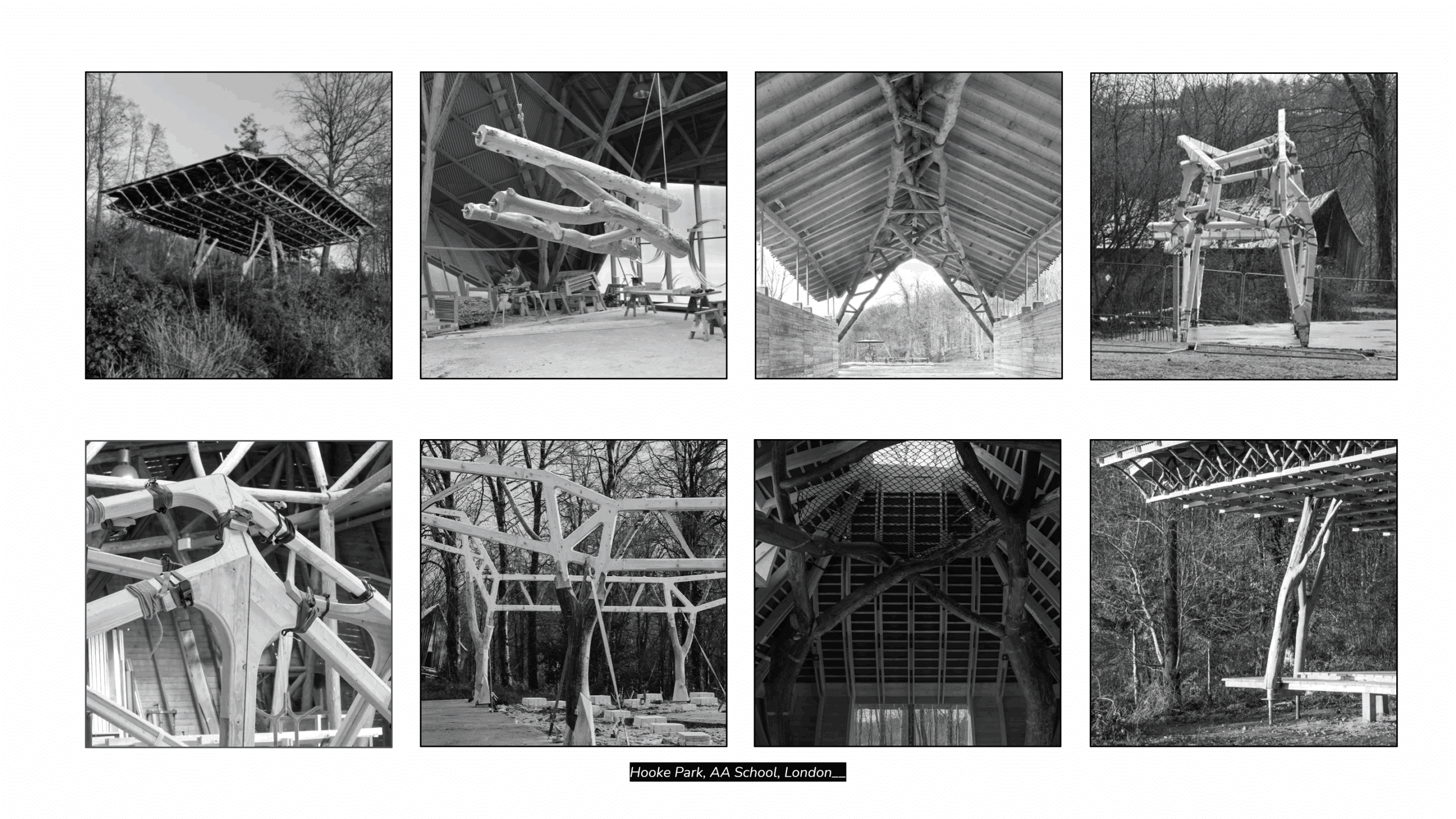

One of the strongest references for our work is Hooke Park, a research center and experimental woodland campus in the UK, known for its architectural projects using irregular timber.

Their approach embraces the natural complexity of the wood — the design adapts to the log.

This methodology values the uniqueness of each tree, finding creative ways to integrate its form into architectural structures.

It’s a powerful precedent for how non-standard materials can lead to expressive architecture.

However, our approach takes a different direction.

Instead of adapting the design to the log, we aim to adapt the log to the design.

Through digital design, material analysis, and robotic fabrication, we explore how to realign, cut, and reshape irregular logs — turning them into precise, structural components that serve a specific architectural intention.

Another important reference is Baubotanik, a design philosophy and practice that also works with natural geometries — particularly living plants and trees.

Their approach is to domesticate and guide growth over time, shaping plants to match a desired architectural form.

It’s a fascinating intersection of biology and design, but it relies on slow, natural processes that unfold over years or even decades.

In contrast, our process shares the same ambition — giving form to irregular natural geometries — but does so through immediate, mechanical transformation.

Instead of waiting for nature to adapt, we use robotic precision and strategic cutting to reshape the log in the present moment.

The result is visible right away.

What – Statement

what are we doing?

At the core of our project is a simple but powerful idea:

The tree, a symbol of nature, begins as a living, irregular form.

Can it be transformed into a precise, load-bearing structure?

Our work explores how these organic, non-standard shapes can evolve into an articulated strucutral system.

Using digital design and robotic fabrication, we develop a process of precise cutting that allows us to domesticate the tree, guide its bending, and align it with specific load points in a structure.

In doing so, the tree shifts from being a discarded remnant to becoming a purposeful structural element — intelligent, efficient, and expressive.

Project aplication

Architectural system

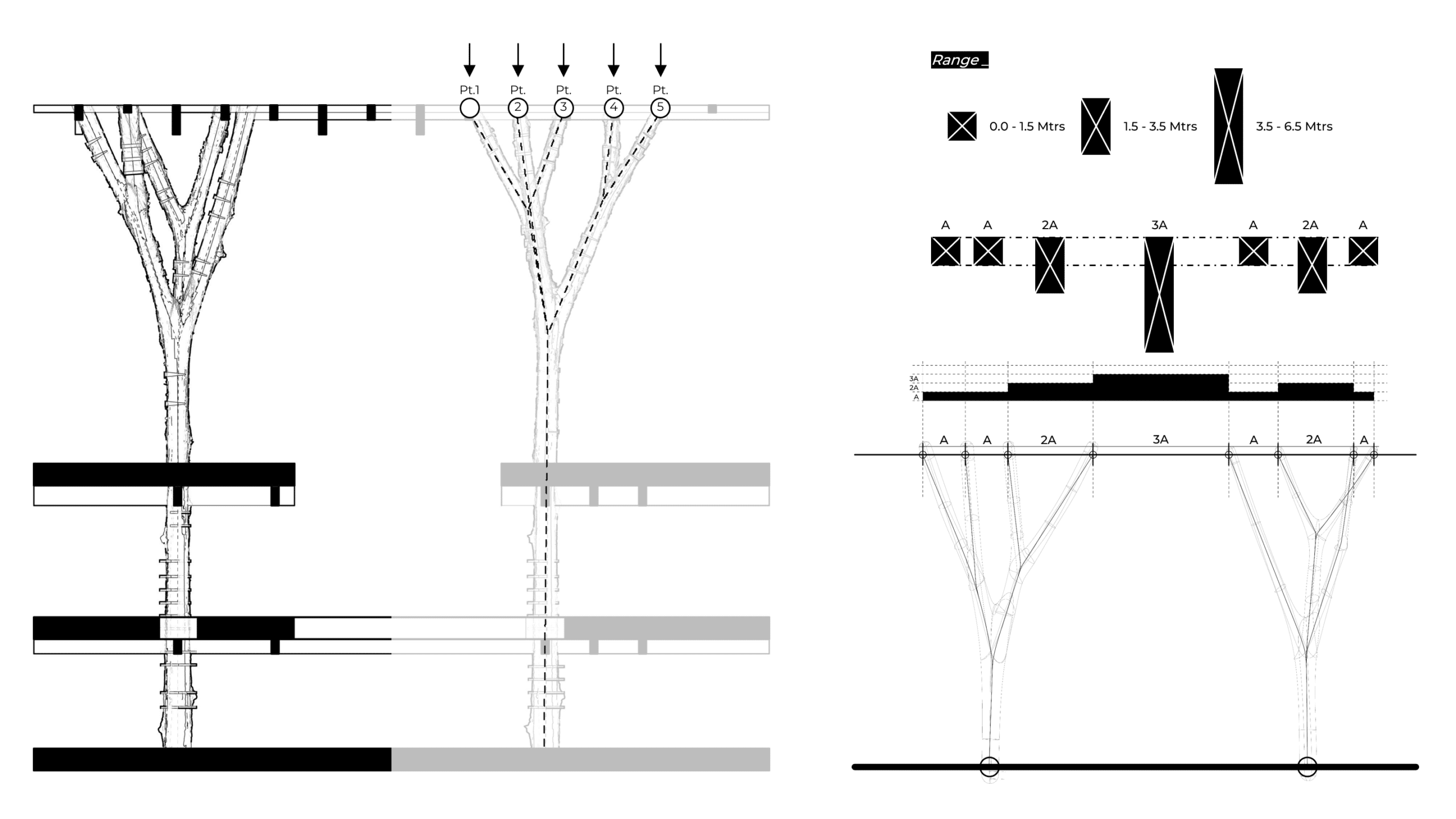

To demonstrate the potential of our research, we developed a speculative architectural intervention within the New Ávila building at IAAC.

Specifically, we focused on one of the main hall, where a three-story vertical void offers the perfect spatial condition to test our structural strategy.

In this context, we propose a system where a series of reshaped trees are used as vertical columns.

These columns work in conjunction with a horizontal structural grid, transferring the loads of the linear elements down through the trunks and into the ground.

This proposal showcases how irregular tree logs — typically discarded — can be realigned and integrated into a larger architectural system, not just as decorative or symbolic elements, but as key load-bearing components.

Design Strategy

Since the amount of reshaping we can apply to each tree is limited, our design strategy works with minimal but targeted transformations.

We modify the shape of each trunk just enough to connect with specific points of a modular structural grid.

This grid acts both as a load-distribution system and as a design guide, dictating connection points and defining the overall spatial rhythm of the intervention.

Thanks to its modularity, the grid allows for variable beam heights, adjusting naturally to the different spans and structural requirements of the space.

You can see this logic clearly represented in our scale model — especially if you view it from a low angle, where the alignment between trunks and beams becomes fully legible.

Structural Performance

When we reshape the trees, our goal is not only to align them with the modular structural grid — we’re also actively enhancing their structural performance.

By slightly shrinking or closing the geometry of the tree, we increase the amount of compressive stress, while simultaneously reducing tensile stress, to which these elements are naturally more vulnerable.

While trees are biologically designed to support their own weight, they are not optimized for external architectural loads.

Through our reshaping process, we redirect forces more vertically, improving how these elements transfer loads to the ground.

This results in less displacement of the branches under stress and a more stable, efficient structural behavior.

How – Kerfing Technique

To achieve the reshaping of the tree logs, we applied a technique known as kerfing — or kerf bending.

This method, often used in furniture design, involves creating a series of strategic cuts (kerfs) to weaken the material and make it flexible enough to bend.

However, in our case, we use a variation of this technique.

Instead of bending the material through compression, we apply a method called wedged kerfing — where wedges are inserted into the kerfs to force the wood open rather than closed.

A wedge is a powerful geometric element: when driven into a narrow gap, it produces strong lateral forces.

We harness this effect to precisely bend and reshape the irregular tree logs, guiding them into the desired alignment for both design and structural performance.

This approach allows us to work with the tree’s natural form while still achieving the architectural control necessary for integration into a load-bearing system.

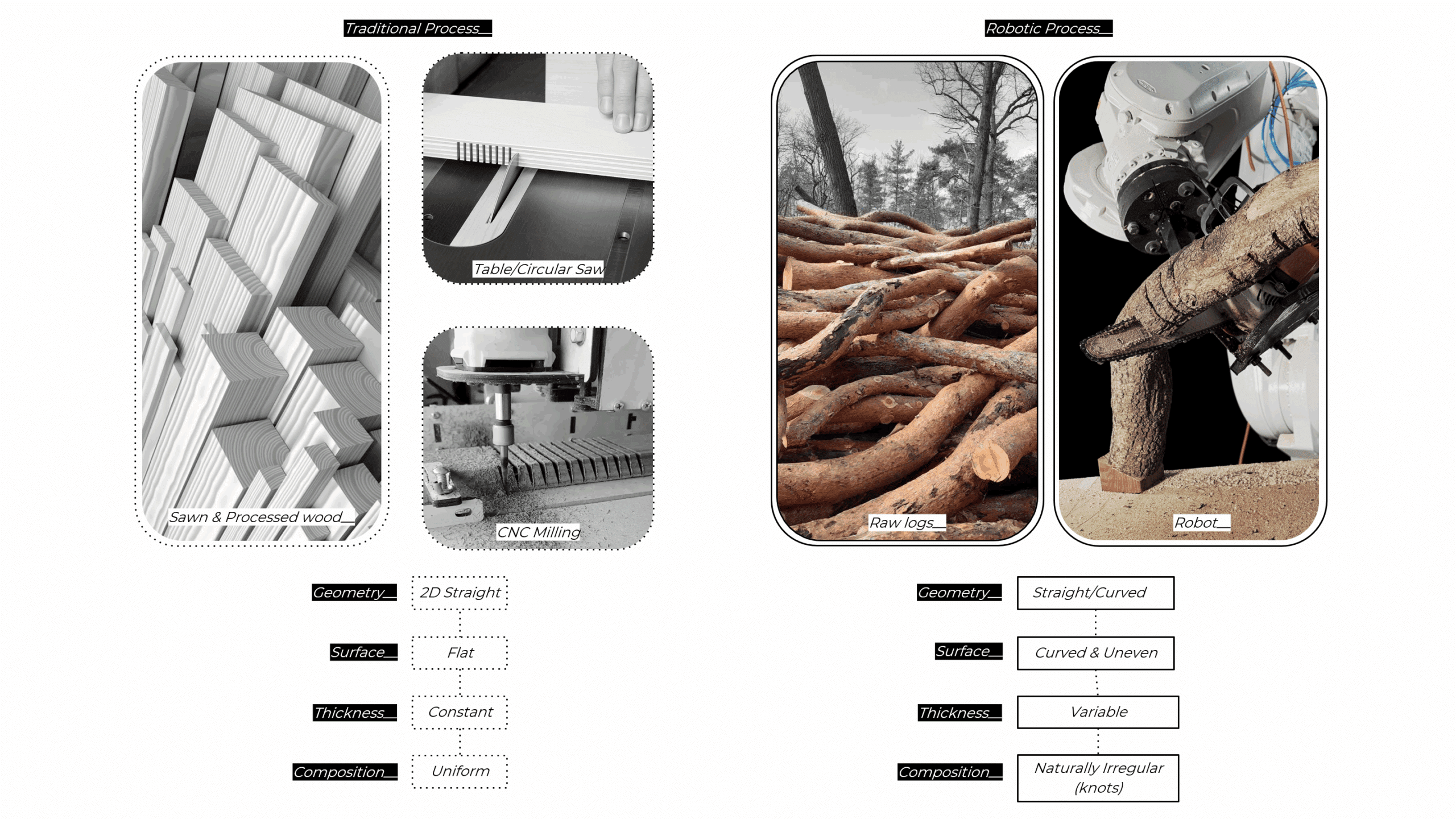

Material Limitations

Applying kerfing to standardized wood elements — like sawn boards or flat panels — is relatively straightforward. These materials are straight, flat, and consistent in thickness, density, and structure, making them ideal for controlled bending with conventional tools.

However, when working with irregular tree logs, the process becomes significantly more complex.

These logs can be:

- Naturally curved

- Varying in diameter and cross-section

- Marked by knots, cracks, and unpredictable grain

- Rough and uneven on the surface

This variability makes it extremely difficult to apply kerfs with precision using traditional tools.

To overcome this, we rely on 3D scanning to capture the exact geometry of each log, and use 6-axis robotic manipulation to execute the kerfing process with the high accuracy required for controlled reshaping.

Hypothesis validation

To explore the performance and limitations of the wedged kerfing technique, we developed a series of prototypes using a chainsaw mounted on a robotic arm.

You can see these prototypes displayed nearby, each one representing a step in our material experimentation process.

We tested variations in:

- Cut depth

- Kerf spacing

- Wedge angle and size

We started with straight, cylindrical pine posts, which allowed us to observe controlled bending under different parameters.

Once we identified the most effective configurations, we advanced to a more complex goal:

reshaping a completely irregular and curved log — and straightening it.

This final challenge pushed the method beyond standard deformation, proving that robotic wedged kerfing could become a powerful tool for realigning non-standard timber.

Workflow

Phase 1 _ Selection & Scanning

The first step in our workflow was the selection and digitalization of the raw material.

Using Polycam, we created a digital database of logs and forks, capturing their geometry through photogrammetry-based 3D scanning. This tool allowed us to work directly with the highly irregular shapes that define natural tree growth.

For our project, it was essential to accurately capture the contours, branching patterns, and surface complexity of each piece — not only for design purposes but to ensure the precision of subsequent robotic operations.

By starting with a precise digital twin of each log, we established a reliable foundation for simulation, analysis, and fabrication.

Phase 2 _ Analysis & Design Process

Since our goal was to align the branches to specific points in a structural grid, this stage of the process was critical for success.

After scanning the log, we moved on to a series of geometric analyses:

- Extracting the internal axis of the log — a central curve representing its natural geometry and deformation.

- Identifying knots and natural segmentation along the axis, based on shifts in angle and branching.

- Using this information, we defined the position, number, spacing, and depth of the kerfs needed to guide the log into its final shape.

This precise mapping allowed us to simulate the bending behavior of the log before cutting, ensuring that each transformation would align with the design intent and structural requirements.

Phase 3 _ Set up & Robotic Fabrication

we moved into the robotic fabrication stage — where precision was absolutely essential.

Given the irregular and unpredictable geometry of the logs, calibration became a critical part of the process.

We dedicated significant effort to ensuring that the log support table was aligned with the robot’s toolpath, minimizing any deviation during cutting.

Special attention was placed on calibrating the chainsaw mounted on the robotic arm, especially in terms of cut depth.

We determined that cutting between 85% and 90% of the total thickness of the log provided the best balance:

- Deep enough to allow effective bending

- Shallow enough to prevent cracking or breakage in the remaining uncut material

This careful calibration ensured structural integrity and control over deformation — two key factors in transforming each log into a functional architectural element.

Phase 4 _ Wedge insertion

Not every step in this process is automated — manual intervention also plays a crucial role.

In this final phase, we inserted the wedges into the pre-cut kerfs by hand. This step required physical strength and coordination, as the wood we were working with — especially oak — is both extremely hard and highly flexible.

Here, you can see how a small group of people was able to reshape a massive wooden element, bending it gradually and precisely by driving wedges into the kerfs.

In one of the key moments, we reshaped a specific branch to correct its angular deviation, aligning it with the structural grid based on the simulations.

This manual step demonstrated the real-time transformation of the material — from a naturally chaotic geometry to a controlled structural element.

Final Outcome & Reflections

Looking at the final results, we can clearly see how our prototypes successfully responded to both design and structural intentions.

We developed two full-scale prototypes, each testing a different challenge:

- The Log Prototype

Here, our goal was to correct and straighten the central axis of a curved log.

Thanks to careful planning, kerfing, and wedge insertion, we achieved a 100% successful alignment, transforming an irregular trunk into a structurally usable, linear element. - The Fork Prototype

In this case, the challenge was to align a trunk and three branching segments to meet specific connection points along a horizontal beam.

By analyzing the angular deviations and applying targeted cuts, we were able to reshape the piece so that each branch aligned with the designed geometry — creating a functional and expressive load-bearing joint.

These results validate our method, showing that natural geometries can be reprogrammed through a hybrid process of digital precision and manual intervention, opening new paths for the architectural use of non-standard timber.

Future Applications

our focus has been on mastering the wedge kerfing technique through the integration of digital fabrication and robotics.

But beyond what we have already achieved, we want to conclude by sharing our vision for the future development and expansion of this research — particularly in terms of scale, which is an inherent condition when working with full trees.

1. Expanding the Scanning Process

We aim to integrate LIDAR technology into our workflow, allowing us to scan not just individual logs but entire forests, creating a comprehensive tree database based on precise 3D geometry.

2. Scalable Logistics

Currently, we know that trees of up to 8 meters in length can be transported by truck. For longer specimens or remote sites, we envision the use of helicopter transport to reach otherwise inaccessible trees without disrupting the terrain.

3. From Forest to Factory

We imagine a future where trees are carefully selected and cut on-site, then transported to a specialized fabrication center — the Unlog Factory — where large-scale robots operate in a space designed for full-tree kerfing and transformation.

4. Structural Optimization

We are also aware that kerfing reduces tensile strength by cutting into the wood fibers. Looking ahead, we want to explore how mechanical solutions can be integrated into the kerfing logic itself to compensate for this loss, potentially by reinforcing the cuts or rethinking their geometry.

Conclusion

This project is not just an exploration of material techniques — it’s a statement about value, transformation, and potential.

By working with what is normally discarded, we challenge the conventions of the forest industry and architectural production. We demonstrate that through design intelligence, digital precision, and robotic fabrication, irregular trees — often seen as waste — can become central structural elements.

Our process merges tradition and innovation:

The ancient logic of working with nature, and the contemporary tools to reshape it.

We believe this approach opens a new path in architecture — one where materials are not standardized, but respected for their uniqueness; where waste is reimagined as opportunity; and where the forest is not a resource to exploit, but a system to collaborate with.