Abstract

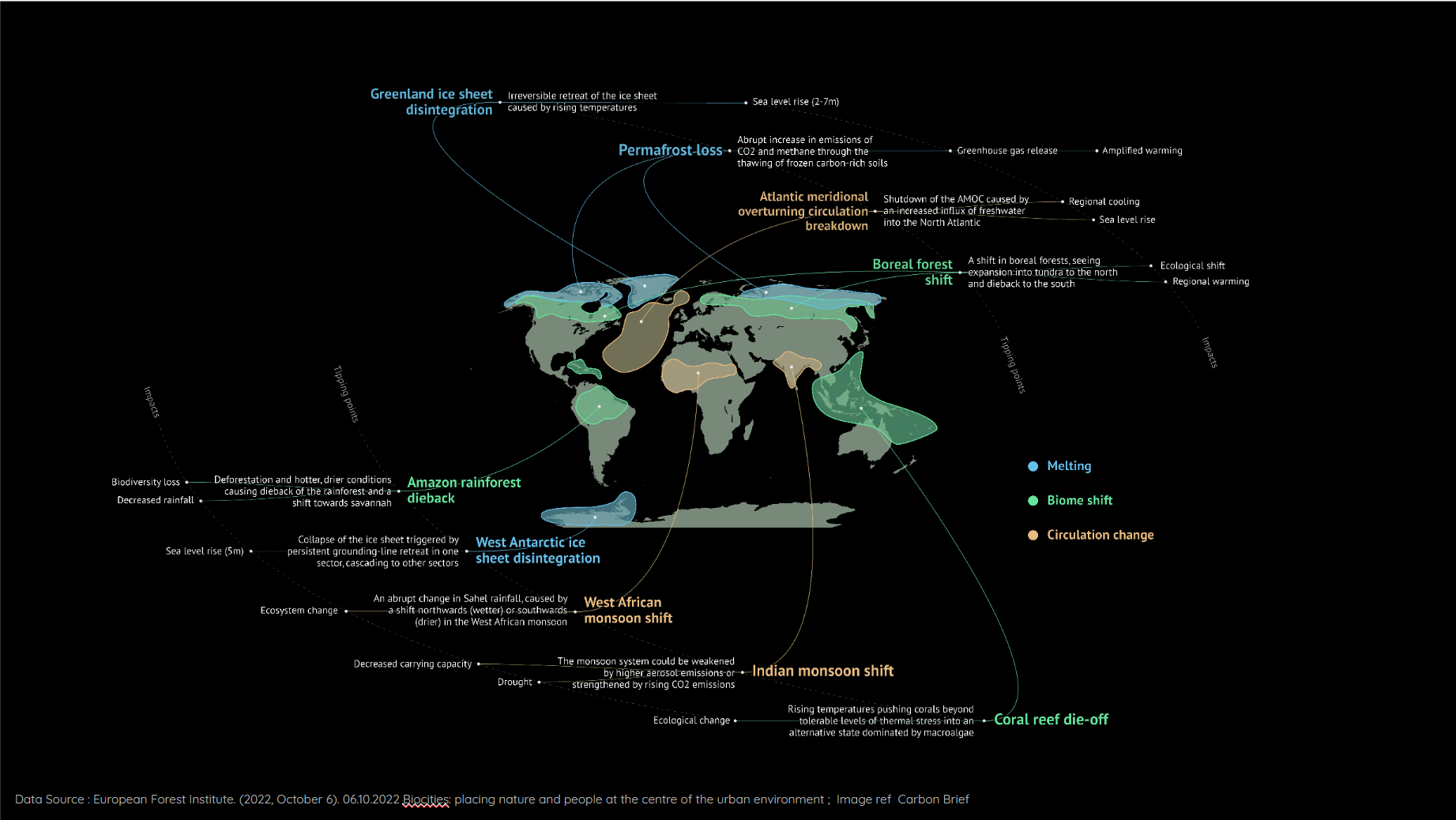

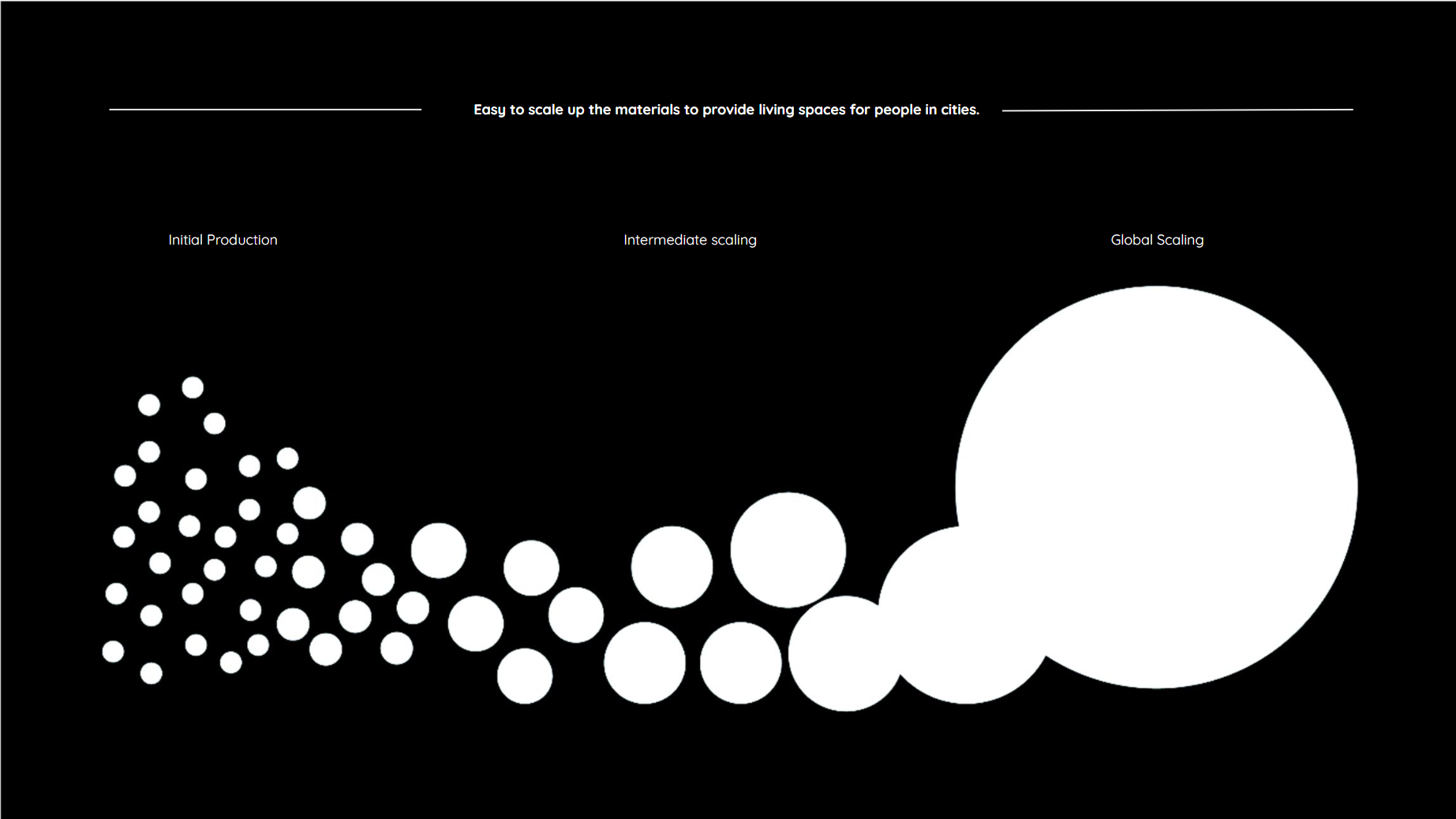

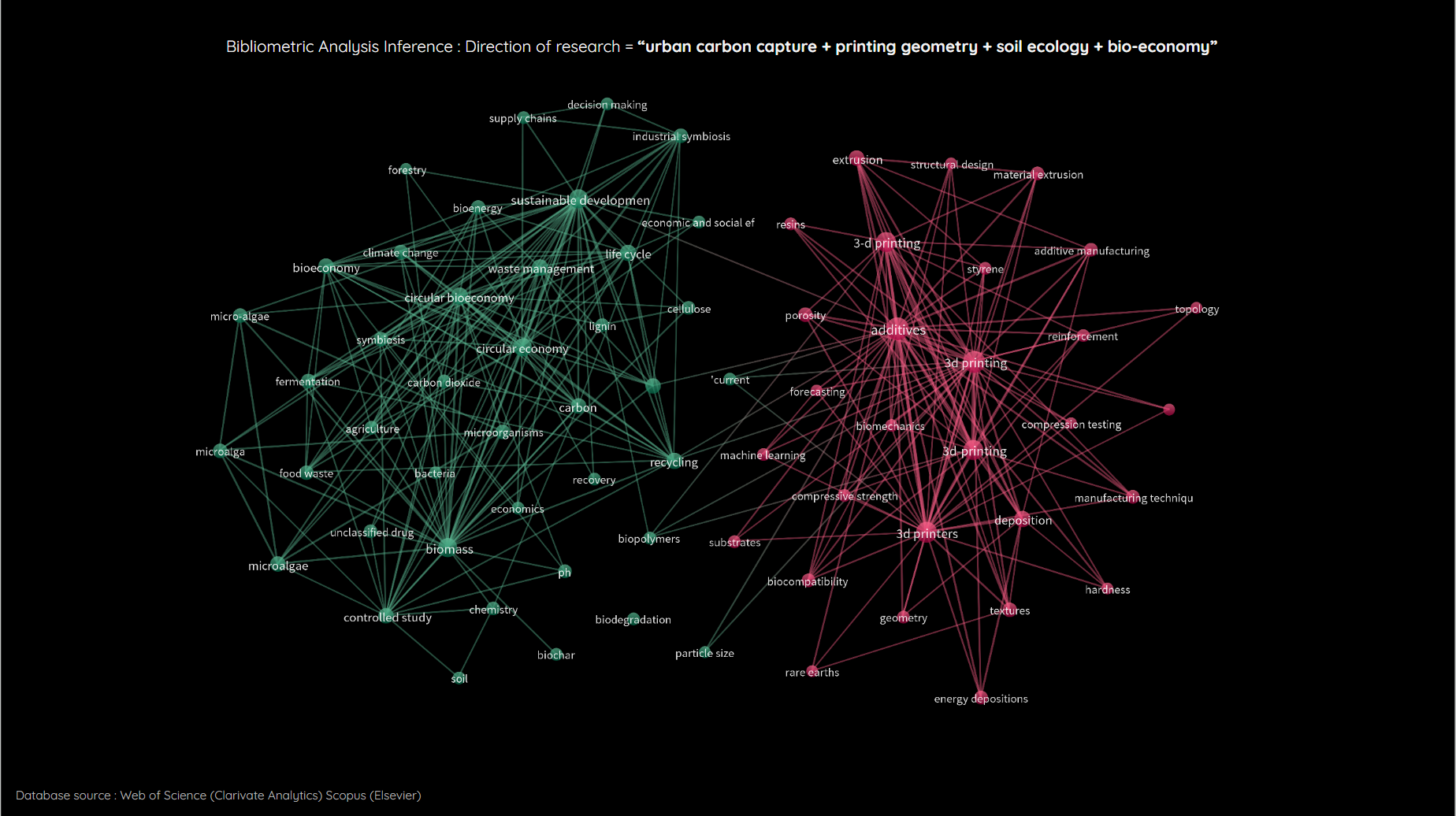

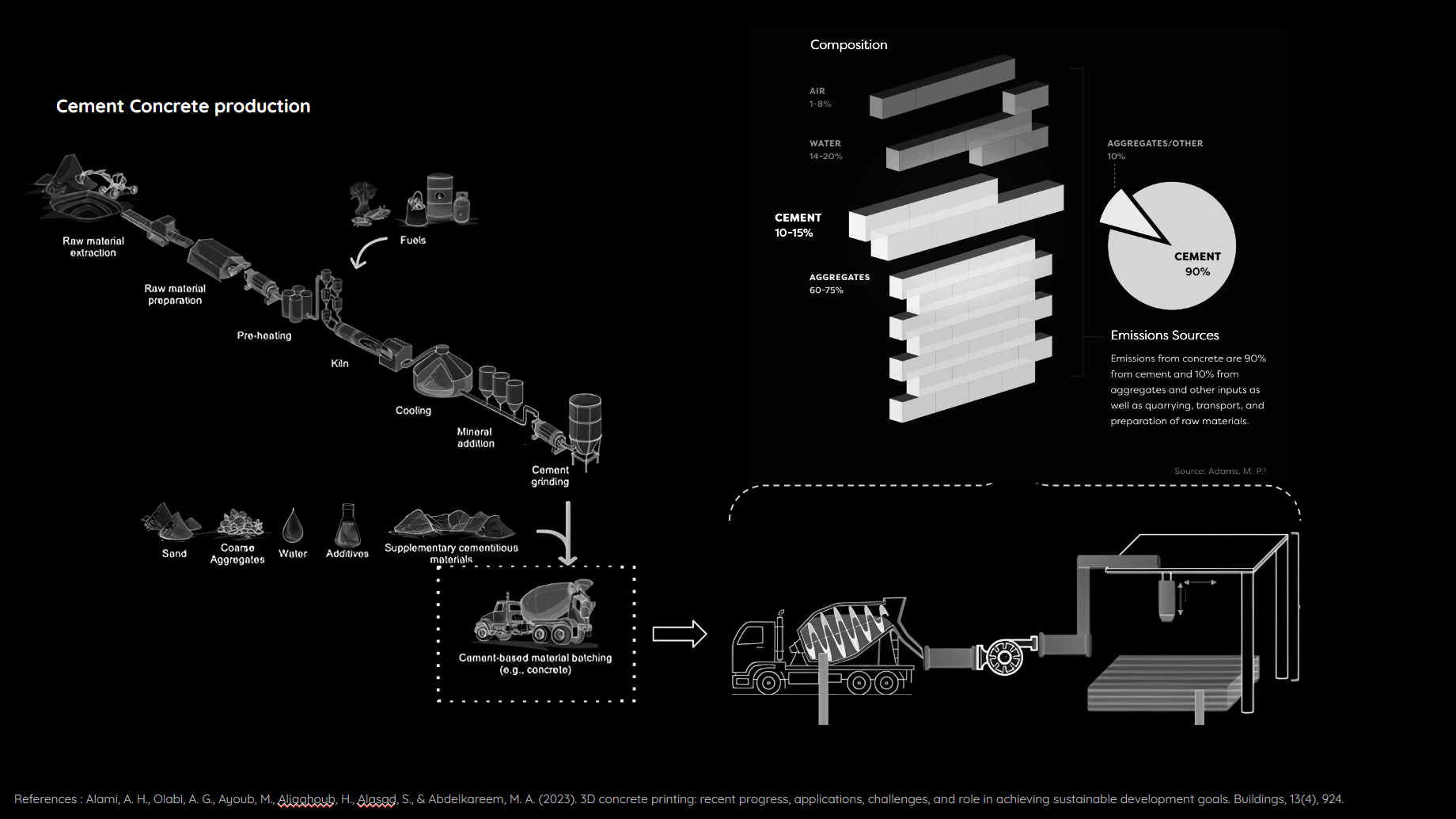

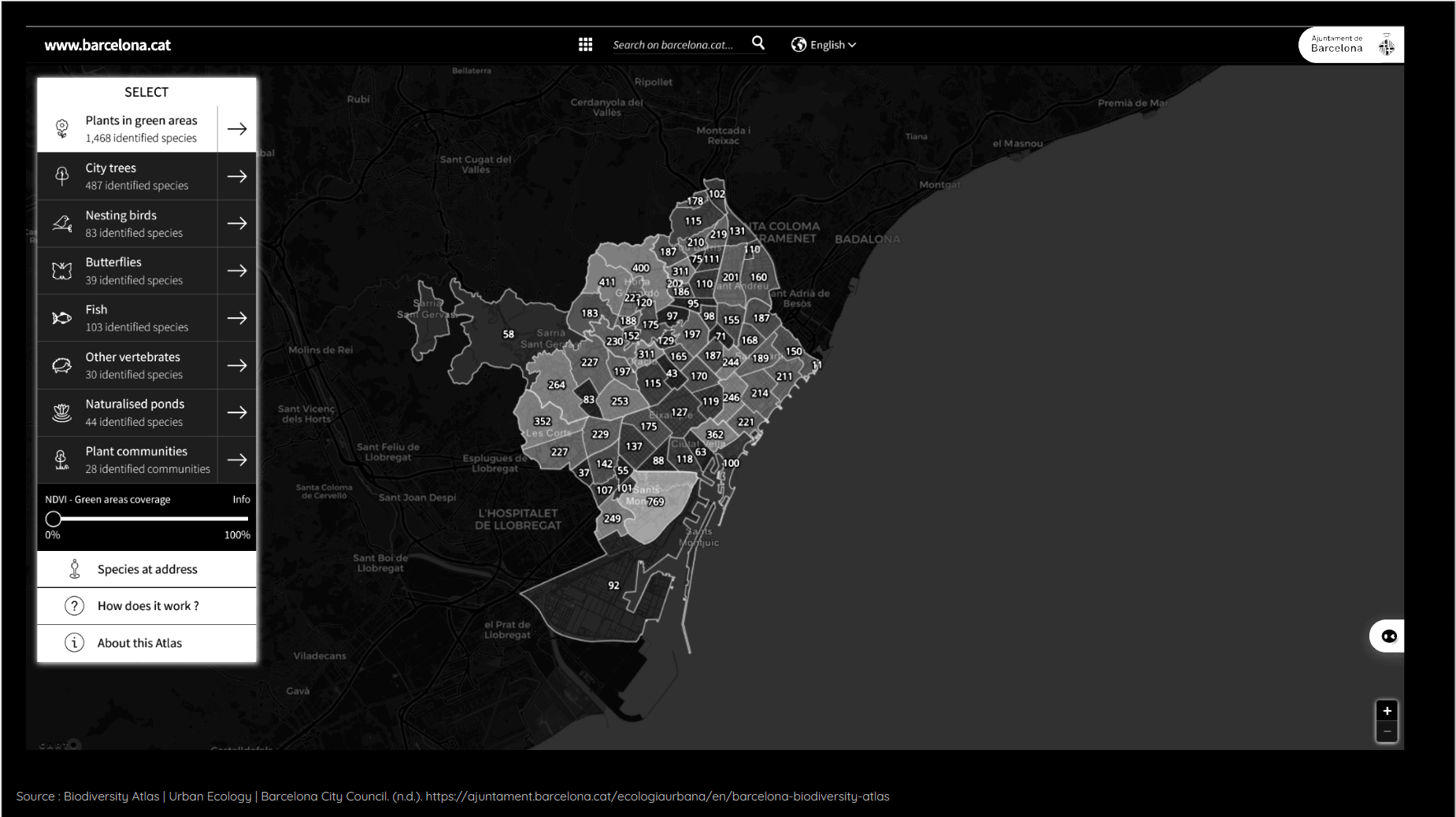

In response to urgent carbon mitigation challenges and biodiversity loss, a paradigm shift toward manufacturing symbiosis and circular bio-economy is crucial for ecologically sensitive design in urban ecosystems. This study explores the transformative potential of a 3D-printed urban Bionook, incorporating layers of Cross-Laminated Timber (CLT) with a natural-locally sourced soil admixture, to enhance strength, optimize viscosity, and study temporal decay’s impact on soil ecology.

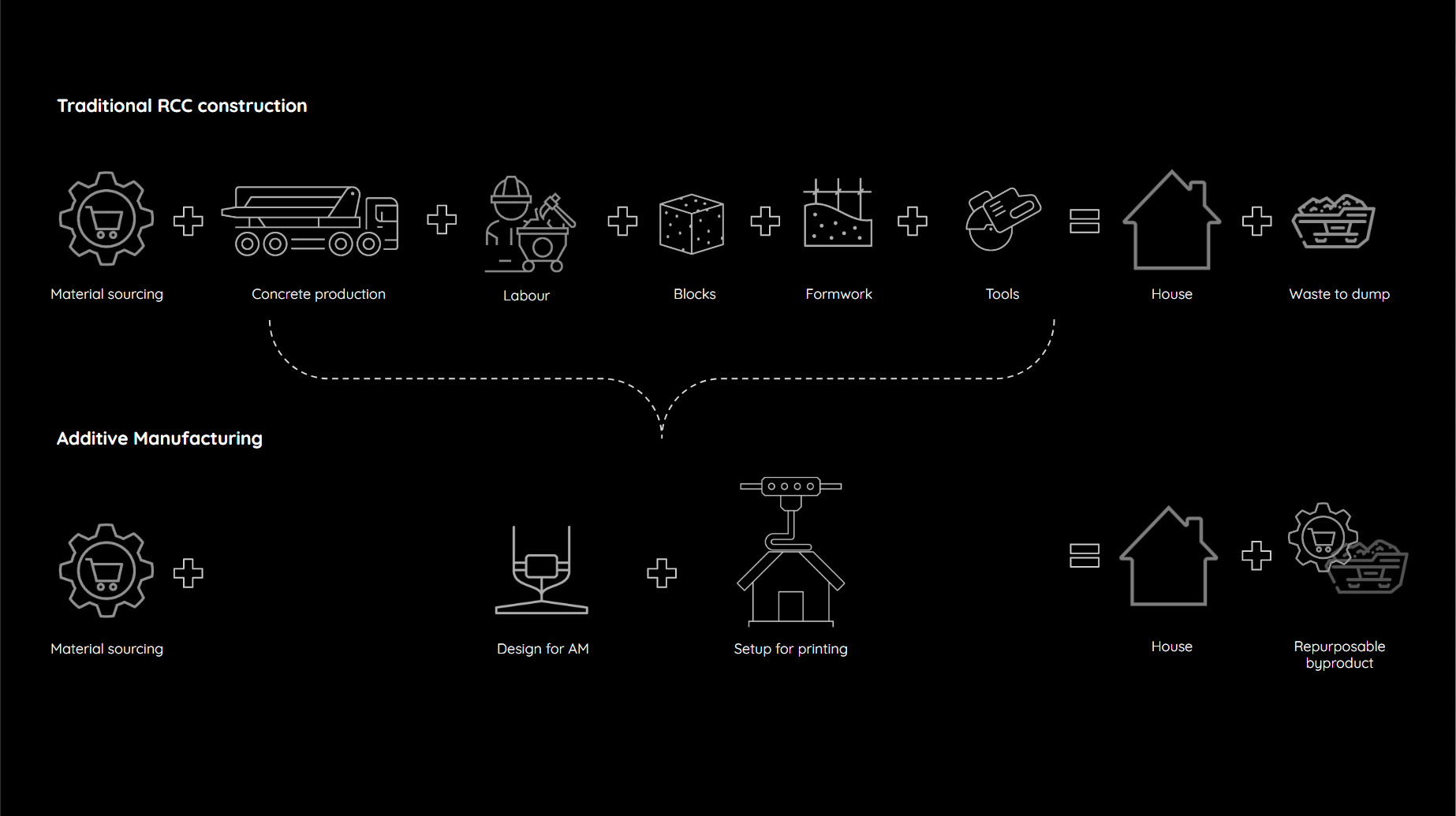

The Bio-nook, marked by ecological sensitivity, addresses carbon challenges and biodiversity loss tied to traditional manufacturing. Serving as an educational platform, it integrates additive manufacturing, emphasizes natural, locally sourced materials, and introduces engineered timber layers for enhanced structural strength and micro-biodiversity. This study navigates 3D printing geometric design intricacies and explores material science, soil ecology, manufacturing symbiosis, and circular bio-economy principles. The Bionook, symbolizes transformative design, blending technology, ecological awareness, and community engagement for a resilient and sustainable urban future.

Background

Research Statement

“In response to the imperative posed by carbon mitigation challenges and the consequential biodiversity loss in traditional manufacturing processes, a transformative paradigm shift towards the integration of manufacturing symbiosis and circular bio-economy principles emerges as a requisite, fostering an ecologically sensitive design approach that systematically incorporates biodiversity to cultivate resilience within urban ecosystems.

How could a 3D-printed urban-Bionooks, made with engineered timber layers and natural-locally sourced soil admixture (including industrial byproducts like sawdust, and orange peels), improve strength, optimize viscosity, and provide insights into the influence of mixture temporal decay on soil ecology—revealing the transformative potential in the domain of engineered wood with soil printing, promoting an ecologically sensitive urban ecosystem?

Literature Study

Literature Reviews and Inferences

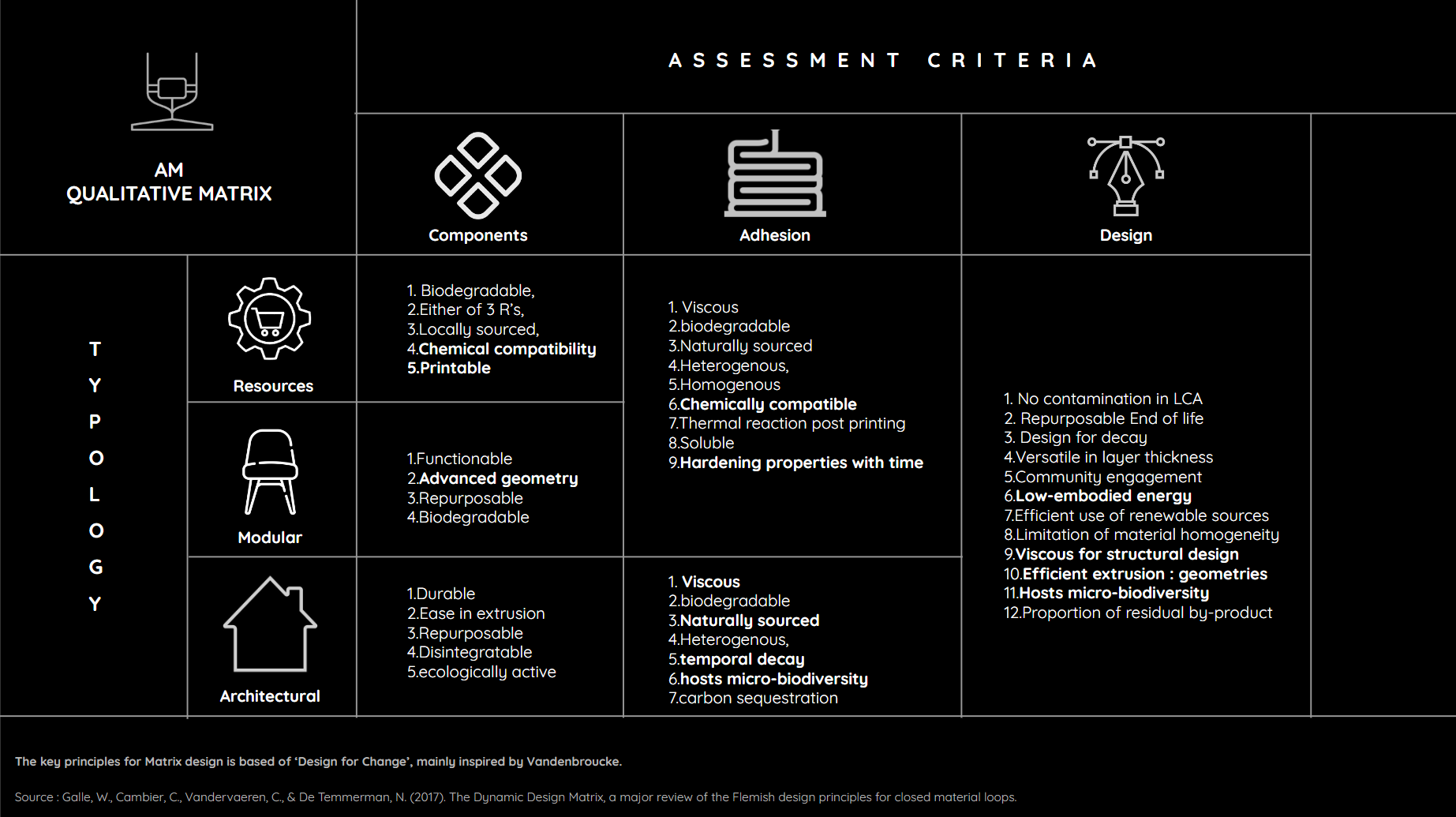

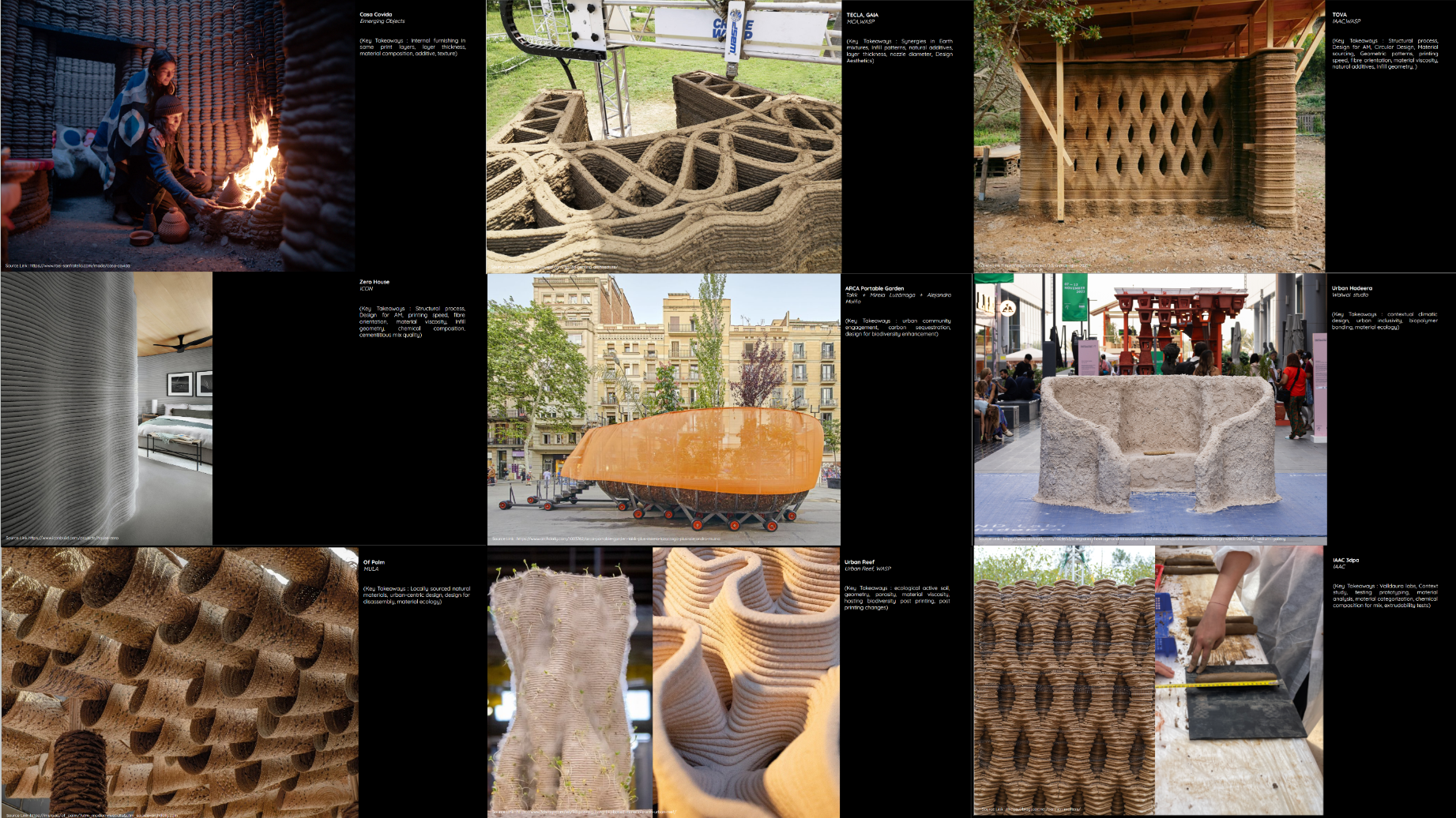

State of the Art

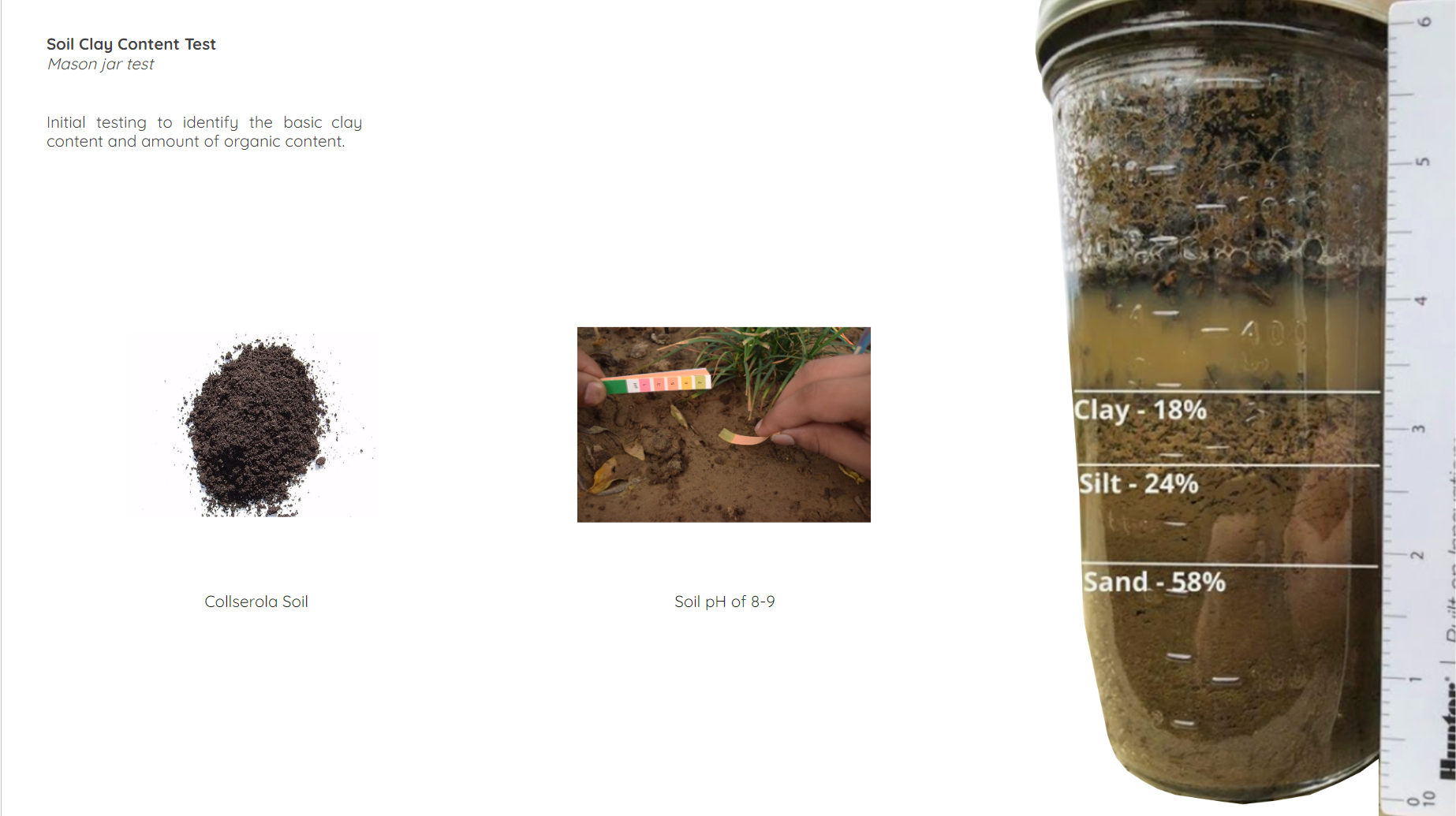

Initial Experimentations

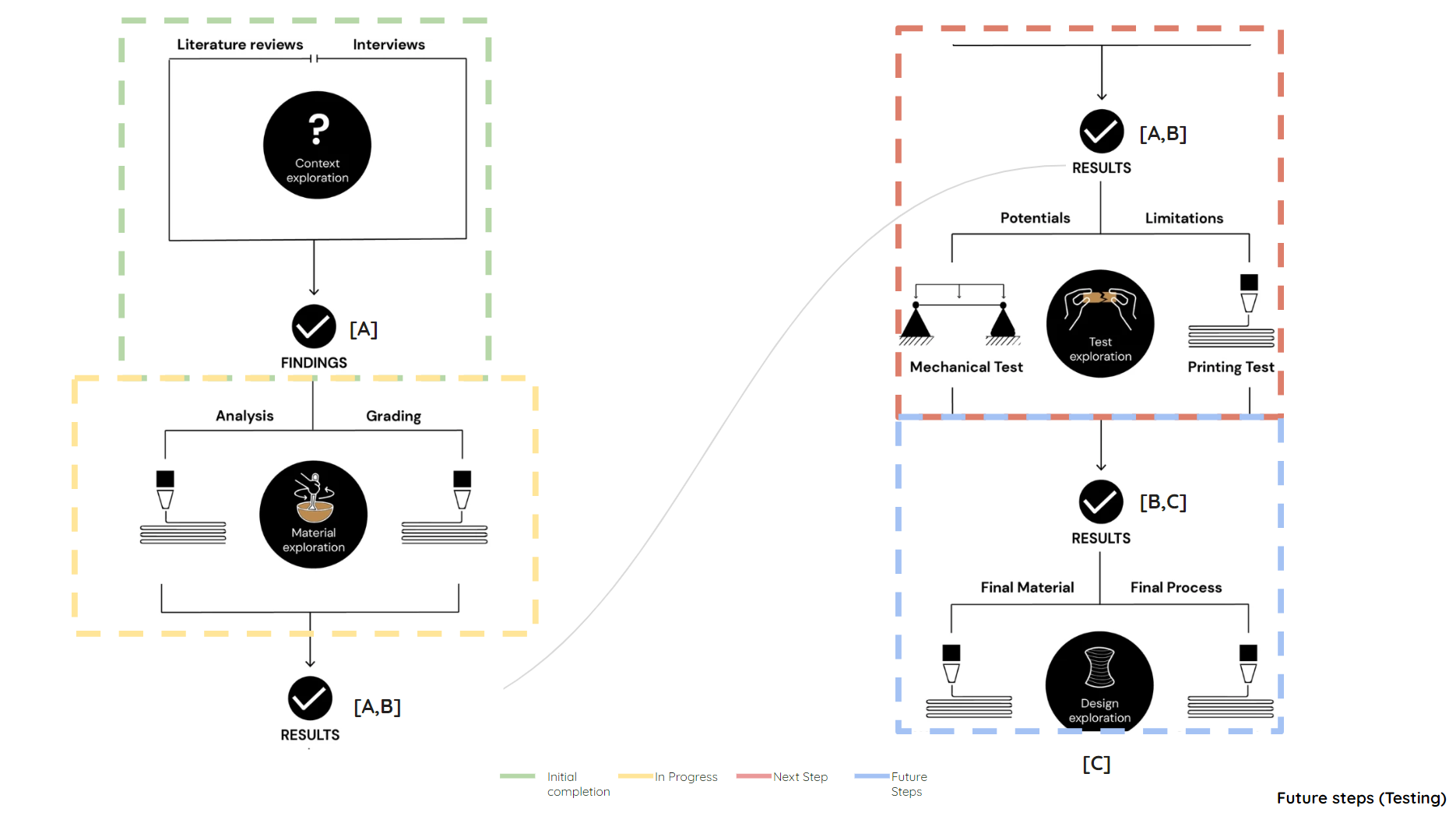

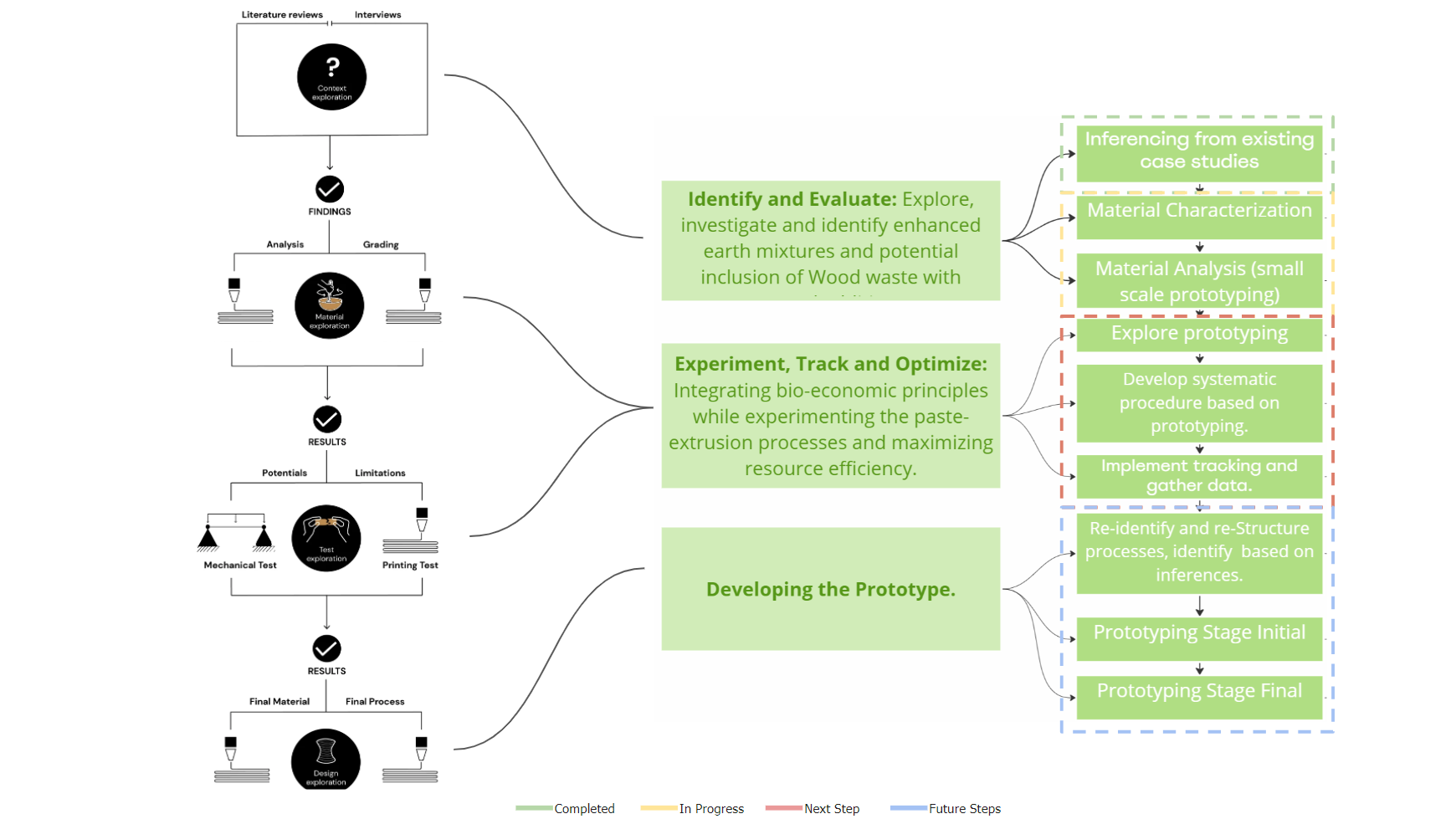

Methodology and Future Steps

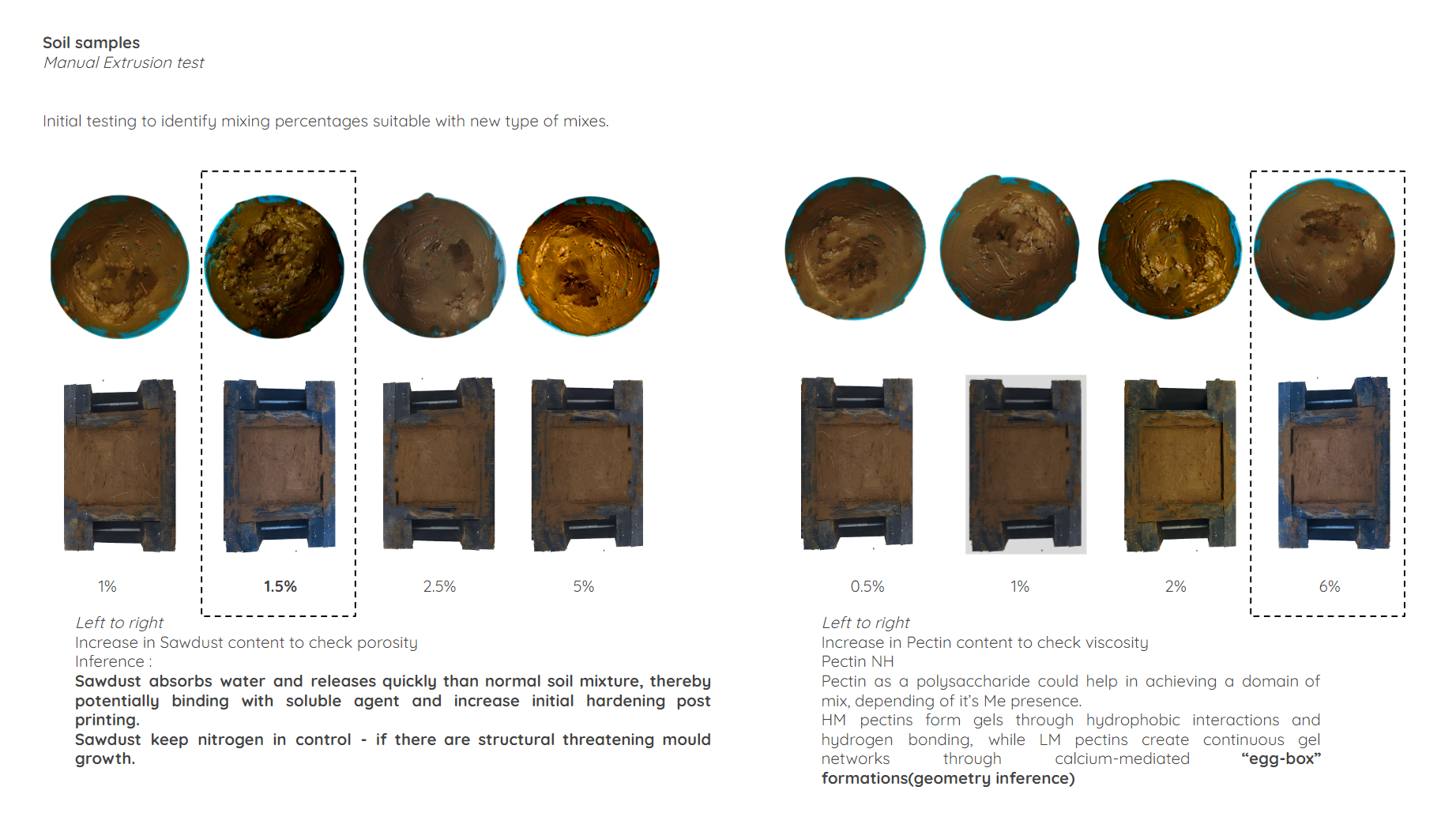

A. Identifying a suitable mixture for extrusion printing.

[This phase forms the basis for choosing locally sourced natural admixture specifically suitable for extrusion paste printing of intricate geometries]

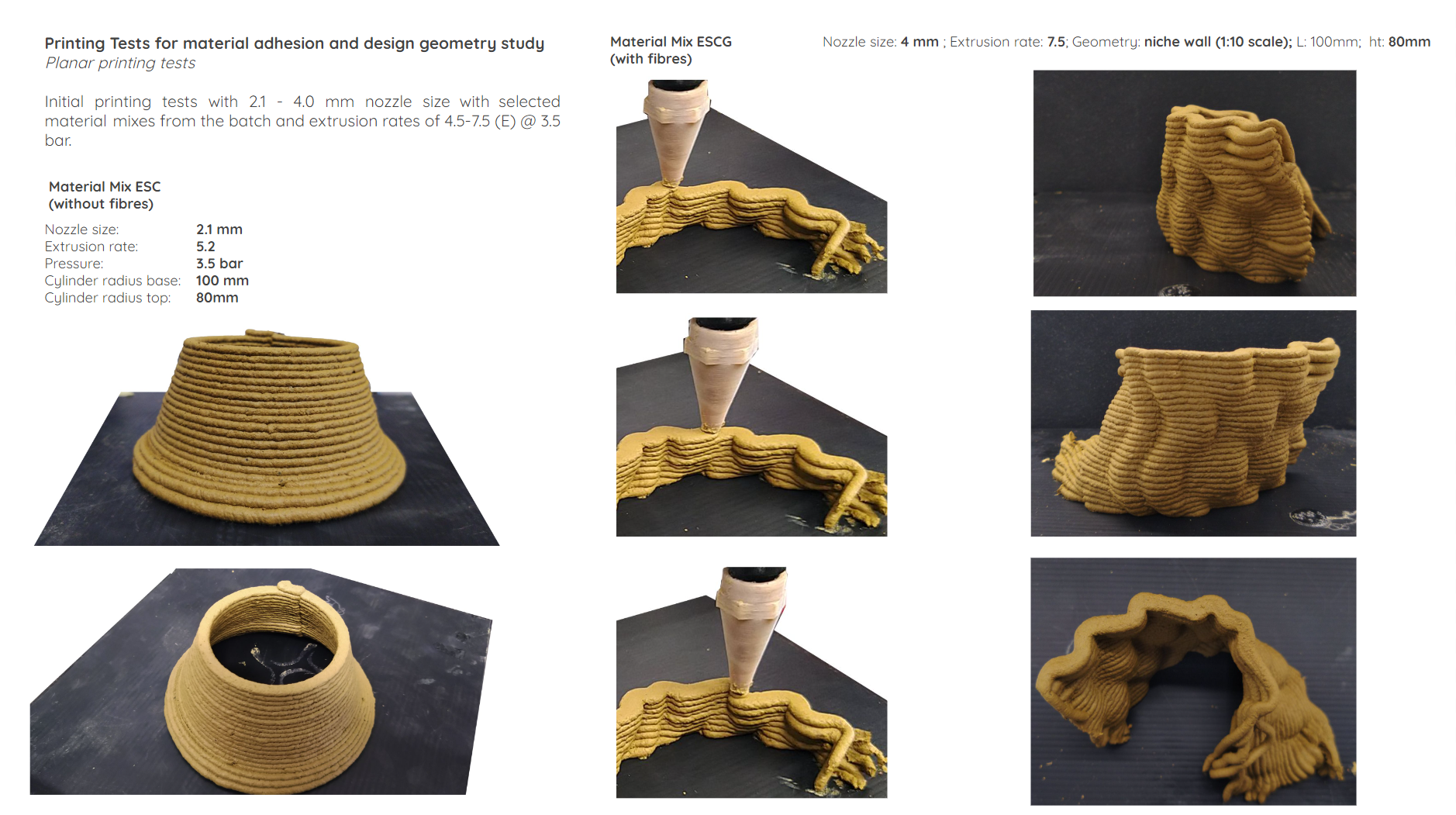

B. Producing geometrically iterative prototypes and testing with identified material mix.

[This phase will facilitate;[A] enhanced printing parameters, geometric iterative prototype, printing extrusion tests with [B] the domain of material mix, channeling material sourcing, and required viscosity,

C. Functional prototyping and examination of temporal decay and its effect in large scale AM structures.

[This phase demonstrates practicality with best derived geometry and the admixture that enhances printing and investigates post printing implications on strength and ecology of printed specimens]