Introduction & Problem Statement

Earthen 3D printing offers a low-carbon, recyclable, and locally sourced alternative to conventional construction materials. However, its architectural use remains limited by a critical issue: wet-state instability during printing. Freshly extruded clay has very low strength and stiffness, so walls usually reach only 15–20 cm per day. Beyond this height, the material begins to deform or collapse. This slows printing, increases construction time, and restricts the range of achievable geometries.

During deposition, the material is still in a highly plastic, moisture-rich state. As a result, the printed layers are exposed to two primary forms of deformation:

Elastic deformation occurs when layers temporarily bend, lean, or bulge under self-weight or tool pressure but later recover.

Plastic deformation occurs when stresses exceed the material’s low yield strength, causing irreversible collapse or loss of geometry. This plastic failure defines the maximum printable height in the wet state.

Because of these limitations, improving early-stage stability is a central challenge in earthen construction.

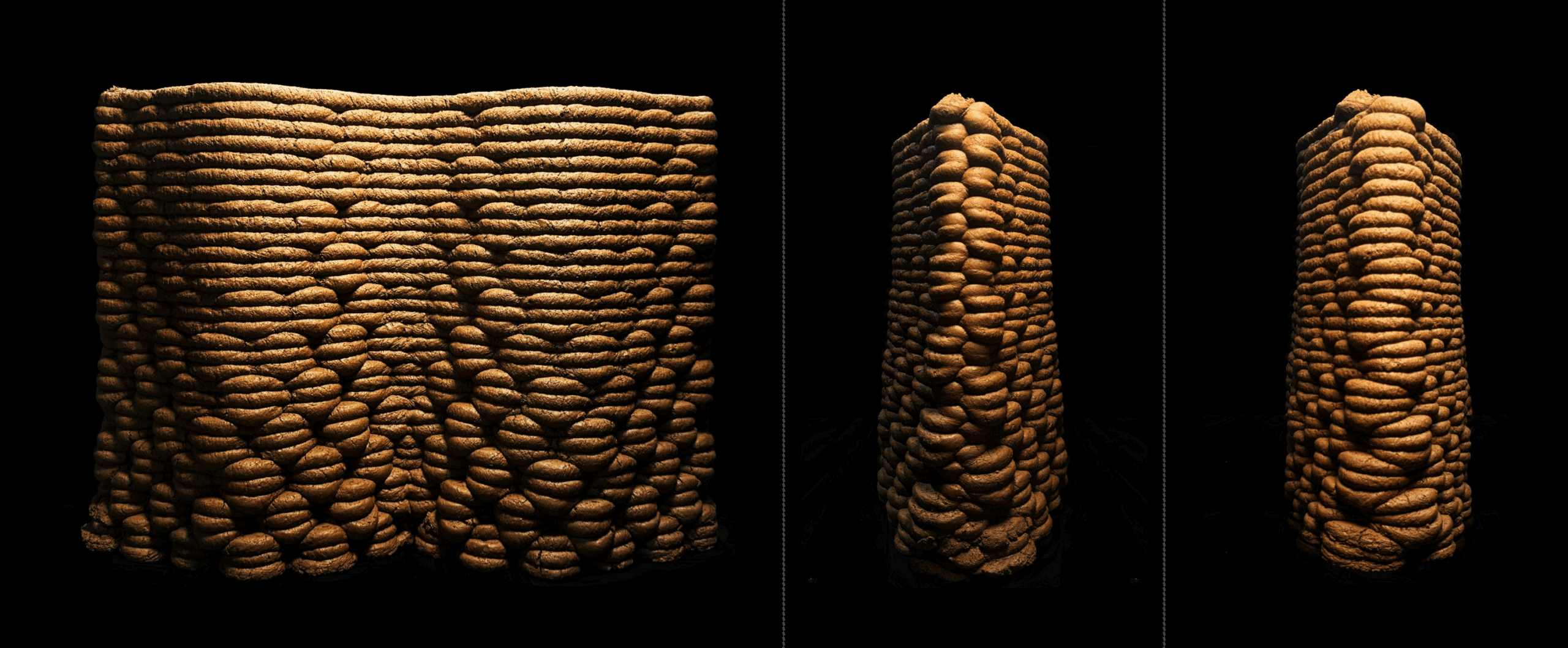

This project studies how façade textures and surface patterns can enhance wet-state stability and reduce deformation during printing.

It also examines how these strategies can increase the maximum height achievable in each printing session.

By analysing pattern-induced stiffness, toolpath alternation, and periodic geometries, the research tests how form can reinforce the material during printing.

———————————————————————————————————————————————————————————————————————

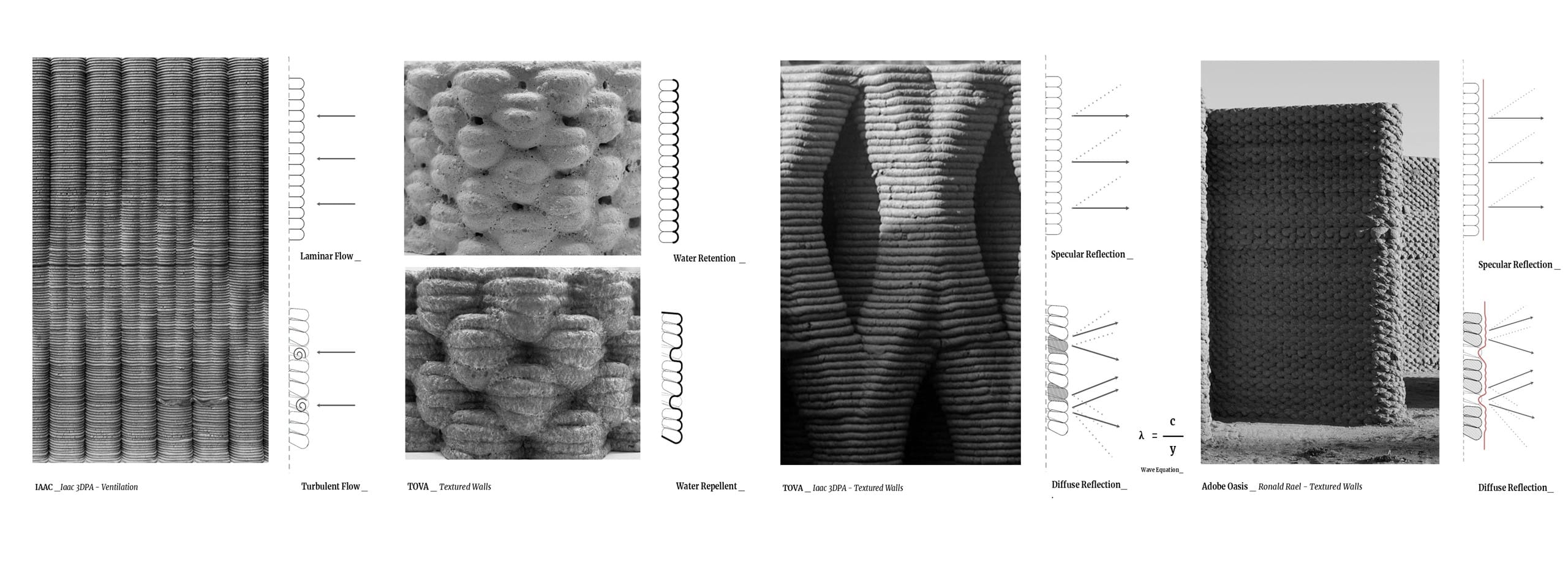

State of the Art / Definition of Texture

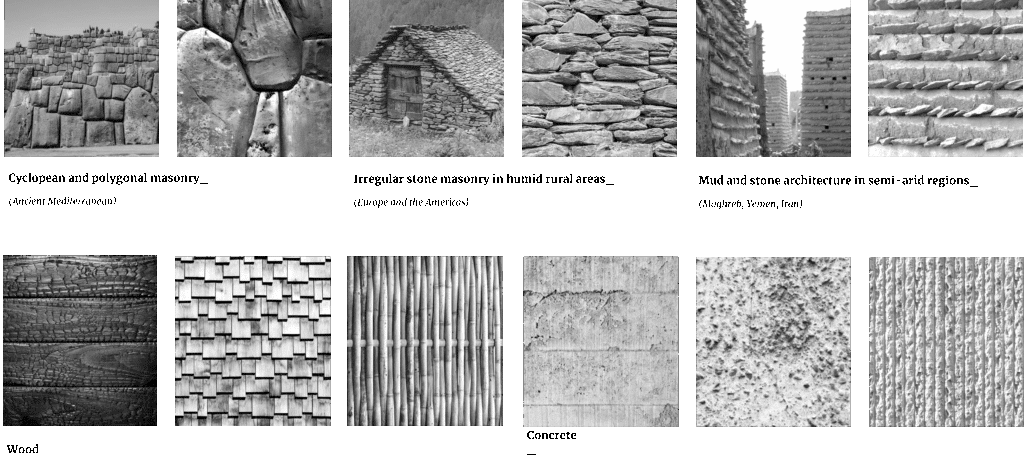

“Texture refers to a relationship between the elements that make up a surface, material, or structure.”

The term originates from the Latin verb texĕre — to weave, to interlace, to construct. This lineage is meaningful: texture is not merely a surface treatment but an act of assembling, ordering, and structuring matter.

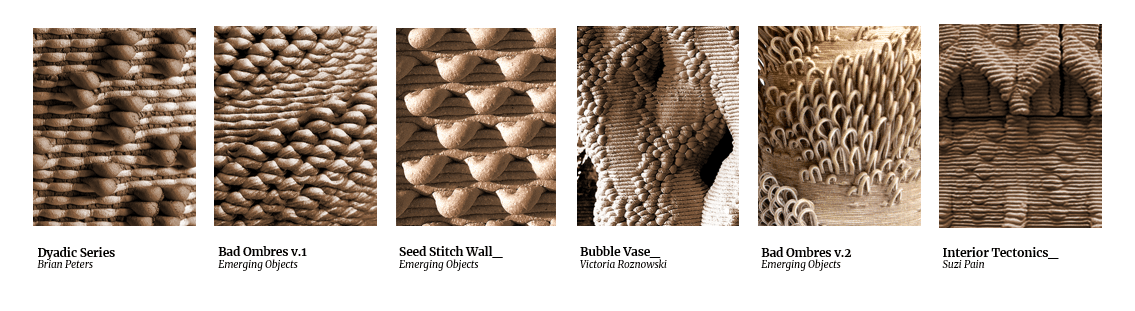

Textures and patterns have long shaped vernacular construction and are gaining attention in ceramic 3D printing. However, they remain underexplored in earthen additive manufacturing. Research often focuses on mix design, rheology, and geometry, with little study on how surface patterns stabilise material during printing.

This project addresses that gap by testing how textures improve wet-state stability, reduce deformation, and increase daily print height. Textures can also affect acoustics, lighting, ventilation, and drying, but these aspects lie outside this study.

Here, texture functions as a structural strategy, improving the performance and reliability of 3D-printed earthen walls.

———————————————————————————————————————————————————————————————————————

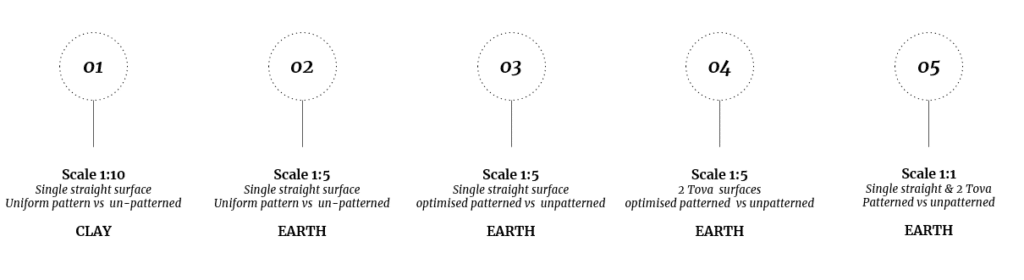

Methodology Overview

The methodology uses a step-by-step, multi-phase approach to study how patterns improve wet-state stability in earthen 3D printing. The research progresses through five sequential phases, each building on the last. It is tested across three scales—1:10, 1:5, and 1:1—to examine how results change when scaled up.

———————————————————————————————————————————————————————————————————————

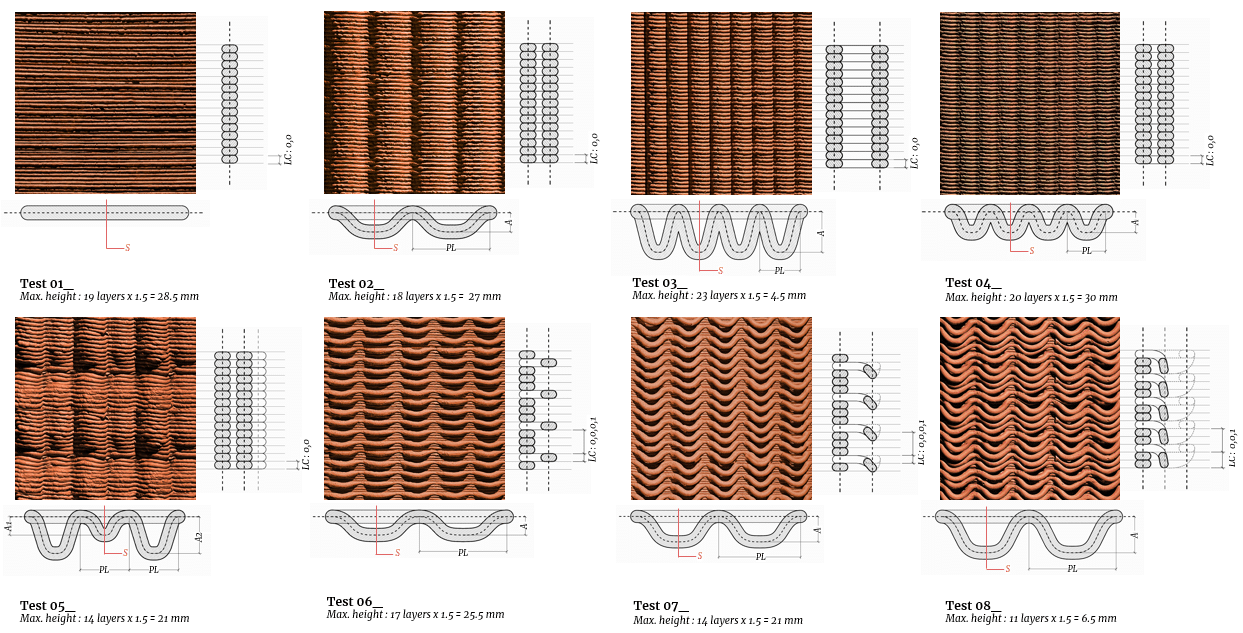

Phase 1 | Single Straight Surface | 1:10

This phase investigates the fundamental research question:

“Can surface patterns improve the printing stability of clay-based 3D prints?”

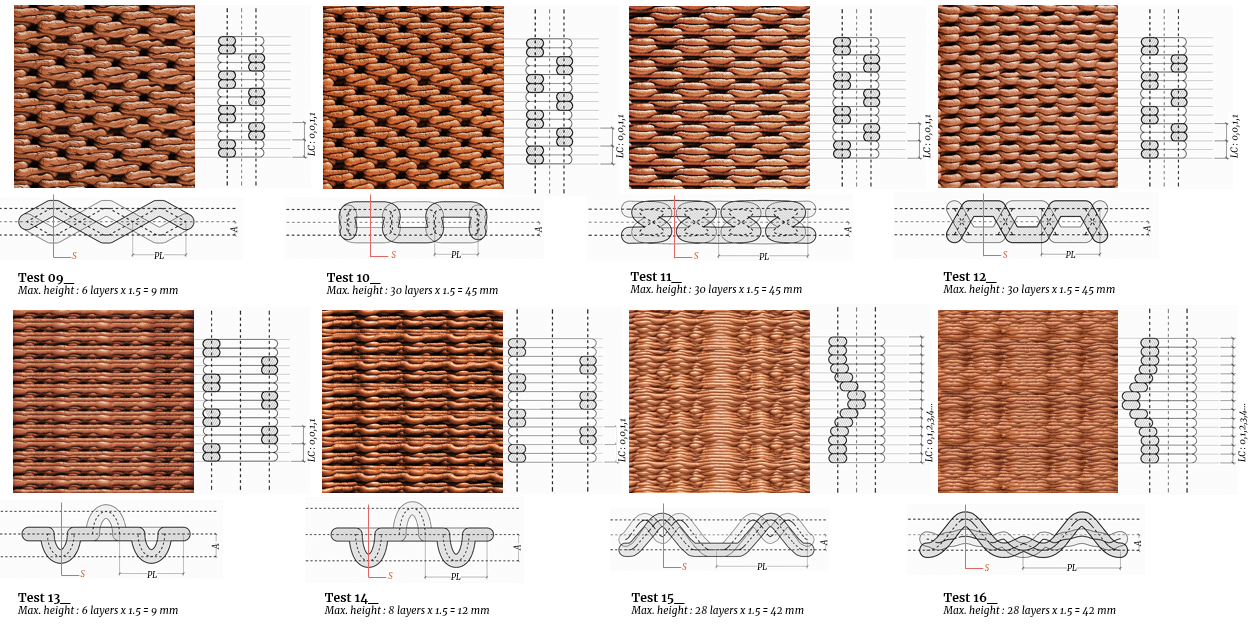

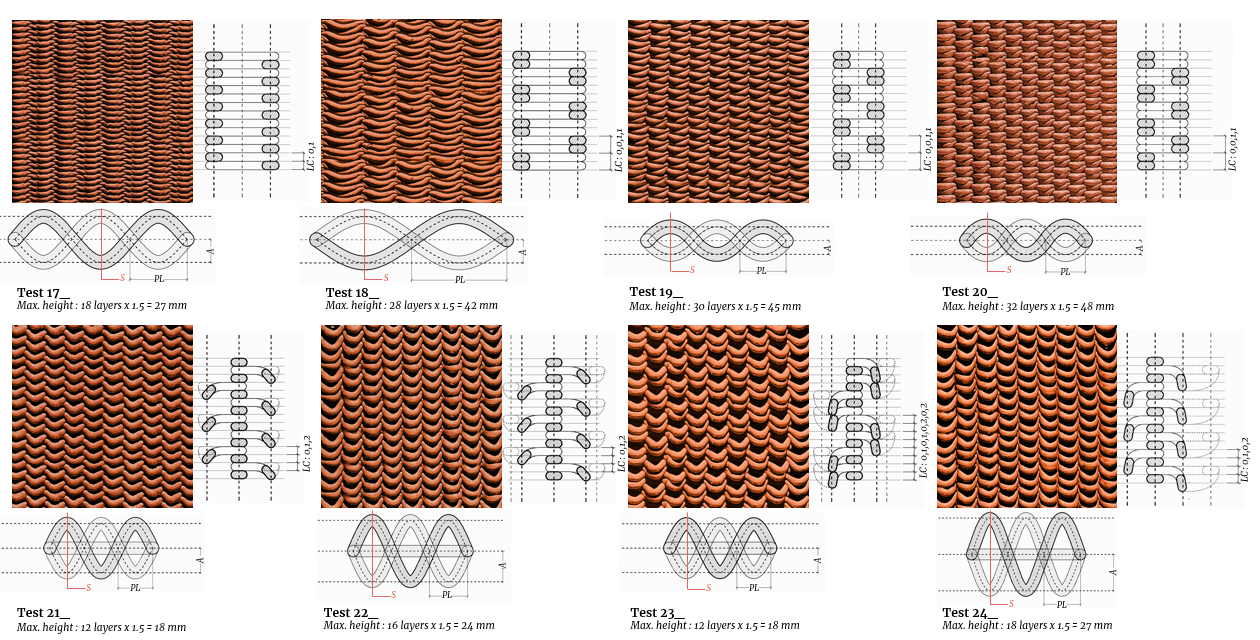

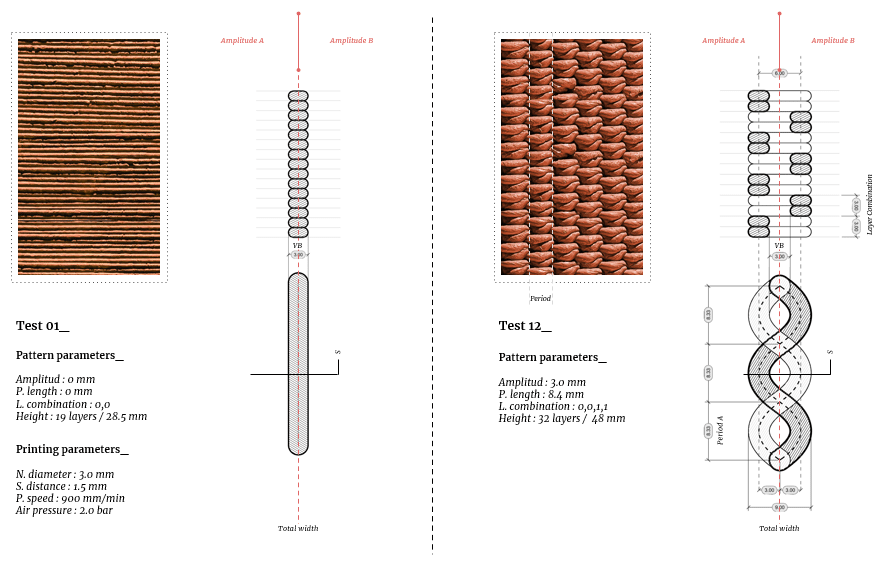

The results from Phase 1 show that surface patterns can greatly improve the wet-state stability of clay 3D prints. The unpatterned reference reached 19 layers (28.5 mm) before deforming, while the optimised 0,0,1,1 pattern reached 32 layers (48 mm). This represents a 68% increase in printable height.

The improvement comes from the added geometric stiffness created by the alternating pattern. Its amplitude and period create a more stable cross-section that resists early leaning and bulging.

These findings form a strong basis for the next phases using earthen materials at larger scales. They confirm that pattern geometry contributes directly to structural stability during deposition, even before drying increases material strength.

————————————————————————————————————————-

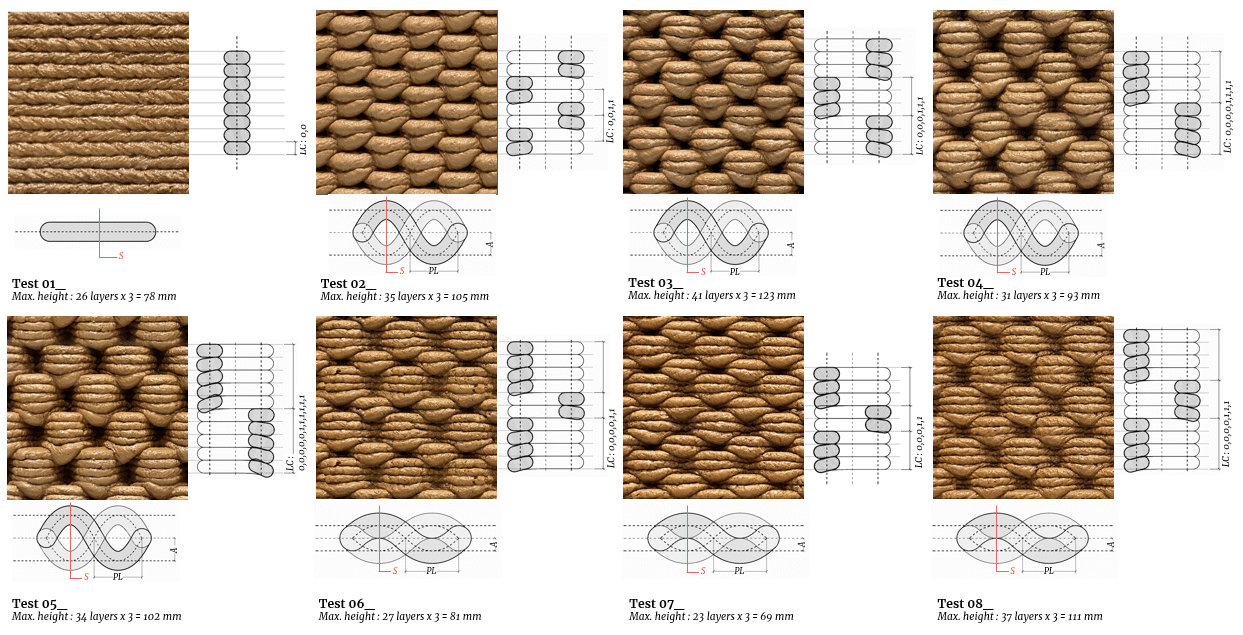

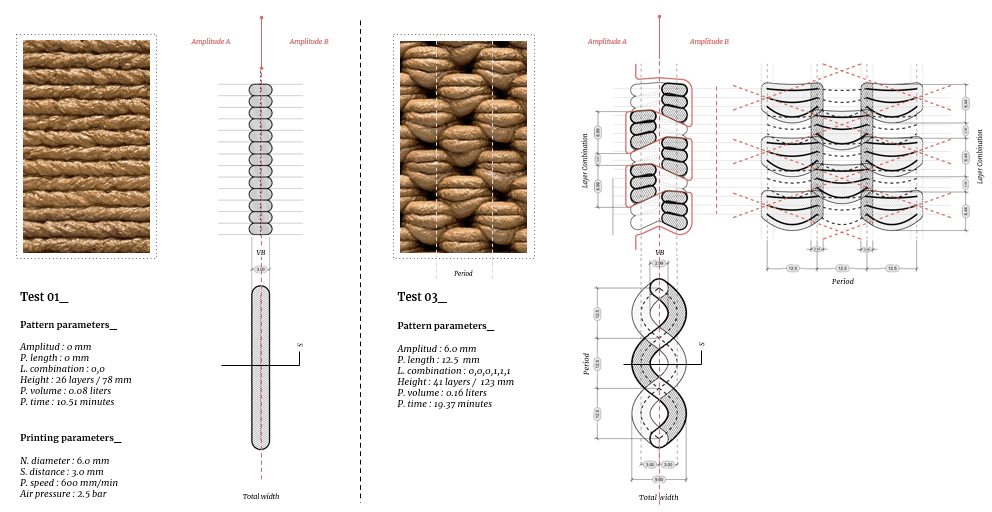

Phase 2 | Single Straight Surface | 1:5

This phase investigates

“How can surface patterns improve the printing stability of straight earthen walls compared to unpatterned surfaces?”

Phase 2 showed that patterned configurations consistently increased material use and printing time, adding new constraints to the design space. This highlighted the need to optimise pattern logic so stability gains are achieved without unnecessary material or time costs.

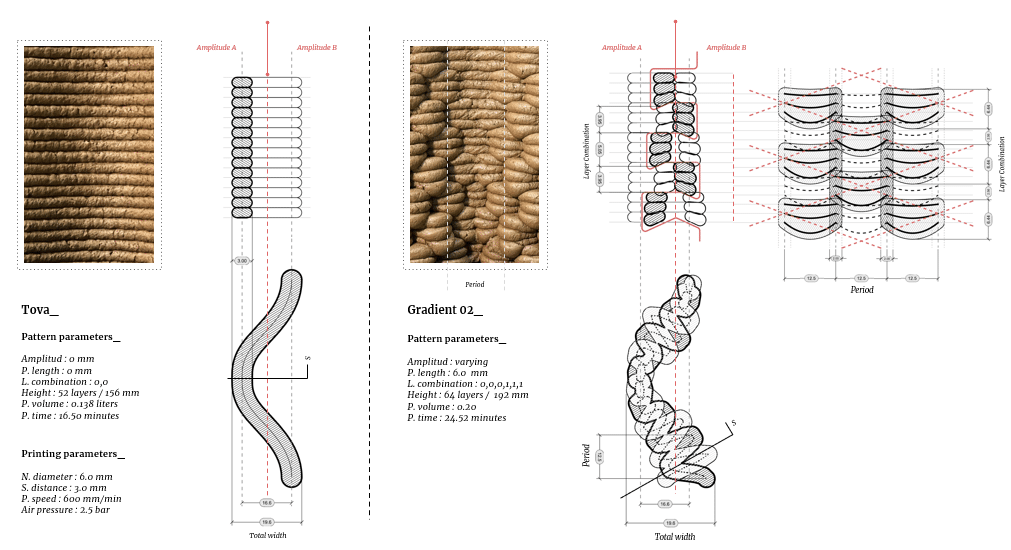

This stage also clarified an emerging structural principle: the position, alternation, and direction of the pattern shape the load path and guide stresses. The alternating pattern created a balanced cross-section around the central axis, improving lateral stability and reducing early deformation. These insights encouraged a parallel optimisation of geometry, printing logic, and material efficiency to maximise printable height while limiting time and material use.

————————————————————————————————————————-

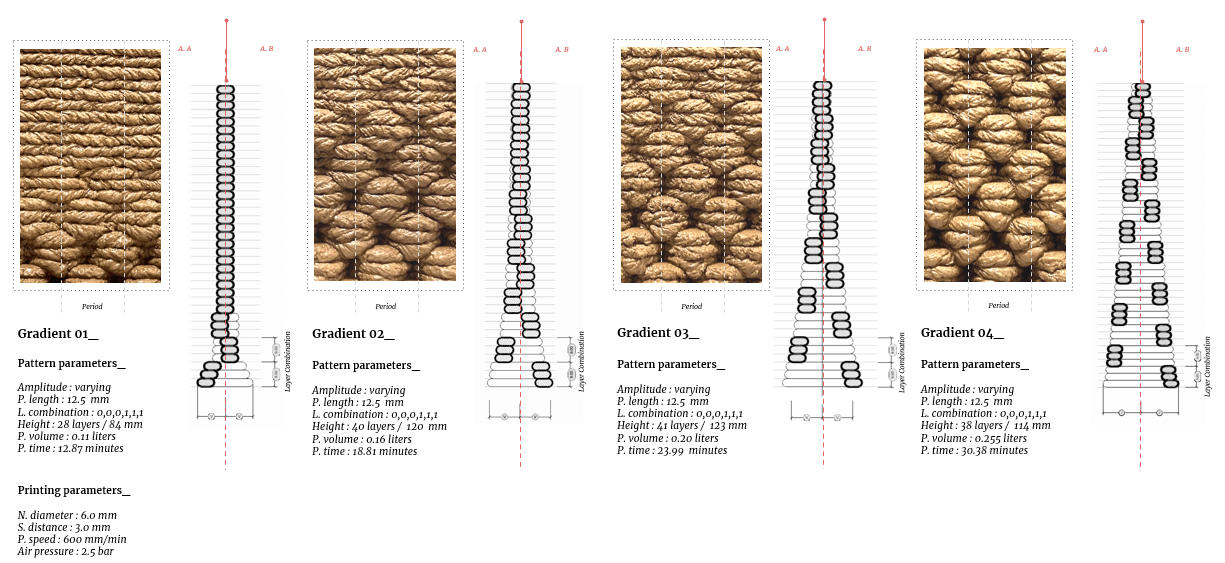

Phase 3 | Single Straight Surface | 1:5

This phase addresses the core research question:

“ How can surface patterning improve the stability of periodic earthen prints compared to unpatterned ones? ”

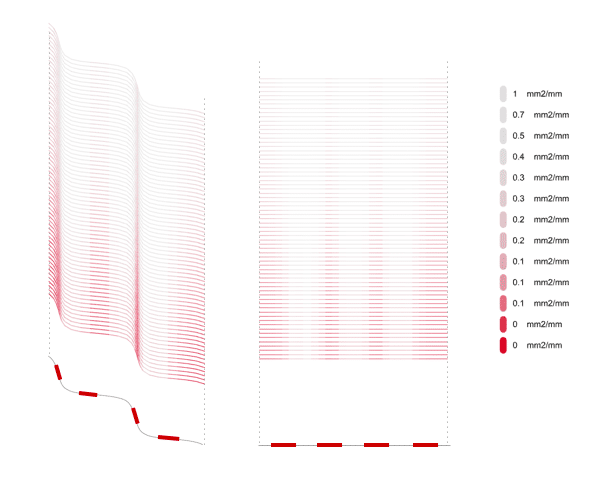

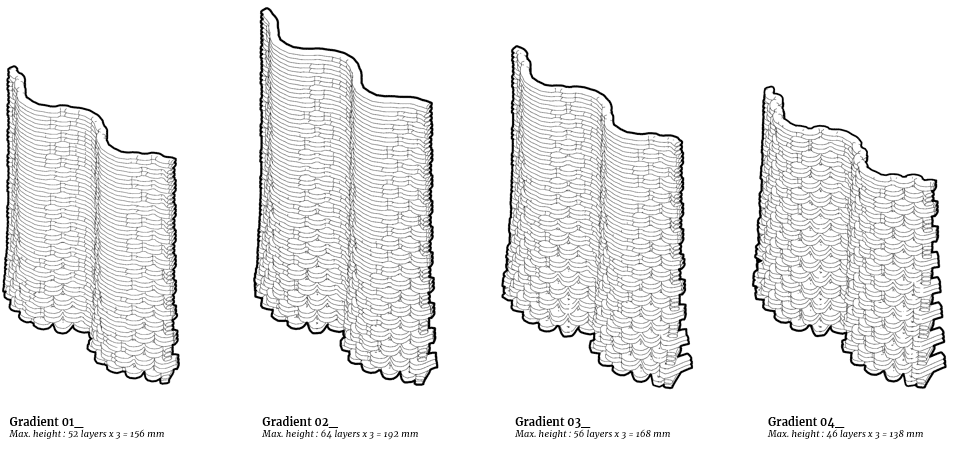

The gradient tests results showed that pattern optimisation can significantly reduce material use and printing time while maintaining high levels of wet-state stability. The optimised gradient surface reached the same height as the uniform patterned surface while using 7% less material and requiring 8% less printing time, demonstrating that full-height patterning is not always necessary to achieve structural stability. At the same time, when compared to the unpatterned reference, the best-performing gradient printed 58% higher, with only 14% more material per layer and a 9% increase in printing time. These results confirm that a strategically applied gradient can deliver most of the stability benefits of a fully patterned surface while being more efficient, offering a balanced approach between performance and resource optimisation.

————————————————————————————————————————-

Phase 4 | Periodic Tova Surface | 1:5

This phase investigates the fundamental research question:

“ How can surface patterning improve the stability of periodic earthen prints compared to unpatterned ones? ”

Based on the local inertia analysis, patterns were strategically planned and positioned along the periodic surface. Low-inertia zones guided where reinforcement was needed most, informing the distribution of the gradients.

The comparison between the patterned and unpatterned periodic surfaces shows a clear performance improvement. The patterned configuration achieved a 23% higher printable height, demonstrating its ability to reinforce weak zones along the geometry. This gain, however, came with measurable trade-offs: the patterned print required 18% more material per layer and 21% longer printing time per layer due to the added geometric complexity and extended toolpath. Overall, the results confirm that while patterning increases resource use, it provides a significant stability advantage that enhances the maximum achievable height during wet-state printing.

————————————————————————————————————————-

Phase 5 | Single Surface & Periodic Tova Surface | 1:1

This phase investigates the fundamental research question:

“How does scaling from 1:5 to 1:1 affect deformation and stability in straight and periodic (Tova) geometries with and without surface patterns?”

Comparison of unpatterned and patterned straight and TOVA surfaces at full scale.

Overall, the comparison across scales shows that the structural logic of patterning is indeed scalable: the stability improvements observed at 1:5 translate to 1:1, though with moderated gains and proportionally higher time requirements. These outcomes confirm that patterning can serve as a valid architectural-scale strategy for enhancing wet-state stability in both straight and periodic earthen geometries.

———————————————————————————————————————————————————————————————————————

Conclusion

This research demonstrates that surface patterns play a decisive role in improving the wet-state stability of earthen 3D printing. Across scales—1:10, 1:5, and 1:1—patterned toolpaths consistently enabled higher printable heights, with improvements ranging between 20–30% on a daily basis. Among the tested configurations, the pattern combining varying curve amplitude with equal layer alternation (0,0,0,1,1,1) proved to deliver the most stable performance, reinforcing weak zones and redistributing stresses during deposition.

Overall, the experiments confirm that geometry itself can act as a structural stabiliser, enabling more efficient and reliable printing processes, and opening new directions for integrating texture as a functional driver—not merely as an aesthetic layer—within earthen architecture.