ELEVURA

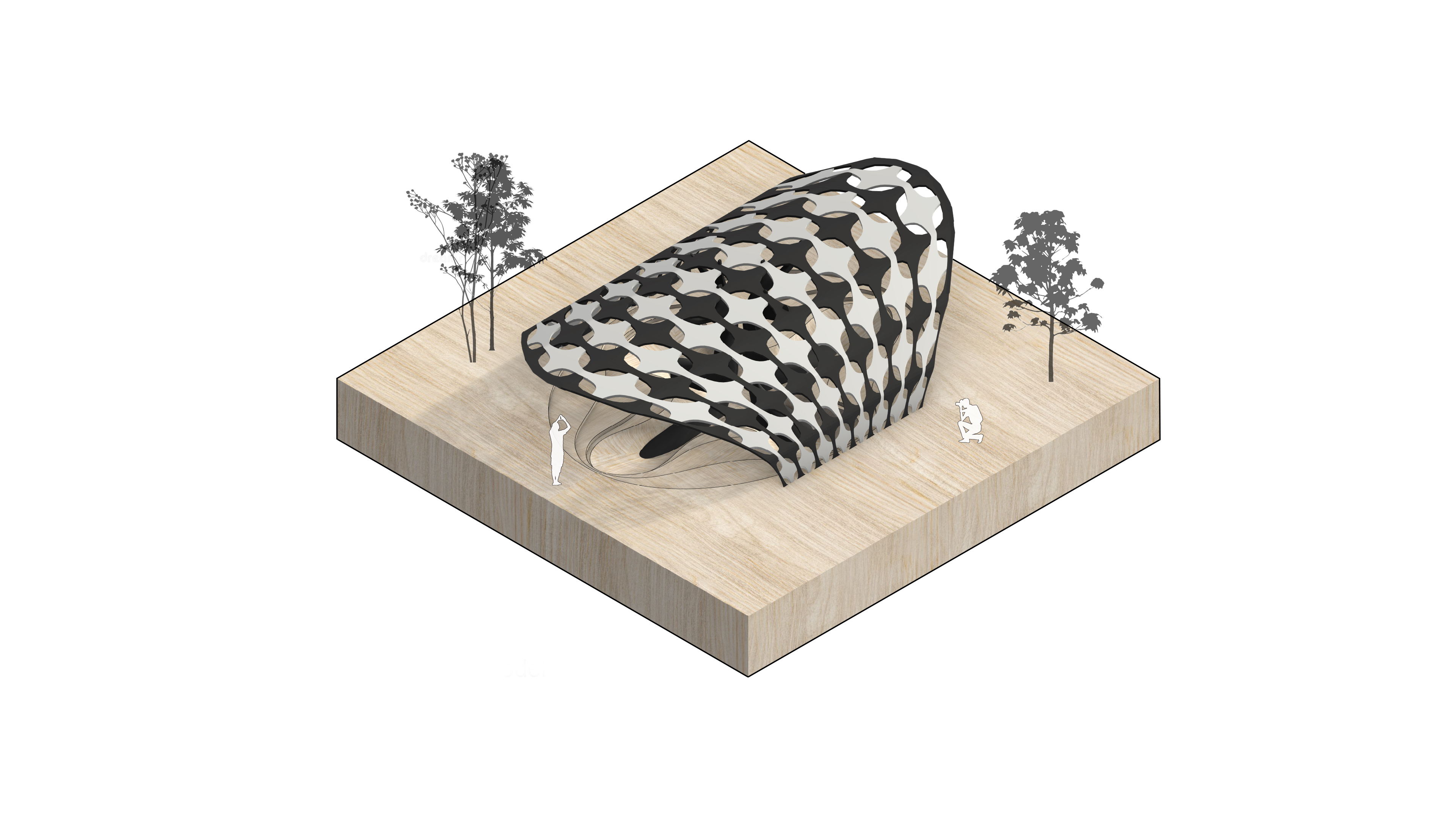

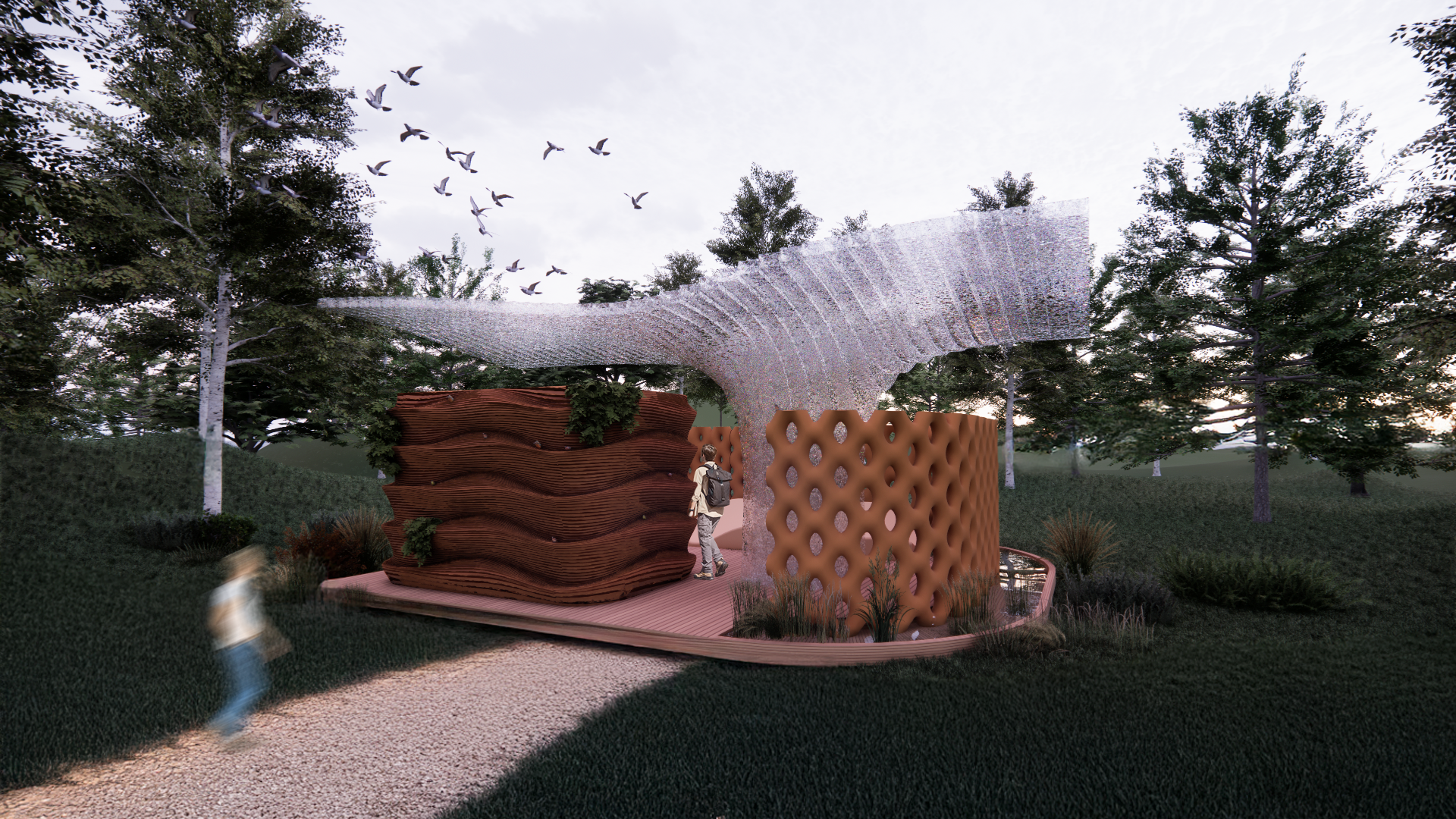

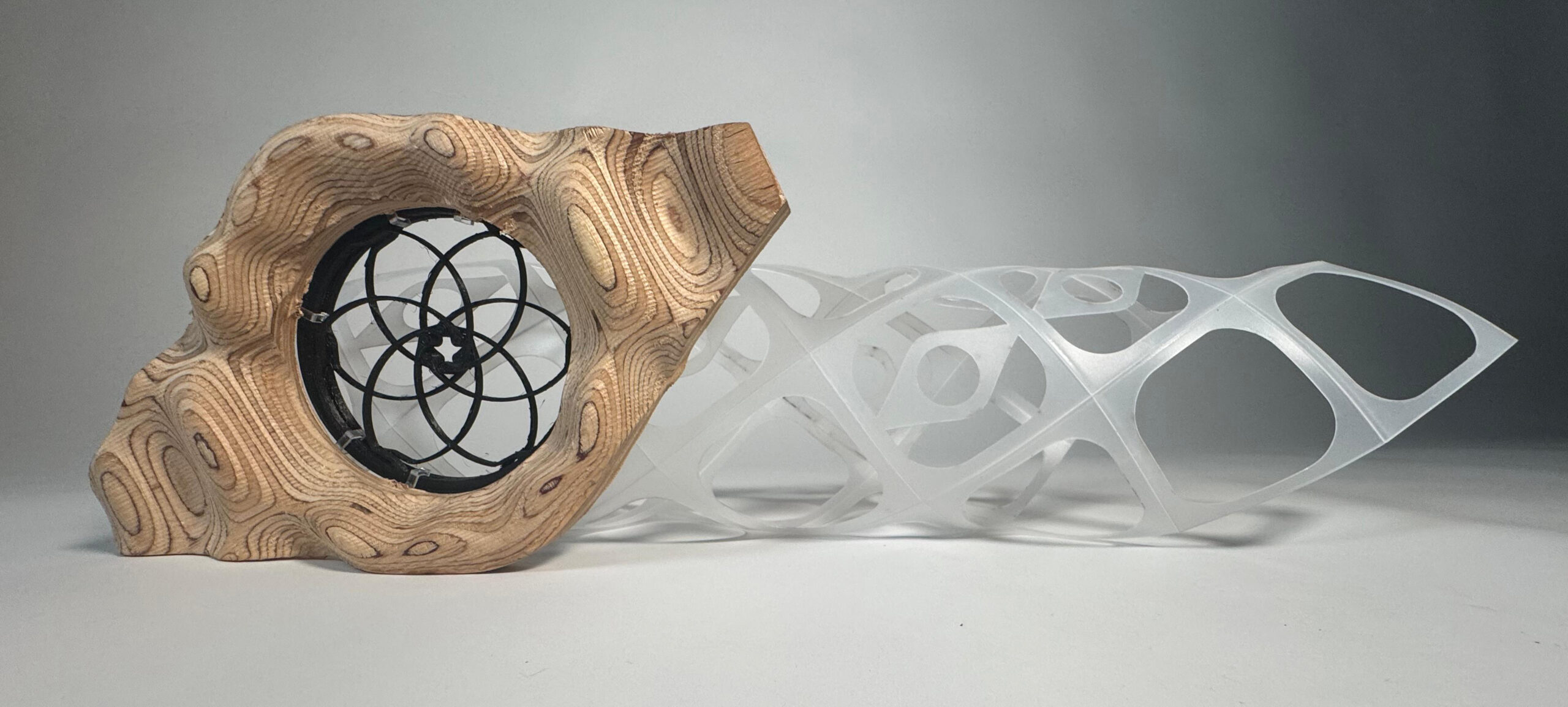

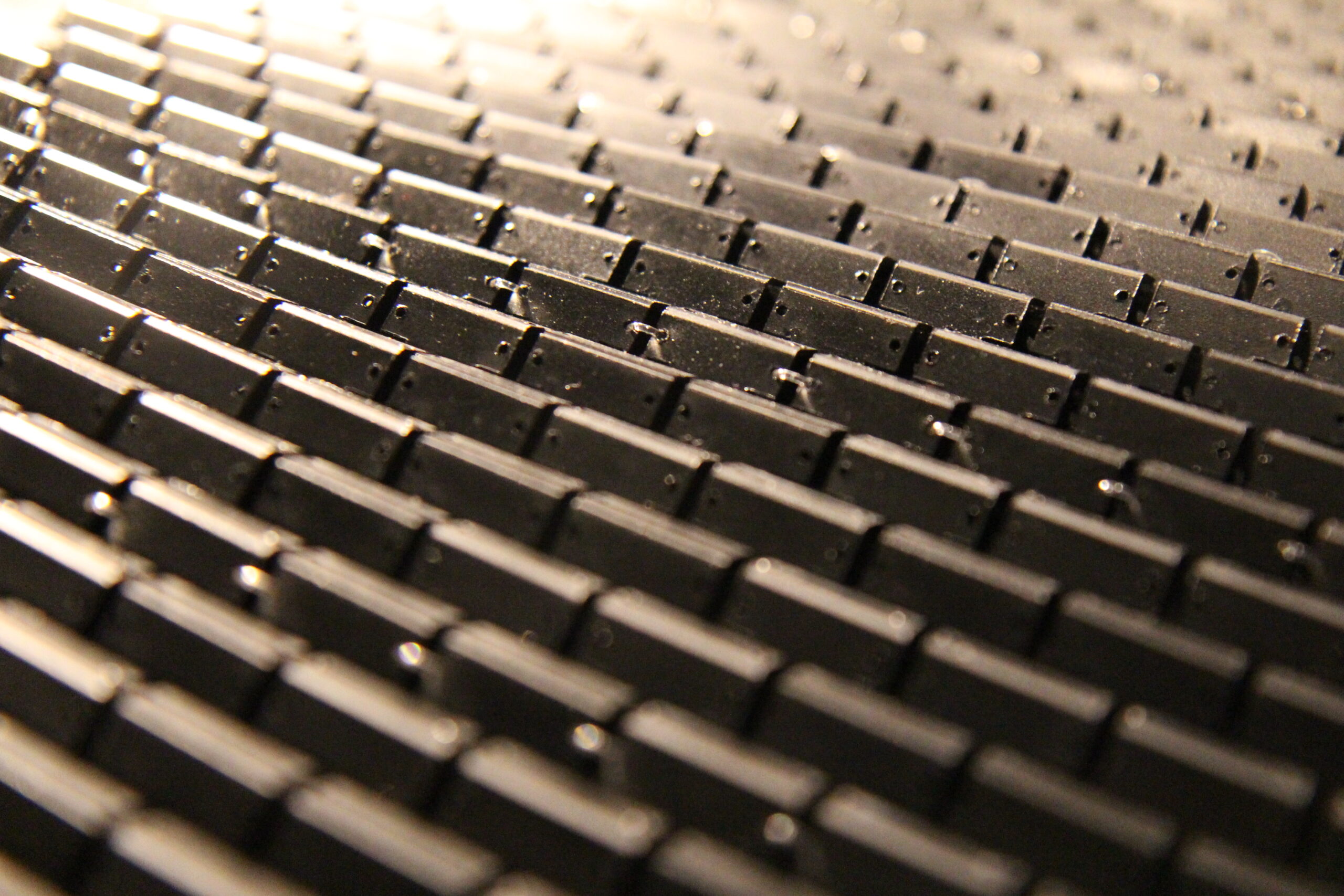

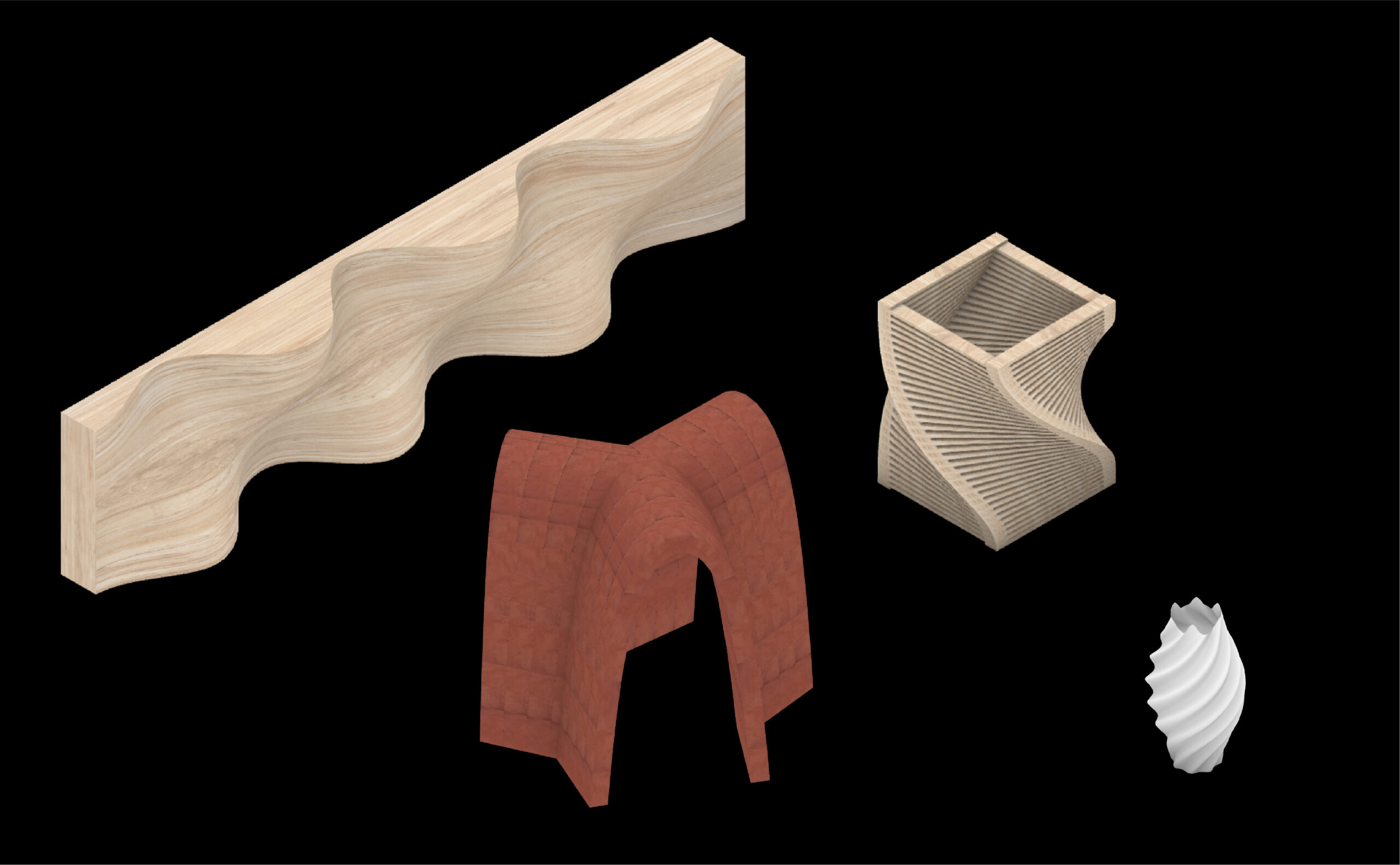

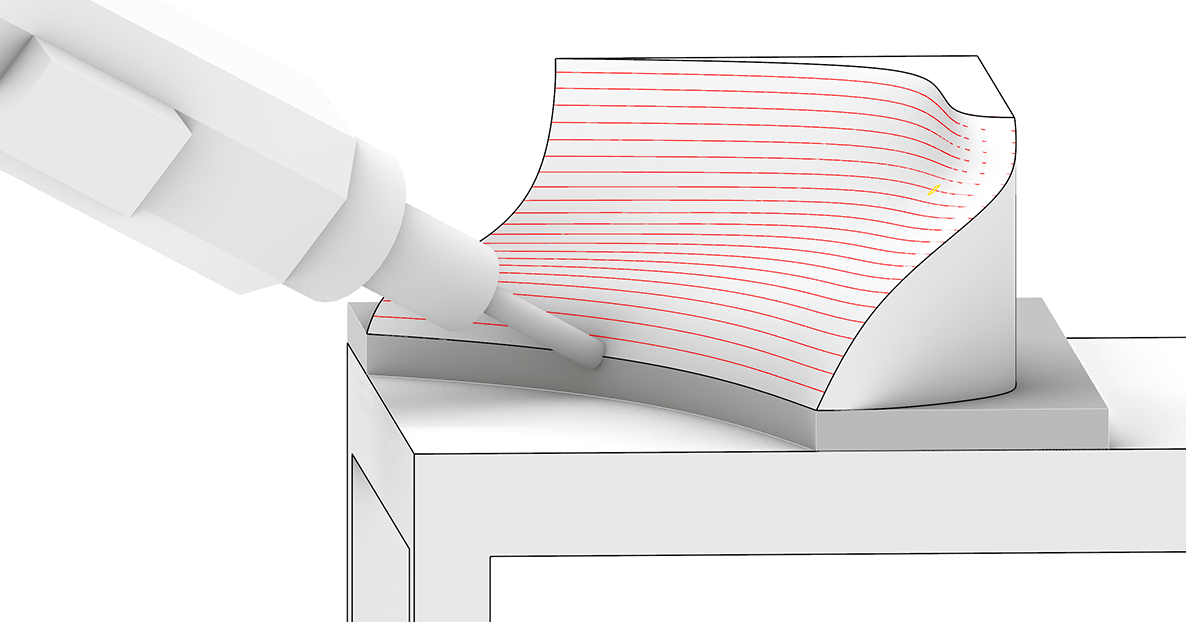

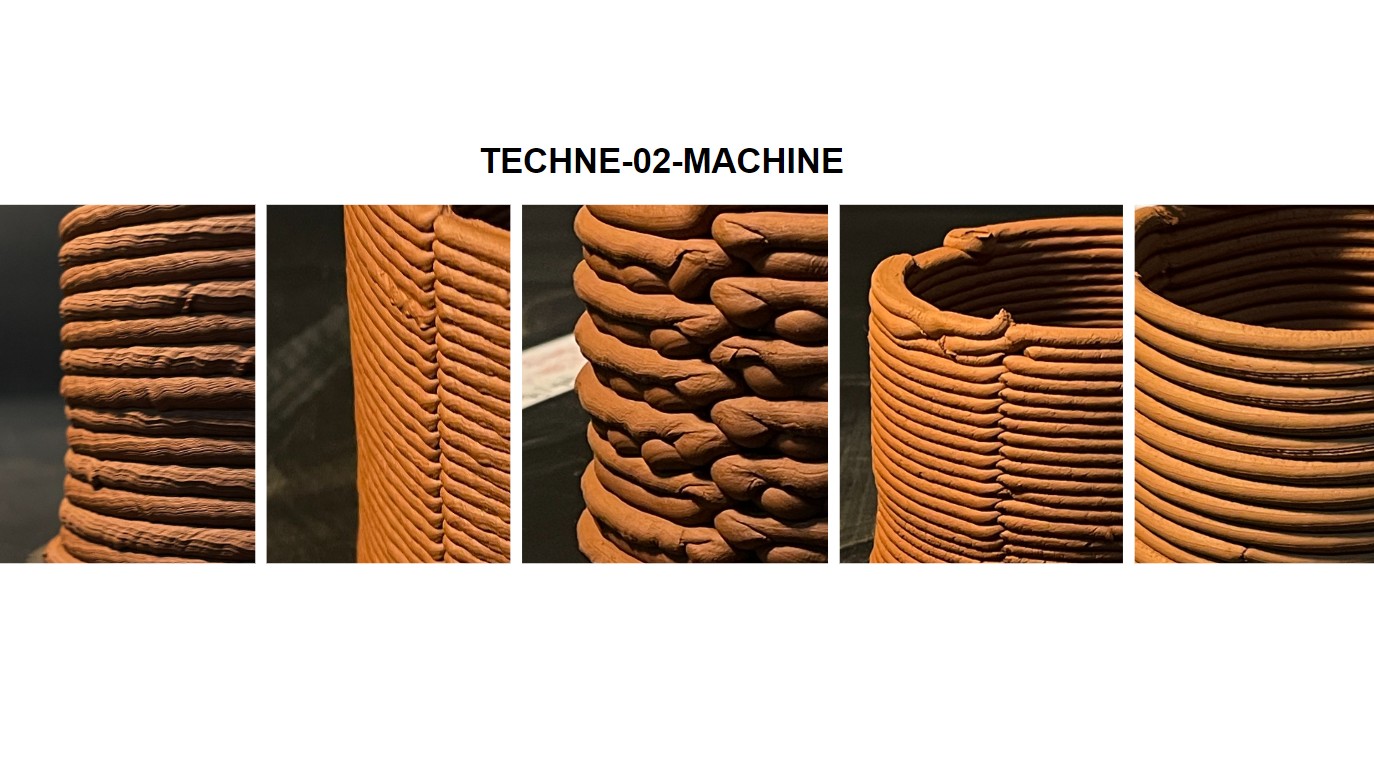

DIGITAL FABRICATION 3D Printing | CNC Milling | Laser Cutting 3D PRINTING As we embarked on this three-week journey of digital fabrication, we began with 3D printing in the first week. Our goal was to create something that could be integrated with our other techniques in the weeks to come. To maintain flexibility and openness … Read more