Turning time-tested vernacular intelligence into scalable, multi-hazard self sufficient building

INTRODUCTION

See this image above? yes, its comparison between two structures that survived a 6.8 rector scale earthquake in year 2005. The ironic part is , that these vernacular structures hold the carbon friendly intelligence responding towards climate adaptation and structural resistance against earthquakes, yet its knowledge is slowly fading away towards the soil itself, until today.

For centuries, vernacular architecture has provided a deep well of low-carbon, disaster-resilient building intelligence. Yet, this wisdom has remained confined to the past, localized and unscalable. The Manufactured Vernacular is a new paradigm that seeks to decode these time-tested principles and transform them into scalable, multi-hazard self-sufficient buildings, bridging ancestral knowledge with the demands of the modern world.

A Real-World Test of Vernacular vs. Conventional Building

The 2005 Kashmir earthquake (magnitude 6.8) served as a stark, real-world comparison between building types. While many conventional structures collapsed, certain traditional vernacular buildings—such as those using the Dhajji Dewari timber-lattice system—demonstrated notable resilience. This event visually underscores the latent hazard-mitigation intelligence embedded in vernacular systems, intelligence that remains largely absent from mainstream construction.

THE PROBLEM – An Urgent, Regulated Crisis

The global construction sector stands as a primary agent of environmental and climate crises, responsible for 34% of global energy consumption and 37% of energy and process-related CO₂ emissions (Source: UNEP – 2023 Global Status Report for Buildings and Construction). This immense impact has precipitated an urgent and increasingly regulated market crisis, creating immediate and substantial demand for empirically validated resilient structures. This demand is directly aligned with major regulatory drivers, most notably the European Union’s mandate for 35 million building renovations, transforming a global environmental challenge into a defined commercial and compliance imperative.

Sources from slide: UNEP – 2023 Global Status Report for Buildings and Construction.

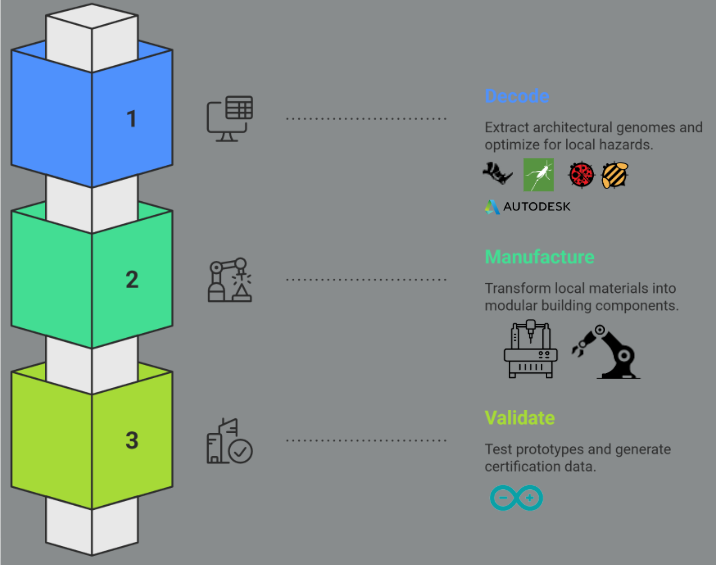

THE SOLUTION- The Hybrid Manufacturing Framework

Engineering Resilience Through Digital Vernacular Intelligence

The proposed solution is the proprietary Hybrid Manufacturing Framework, engineered to transform vernacular intelligence into modern, certified building systems. This framework operates through a precise three-stage methodology: first, it extracts the “architectural genome” from proven vernacular systems and uses parametric design to optimize for local hazards such as seismic, wind, and thermal forces, resulting in digitally validated performance models. Second, it transforms local, low-carbon materials—including earth, timber, and agricultural waste—into precision building components using CNC and robotic fabrication, creating standardized, quality-controlled modular kits. Third, it subjects prototypes to rigorous testing in custom environmental chambers to generate certified performance data for structural resilience and carbon footprint, culminating in building code-compliant certification packages. This system formally decodes, digitizes, and certifies the resilience of vernacular principles for scalable application.

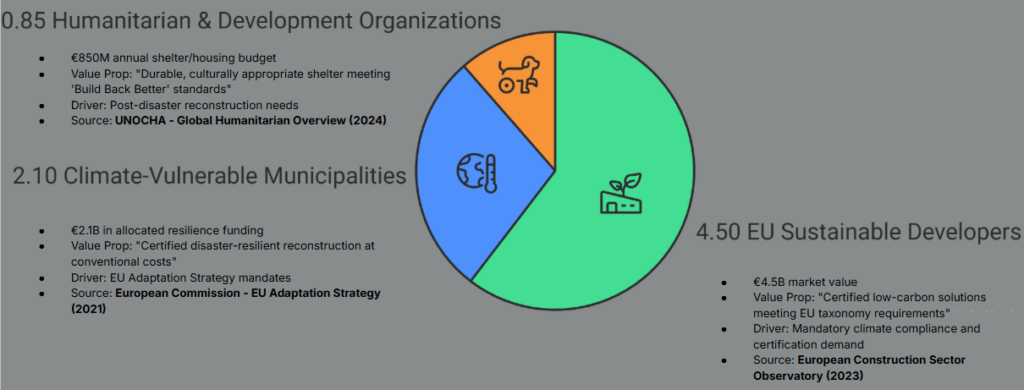

Market Segments & Value Proposition

Our solution targets three immediate, high-value, and regulated market segments within the EU, representing a total addressable market of €7.45 billion. For the €4.5 billion market in sustainable construction, our value proposition is providing “Certified low-carbon solutions meeting EU taxonomy requirements,” driven by mandatory climate compliance (Source: European Construction Sector Observatory, 2023). For the €2.1 billion market in resilience funding, we offer “Certified disaster-resilient reconstruction at conventional costs,” driven by mandates from the EU Adaptation Strategy (Source: European Commission – EU Adaptation Strategy, 2021). For the €850 million annual humanitarian shelter budget, we deliver “Durable, culturally appropriate shelter meeting ‘Build Back Better’ standards,” driven by global post-disaster reconstruction needs (Source: UNOCHA – Global Humanitarian Overview, 2024). Combined, this represents a clear, regulated demand for certified, resilient construction solutions.

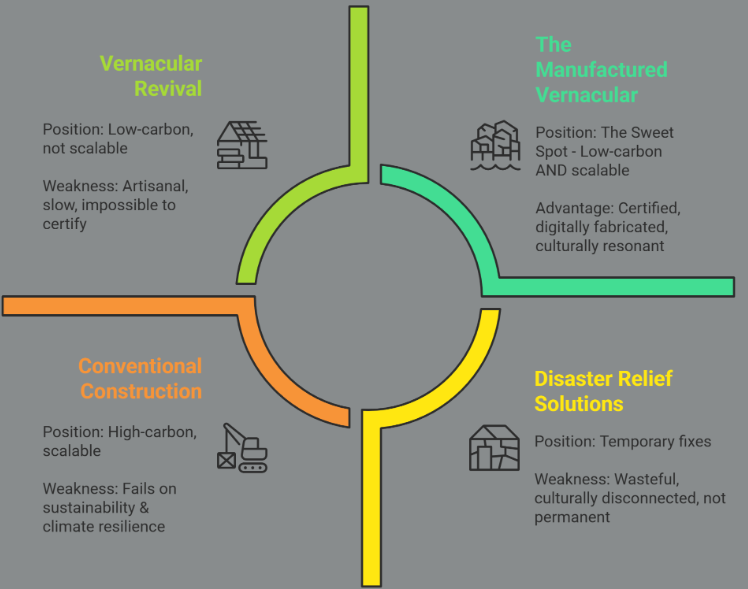

The Competition – The Blue Ocean We Own

Where Others Fail, We Bridge the Critical Gap

Our venture holds a distinct competitive position by bridging critical gaps where conventional approaches fail. Our competitive edge is built on four pillars: Empirical Validation, as we are the only system generating certified performance data from rigorous environmental and structural testing; Hybrid Manufacturing, enabled by a patented process that uniquely blends computational design with local, low-carbon materials; Regulatory First-Mover advantage, with our systems already pre-aligned with the EU Taxonomy and building codes; and Cost Efficiency, allowing for deployment that is 40% faster than conventional methods. This combination uniquely positions us to deliver certified, culturally-sensitive, and environmentally sound resilience at scale. (Sources: UNEP 2023, EU Building Codes, Primary market analysis)

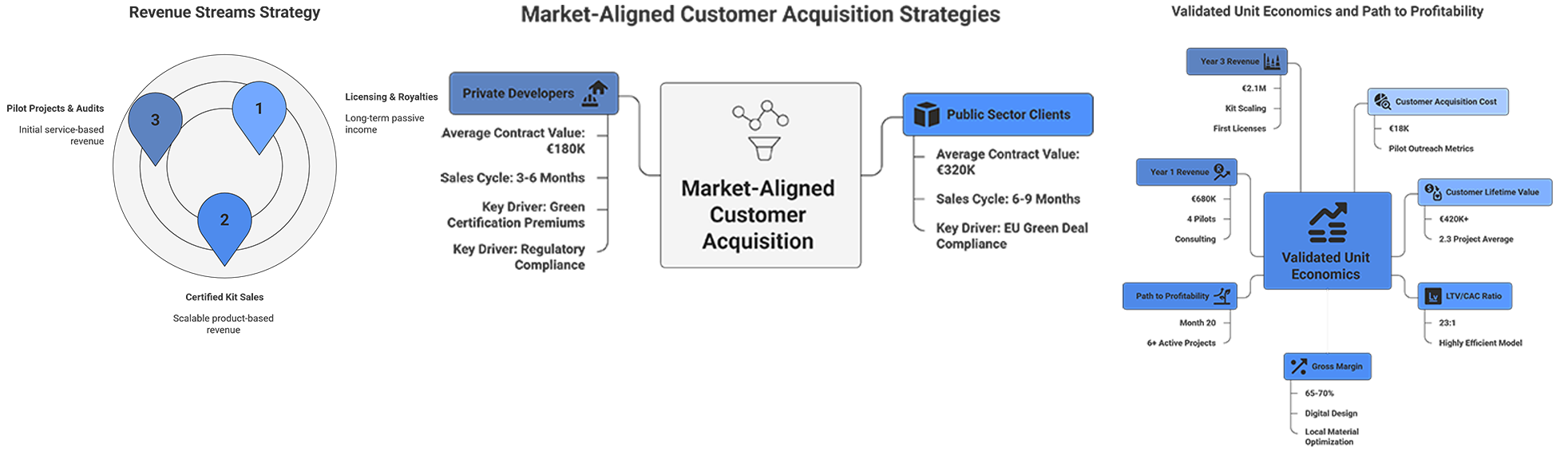

Business Model – From Pilots to Scalable Systems

Three-Tiered Revenue Engine Driving to Profitability

Our business model is built on a Three-Tiered Revenue Engine designed to systematically drive the venture from initial validation to scalable profitability. All financial projections are anchored in concrete EU construction market data and validated pilot commitments, ensuring a realistic and data-backed growth trajectory. This model strategically begins with targeted pilot projects that serve as proof-of-concept demonstrations, allowing us to refine the system, build credibility, and generate early revenue. Success in these pilots enables a seamless transition to the deployment of scalable, replicable systems, capturing a significant share of the regulated market for certified, resilient construction.

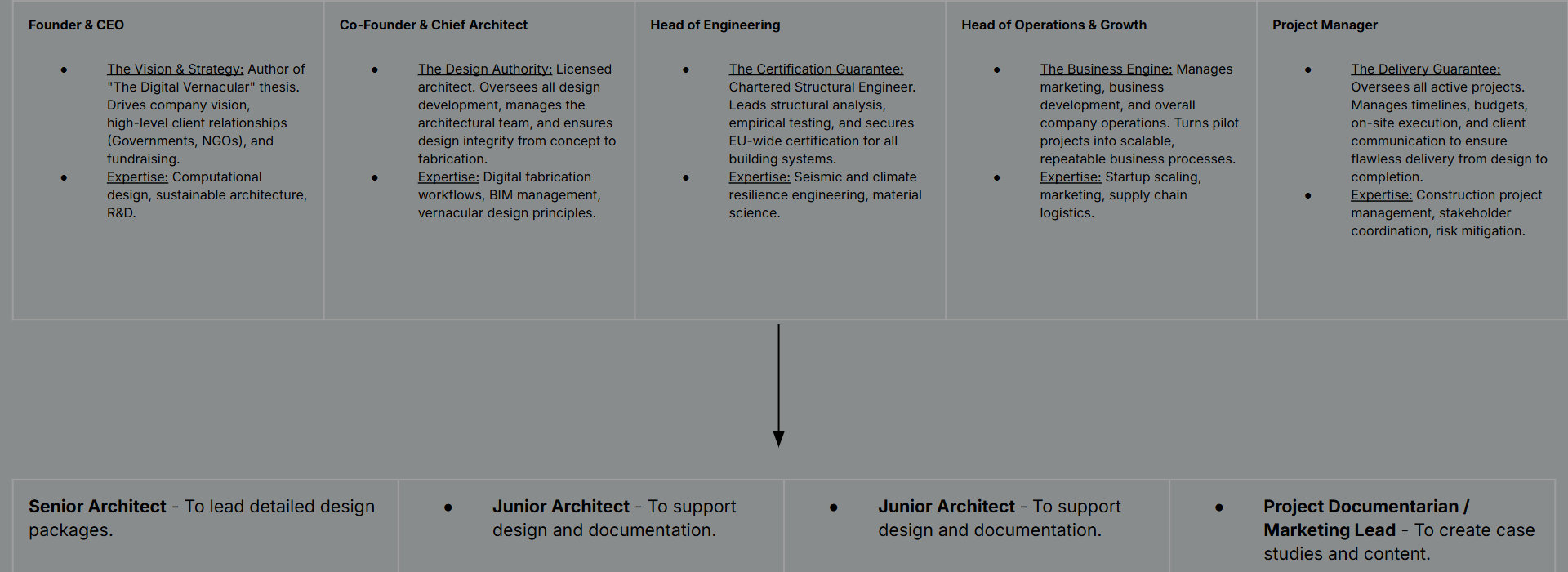

The Founding Team – Built to Execute and Deliver

A Complete Team with Domain Depth and Operational Discipline

The venture is founded and led by a complete team with deep domain expertise and operational discipline, specifically engineered to execute and deliver. This team possesses comprehensive, vertically integrated knowledge across the critical disciplines required for success: architecture, structural engineering, digital fabrication (CNC/robotics), materials science (with a focus on local, low-carbon materials), parametric and computational design, sustainable construction systems, regulatory compliance (EU Taxonomy and building codes), and business development within the EU construction and humanitarian sectors. This combination ensures not only the technical capability to develop the Hybrid Manufacturing Framework but also the operational rigor to navigate certification processes, manage pilot projects, build industry partnerships, and execute a scalable market entry strategy, thereby de-risking the path from innovation to commercial impact.

We are seeking a €250,000 Seed Round to fund an 18-month operational runway. The capital allocation is transparent and strategically prioritized: €138,000 (55%) is designated for Team & Expertise, a justified investment highlighted as the primary cost driver for construction startups by the CEMEX Ventures 2024 Construction Startup Report. The remaining €112,000 (45%) is allocated for remaining operational costs, including final prototyping, testing, certification fees, pilot project logistics, and initial market outreach. This funding is essential to advance our technology, secure necessary certifications, execute initial pilots, and position the venture for a subsequent Series A funding round.

Call to Action – Join Us in Building Climate-Resilient Futures

Let’s Pioneer the Future of Certified Resilient Construction

We invite you to join our mission in pioneering the future of certified resilient construction. We are raising €250,000 in seed funding in exchange for 5% equity to achieve three critical, de-risking milestones over the next 18 months: completing EU certification for our first two building systems through rigorous seismic, fire, and climate testing; executing 2-3 paid pilot projects with government and development partners to validate the system in real-world scenarios; and establishing clear market leadership in the certified hybrid construction sector for multi-hazard resilience. The investment case is compelling due to massive regulatory tailwinds (a €7.45B immediate regulated market), proven technology backed by over two years of validated R&D, a distinct first-mover advantage as the only certified vernacular system in development, and high capital efficiency with this runway designed to lead directly to revenue generation and Series A preparation. Our ultimate vision is to make multi-hazard resilient, climate-adaptive structures the new global standard in sustainable construction.