The competition proposal of a 1:1 3d printed arched clay vault should be characterized by feasibility in construction. To achieve feasibility, the design of the vault uses bended sheets of wood to carry arches, dwells on strong connections in the infills, and complies by site printing restrictions [4,500 meters of print length alongside a maximum height and width].

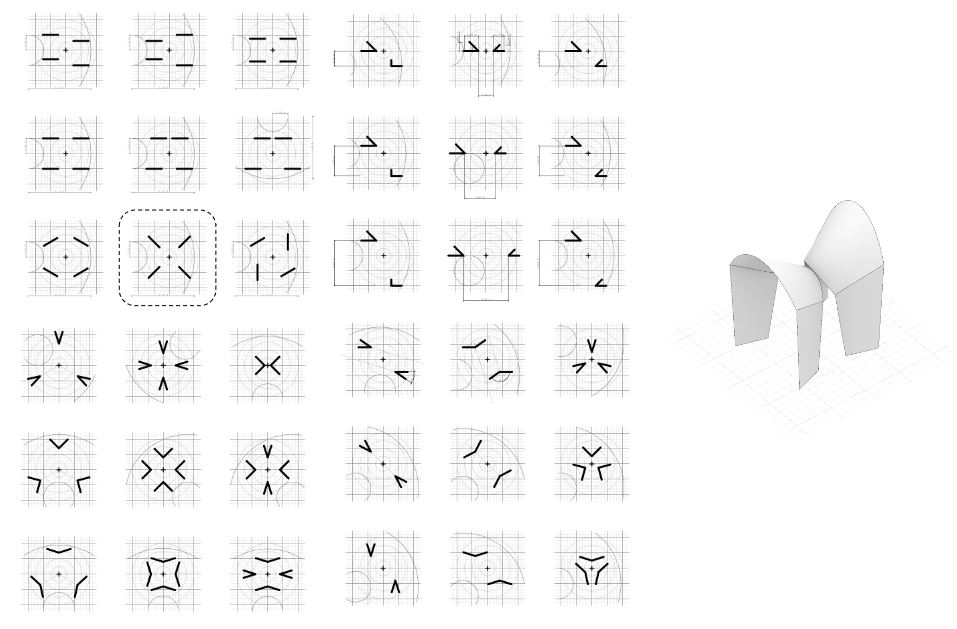

A catalogue of more than 100 plan sketches were drawn. The iterations explored entrances, exits, central spaces, and types of passages. They were achieved by modifying directions of segments, connections of segments, angles of rotations of segments, and size. One typology was chosen due to its compliance with printing restrictions, potential architectural value, and feasibility

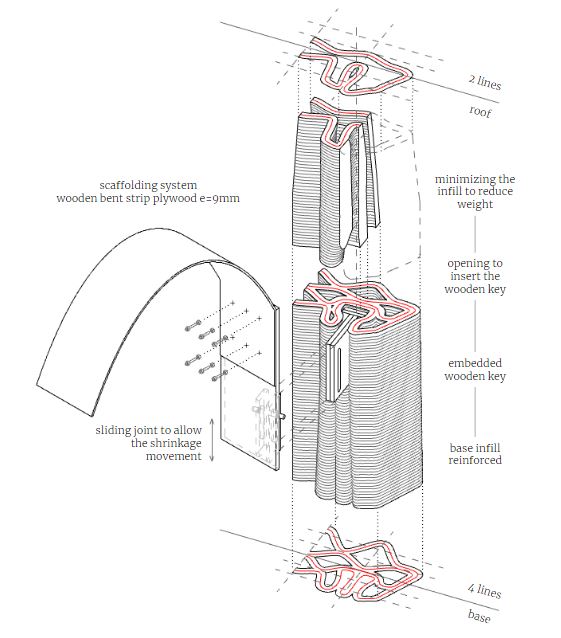

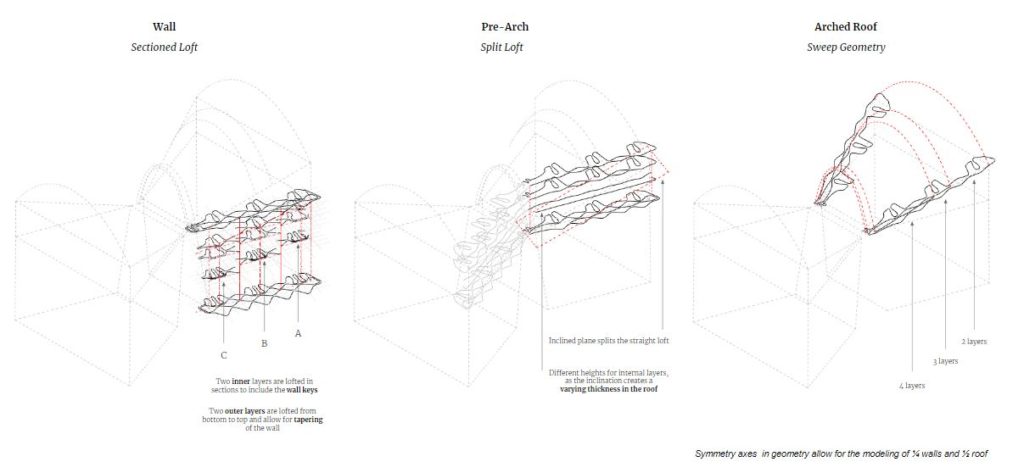

In plan, the exterior walls and interior walls are easily distinguishable. The outer walls are a manipulated version of the TOVA infill. They extrude to increase surface area contact with the ground which achieves stability and mass. The inner walls are mostly composed of ribs. The ribs have two necessary roles: the first role is to have the capacity to accommodate for voids that carry wooden keys, and the second role is to create strong connections once the arch begins to form.

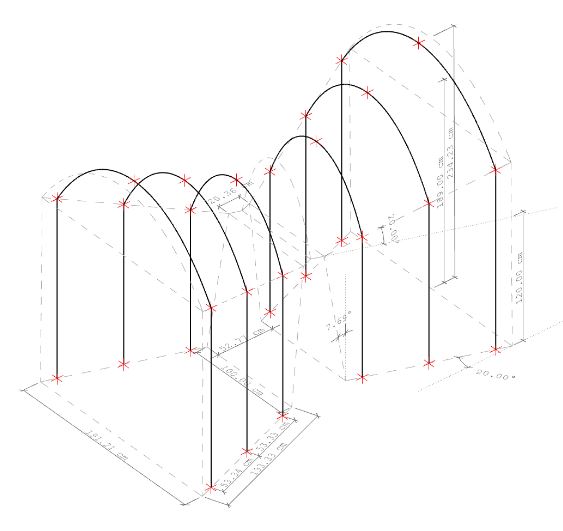

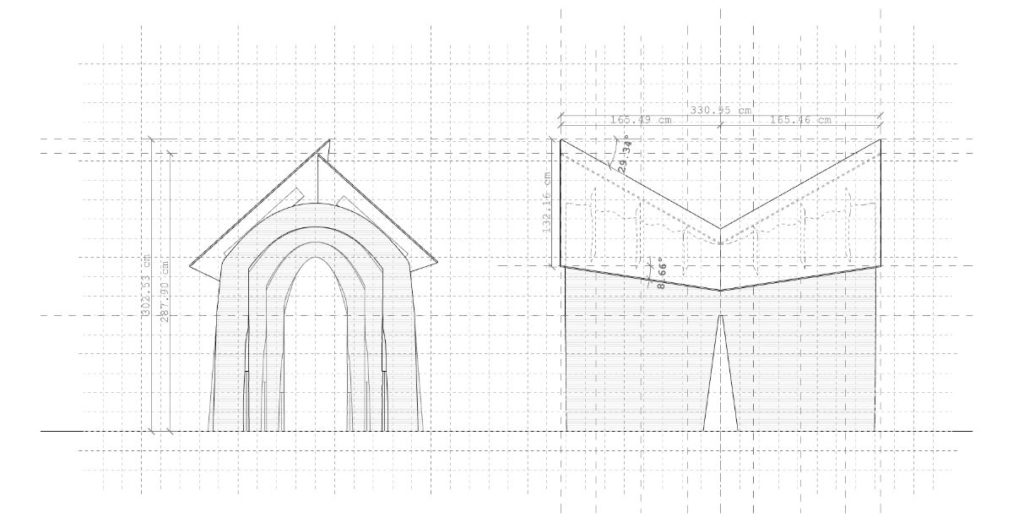

These ribs must be able to form strong connections along specific axes that receive support. In a diagram for the skeleton of the geometry, the physical interface between the arched rib and the bended wooden sheet, which supports the arched print, was explored.

The way in which said bended wooden sheet is connected relies on the standing of the supportive wooden key embedded in the clay wall. The reason that the wooden key is located inside the clay wall rather than outside of it is to ensure that the design exhausts every opportunity of the technology: it is of the essence to embed needed information into the design of a wall.

The information of wooden keys that was embedded requires 6 voids on each side of the arched vault. The central one, being the largest, is aimed to assist two ribs and the strong infill connection that is created while the two walls on each side of the arched print ‘kiss’ each other.

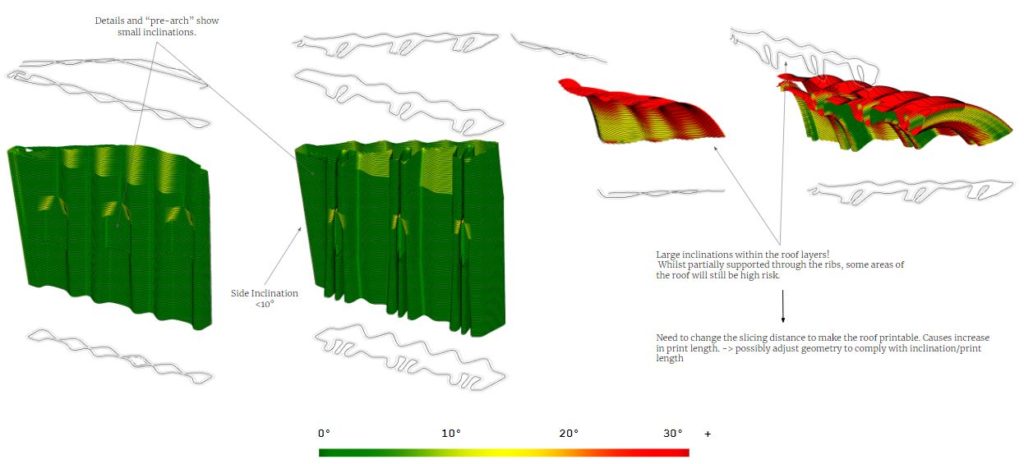

This ‘kiss’ was meticulously monitored via editing the base infill before it. It was an intention to extrude the arched vault along a series of infill lines. On the ground, the infill lines start at 4 lines, decrease to 3 before the arch emerges, and becomes 2 as the design is roofing.

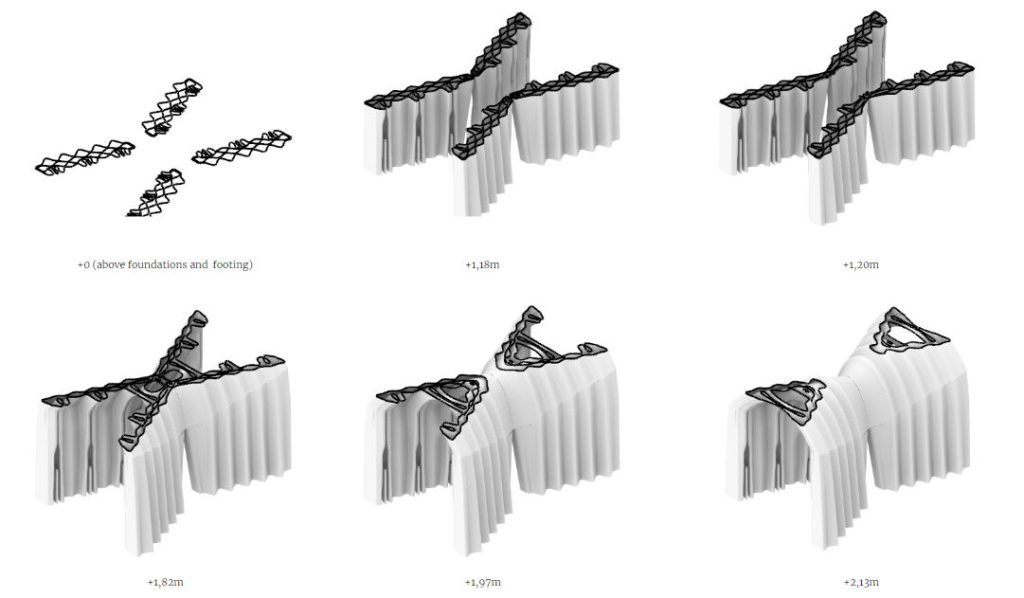

The feasibility of the design was evaluated by its constructability within the given time frame of 15 printing days, and a discussion around risk assessment. In the first 5 days, 60 layers would be printed, all the wooden keys would be constructed, 8/12 keys would be inserted, and bended wooden arches would begin to be constructed. Of course, layer printing is always interrupted for the purpose of drying, wooden keys insertion, and other purposes. The risks during this process vary but the most important ones are that the print will have had little time to dry which will not be enough for the keys to sit safely inside the pockets. The solution was to ensure at least 72 hours for drying. Artificial drying can also be used. The biggest risk in the next two weeks regarding the construction and installation of bended wooden sheets is the possibility of Incompatibility of digital arch in modelling to physical wooden arch. Remapping the physical arch and appropriating it to the digital arch can solve this. Also, the nozzle size is lengthened. This is needed to avoid the collision of crane to scaffolding. It is extended by 40 cm. This solution also avoids the collision of the crane to scaffolding. A solution would be to manage the G-code in a way that avoids that.

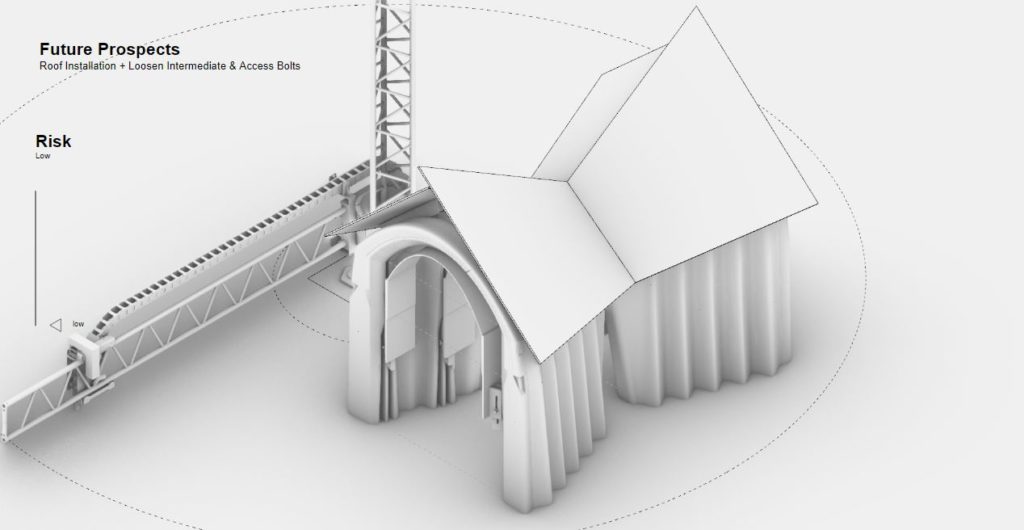

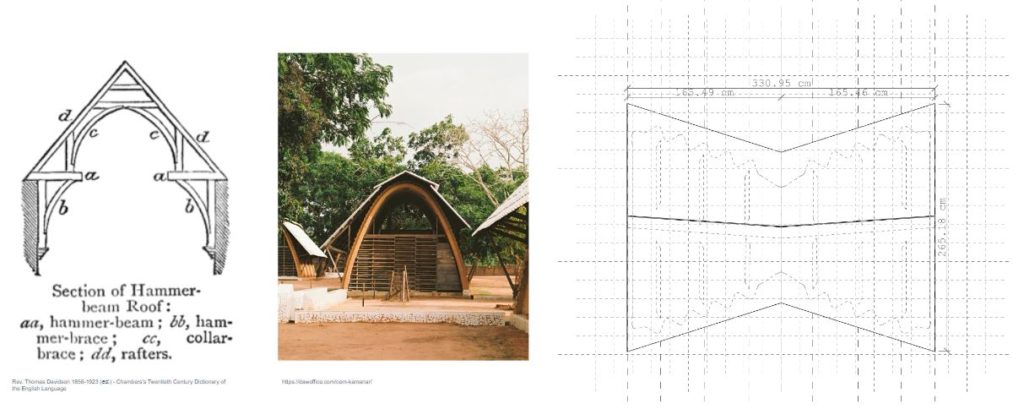

In history, there had been steps to roofing a vaulted structure, or perhaps using structural systems that create a symbiosis between roofs, pitched roof per say, and arched geometries right underneath. The hammer beam roof acts as a precedent to the roofed arch design by DAWOFFICE. The roof design in the competition proposal takes a similar form, and in top view, it can be observed that the roof sticks outside of the wall by some centimeters. The roof structure was maintained for further research, but the prospects tell that an adhesive layer on the exterior wall can be made with voids that accommodate the wooden keys that can carry a roof. The surfaces of the roof are pitched to navigate rainfall and have a strong yet low maintenance joinery to close the roof planes.

The roof is installed after the last day of construction and it is also the day that the bolts that fasten the bended wooden sheets at specific heights are loosened in order to move actively with the retraction of the clay print.