Introduction

This project was done in collaboration with Heatherwick Studio. Our starting point was a problem that emerged when patterned ceramic tiles were deployed at scale. Specifically, factory-produced tiles create repetitive patterns, which detract from their crafted intricacy. On the other end of the spectrum, hand glazing is a highly skilled and time-consuming process that must be painstakingly carried out by artisans, making it costly and inefficient at scale.

Our project aims to bridge the gap between the uniqueness of handcraft and the scalability of robotic techniques. By combining motion tracking with 6-axis robotics, we seek to leverage technology to integrate the advantages of both industrialized and artisanal processes.

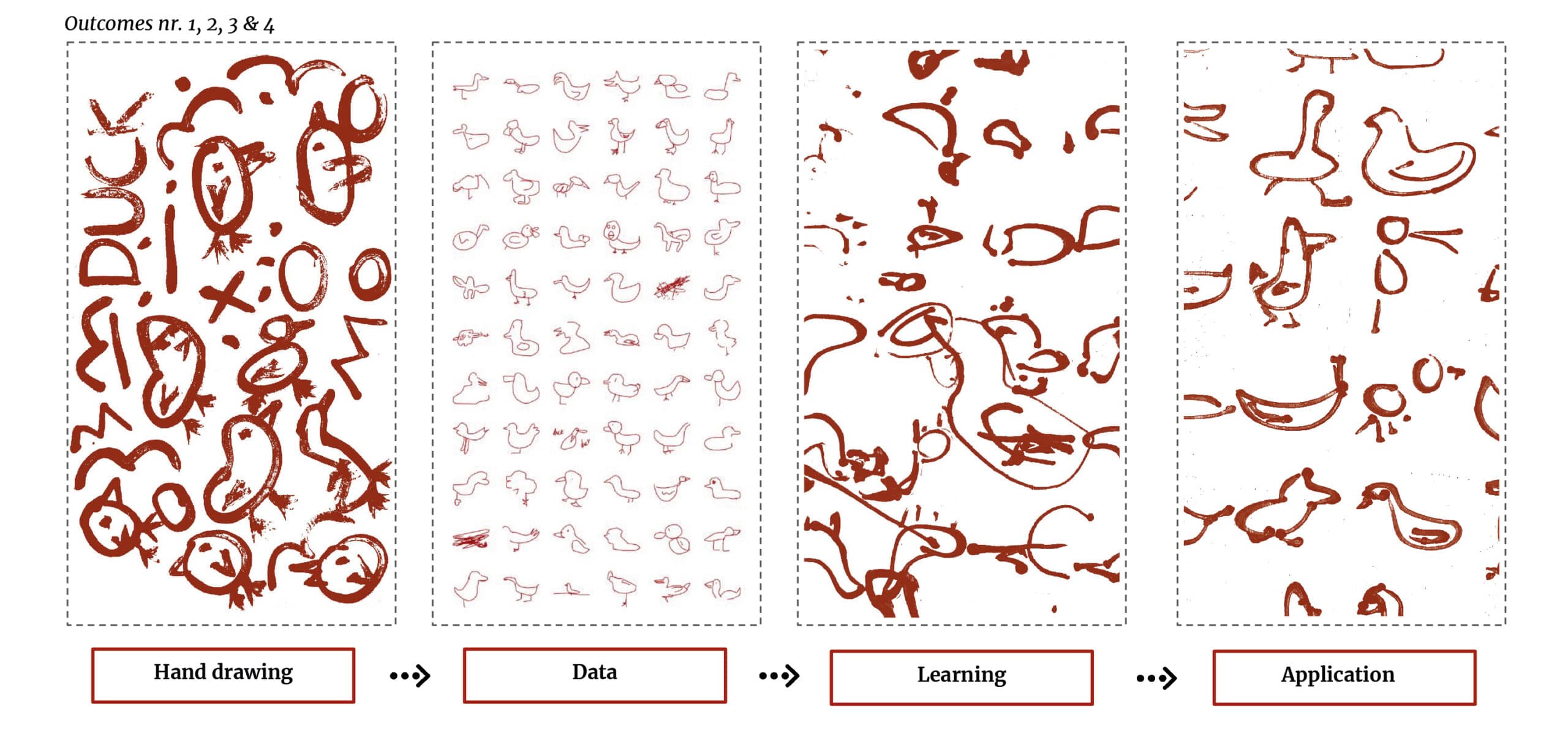

For this project, we focused on brush-on glazing, a technique similar to painting that allows for intricate designs. We used duck motifs as a way to test and refine our drawing and tracking capabilities.

MULTIPLE ELEMENTS TOOLPATH

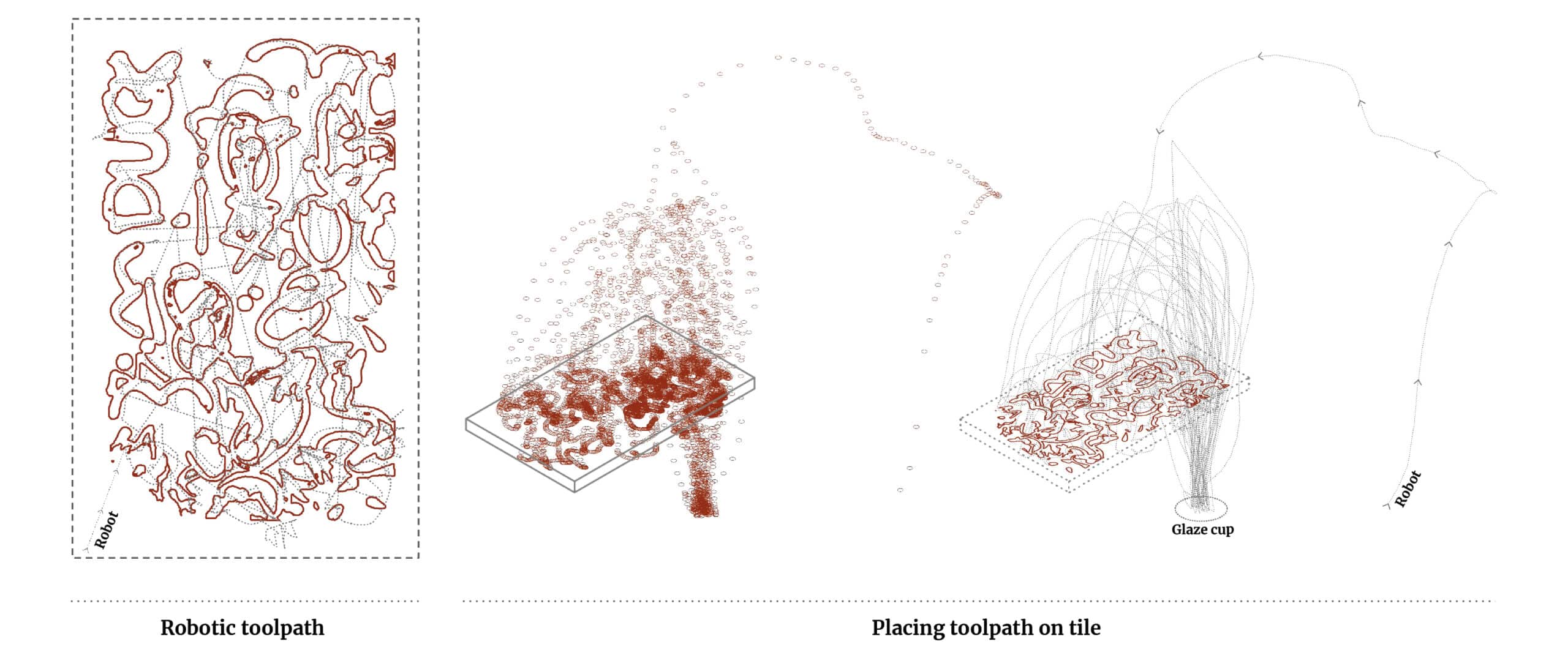

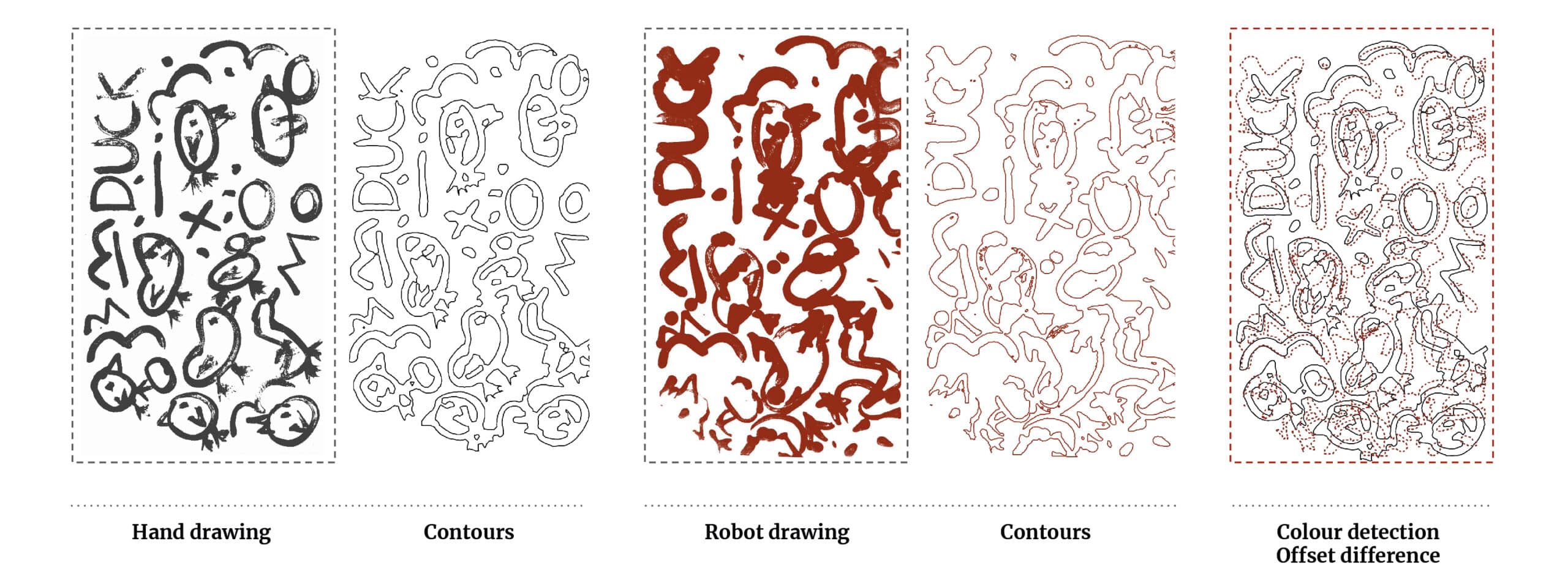

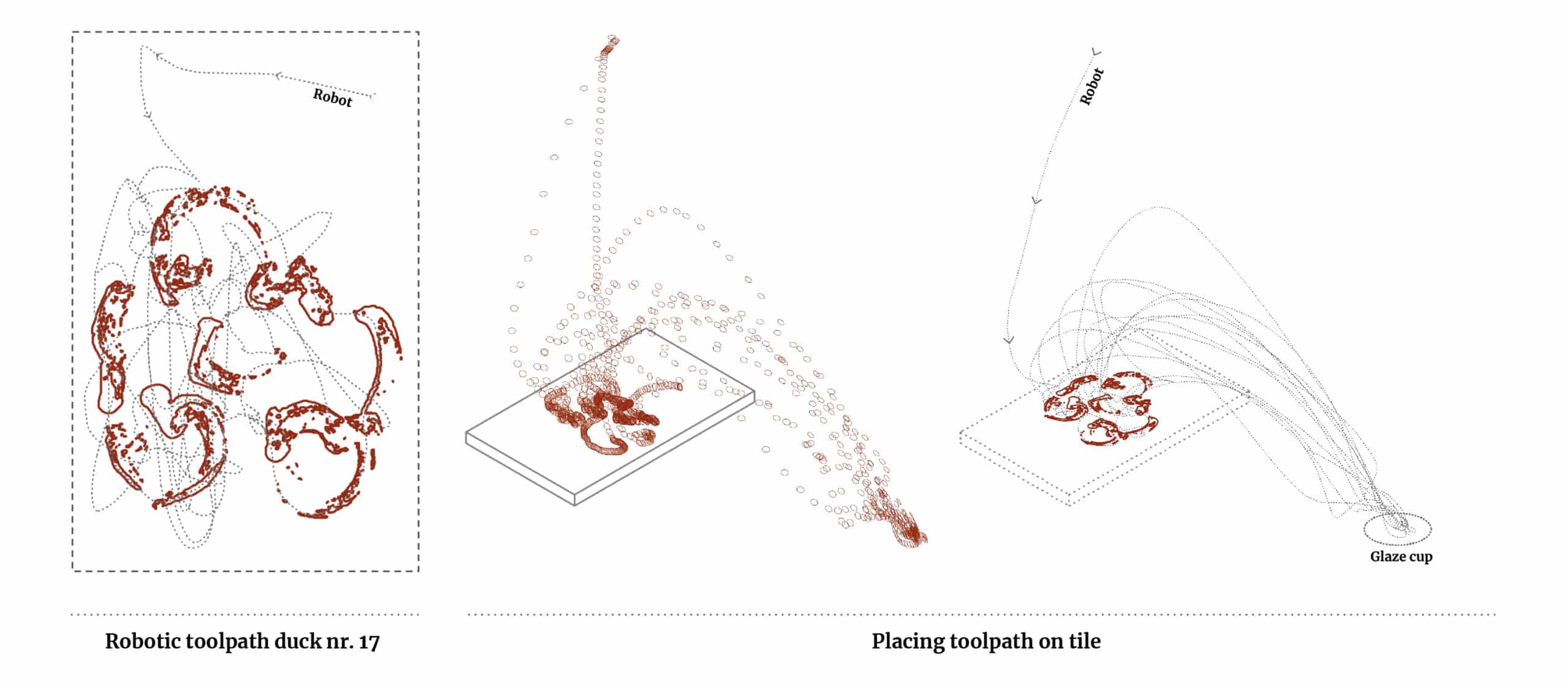

The first toolpath we tracked involved a tile composed of multiple duck drawings alongside simple words. We captured this tile as a continuous toolpath, then cleaned and converted the data into usable G-code. The motion-tracked tile was then replicated by an ABB 140 6-axis robotic arm.

To evaluate accuracy, we used computer vision to compare the original hand-painted tile to the robotic reproduction. This analysis revealed significant inaccuracies across the entire tile, with noticeable drift and warping. However, we observed that individual elements were locally well-tracked.

HAND TRACKING TO ROBOTIC IMPLEMENTATION_Test nr.1

Comparative analysis of a tracked tile to the robotically painted tile_Multiple Elements

INDIVIDUAL ELEMENT TOOLPATH

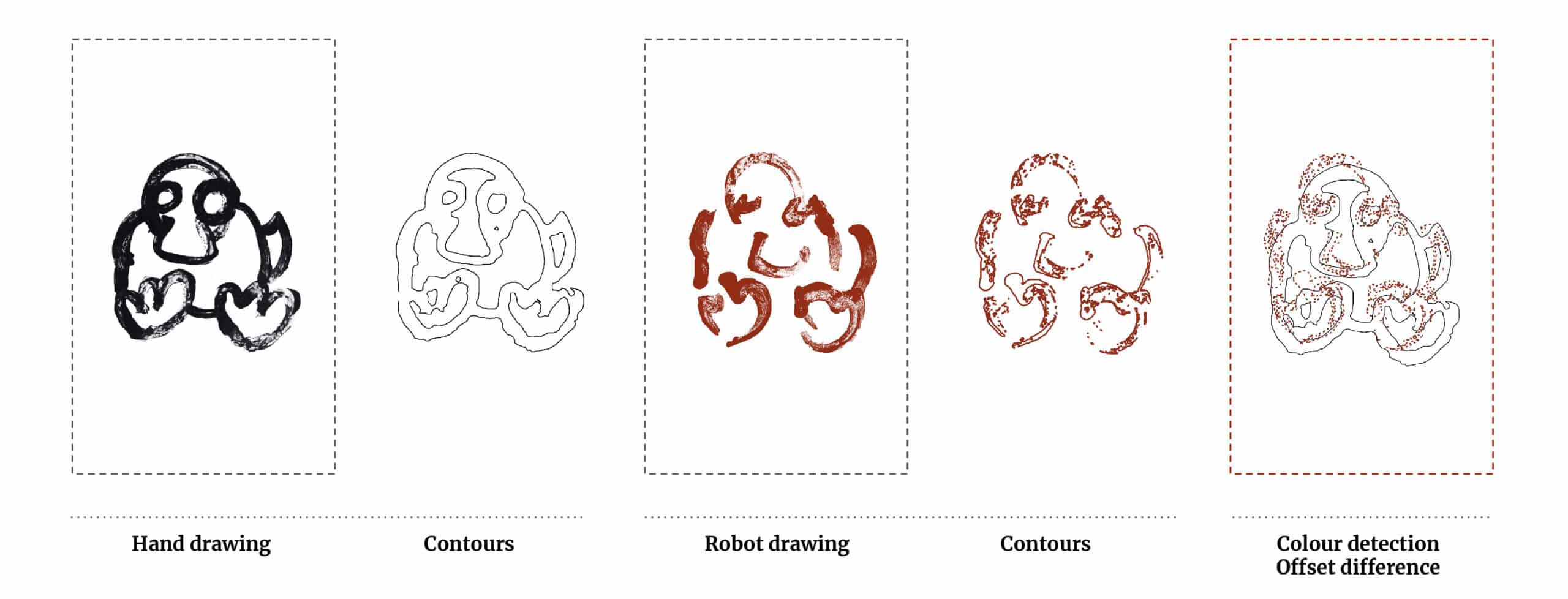

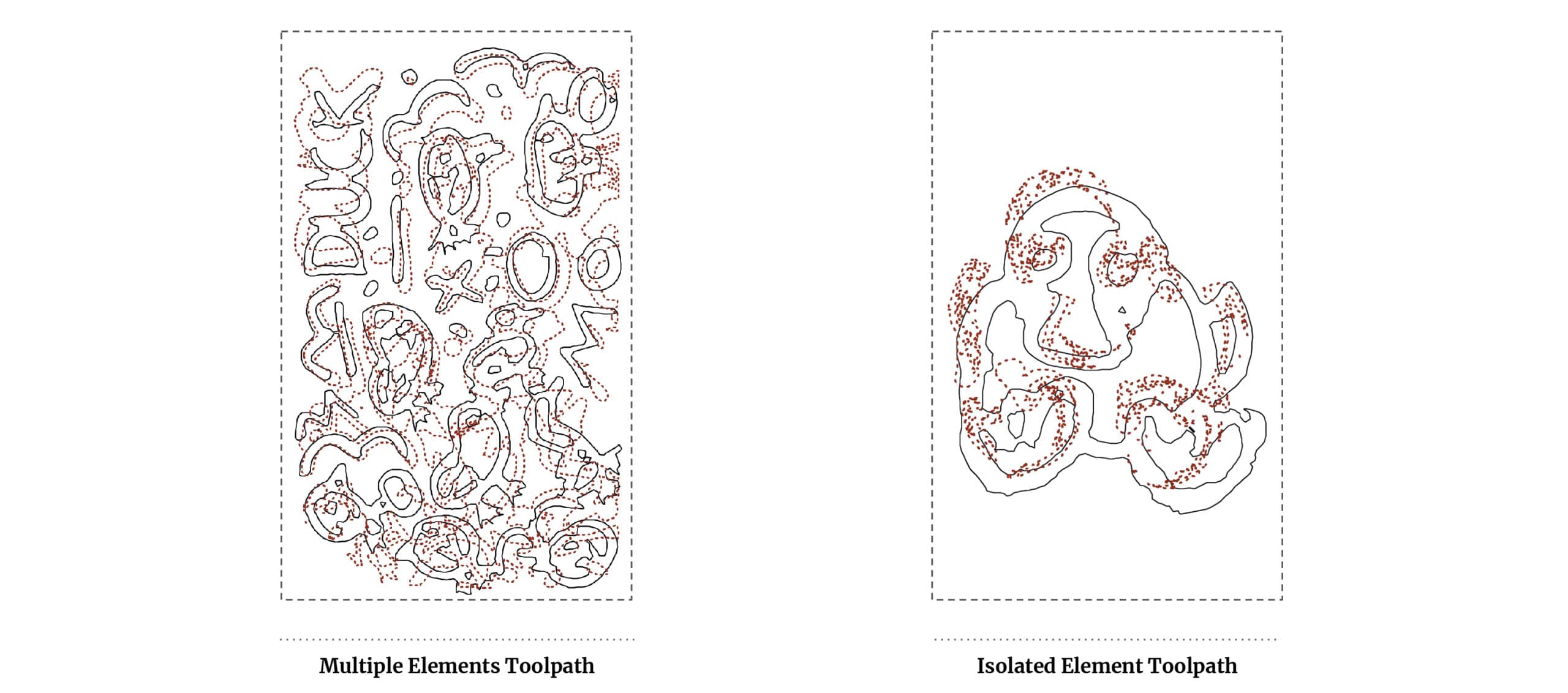

Our second tracking exercise focused on a single element within a tile to assess whether isolating components improved accuracy. The results showed a clear improvement: the singularly tracked duck had significantly higher fidelity compared to the original full-composition toolpath.

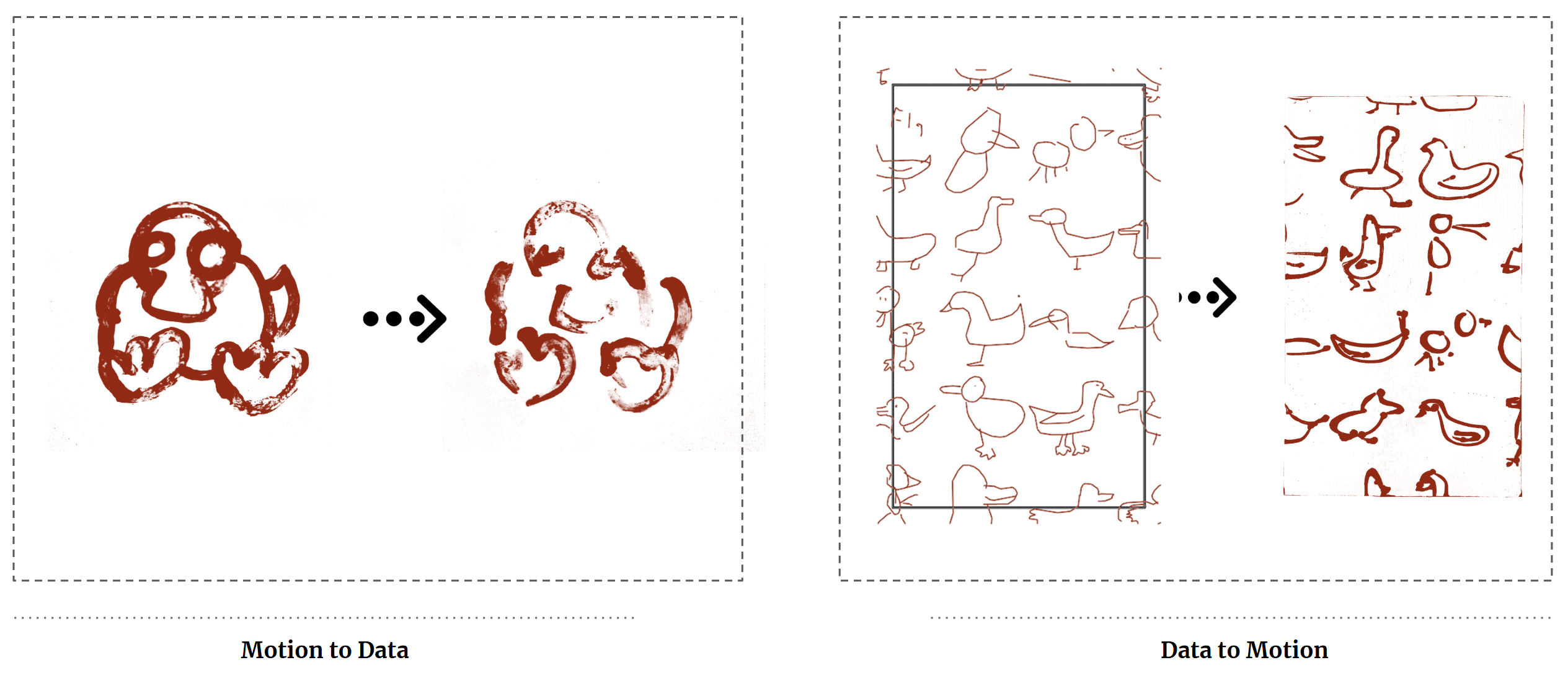

This exercise led to a key insight: rather than tracking a continuous toolpath of a large composition, it is far more effective to track individual elements and recompose them later.

HAND TRACKING TO ROBOTIC IMPLEMENTATION_Test nr.2

Comparative analysis of a tracked tile to the robotically painted tile_1 Element

TRACKING TECHNIQUE COMPARISON

Drawing single elements begins to improve the technique and the tracking of the movement

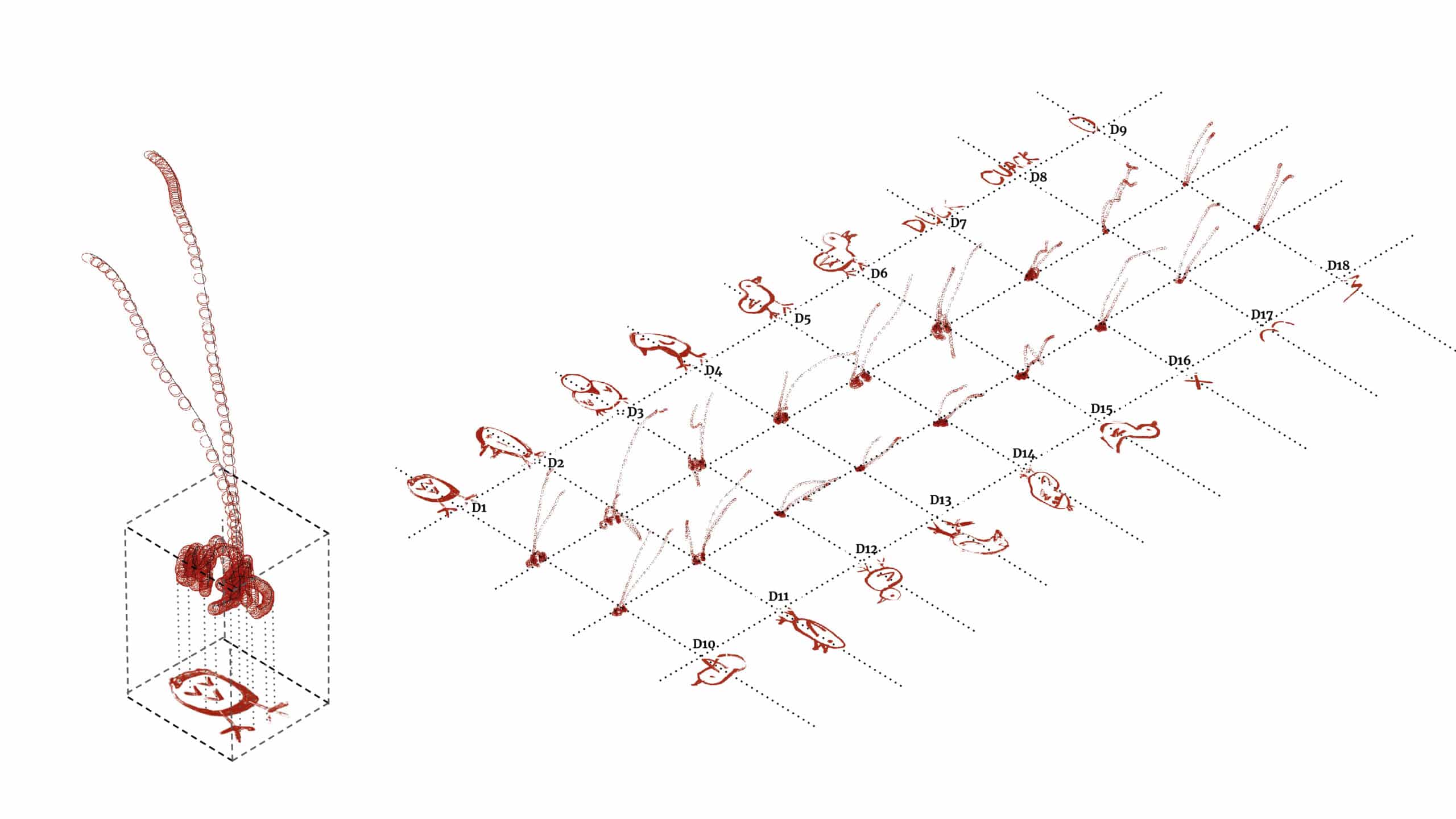

DUCK LIBRARY

From this realization, we developed the concept of a Library of Duck Drawings—a collection of three-dimensional motion data corresponding to a two-dimensional archive of duck illustrations. One of the most exciting potentials of this library is that it enables not only the composition of a single tile but also the generation of infinitely large, entirely novel patterns.

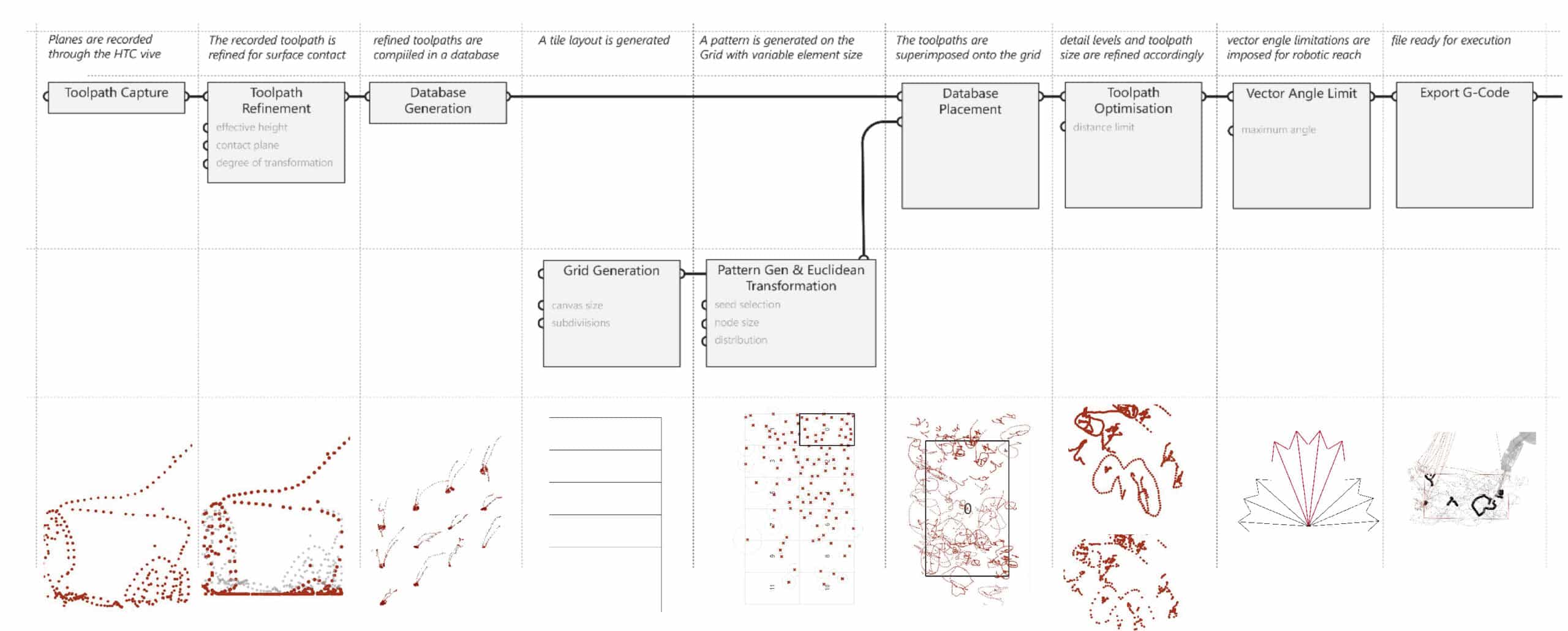

CODE STRATEGY

CODE PERFORMANCE

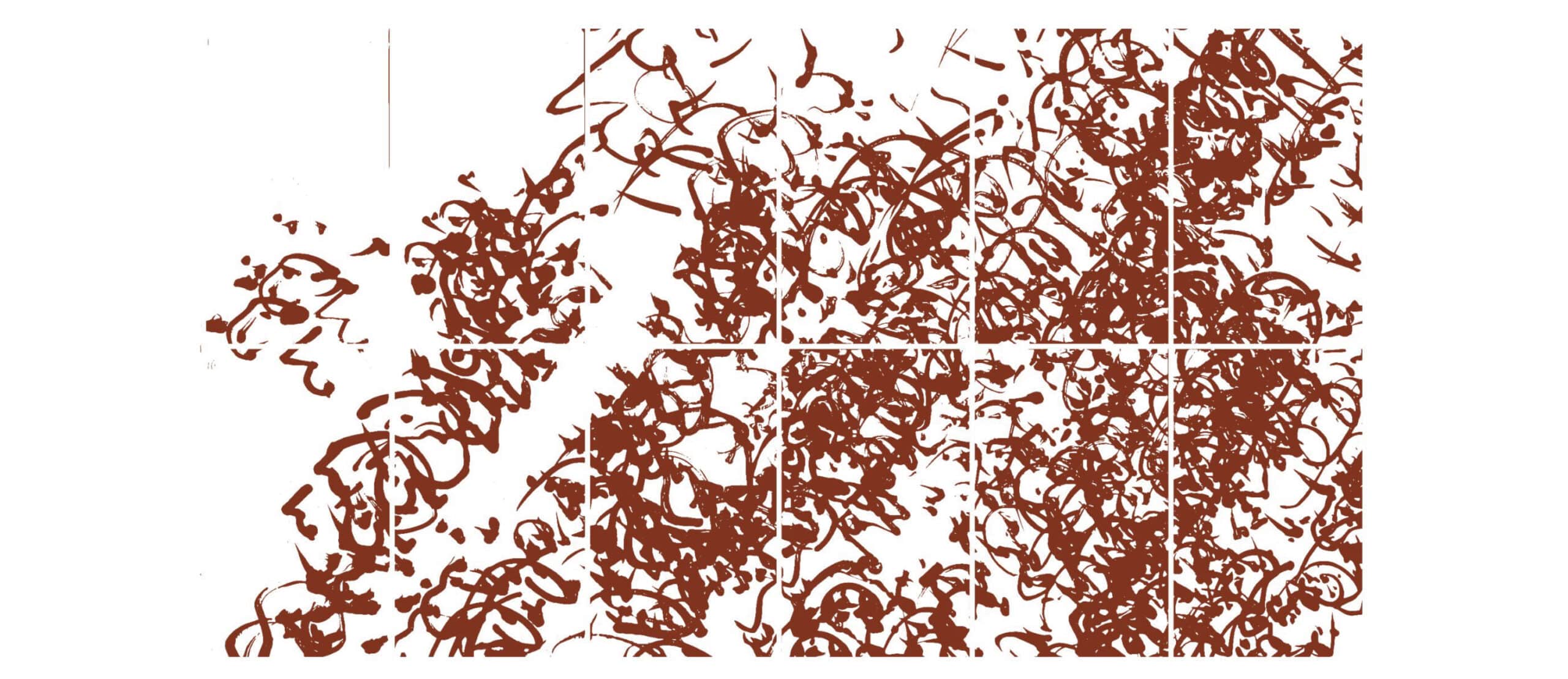

OUTCOME

ITERATIONS

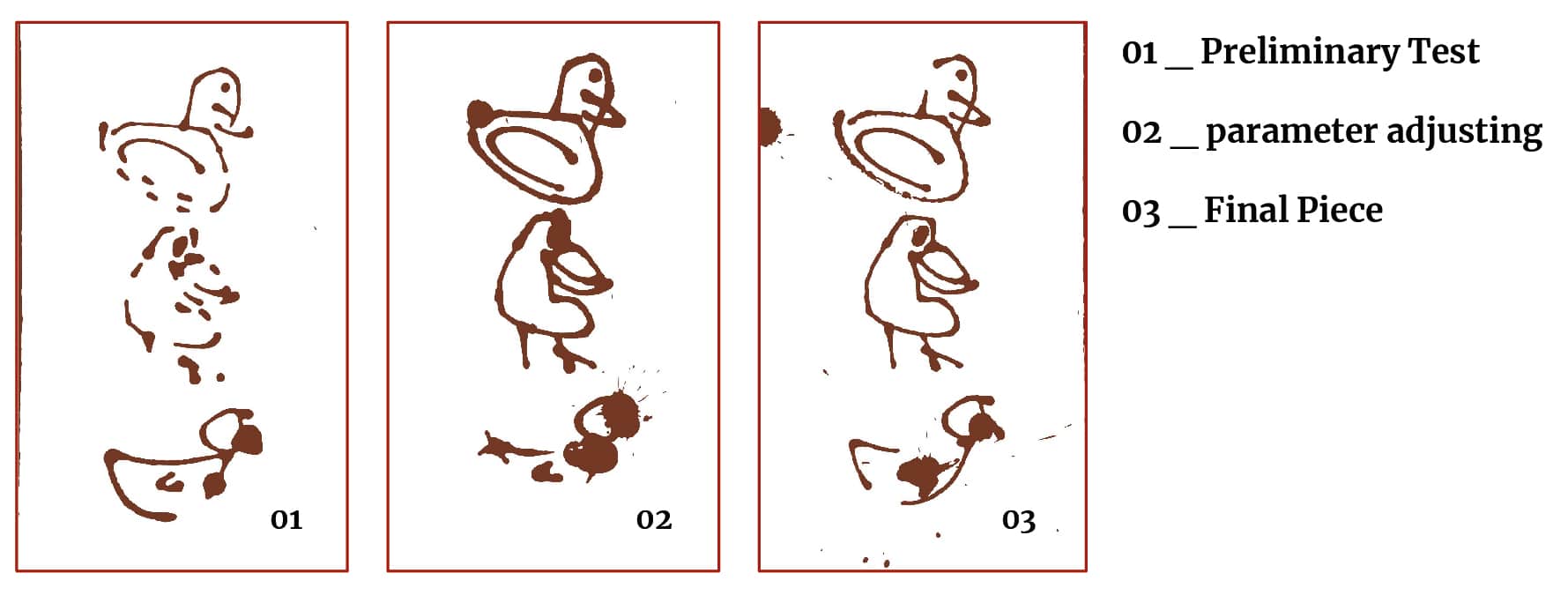

We conducted multiple tests with both simple and complex compositions to refine our dataset and improve accuracy. Through continuous iterations, we worked on increasing precision to more faithfully reproduce the original 2D patterns.

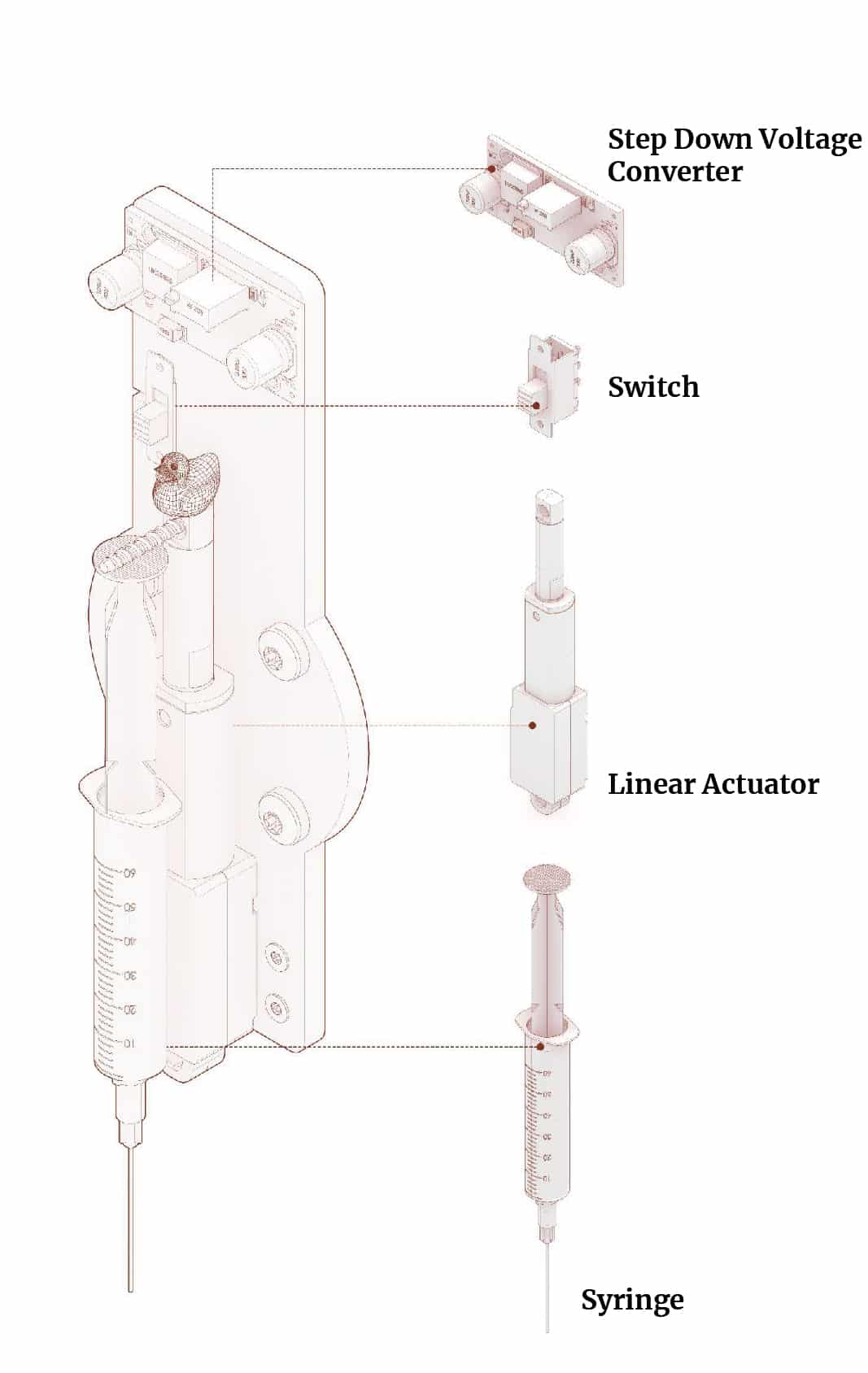

CUSTOM END-EFFECTOR

Further, we investigated the development of a custom end effector to optimize precision. This end effector incorporates a small solenoid actuator that controls a syringe holding the glaze, allowing for precise flow and control. However, one challenge we encountered was the incompatibility between the rigid syringe and the hard ceramic surface. Replacing the syringe tip with a more compliant material could significantly enhance the effectiveness of this system.

CONCLUSION

Motion tracking and robotics enable the generation and implementation of novel patterns. One of the key potentials of this approach lies in capturing discrete datasets and proliferating them at scale, blending idiosyncratic human movement with industrial efficiency.

However, one of our biggest challenges was achieving accurate motion tracking. Much of our effort went into calibrating and refining the tracked data to function as a toolpath on a flat plane, but the raw data consistently fell short. We believe this process can be further improved by optimizing and refining the motion-tracking stage.

Ultimately, we see the true potential of this technology in mapping 2D drawing outputs to robotic toolpaths. With enough data, it should be possible to generate toolpaths directly from hand-drawn strokes, preserving the nuances of human gesture within a scalable, automated system.