Techne W6: Volume

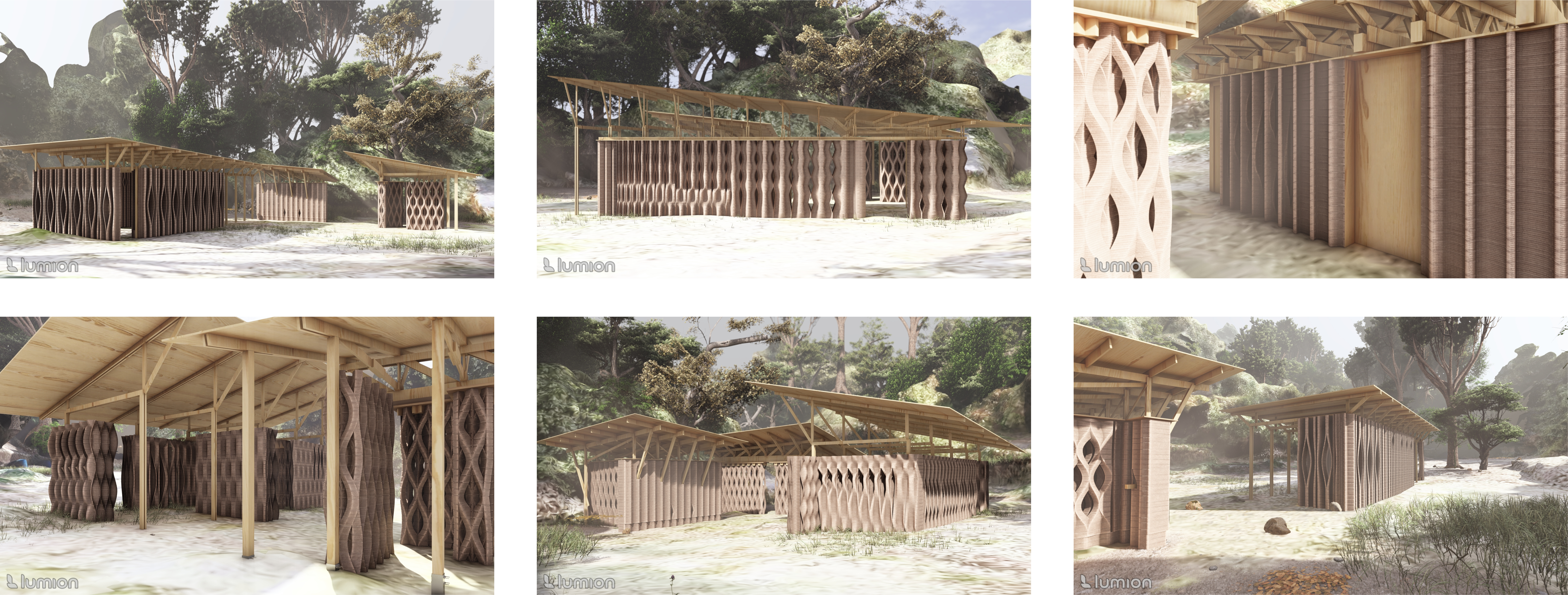

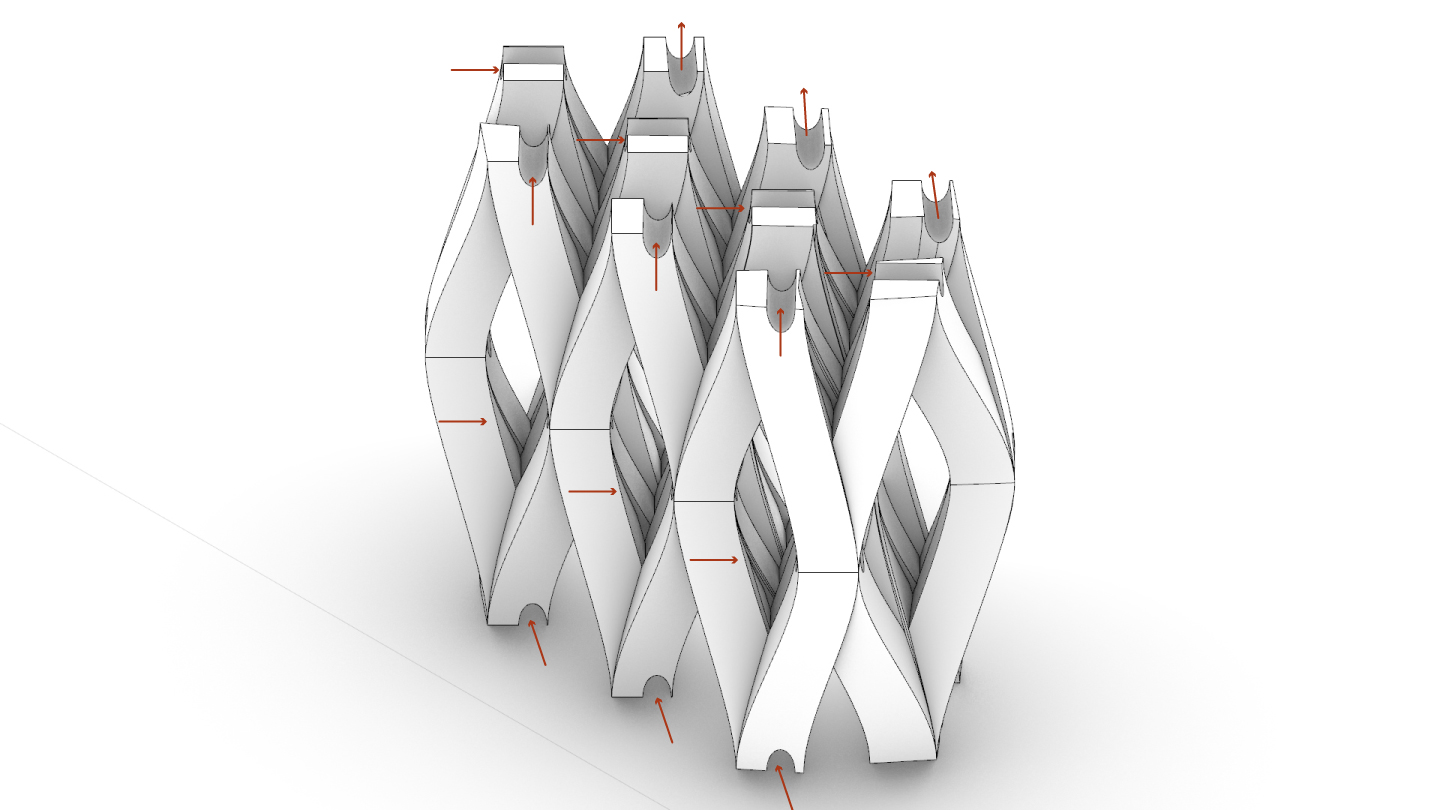

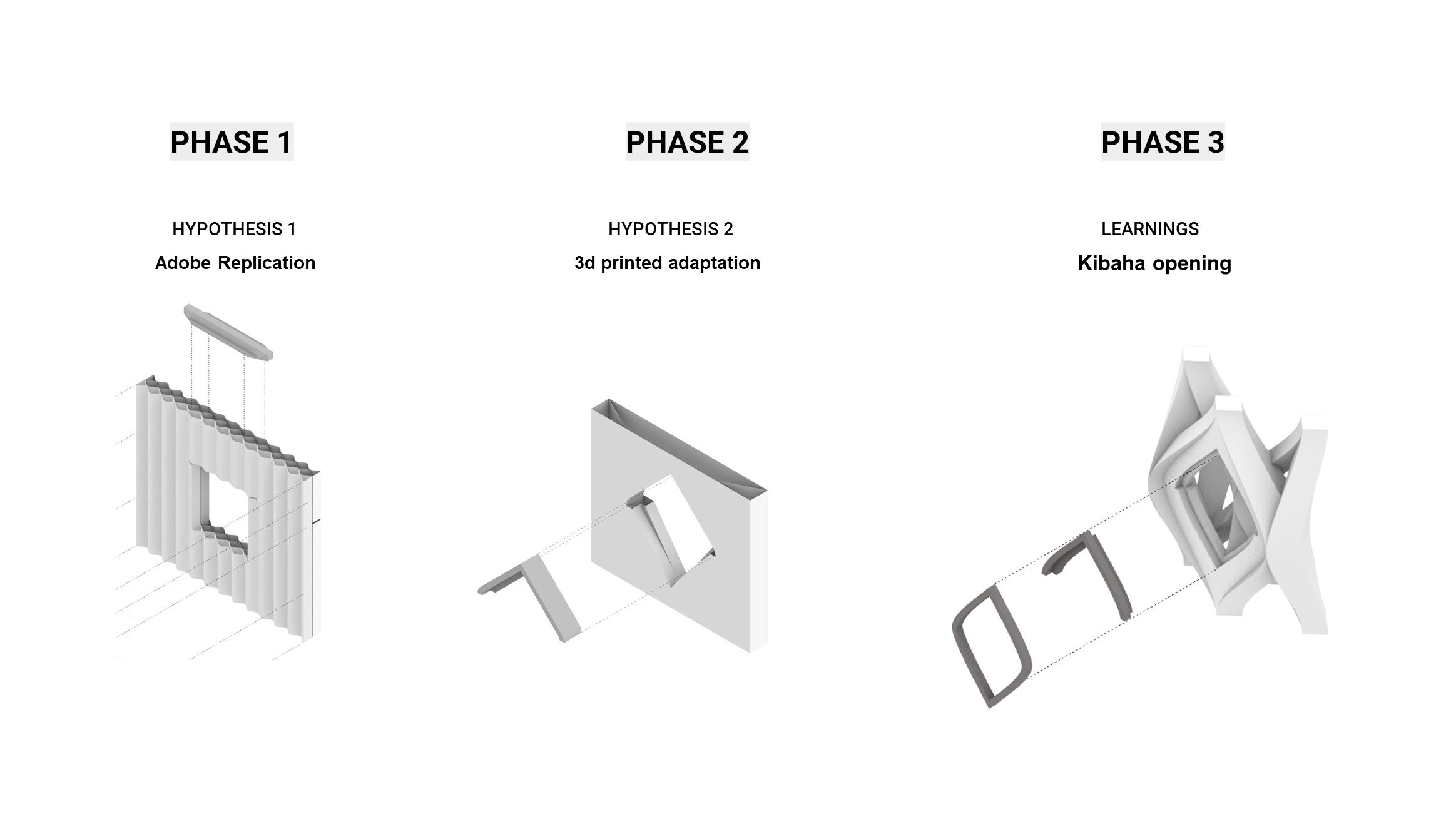

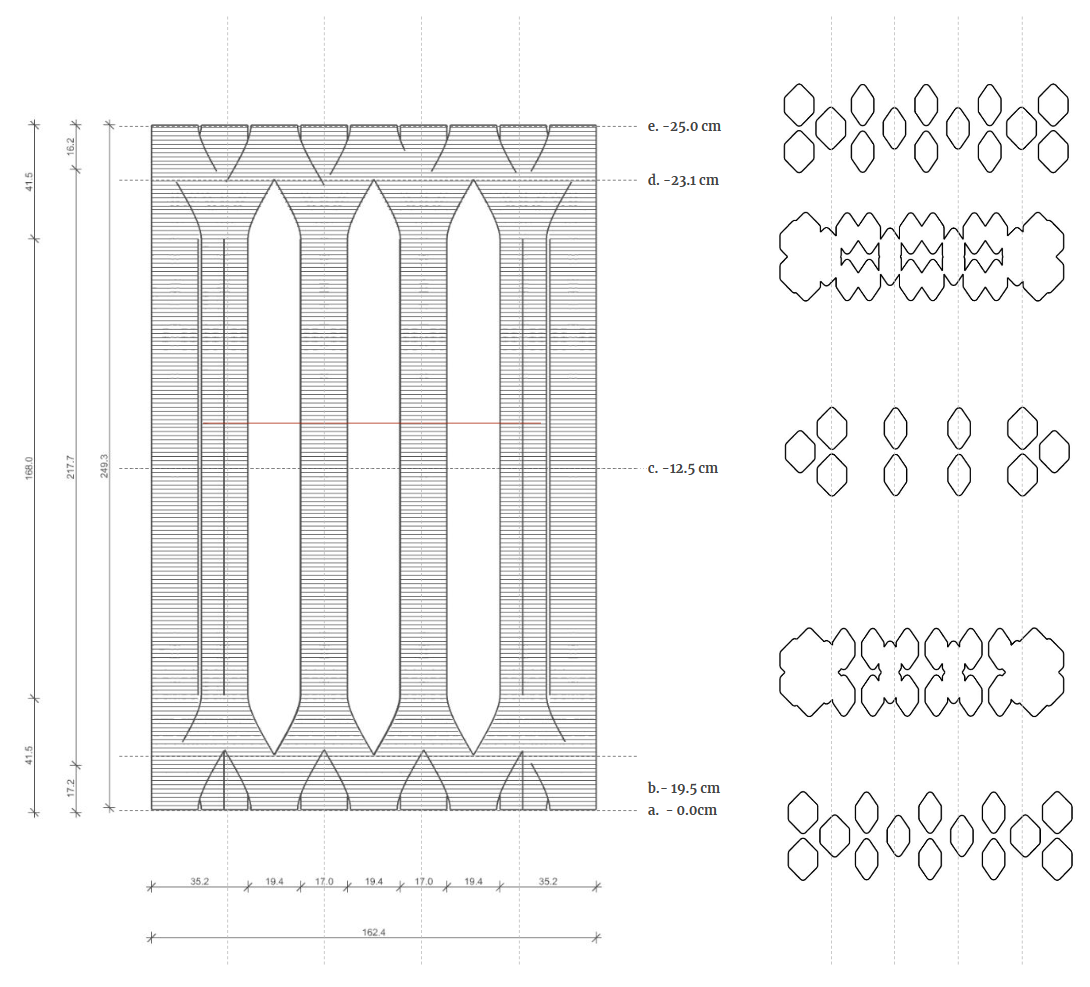

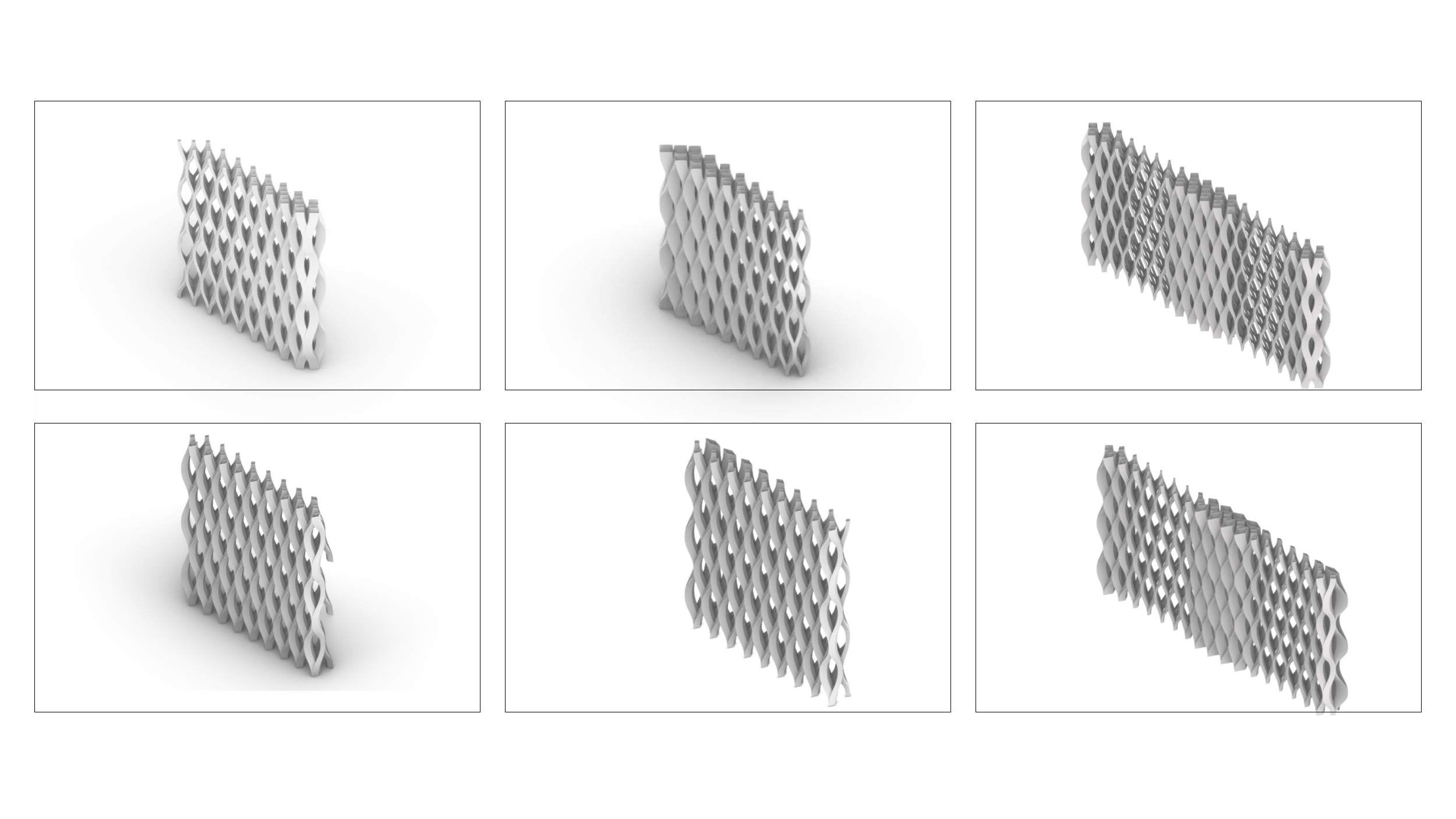

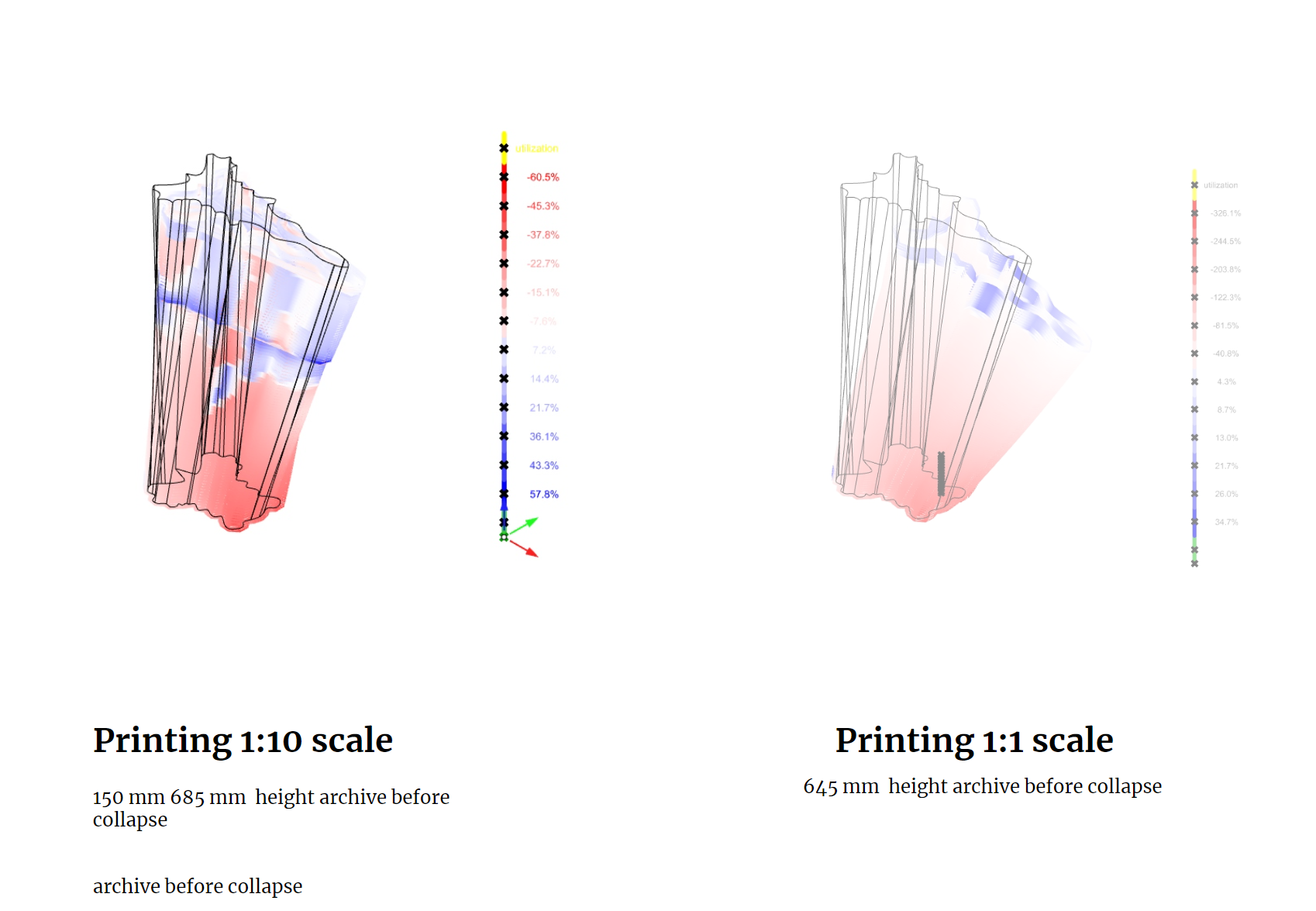

In Valdaurra Labs, the design of 3D-printed earth walls needs to incorporate strategic grid/period deformations to optimize for natural light and ventilation. By adjusting the curvature and openings in these periods and grids, the structure allows for more sunlight to penetrate while improving airflow and maintaing the building cool. This strategic deformation allows for play … Read more