Limitless Project

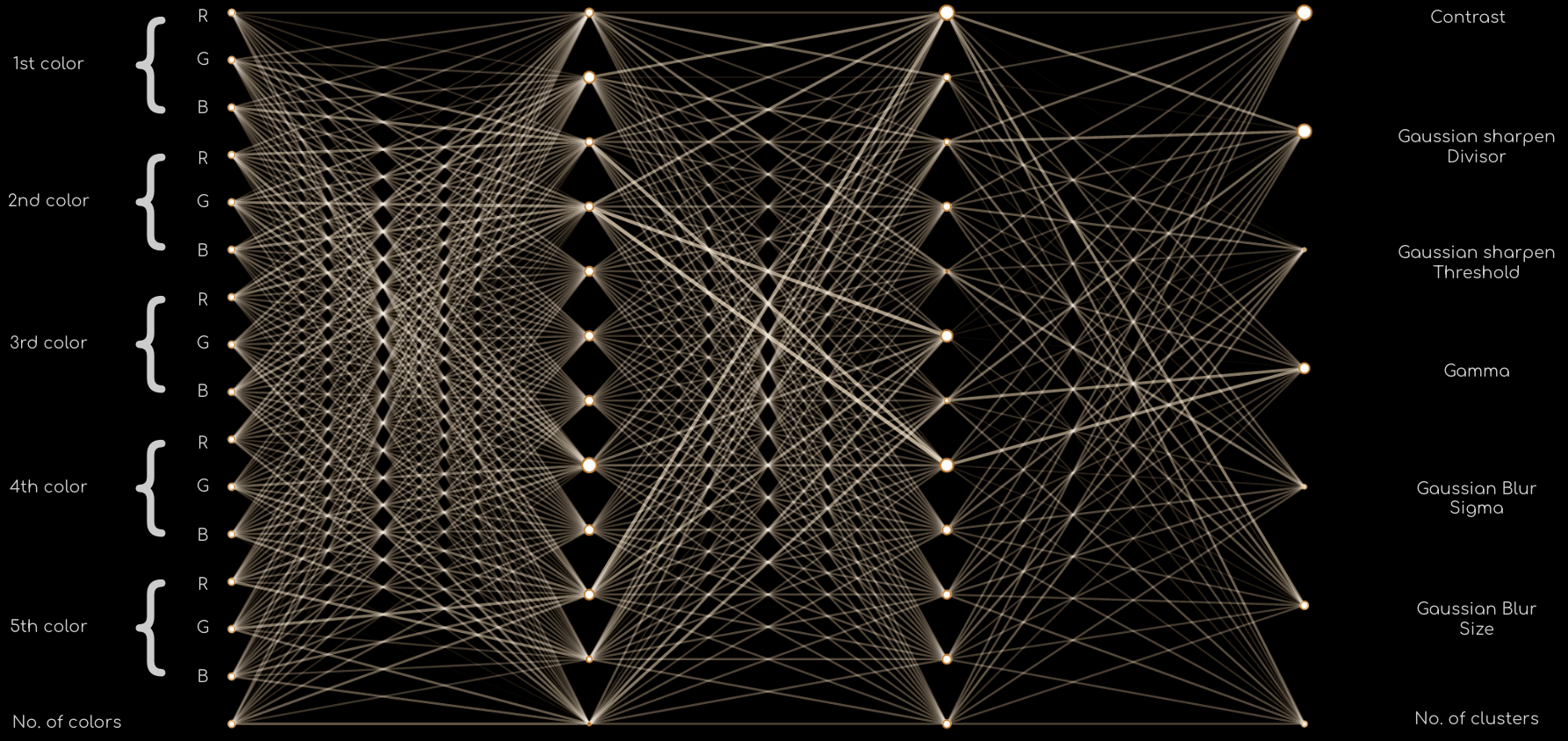

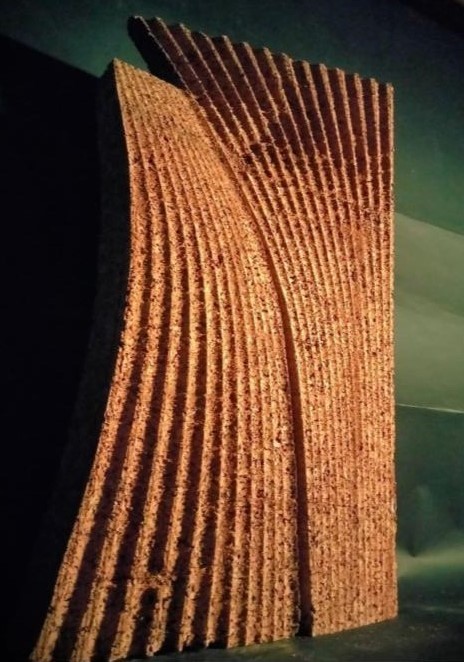

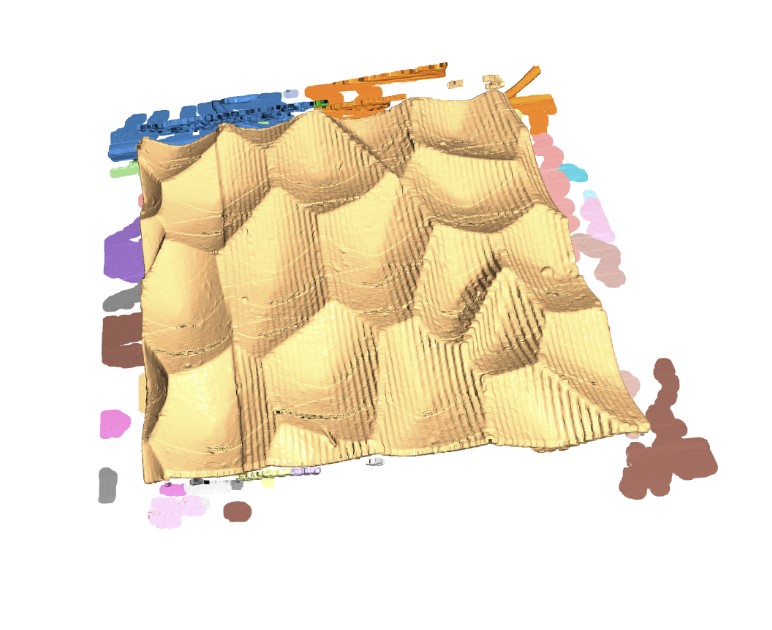

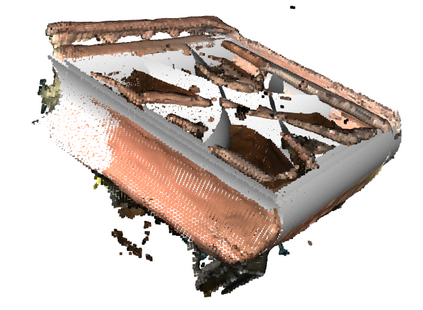

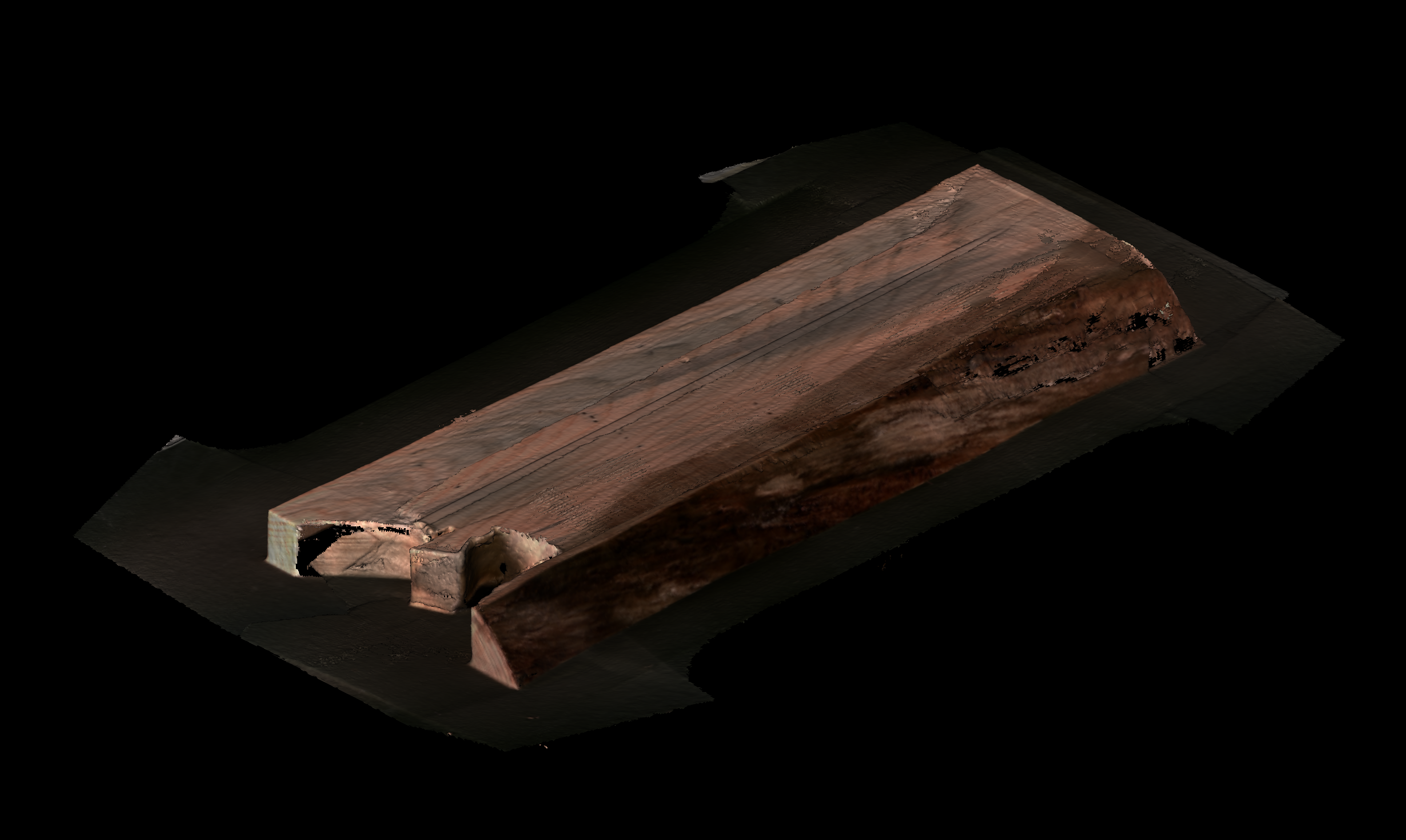

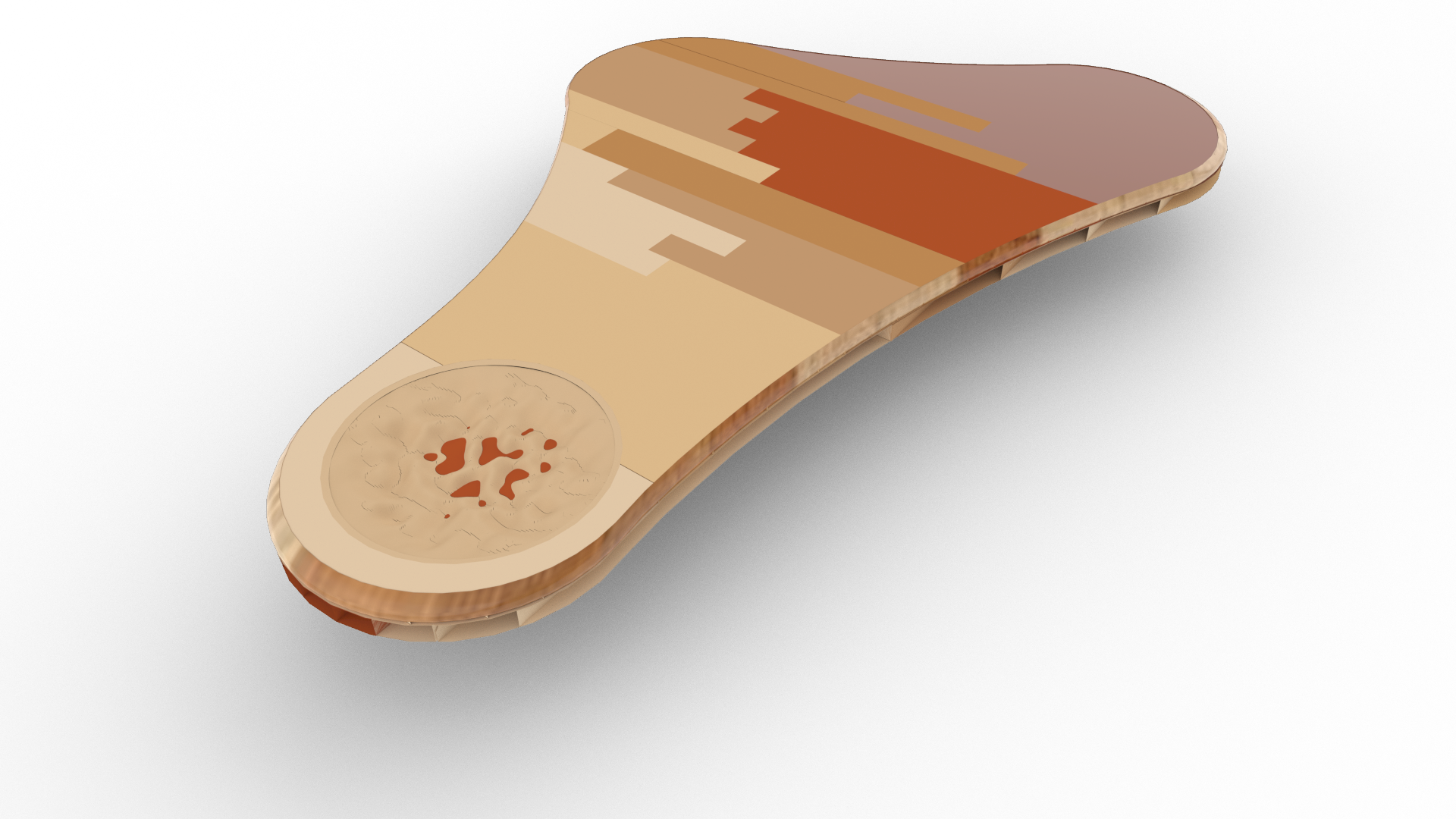

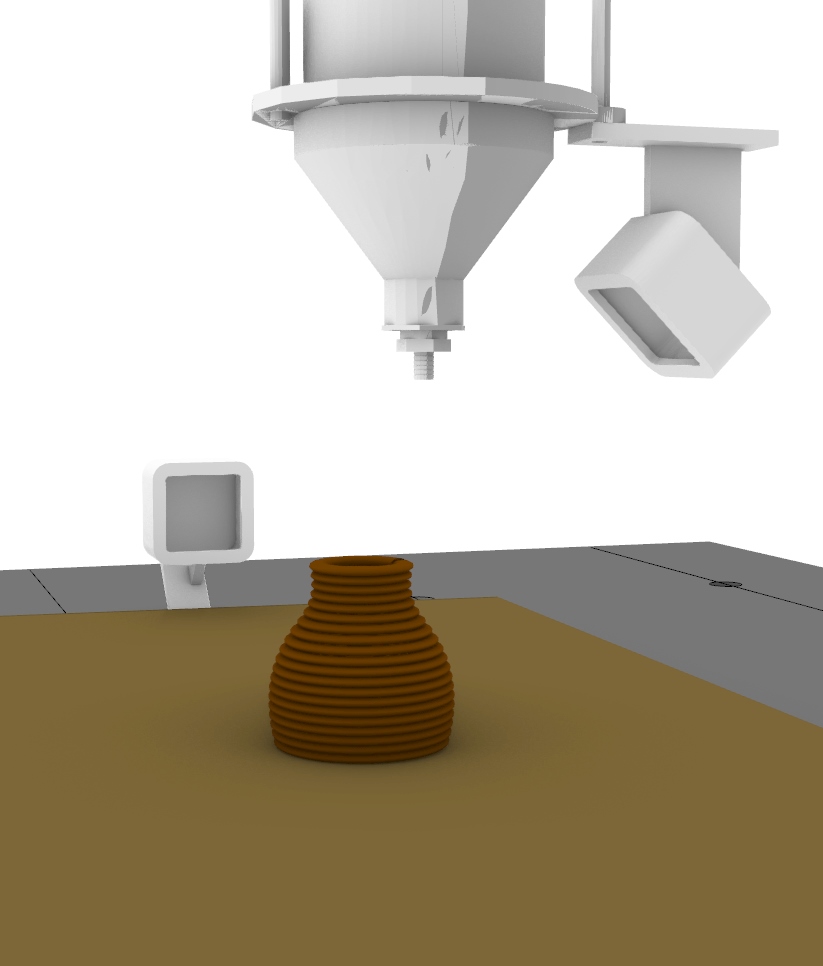

The industry of construction creates most of the waste in the world. By 2025 we expect to reach 2.2 billion tons globally. As a solution of this problem, industry 4.0 proposed the Additive manufacturing process, which is looking for the optimization of fabrication and construction adding layer by layer different materials; this process started being … Read more