Thermal Sensing for Advanced Cork Manufacturing

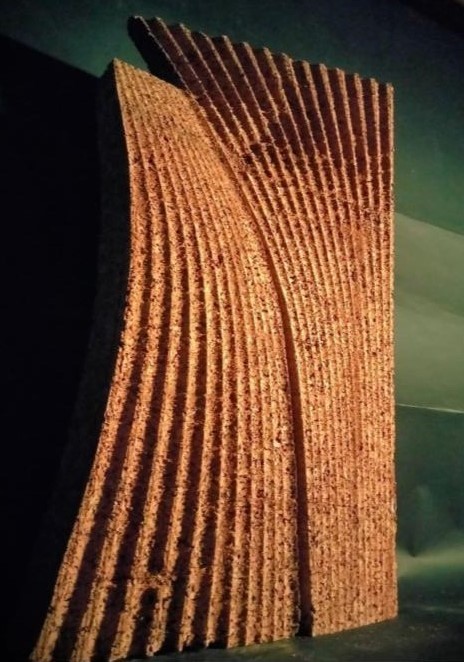

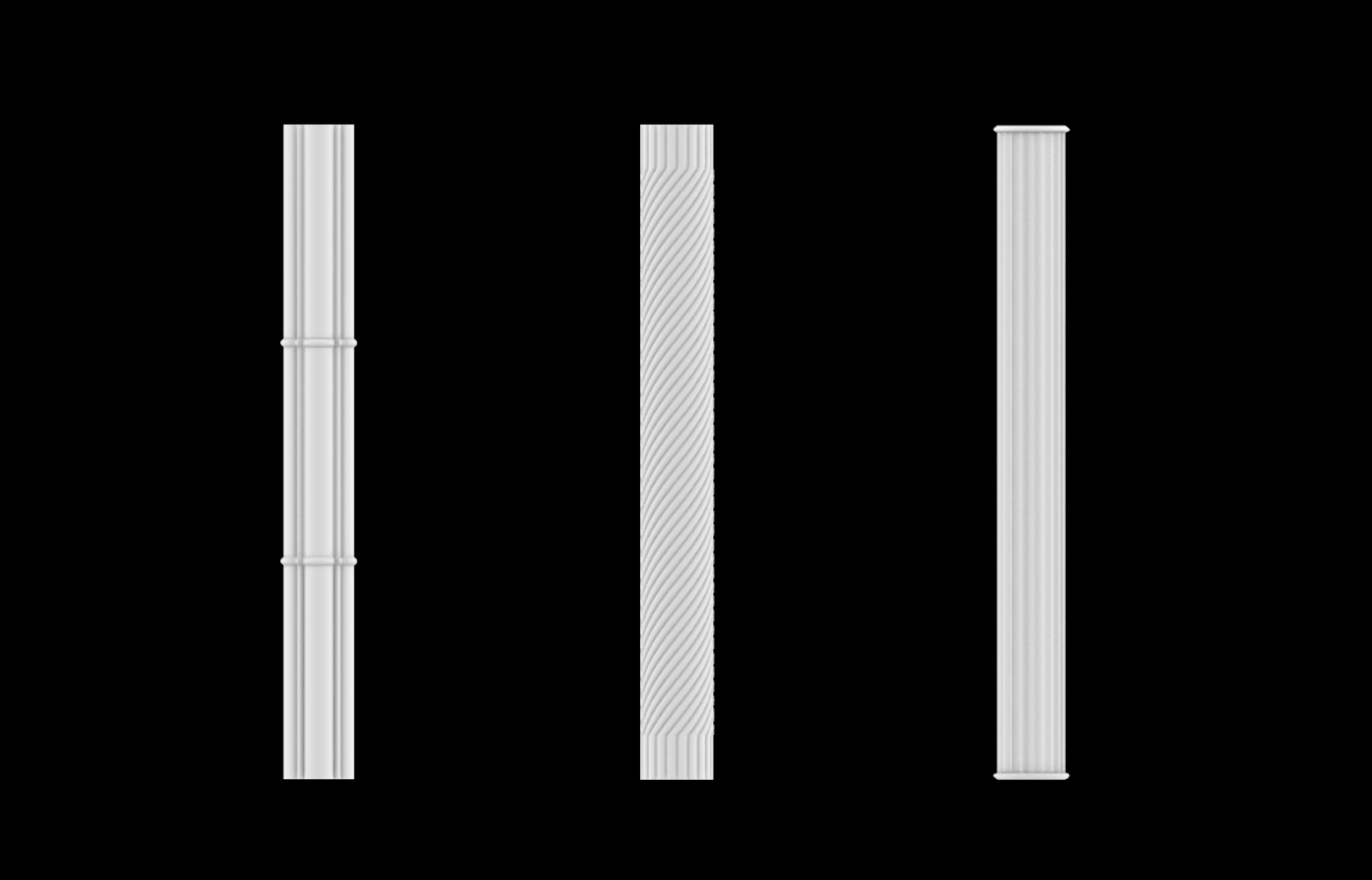

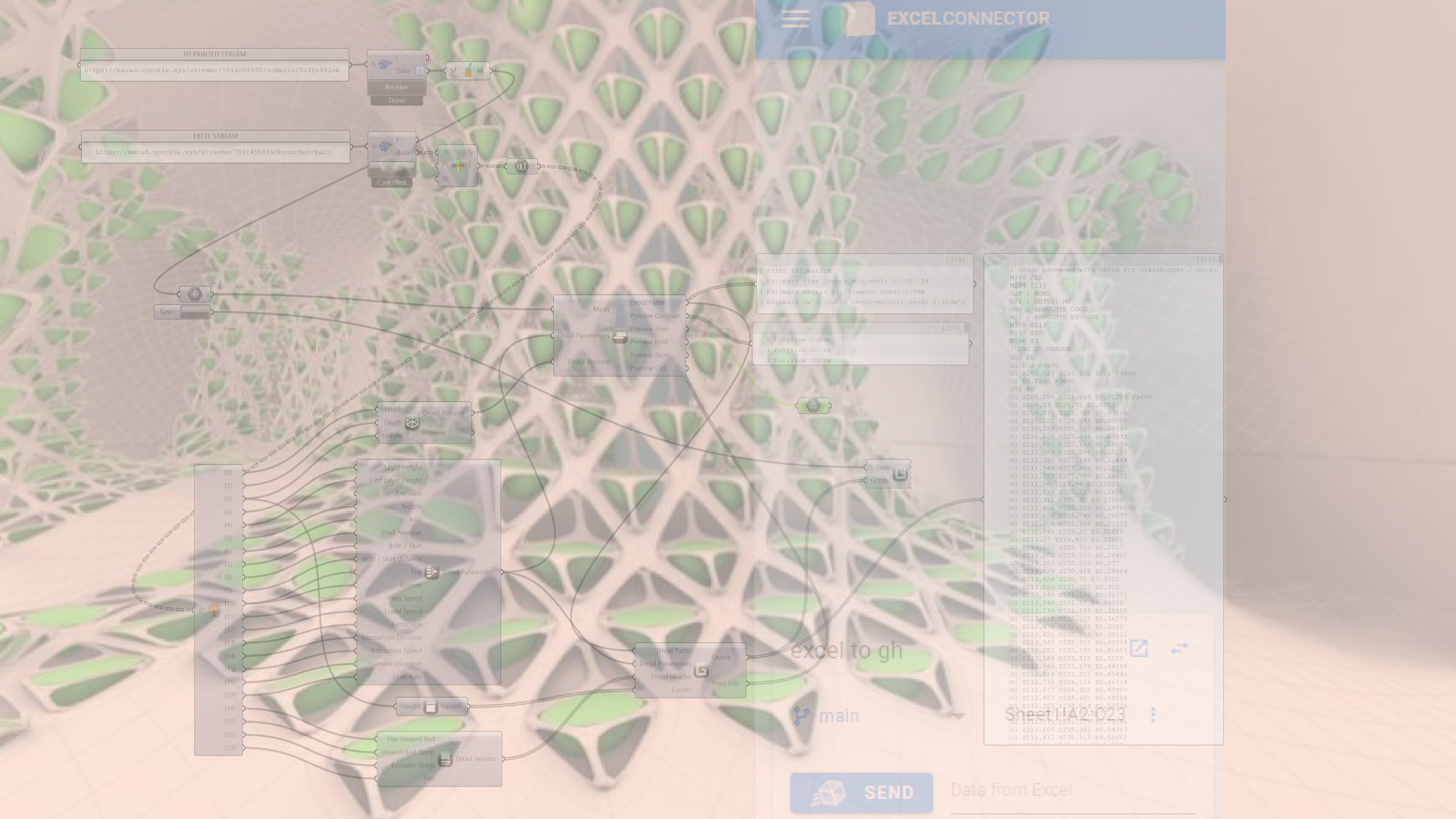

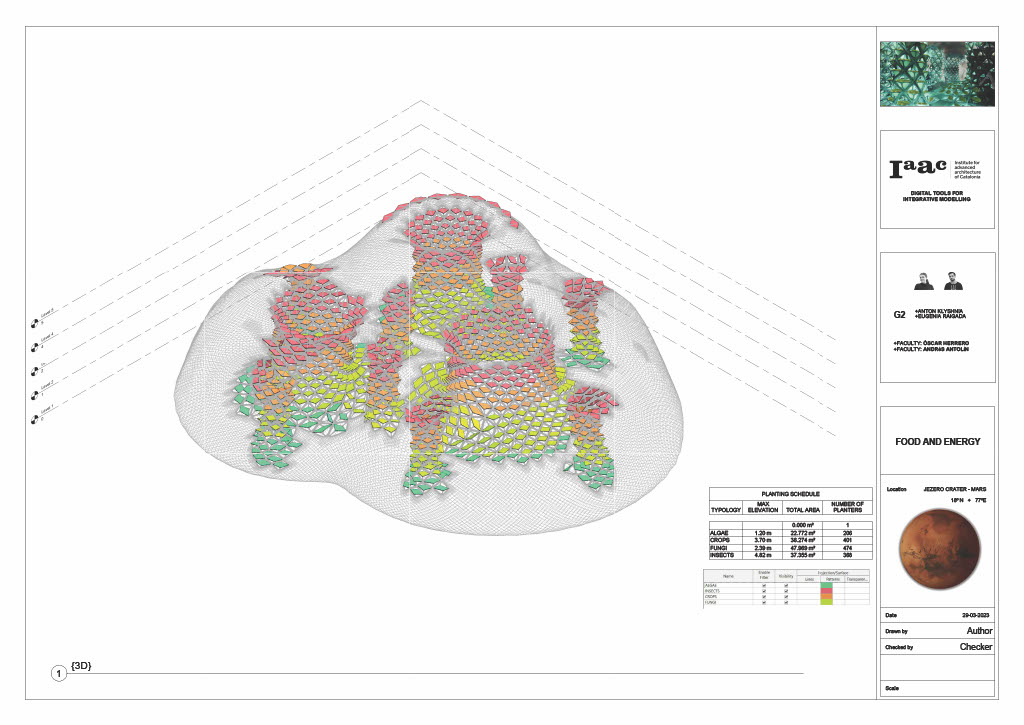

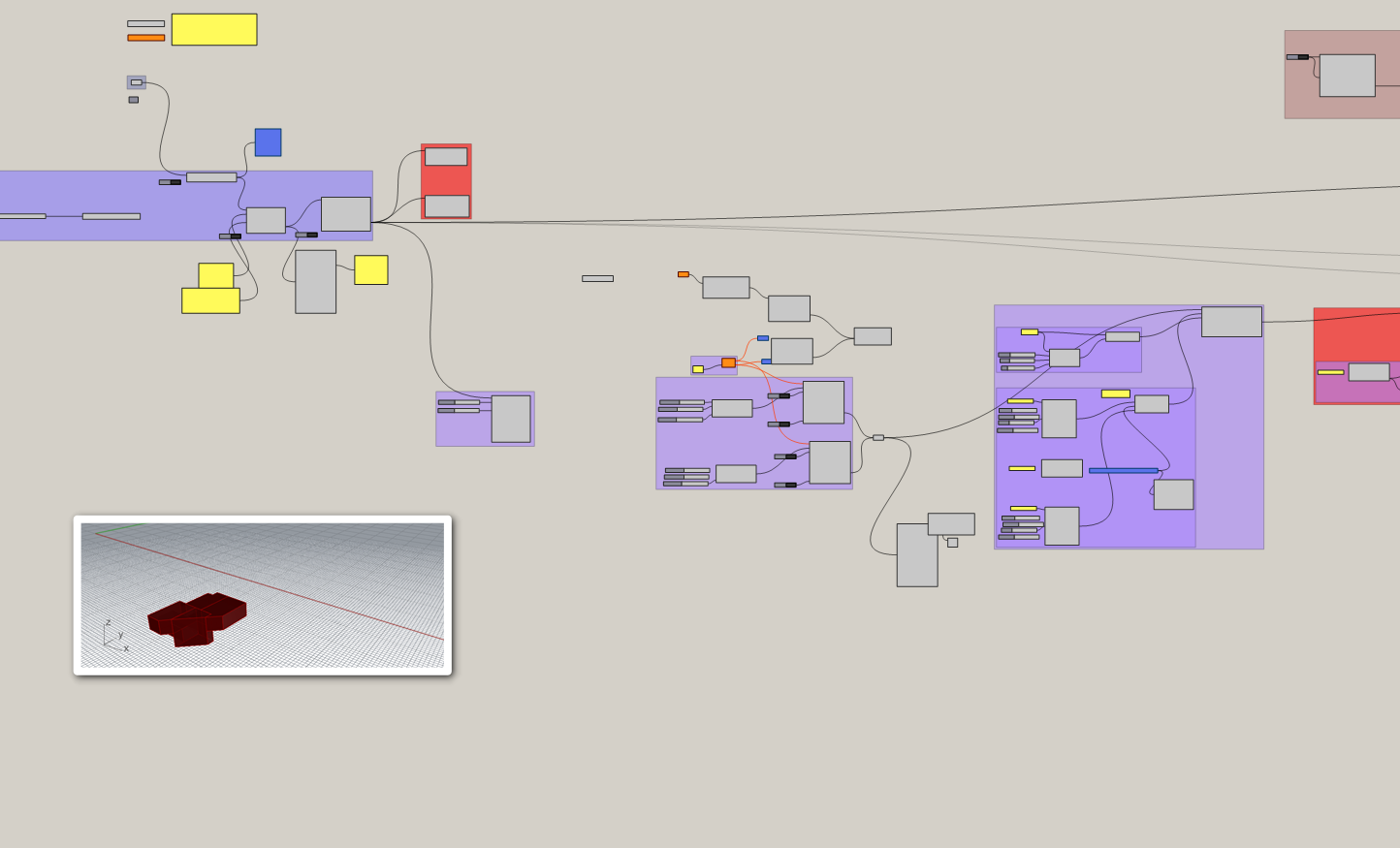

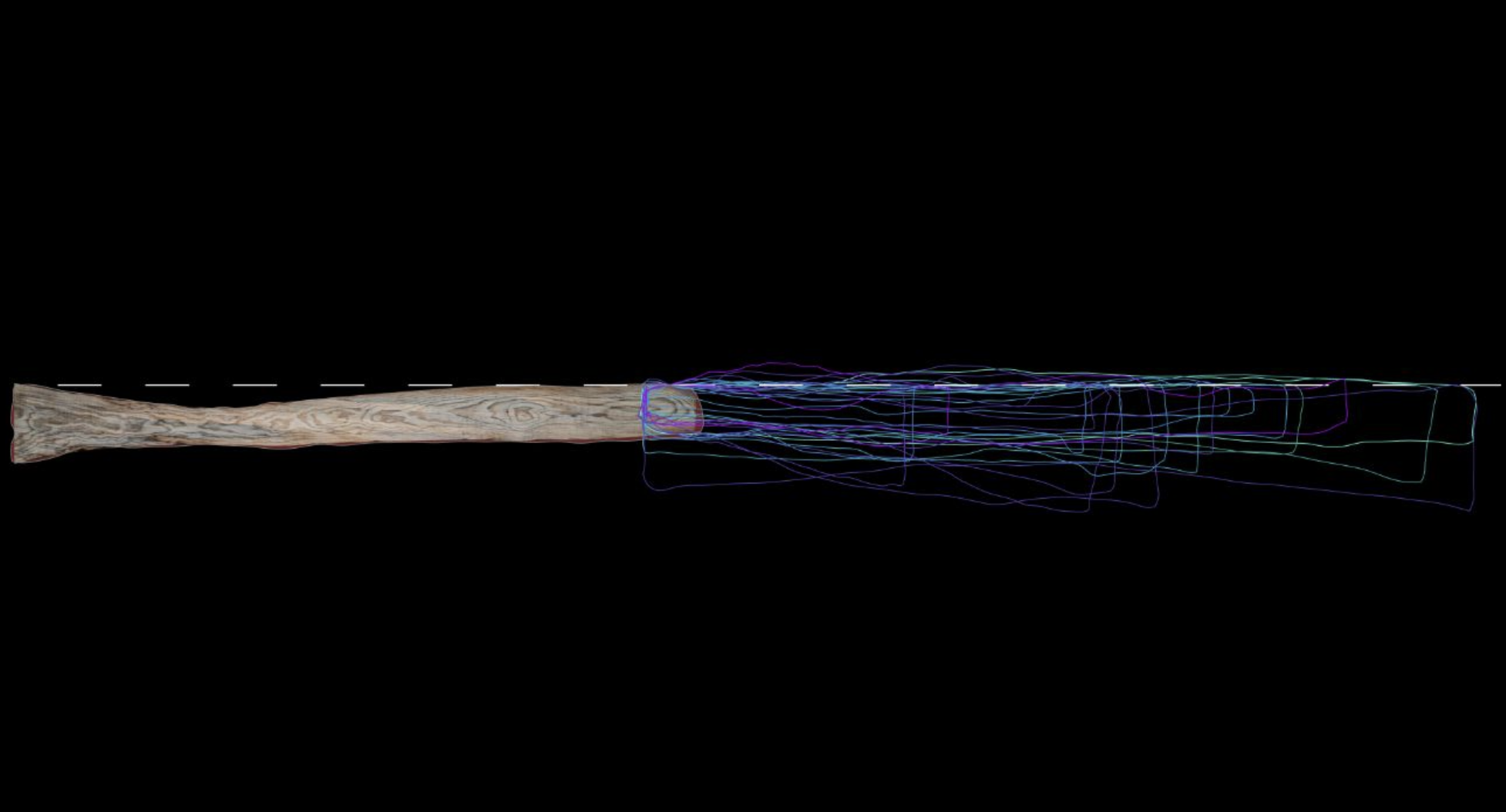

This research study delves into the realm of advanced robotics and semi-automated manufacturing processes that take into account the material properties of cork. Specifically, it explores the design and fabrication of a surface system that is optimized for both aesthetic appeal and functional performance. Building on the knowledge gained in a previous term on robotic … Read more