Introduction to Digital Fabrication

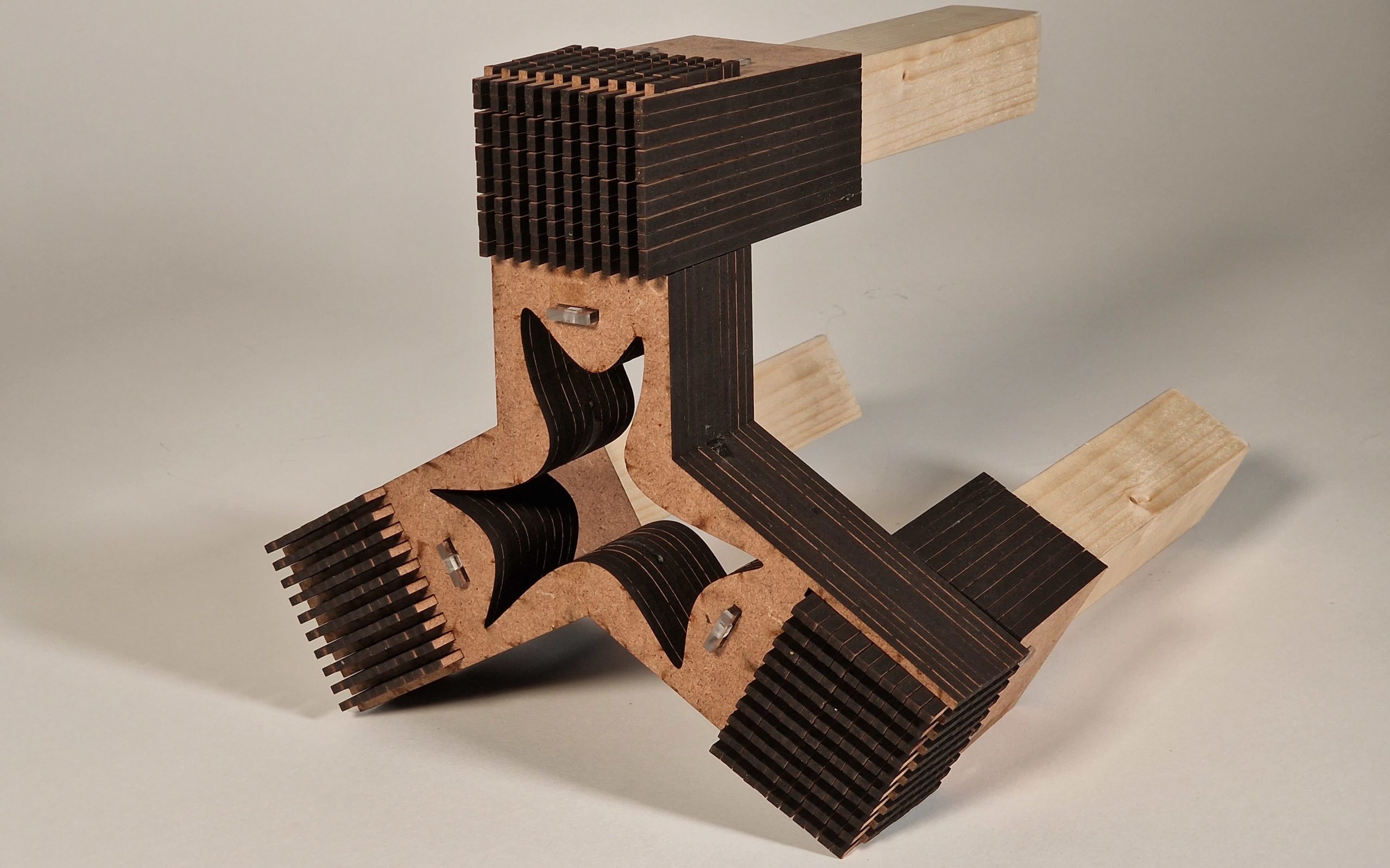

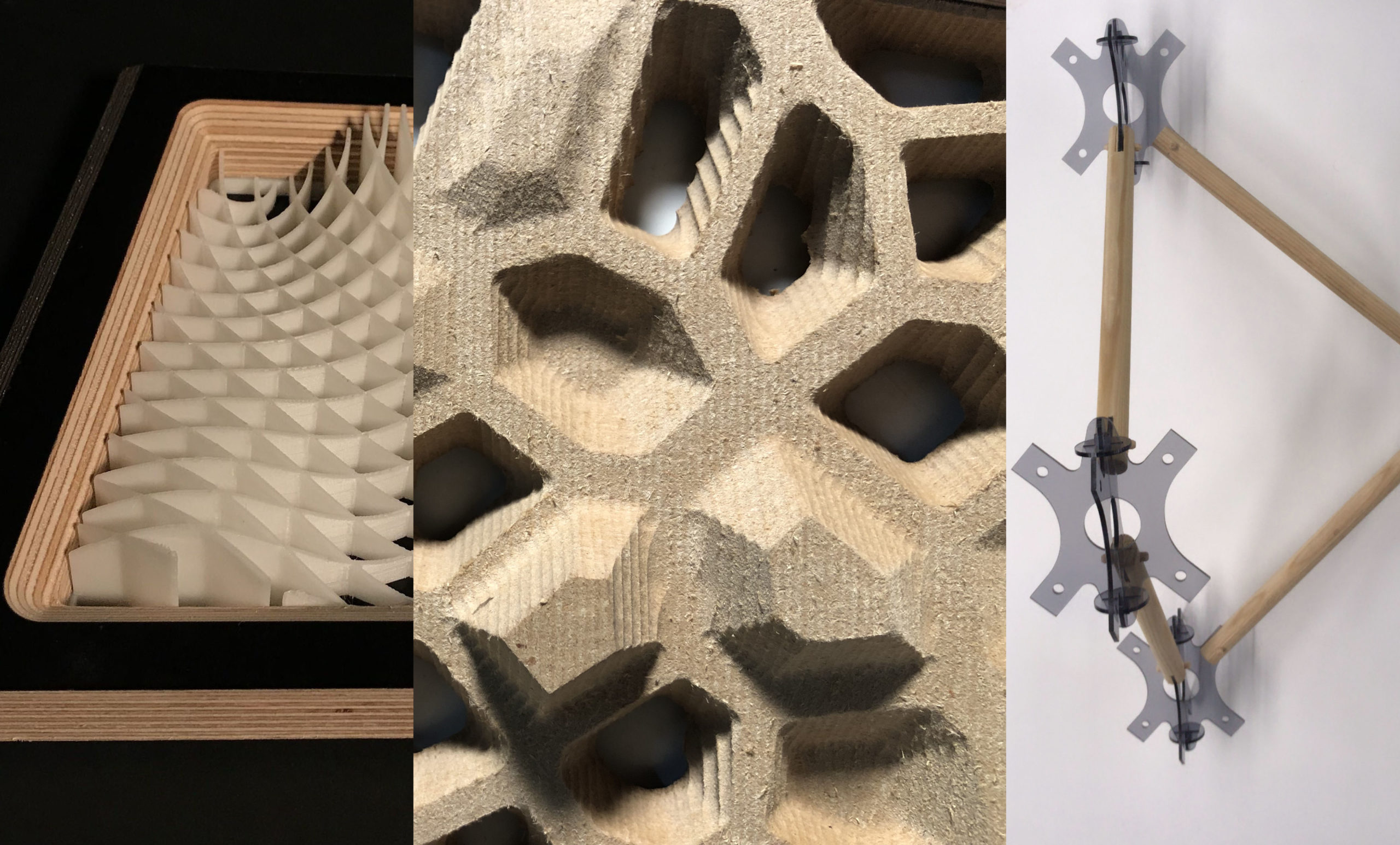

Group 20 Timber Spatial Joint Concept The aim of this timber spatial joint was to explore the bending technique applied to plywood or MDF using kerfing but also apply it in 2 directions instead of 1. The bent joint is then inserted into the circular wooden sticks and fixed in place using a wooden dowel. … Read more