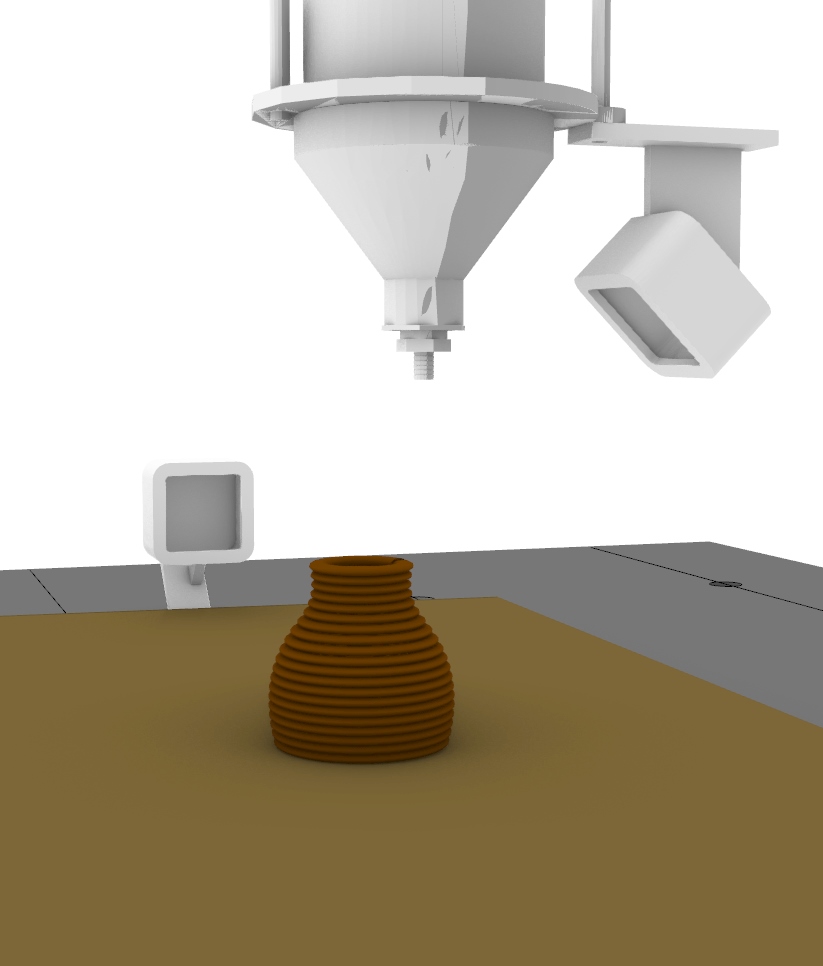

Print – Scan – Cut

Preliminary steps towards a hybrid workflow for smooth 3D printed surfaces. Aim To develop a hybrid workflow to obtain smooth surfaces on 3D printed clay for improved alignment and surface finish. State of the Art Additive manufacturing enables the precise and cost-effective creation of complex designs while minimizing waste. One of the shortcomings common to … Read more