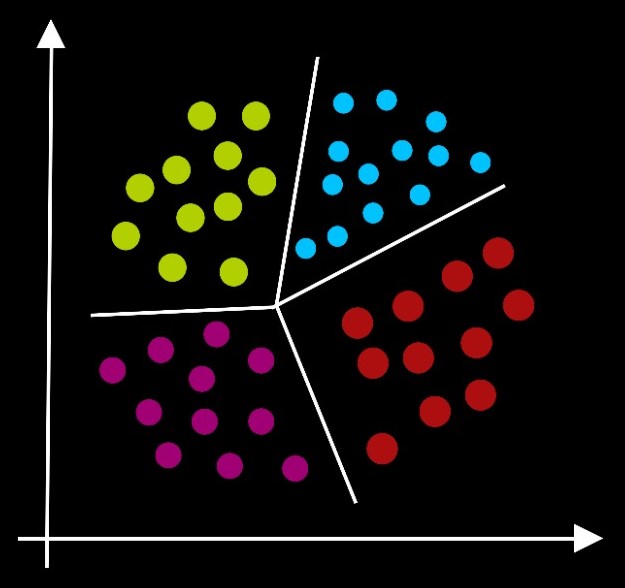

Discrete Assemblies

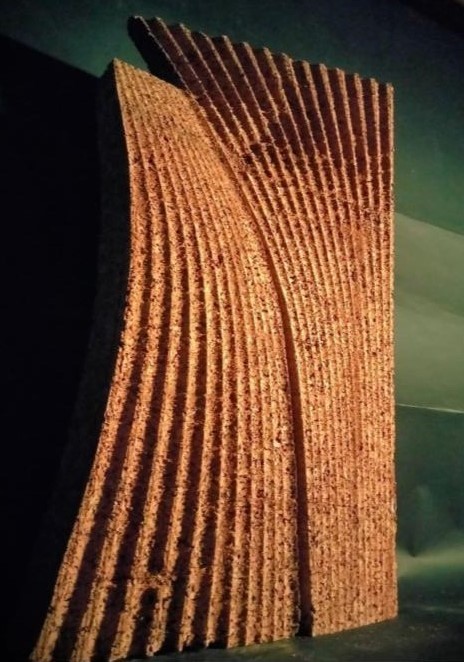

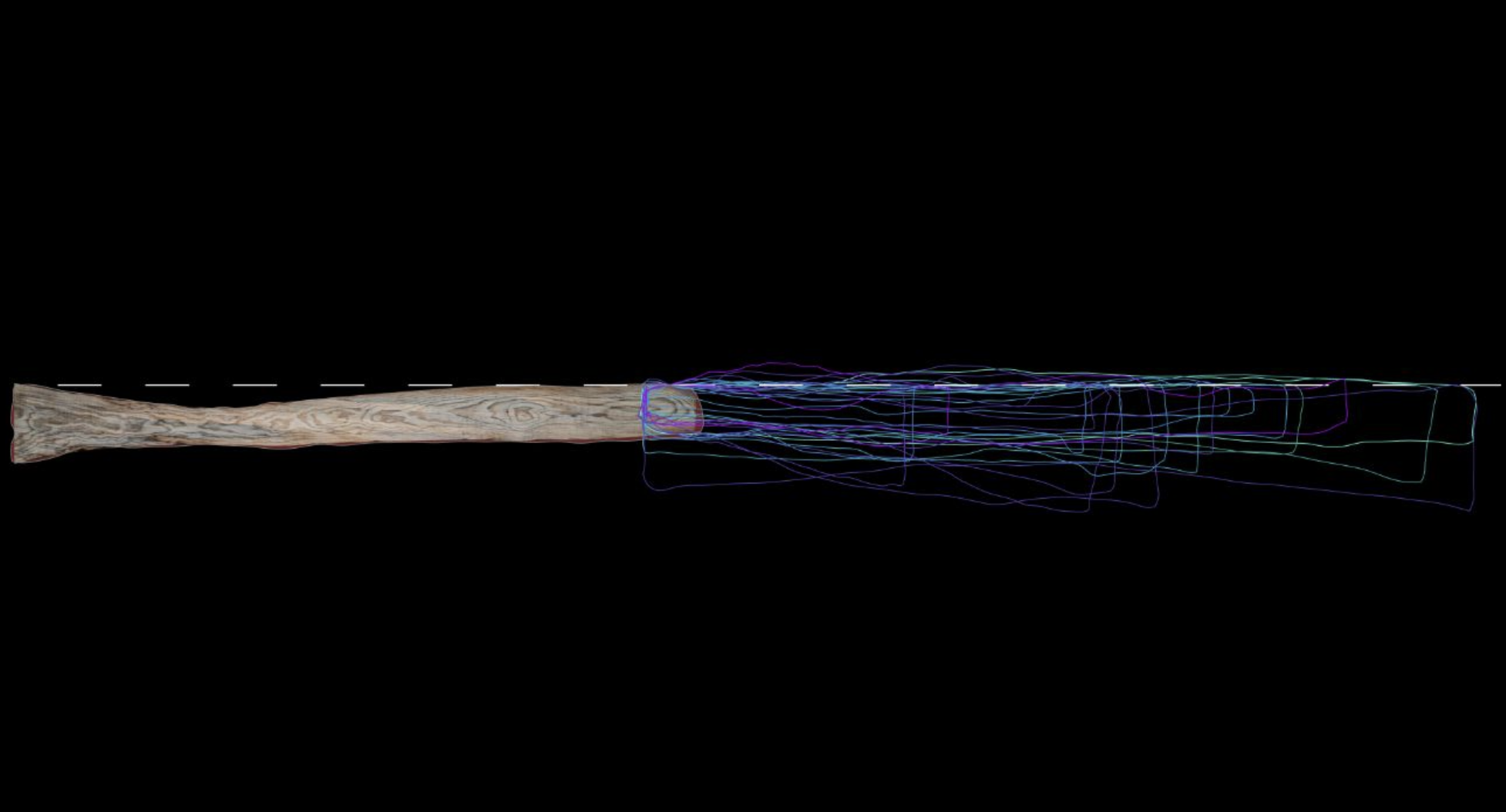

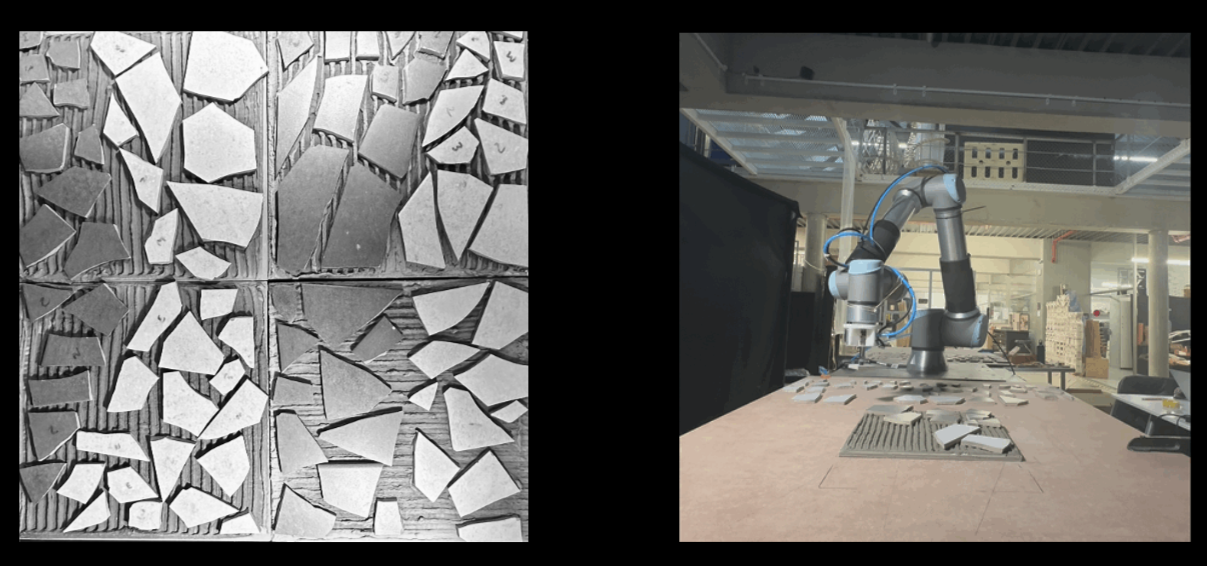

Parts that Precede Buildings This course helped us to gain a comprehensive understanding of discrete building systems with the use of prefabrication and automation. During this one week workshop, discussed topics such as timber prefabrication, robotics and discrete computation for later on participating with a hands-on approach to build several structures using timber boxes and … Read more