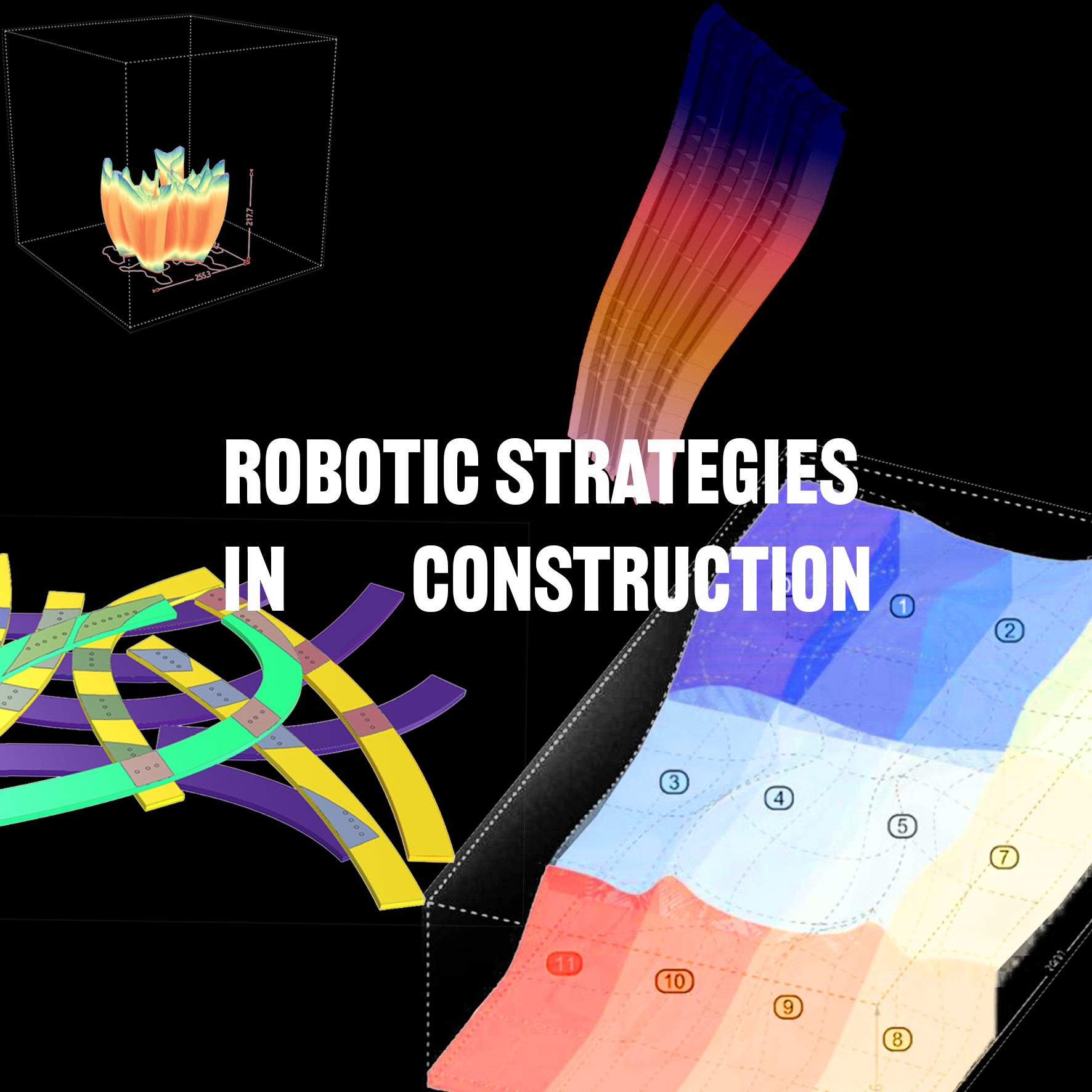

BIO-ADDITIVE MANUFACTURING / MRAC Workshop 1.1

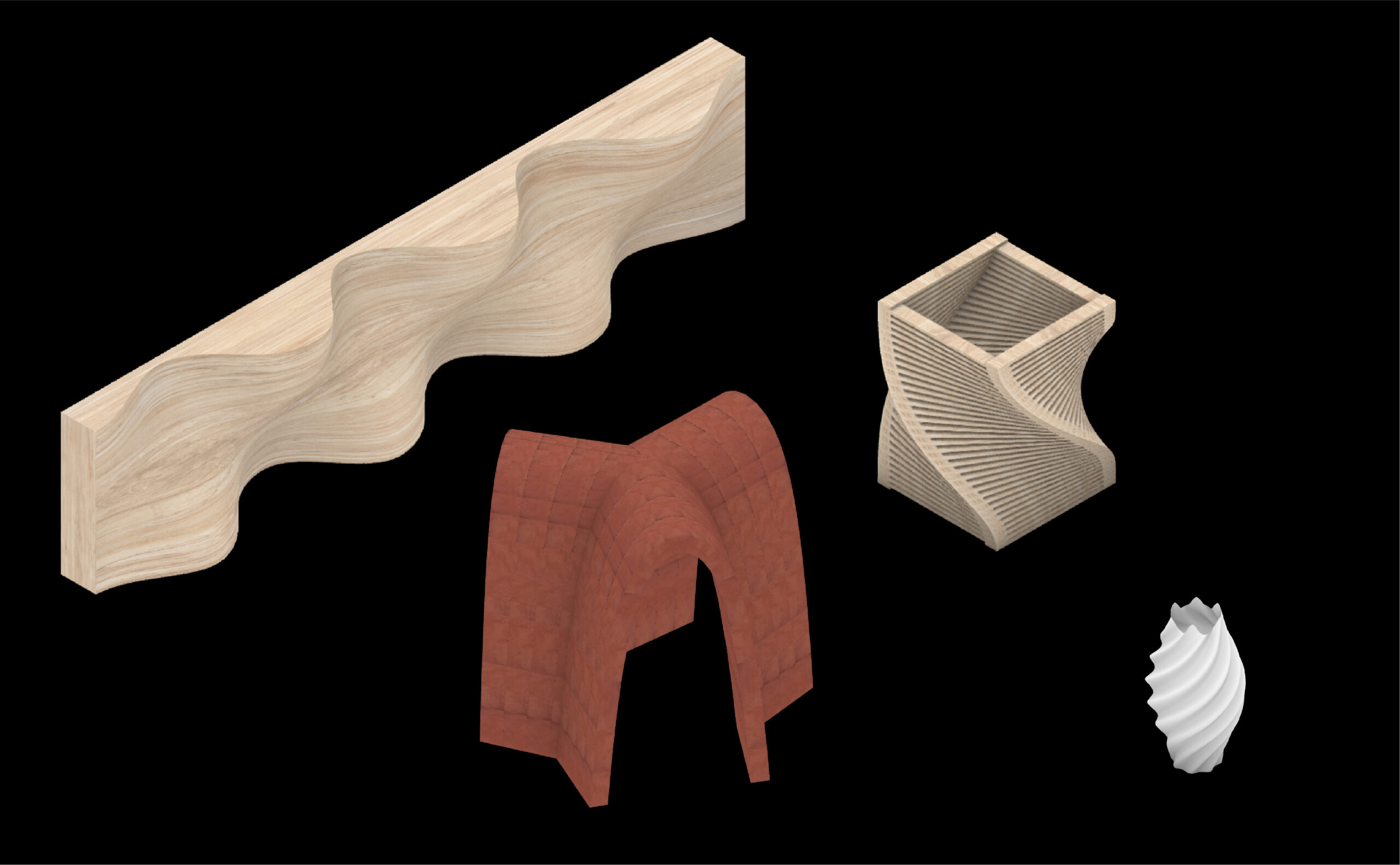

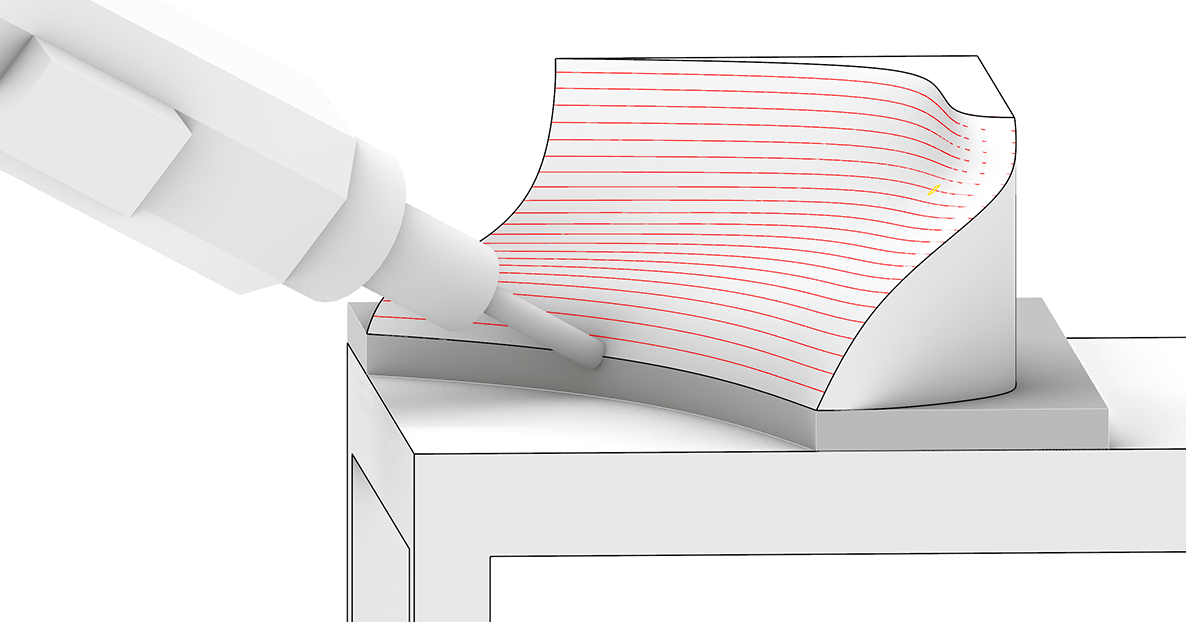

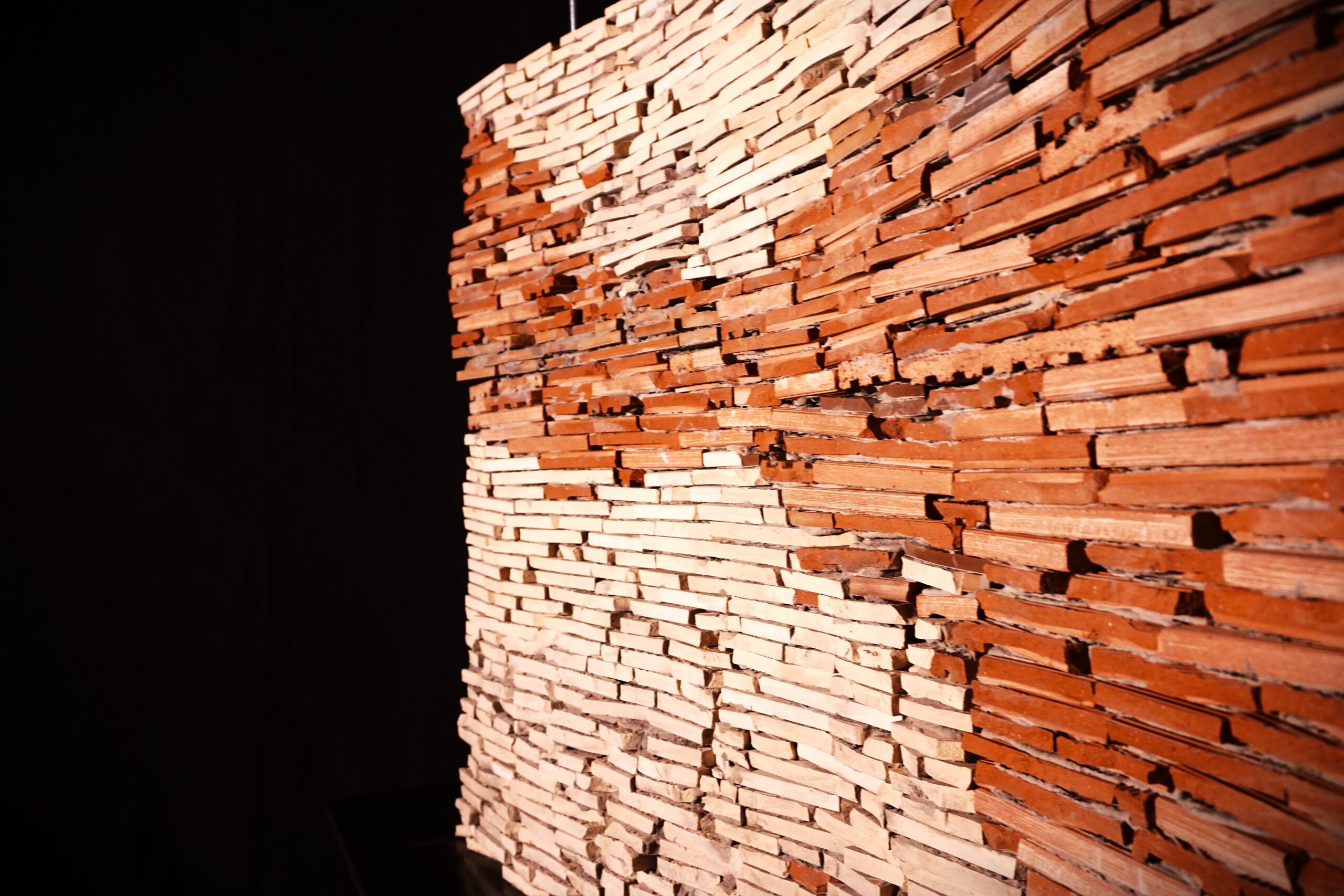

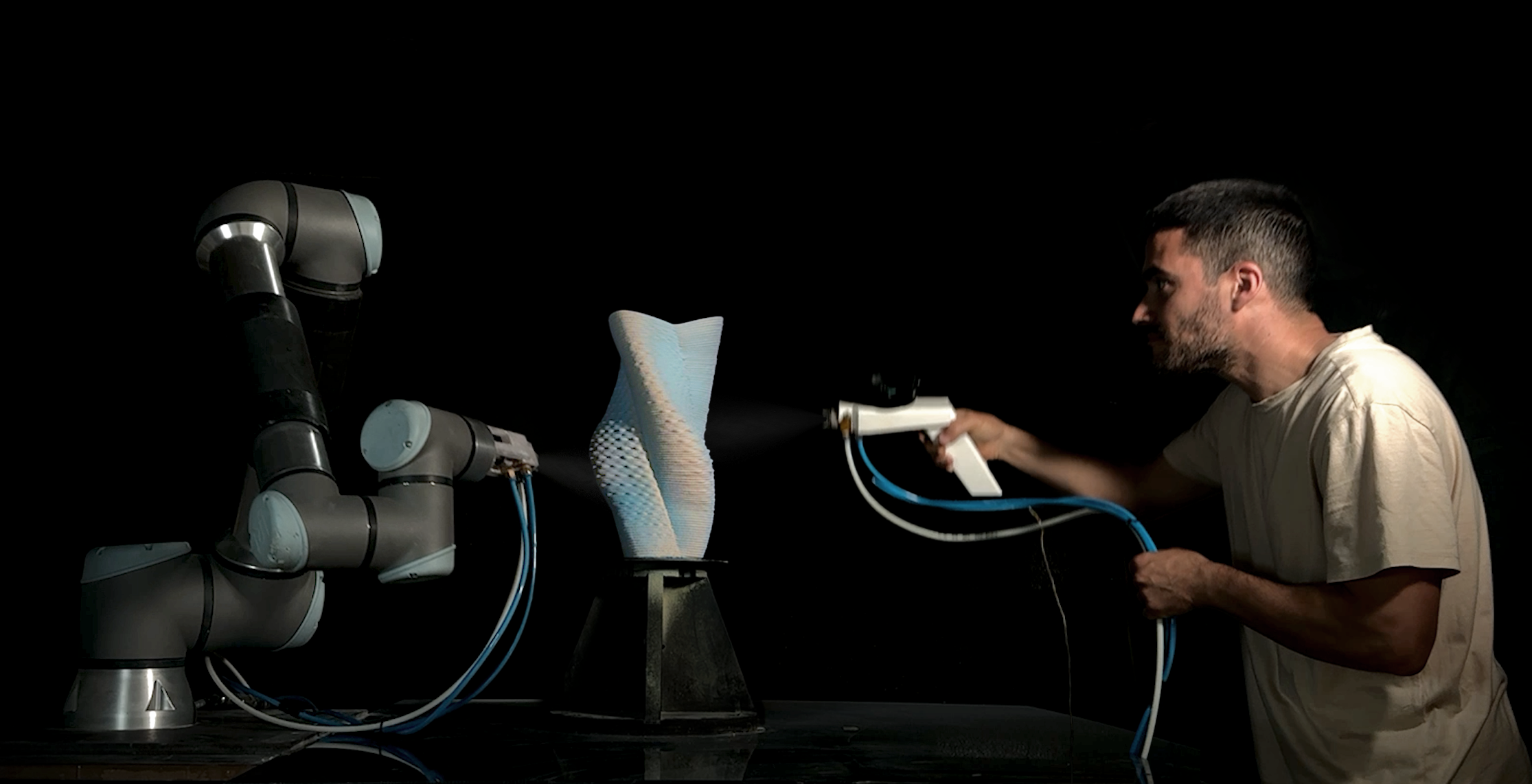

Cork-based 3d printing – Topological Optimisation Design Introduction The seminar invites students to explore new materials, additive processes and new fields of applications through robotic 3d printing taking advantage of the potential of the 6-axes of the robotic arm. Context Recently we have clearly observed immense changes in architectural design development. Architecture has been influenced … Read more