Weaving Natural Materials – Breathing Curtain Wall

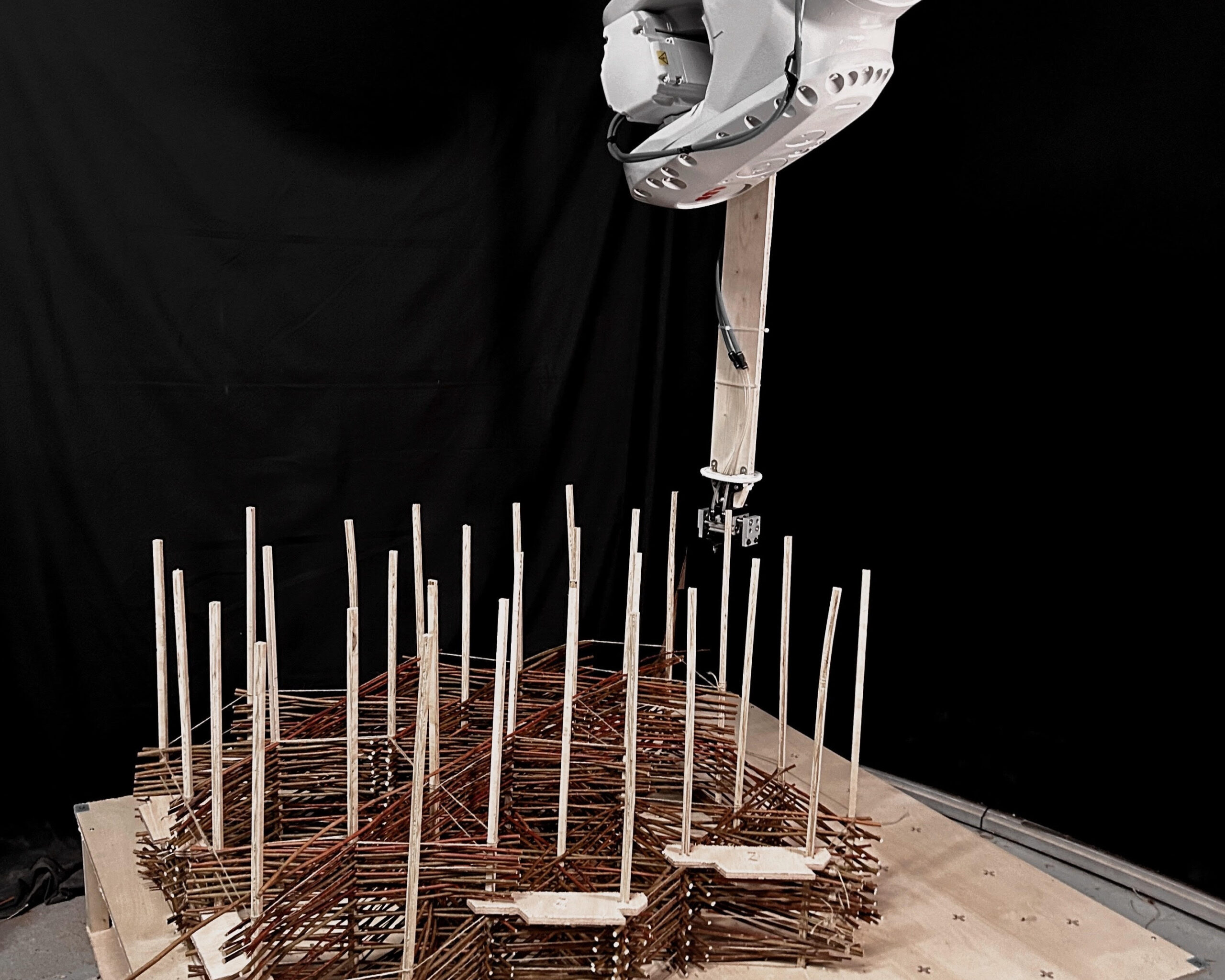

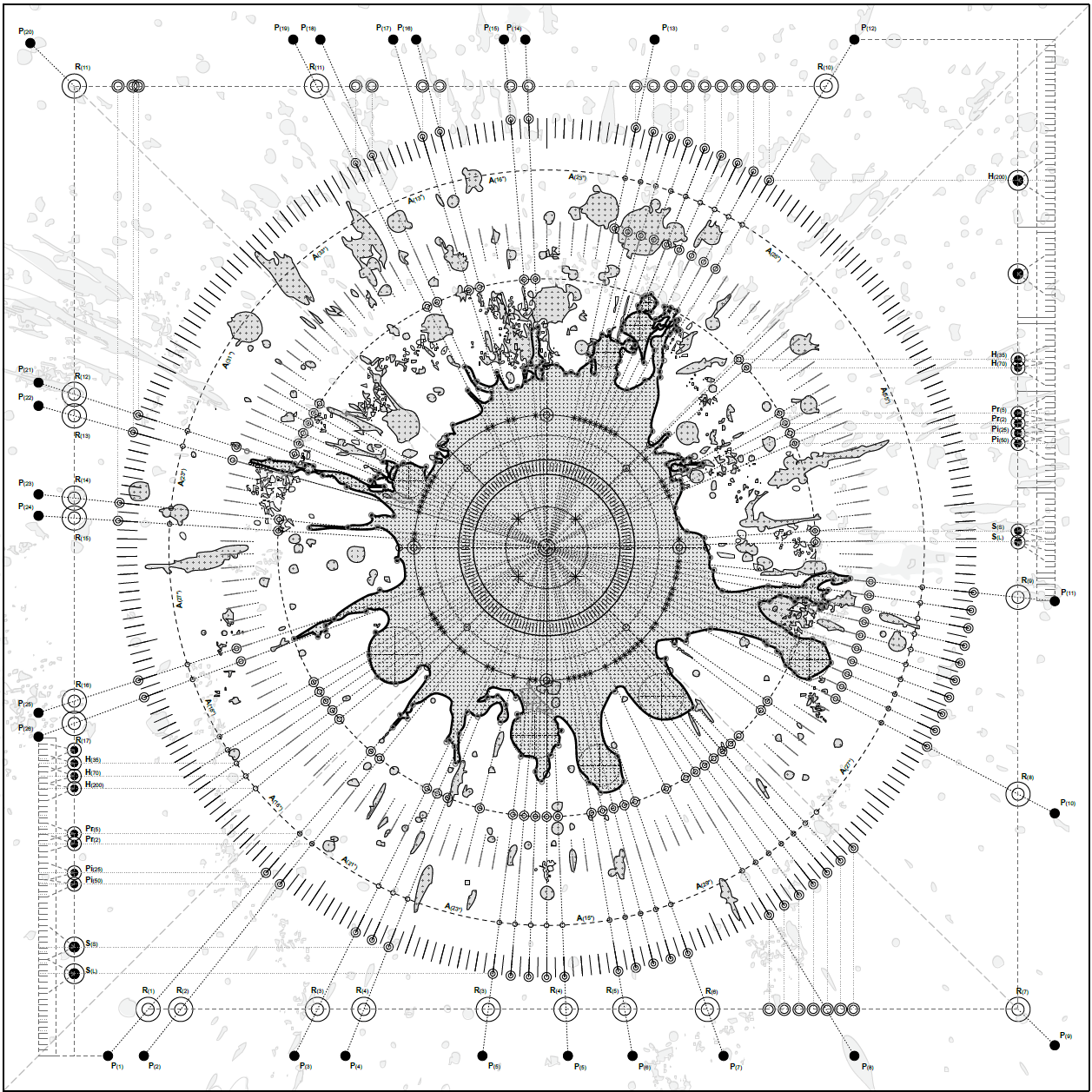

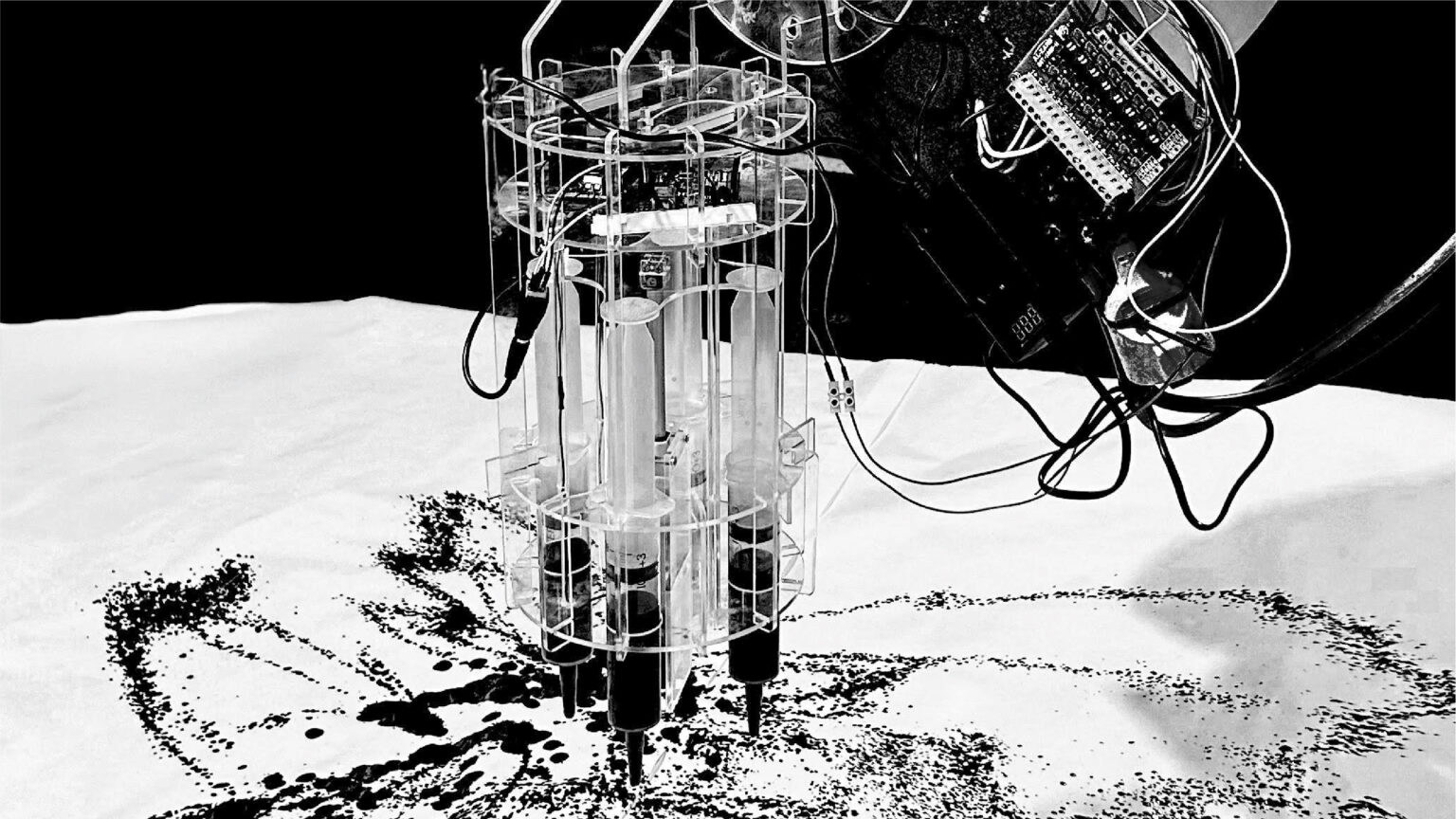

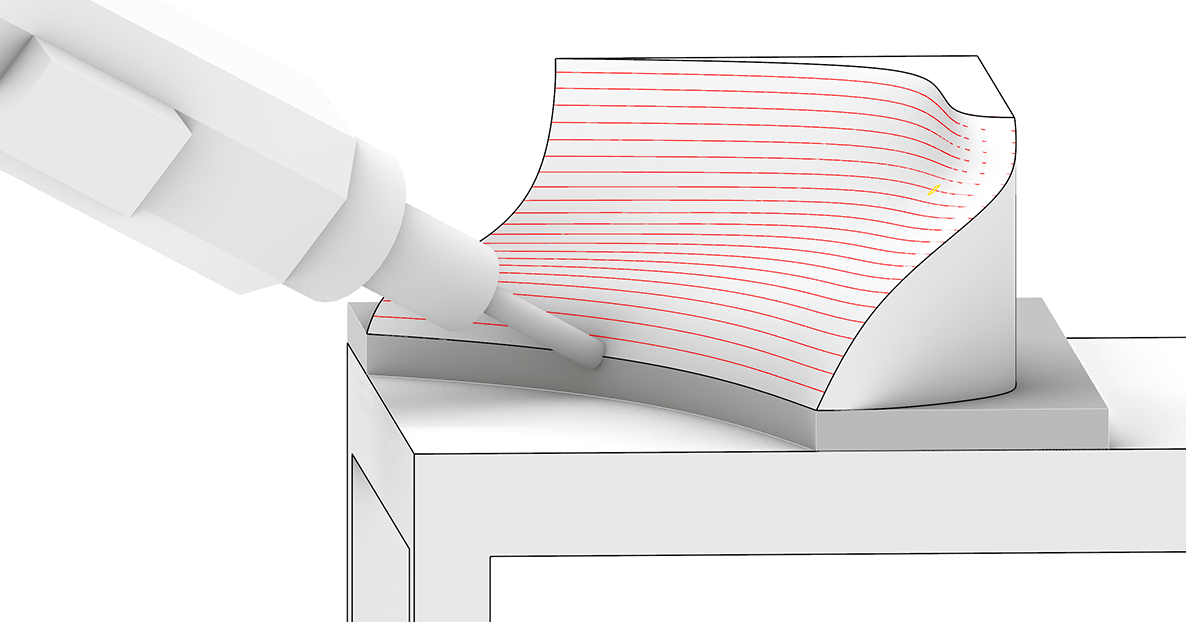

Introduction As part of the workshop led by Javier Fuentes and Moritz Dörstelmann the Chair of Digital Design and Fabrication (DDF) at the Karlsruhe Institute for Technology (KIT), our team explored the potential of willow as an innovative material in architecture. This project merges sustainability, advanced design, and robotic technology to develop breathable and adaptive … Read more